Explore automated manufacturing solutions built using rheonics process viscometers and density meters

Used by industry leaders in printing, chemicals, food, pharmaceuticals, and other manufacturing industries.

Rheonics instrumentation and standalone solutions offer highly efficient monitoring, control and optimization of manufacturing processes. Companies using our sensors and solutions demonstrate improved margins, increased safety while saving energy and reducing their emissions.

Monitor ➜ Control ➜ Optimize ➜ Monetize

- All

- Adhesive

- Consumer Goods

- Coolants and Refrigerants

- Cosmetics

- Printing and Coating

- Industrial Mixing and Grinding

- Food and Beverages

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Coil coating is a high-speed, precision process where fluid properties directly affect coating uniformity and adhesion. Inline viscosity and density…

Consumer care products enclose a wide range of personal and household items designed to support hygiene, grooming, and overall well-being…

Capsules are a solid oral dosage form used for the delivery of medical drugs, vitamins, minerals, and other health-related ingredients…

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Mayonnaise, a globally enjoyed condiment, is a classic oil-in-water emulsion, distinct from water-in-oil emulsions like butter and margarine. Its rheological…

Rheonics process viscometer SRV or Rheonics process density and viscometer SRD can be installed in a variety of locations in…

Polyurethane is a versatile material with a wide range of applications, including adhesives, sealants, coatings, foams, and elastomers. It is…

Summary: a single sensor to monitor effects of oxidation (TOTOX), fatty acid (TBA), and Polar compounds (TPC) on frying oil…

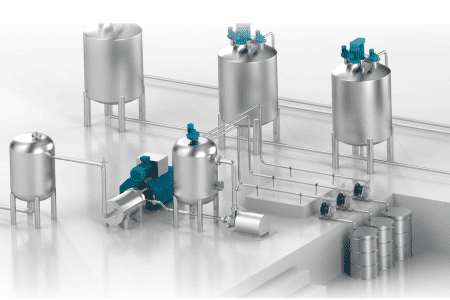

Emulsions are used in almost every aspect of daily lives. Their processing and development expands across many industries – chemicals,…

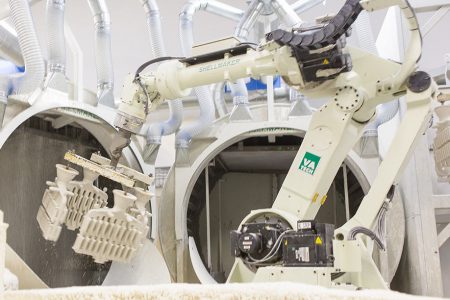

Assuring compliance of intermediate and final quality attributes in a continuous pharmaceutical manufacturing campaign is of utmost importance. Companies strive…

The global electrical insulation coatings market size in 2015 was USD 2 billion and is expected to grow significantly in…

Polymers have gone from being cheap substitutes for natural products to providing high-quality options for a variety of industrial applications…

Polymer production is one of the most important areas of applied chemistry due to its significant number of applications industry…

Film coating of solid oral dosage forms is a well-established process in the pharmaceutical industry. Most tablets dosage forms undergo…

Product marking has come under increased scrutiny in the pharmaceutical industry due to pressure from three factors: regulations, aesthetics, and…

The engineering of well logging sensors into the drill collars is simulating a revolution in logging and drilling. LWD, MWD…

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts,…

Being one of the most versatile building materials, concrete is used in many forms of construction. Concrete is often used…

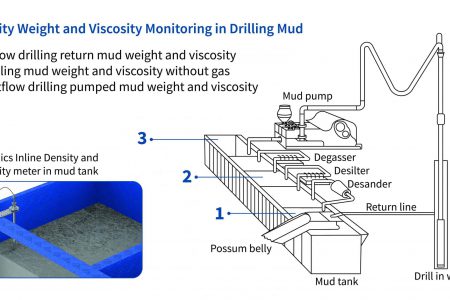

As a part of the industry’s drive for continuous cost-effectiveness, drilling fluid performance and management have come under closer scrutiny…

In the food processing industry, manufacturers are looking for two things - taste and texture. Texture is the “feeling” in…

Through all the advancement in automotive design and manufacturing over the years, there has been one constant – vehicle’s aesthetics…

PVT analysis is performed to relate surface production to underground withdrawal for an oil reservoir and to simulate what takes…

Automation Solutions by Industry

Rheonics Type-SR, Type-DV, and Type-BT sensor probes are now available with Korean KCs Ex certification…

Rheonics SRV and SRD sensors are now available with Japanese Ex certification Rheonics inline process…

Rheonics is a member of the Modbus Organization as a vendor of hardware, software, and…

Rheonics SRV and SRD sensors and hygienic accessories are now available with 3-A Sanitary Standards…

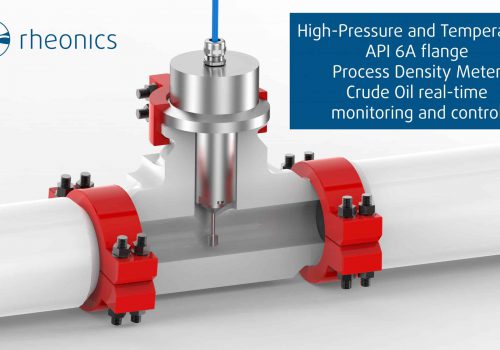

Rheonics density and viscosity meter SRD can be specially designed for installation with API hubs…

Rheonics is proud to announce its partnership with FieldComm Group. FieldComm Group owns the HART…

EtherNet/IP: The standard protocol for communication in industrial networks EtherNet/IP is a widely used Ethernet-based…

A leading business-to-business media brand covering the transportation construction and maintenance marketplace Roads & Bridges…