Key advantages of viscosity management in mixing applications:

- Accurate and efficient mixing operations – significant savings in material costs and energy

- Seamless product change-over: agility in dealing with different and new product variants and product provenance

- Compliance with regulations

- Optimizing CIP systems

Introduction

In many manufacturing processes, mixing is a crucial step. It may not have strict precision requirements, but over-mixing still wastes energy and time. In most cases, mixing however, is much more precise. Under mixing leaves various components unevenly distributed, whereas over mixing might alter the end product.

There is a number of reasons why a reactor isn’t producing to its full capacity. In general, the mixing system should be checked as one of the first things to check depending on the symptoms. The agitation process, after all, is a critical part of the reaction process and it is one of the technologies that can be tweaked or upgraded to optimize the entire process.

There are more factors to consider than the agitator itself when establishing a unique mixing environment – including agitator blades, baffles, mechanical seals, drives, and operating procedures (blade angle, rpm, number of tiers, etc.). Product characteristics and temperature requirements create a complex array of options. It is essential to consider all of these factors when establishing or reconstructing the parameters of the process.

What makes mixing processes complex?

Difficult products and processes

Physical properties of certain products make them difficult to mix. Because those properties might be what makes a product effective or desirable, the product cannot be made with different properties for increasing the ease of mixing.

Non-Newtonian behavior

One particularly difficult property is non-Newtonian viscosity, a characteristic of common everyday items like personal care products, paints, and foods. Viscosity has the effect of resisting fluid motion, so the motion created by a mixer impeller in a viscous fluid may die out before it moves the entire contents of the tank. With all non-Newtonian fluids, the potential exists that a portion of a tank will remain unmixed because of inadequate fluid motion.

Non-Newtonian behavior generally becomes evident in fluids with viscosities higher than about 1,000 cP (1 Pa-sec). At that point, the viscosity alone makes mixing the fluid more difficult than mixing low-viscosity, water-like fluids. Small impellers may just bore a hole in the fluid, whereas large impellers can move an entire batch. One approach to mixing non-Newtonian and other viscous fluids is to use large impellers or multiple impellers, so the fluid does not have to travel as far from the mixer to reach other parts of the tank.

Non-Newtonian fluids exhibit shear dependence — i.e., the viscosity changes as the fluid is sheared (moved) by the mixer. A fluid that experiences a decrease in viscosity when subjected to shear is called shear-thinning, while a fluid that experiences an increase in viscosity under shear is called shear-thickening. Shear influence on apparent viscosity is proportional to the rotational speed.

Time-independent non-Newtonian fluids are influenced by the shear rate applied to them. Time-independent, shear-thinning fluids are often called pseudoplastics, because they behave like molten polymers. Shear-thickening fluids are sometimes called dilatant fluids, because many are high-concentration slurries that must expand (dilate) at the particle level in order to flow.

Time-dependent non-Newtonian fluids change apparent viscosity not only with shear rate, but also during and following the applied shear. Time-dependent, shear-thinning fluids are described as thixotropic. Latex paint is a common thixotropic fluid. The paint thins when it is sheared by the brush or roller as it is applied. While the paint is thin, it spreads evenly and the brush strokes disappear. After the shear of the application process ends, the paint begins to thicken again, so it does not run down the wall or off the painted item. This thixotropic behavior can make even mixing latex paint in preparation for use problematic. Some time-dependent, shear-thinning fluids experience a permanent reduction in viscosity, making mixing time an important factor in obtaining the desired product properties. Time-dependent, shear-thickening fluids are called rheopectic fluids. Printing ink can exhibit rheopectic properties.

Some more-difficult non-Newtonian fluids have viscoelastic, or yield-stress, properties. A viscoelastic fluid behaves like bread dough or pizza dough as it returns to its original state. As the dough is mixed or kneaded, it can stretch and move; when the applied force is removed, the dough tends to (at least partially) creep back to where it was before being stretched. Because of both the high viscosity and the elastic behavior, special equipment is often required for mixing viscoelastic materials. Dough mixing equipment, for instance, typically has blades that stretch and fold or cut the dough (e.g., a paddle or dough hook in a kitchen mixer). Yield-stress fluids are most readily identified by their gel-like characteristics and their initial resistance to motion. Some common yield stress fluids include ketchup, mayonnaise, hair gel, and hand lotion. A certain minimum force must be applied before a yield-stress fluid will flow. Yield-stress fluids can form a cavern of moving fluid around the impeller, with stagnant fluid surrounding the volume that is moving.

