References:

[1]: API American Petroleum Institute

[2]: API Flanges, API 6A Flanges, API Connections, API Studded Blocks

Table of Content

The Hydrocarbon Processing Industry – HPI, is involved in the exploration, extraction, transportation, refining, and marketing of petroleum, natural gas, and chemicals, to be used as a source of energy around the world. The industry is divided typically into three segments which are Upstream, Midstream, and Downstream, each handling the crude oil until obtaining finished products like gasoline, diesel, lubricants, precursors for polymers, etc.

In this industry, efforts are made to ensure high-quality monitoring and control of the processes with the use of advanced technology, Rheonics plays an important role by introducing robust inline process density meters designed to meet the HPHT (High Pressure High Temperature) demands in Hydrocarbon Production.

The API 6A (American Petroleum Institute) is used internationally for specifications on wellhead and christmas tree equipment in the hydrocarbon industry. Norm relates with API 16A, specification for Drill Through Equipment, defines the use of hubs as process connections in the industry.

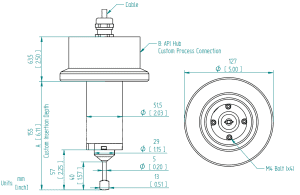

The SRD sensor is Rheonics solution for inline density and viscosity measurement with simultaneous temperature output. For Hydrocarbon Industry, HPHT conditions are required and the SRD probe can reach pressures up to 500 bar (7500 psi) and more than 200 °C (400 °F). However, pressure rating is also defined by the process connection used to install the probe in the pipeline.

API hubs and clamps are used for installation in wellhead parts. They follow the size and pressure ranges from API flanges but are smaller, lighter, and easier to assemble. The complete connection includes two hubs (one of which is from the sensor probe), a seal ring, clamps, and 4 bolts.

Rheonics density and viscosity meter SRD can be specially designed for installation with API hubs and sustain the working requirements of temperature and pressure.

API hubs have an equivalent from Grayloc hub, with a different seal groove. Rheonics SRD can be ordered with these and other customizable connections and insertion depths.

In addition, Rheonics SRD HPHT API 6A can be ordered with an EX certificate approval to use the sensor probe in explosive atmospheres. If this is needed, the user must follow Rheonics EX manual of the sensor for correct installation.

| Specifications | |

|---|---|

| Sensor | Rheonics SRD |

| Order code | SRD-HPT |

| Insertion length A | Customizable |

| Connection type B | API hub or customizable flange |

| CAD files | Drawing - ZIP file |

| Pressure rating | 500 bar (7500 psi) |

| Temperature rating | 200°C (400 °F) |

| Certifications available | ATEX, IECEx |

General Installation Guidelines

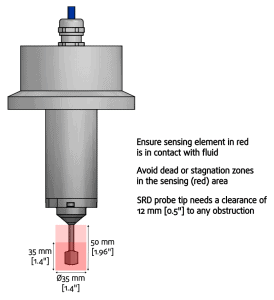

The Rheonics SRD has the following installation criteria that should be met to ensure accurate, repeatable, and reproducible density (and viscosity) readings.

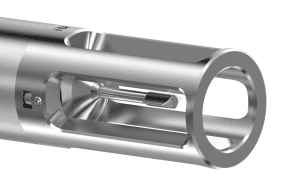

Figure 2: SRD HPHT API sensing element

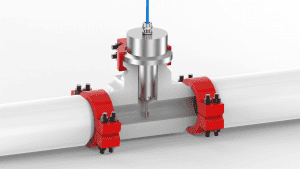

The SRD HPHT can be integrated into a wellhead piping with an API hub connection. In the next example the sensor probe is mounted vertically to a tee section, clamped to a matching plug, and has the sensor cable coming out the back, to be connected to the electronics unit.

Sensor cable can be standard or EX certified based on customer order.

Figure 3: SRD HPHT API installation example

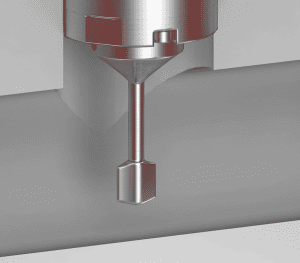

Cross section view shows how the sensing element is correctly placed in the main pipeline and not in dead zones. Furthermore, the sensing tip is aligned with the pipe to avoid recirculation zones. Find out more about this topic here.

Figure 4: SRD HPHT API sensing tip aligned with the pipe

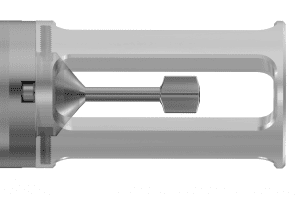

For processes with possible solids or particles hitting and potentially damaging the sensing element, Rheonics offers a protective cage that prevents this from happening. Care should be taken to avoid external machinery from colliding with the probe even if protected with the cage.

The protective cage is fixed to the sensor probe with screws on each side.

Figure 5: SRD HPHT API optional protective cage

Use the online Request for Quotation RFQ for SRD and specify the required ranges, calibration, operation conditions, etc. As Process Connection, select X5 and specify parameters A (insertion depth) and B (process connection e.g. API) in respective boxes. Add in “Additional Comments” section the HPHT requirement.

| How to Order Rheonics HP Sensor? | |||

|---|---|---|---|

| 1 | Rheonics SR-Type sensor SRD: Inline Density and Viscosity meter SRV: Inline Viscometer | 4 | Insertion Length "A" Distance from sensor connection to tip. Defined by client, e.g. A155: 155 mm |

| 2 | Probe Design X9: Special variant for Type-SR probe | 5 | Process Connection "B" Norm/Standard and size defined by the client. For API Hubs, define pressure rating and type. Code is then defined by Rheonics, e.g. BAP0501: API Hub 16A 5000 psi Clamp number 1 |

| 3 | HP Variant HP: High pressure design | ||

[1]: API American Petroleum Institute

[2]: API Flanges, API 6A Flanges, API Connections, API Studded Blocks