Mixing non-Newtonian fluids may be doubly complicated when the mixing process creates the non-Newtonian properties. For example, a formulation process may start with a low viscosity liquid, and mixing causes the viscosity to increase until the fluid becomes non-Newtonian. Sometimes mixer power may be used as an indicator of final fluid viscosity.

The intent of virtually every mixing process is the same – to achieve required level of homogeneity. Mixing and blending are common steps throughout the process industries:

- Food

- Pharmaceuticals

- Chemicals

- Cosmetics

- Inks, Paints and coating

- Battery

- Adhesives and Sealants

Not only does the mixture require the correct composition and percent solids, the viscosity should be maintained so that consistent product is produced. The entire process of mixing/blending needs to be regulated continuously. Degree of variability of viscosity of various parts of the sample is a true indicator of degree of homogeneity of the mixture. Continuous viscosity monitoring throughout the mixing process is an accurate method to measure and eventually control the key parameters (like % solids) to achieve target properties.

Application FAQs

How and why does viscosity affect mixing?

Fluid viscosity inhibits fluid motion, so the motion of an impeller in a viscous liquid may die out before it moves the entire contents of the tank. In non-Newtonian fluids, there is the possibility that a portion of the tank remains unmixed due to insufficient fluid motion.

Mixing time, speed, agitator impeller selection, and mixing vessel characteristics can all be altered to achieve desired mixing results.

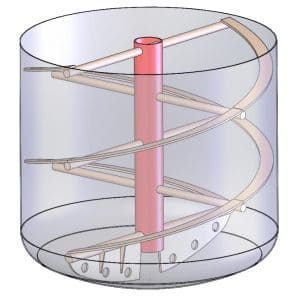

Design and selection of agitator impellers are influenced by material densities, shear characteristics, and blend time. Proper impeller selection is crucial for efficient mixing.

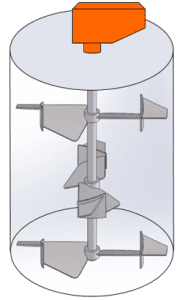

High-viscosity blending usually requires a low-shear impeller to keep fluids uniformly viscous. Blending tanks often require close clearance impellers, such as spiral or anchor-style impellers, or high-viscosity aerofoils to maintain uniform viscosity. All contents of the container are mixed adequately by a low-shear impeller. Highly viscous fluids, when mixed with a high-shear impeller, will behave differently from fluids in the outer parts of the mixing tank. It may result in an inferior final product. Viscosity increases drag on tanks and other internal elements (like baffles). For highly viscous fluids, baffles may not be needed.

Low viscosity fluids may benefit from baffles’ extra agitation. Design of mixing systems must take into account not only the initial viscosity of the fluids but also changes in viscosity as a result of temperature and shear rate changes.

How do you mix or blend high and low viscous liquids?

To blend liquids of different viscosities, start with a liquid of lower viscosity, then add liquid of higher viscosity. This is more energy efficient because the mixer doesn’t have to be sized to handle very high viscosities. Color and dye can be added at the end, as this will act as a visual indicator that a consistent mix has been achieved.

How do you mix high viscosity liquids?

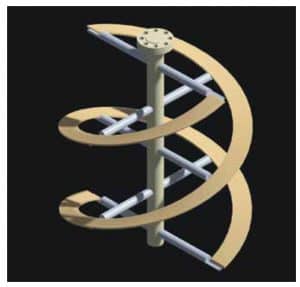

High viscosity fluids require a mixing impeller that can effectively operate in a laminar flow regime with high viscosity. Anchor impellers, gate impellers, and double-helix impellers are typical laminar flow impellers.

The large diameter Double-Pitched HiFlow impeller creates a mixing zone essentially across the diameter of the mixing tank, allowing top-to-bottom circulation for applications such as adhesive/glue manufacturing. Viscose materials cannot bypass the mixing zone since the impeller sweeps the entire diameter of the vessel. It provides excellent agitation in the transition zone (Reynolds numbers in the range of 10-10,000) without the need for baffles.

Double Helix Impellers | Source: https://proquipinc.com/industrial-mixing-basics-high-viscosity-mixing-impellers/

Doubly pitched high-flow impellers | Source: https://proquipinc.com/industrial-mixing-basics-high-viscosity-mixing-impellers/

How do you create homogenous powder mix?

Mixing powder and granular materials is important in many processes in food, pharmaceutical, paper, plastics, and rubber industries. The final product must fulfill three important requirements: flow, homogeneity, and sampling to evaluate mixedness.

In general, to characterize a mix’s quality, several samples need to be taken and analysed. By understanding the mechanism of mixing, sampling position can be chosen so that slowly moving regions or sections have tendency to show segregation. The sampling methods are designed to theoretically give representative samples, assuming that any sampling error is negligible. Since variations in powder blend samples would be related to particle size distribution, it is impossible to measure the absolute efficiency of the technique.

How are online monitoring tools advancing mixing technology?

Blend homogeneity is of utmost importance in the pharmaceutical industry in order to guarantee that the drug substance is distributed evenly throughout the powder/granule blend. It is common to use sampling thieves to sample pharmaceutical blends. Thief sampling has the advantage that samples can be collected in large blenders and subsequently blended until the optimum blending time is reached. Stream sampling is another alternative to sampling thieves. It cannot target locations suspected of providing suboptimal blending. Sampling streams is designed to obtain representative samples, not to focus on specific locations. When the active pharmaceutical ingredient in the blend is found to be within specification, the blend is considered homogeneous. Results are usually expressed as milligrams per gram of active ingredient in the pharmaceutical blend and as standard deviation or relative standard deviation of the drug content. To obtain reliable estimate, one must withdraw numerous samples. A mix’s quality cannot be determined quickly due to the variance in sample quantities taken by people and the variance that may occur during analysis. Today, there are more promising alternatives to sampling for mixing monitoring and studying the process dynamics.

Using near-infrared (NIR) or inline viscosity measurements to measure mixing profiles in real time can be useful for studying powder mixing dynamics. As sensors such as viscometers, NIR and data processing become more advanced, more parameters can now be monitored online. This automation has led to a significant increase in collectible test data, making statistical analysis more thorough.

What are some different methods for quantitative measurement of mixing times?

- Offline sampling: If an off-line analysis technique is used, a chemical marker such as a particular salt, dye, or acid is added to the mixing vessel, and samples are removed regularly. The concentration of the marker in each sample is measured, and the degree of uniformity is inferred from these measurements. Installation of a suitable sampling system can be difficult, and this technique is not suitable if the mixing time is very short, since there will generally be a finite sampling time.

- Schlieren Effect-Based Mixing Measurements: The Schlieren-based technique relies on the light scattering that occurs when two liquids with different refractive indices are mixed.

- Thermocouple-Based Mixing Time Measurements: A thermocouple-based mixing time test can be performed by adding a liquid that has a different temperature from the bulk.

- Conductivity Probe Technique: The conductivity probe mixing time technique uses an electrolyte in the added liquid as the marker. Conductivity probes monitor the local conductivity as a function of time.

- Processing Mixing Time Data: Data collected by the conductivity, thermocouple, or pH techniques must be processed to obtain a characteristic mixing time for the system under investigation.

- RTD for CSTR: The conductivity probe technique can also be used to measure the residence time distribution of continuous flow systems by installing probes at the inlet and outlet of the mixing vessel.

What are some of the most common mixing problems with respect to viscosity?

Solid suspension makes measuring viscosity difficult. The viscosity of solid suspensions needs to be measured using a viscometer which keeps solids in suspension as it measures viscosity over a range of shear rates.

Using too many baffles in the tank can hinder the mixing process. Highly viscous fluids are naturally baffling because of their resistance to flow so baffles that are too large or numerous cause low or no flow at the tank walls.

Using an impeller that’s too small – impellers that are too small don’t create enough flow near the tank walls. Having knowledge of agitator impeller design is critical when creating the perfect mixing system for viscous materials.

Why is viscosity management critical in mixing applications?

The broad and significant factors which make viscosity management important in virtually every mixing application:

- Quality: Viscosity of the mixture is an indicator of key target properties, thus making it critical to the quality. Depending upon the application, the viscosity essentially determines key properties of the produced mixture. Under mixing will give rise to non-homogeneity and over mixing will affect the end product quality, thus making continuous viscosity monitoring indispensable to desired quality. In many mixing/blending processes, continuous monitoring of viscosity is important to ensure the product conforms to the specifications throughout the process.

- Waste: Over-mixing can not only change the state of end product but is a waste of time and energy. Viscosity management in the mixing process can enable identifying the endpoint reliably and accurately, thus leading to significant reduction in rejects and wastes.

- Efficiency: Hassle free, real time monitoring of mix viscosity can save a lot of time and effort which is involved in offline analysis of the sample and making process decisions based on that analysis. In many industries, it results in enhanced operator safety.

- Environment: By managing viscosity continuously in a mixing process not only can product quality be improved, but also power/energy consumption can be optimized and CO2 emissions can be reduced.

Other Considerations for food and pharmaceutical mixing applications

Ease of cleaning. Another important aspect is the ability to clean the equipment easily and without issue. The easier machinery is to clean, the less time is needed to spend cleaning parts and machines, and the faster it can be up and running again. Machinery that’s easy to disassemble will help keep the cleaning process efficient. One example of this is for the customer to purchase equipment that offers either a manual or automatic clean in place (CIP), which is the most efficient way to clean a filler. CIP will cycle the cleaning solution through the machine to ensure that all wetted parts are clean.

Image Source: https://www.amixon.com/en/industries/food

Ease of flexibility, changeover and scalability. The machinery’s ease of changeover and flexibility are also integral to an efficient packaging system. This means that equipment should be able to accommodate multiple types of containers or liquids without the need to change parts. Some manufacturers have machinery that’s capable of handling multiple bottle sizes through the use of a single piece of equipment as long as the liquids’ viscosity is consistent. Machinery should also be easy to upgrade, which is particularly important as business grows.

Viscosity measurement and process challenges

Across industries, mixing operators recognize the need to monitor viscosity but making that measurement has challenged process engineers and quality departments over the years.

Challenges with Off-line viscosity measurements

Existing laboratory viscometers are of little value in process environments because viscosity is directly affected by temperature, shear rate and other variables that are very different off-line from what they are in-line. The condition of the off-line viscosity measurement is often a non-agitated sample that may not give a true representation of the coating’s resistance to flow, viscosity. Collecting samples to be tested in the laboratory and making process decisions based on the findings in the laboratory can be highly cumbersome, time-consuming and extremely inefficient. It is pretty inaccurate, inconsistent and non-repeatable even with an experienced operator.

Challenges with Rotational viscometers

Rotational viscometer measures mix viscosity by monitoring the torque required to rotate a spindle at a constant speed within the fluid. The viscosity measurement principle is as follows – the torque, generally measured by determining the reaction torque on the motor, is proportional to the viscous drag on the spindle, and thus to the viscosity of the fluid. This technique however poses more problems than it solves:

- Torque monitoring is carried out by measuring the supply current during the mixing process. Fluctuations in supplied power to the motor renders the measurements completely unreliable, making is difficult to keep costs at a controllable level and generates higher quantities of waste concrete. Controlling power fluctuations by switching to a more reliable power supply in form of a generator can be a very expensive option.

Because the spindle is rotating, the wires attached to the torque sensor on the shaft would wind up and snap. Slip rings can be alternatives, but not ideal because of set-up times, costs and inevitable wear and tear.

Rheonics’ Solutions for improving mixing performance

Automated and continuous in-line viscosity measurement is crucial to concrete mix. Rheonics offers the following solutions for the concrete mixing process:

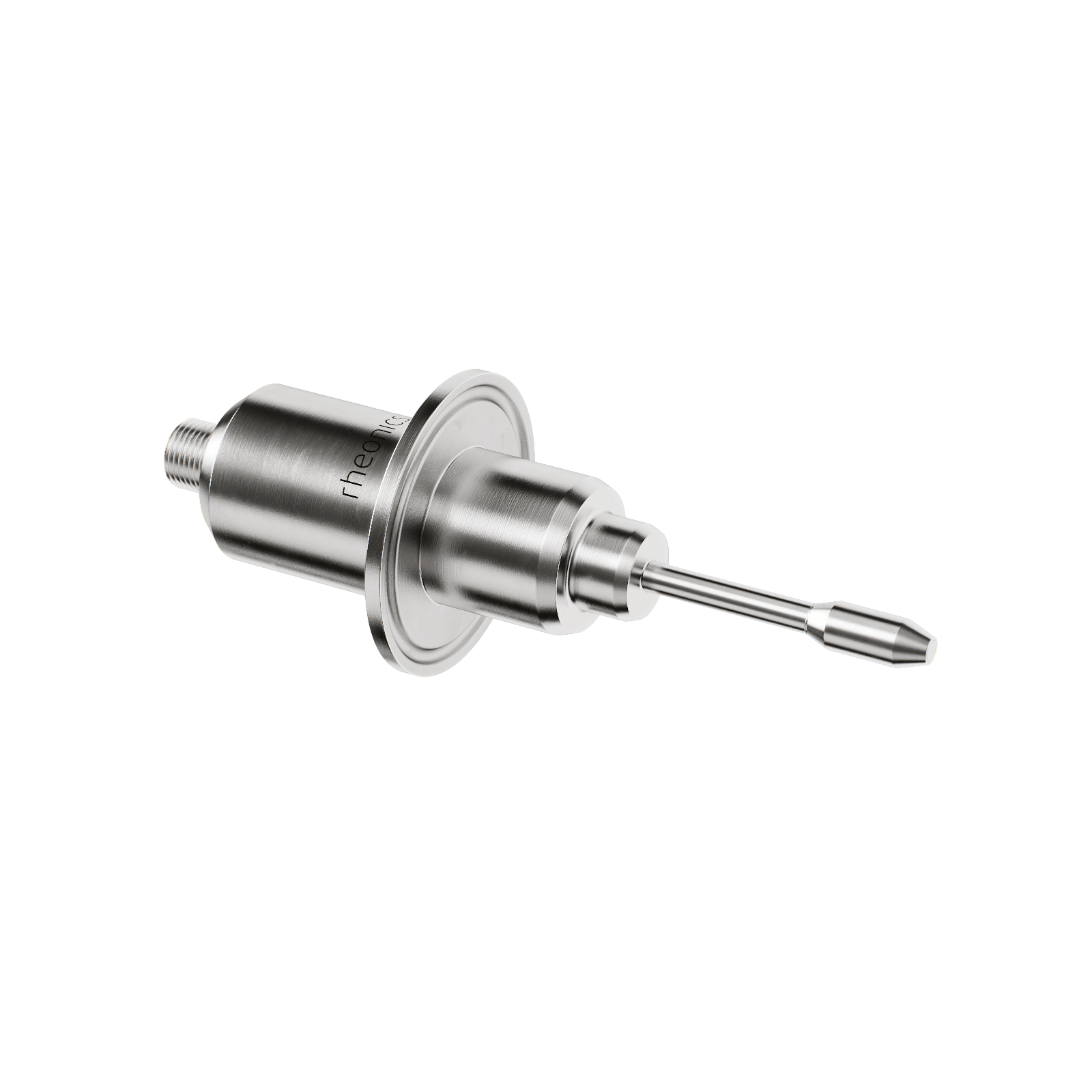

- In-line Viscosity measurements: Rheonics’ SRV is a is a wide range, in-line viscosity measurement device with inbuilt fluid temperature measurement and is capable of detecting viscosity changes within any process stream in real time.

- In-line Viscosity and Density measurements: Rheonics’ SRD is an in-line simultaneous density and viscosity measurement instrument with inbuilt fluid temperature measurement. If density measurement is important for your operations, SRD is the best sensor to cater to your needs, with operational capabilities similar to the SRV along with accurate density measurements.

Automated in-line viscosity measurement through SRV or an SRD eliminates the variations in sample taking and lab techniques which are used for viscosity measurement by the traditional methods. Rheonics’ sensors are driven by patented torsional resonators. Rheonics balanced torsional resonators together with proprietary 3rd generation electronics and algorithms make these sensors accurate, reliable and repeatable under the harshest operating conditions. The sensor is located in-line so that it continuously measures the mix viscosity. The consistency of the concrete mix can be ensured by automation of the dosing system through a controller using continuous real-time viscosity measurements. Both the sensors have a compact form factor for simple OEM and retrofit installation. They require no maintenance or re-configurations. Using no consumables, SRV and SRD are extremely easy to operate.

Rheonics' Advantage

Compact form factor, no moving parts and require no maintenance

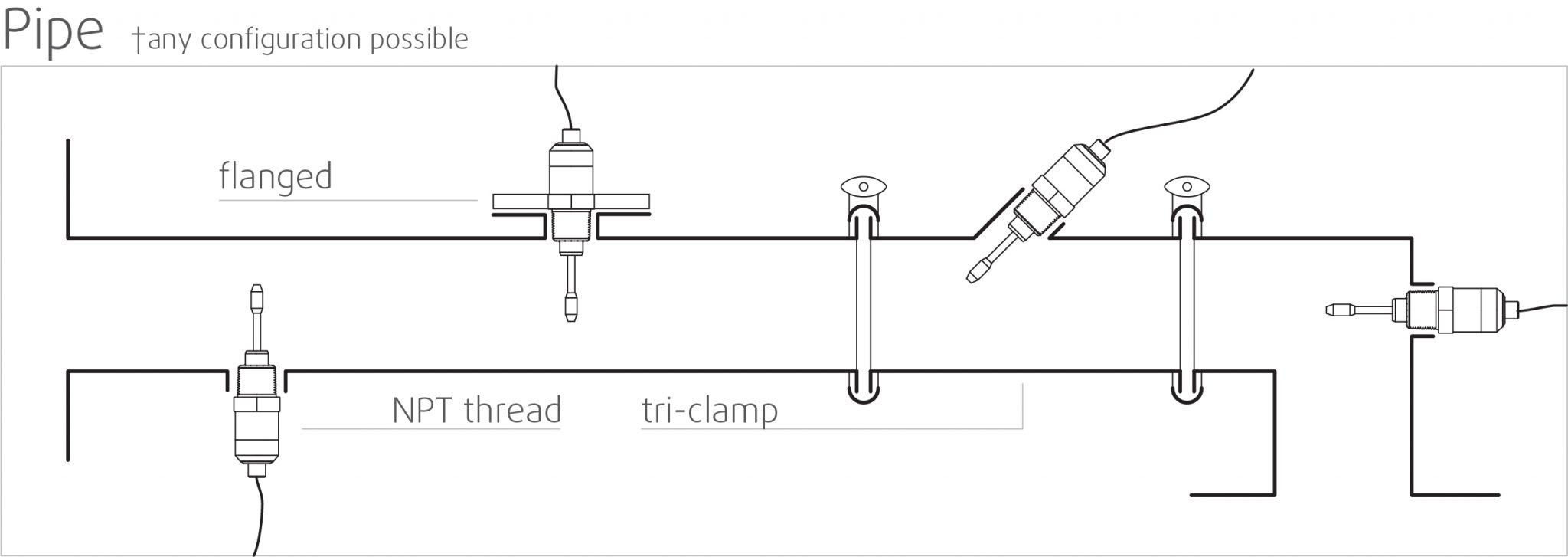

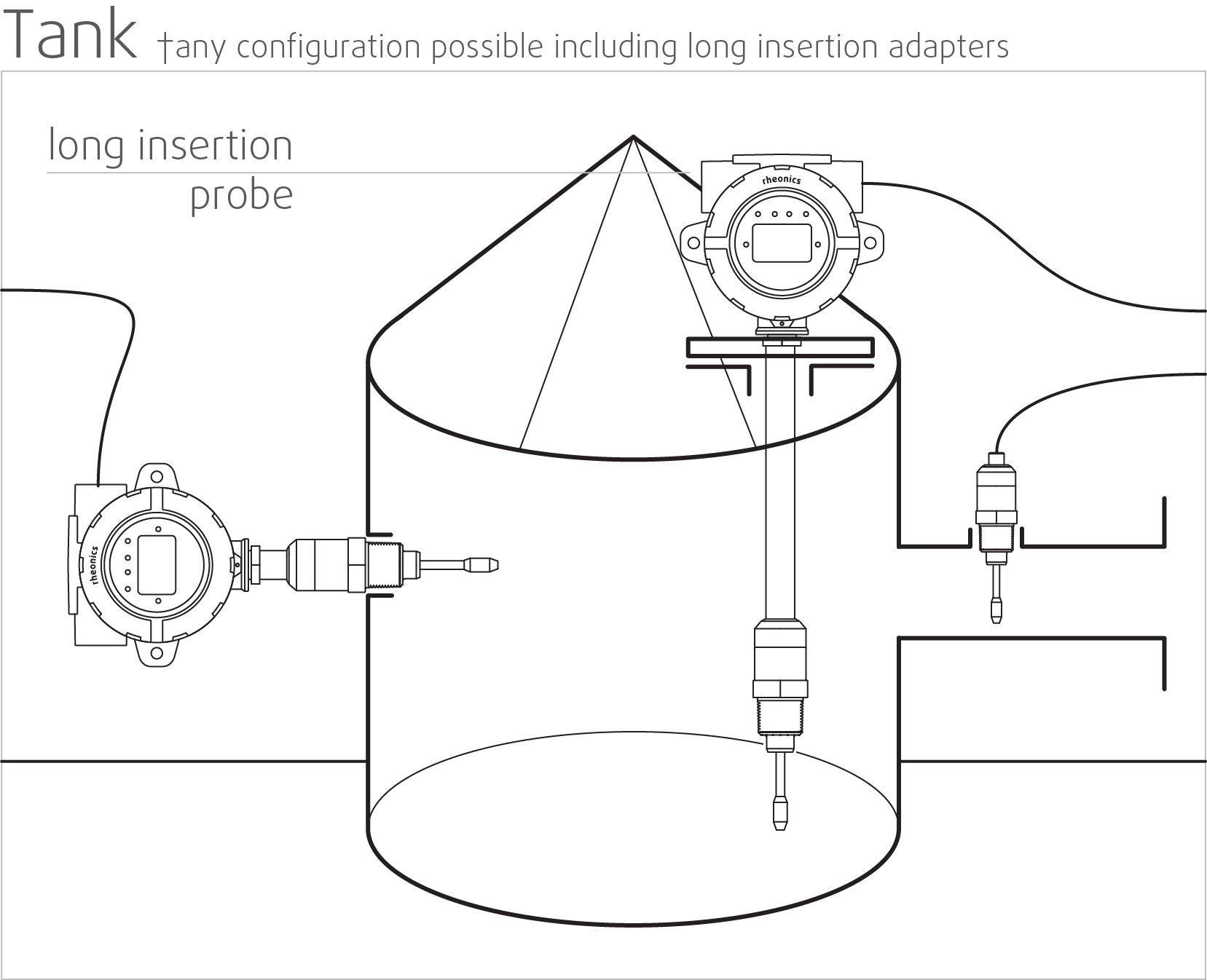

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations. They have a small footprint enabling Inline installation in any process line, avoiding any additional space or adapter requirement.

Hygienic, sanitary design

Rheonics SRV and SRD are available in tri-clamp and DIN 11851 connections besides custom process connections.

Both SRV & SRD conform to Food Contact Compliance requirements according to US FDA and EU regulations.

High stability and insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions and flow rates. Sensor element sits directly in the fluid, with no special housing or protective cage requirements.

Instant accurate readouts on ‘flowability’ – Complete system overview and predictive control

Rheonics’ RheoPulse software is powerful, intuitive and convenient to use. Real-time process fluid can be monitored on the integrated IPC or an external computer. Multiple sensors spread across the plant are managed from a single dashboard. No effect of pressure pulsation from pumping on sensor operation or measurement accuracy. No effect of vibration.

Directly install in the tank or make inline measurements on bypass line

Directly install the sensor in your process stream to do real time viscosity (and density) measurements. The sensor can be immersed in-line in the by-pass line; flow rate and vibrations do not affect the measurement stability and accuracy.

Easy installation and no reconfigurations/recalibrations needed – zero maintenance/down-times

In the unlikely event of a damaged sensor, replace sensors without replacing or re-programming electronics. Drop-in replacements for both sensor and electronics without any firmware updates or calibration changes. Easy mounting. Available with standard and custom process connections like NPT, Tri-Clamp, DIN 11851, Flange, Varinline and other sanitary and hygienic connections. No special chambers. Easily removed for cleaning or inspection. SRV is also available with DIN11851 and tri-clamp connection for easy mounting and dis-mounting. SRV probes are hermetically sealed for Clean-in-place (CIP) and supports high pressure wash with IP69K M12 connectors.

Rheonics instruments have stainless steel probes, and optionally provide protective coatings for special situations.

Low power consumption

24V DC power supply with less than 0.1 A current draw during normal operation.

Fast response time and temperature compensated viscosity

Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest, versatile and most accurate in the industry. SRV and SRD give real-time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions.

SRV is available with the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi

- Temperature range from -40 up to 200°C

- Viscosity range: 0.5 cP up to 50,000 cP (and higher)

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Manage dispensing/filling more efficiently, cut down costs and enhance productivity

Integrate an SRV in the process line and ensure consistency over the years. SRV constantly monitors and controls viscosity (and density in case of SRD) and activates valves adaptively for dosing the mixture constituents. Optimise the process with an SRV and experience fewer shutdowns, lower energy consumption, lesser non-compliances and material cost savings. And at the end of it all, it contributes to a better bottom line and a better environment!

Clean in place (CIP) and Sterilization in place (SIP)

SRV (and SRD) monitors the cleanup of the fluid lines by monitoring the viscosity (and density) of the cleaner/solvent during the cleaning phase. Any small residue is detected by the sensor, enabling the operator to decide when the line is clean/fit for purpose. Alternatively, SRV (and SRD) provides information to the automated cleaning system to ensure full and repeatable cleaning between runs, thus ensuring full compliance to sanitary standards of food manufacturing facilities.

What is CIP? Optimizing CIP (Clean In Place) Systems with inline viscosity & density measurements

What is CIP? In CIP systems, cleaning takes place without dismantling the system. CIP refers to all those mechanical and chemical systems that are necessary to prepare equipment for food processing, either after a processing run that has produced normal…

Superior sensor design and technology

Sophisticated, patented electronics is the brain of these sensors. SRV and SRD are available with industry standard process connections like ¾” NPT, DIN 11851, Flange and Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV/SRD giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Electronics built to fit your needs

Available in both a transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process lines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

Analog and Digital Communication Options

Optional Digital Communication Options

ATEX & IECEx Compliance

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Implementation

Directly install the sensor in your process stream to do real-time viscosity and density measurements. No bypass line is required: the sensor can be immersed in-line; flow rate and vibrations do not affect the measurement stability and accuracy. Optimize mixing performance by providing repeated, consecutive, and consistent tests on the fluid.

In-line Quality control locations

- In tanks

- In the connecting pipes between various processing containers

Instruments/Sensors

SRV Viscometer OR an SRD for additional density

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers and density meters have the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed