The process of converting liquid milk into dry powder involves removing most of the water. The amount of water removed is many times greater than the amount of water in the finished product. Significant changes occur to the properties, structure, and appearance of the building during this process. A milk product is quite sensitive, and its quality can be drastically affected by factors such as heat or bacteria.

The viscosity of the milk at the atomisation step has a crucial effect on the characteristics of the resulting milk powder. Installed at the pre-atomiser point, a viscometer offers significantly better control of the atomisation process, leading to reductions in wastage, lower energy consumption and better control of product texture, bulk density and moisture content.

Application

Powdered milk, also known as dried milk, is a dairy product that is made by dehydrating liquid milk through several drying processes until it is a powder.

Dried milk can be used for various applications, such as:

- Recombination of milk and milk products

- In the bakery industry to increase the volume of bread and improve its water-binding capacity. The bread will then remain fresh for a longer period of time

- Substitute for eggs in bread and pastries

- Producing milk chocolate in the chocolate industry

- Producing sausages and various types of ready-cooked meals in the food industry and catering trade

- In baby foods: baby milk powder

- Production of ice cream

- Animal feed, calf growth accelerator

- Baked goods, snacks and soups

- Cheese milk extension (powder is added to local fresh milk to increase the yield of cheese)

- Dairy desserts

- Direct consumer use (home reconstitution)

- Infant formulae

- Nutritional products for invalids, athletes, hospital use etc.

- Recombined “fresh”, UHT, evaporated and sweetened condensed milks

- Recombined cheeses, mainly “soft” or “fresh”

- Recombined coffee and whipping creams

- Recombined yoghurts and other fermented products

Dried milk is a manufactured dairy product made by evaporating milk to a dry material. One purpose of drying milk is to preserve it; milk powder has a far longer shelf life than liquid milk and does not need to be refrigerated, due to its low moisture content. Another purpose is to reduce its bulk for economy of transportation. Powdered milk and dairy products include such items as dry whole milk, non-fat dry milk, dry buttermilk, dry whey products and dry dairy blends. Each field of application makes its own specific demands of milk powder.

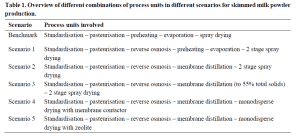

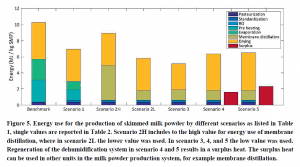

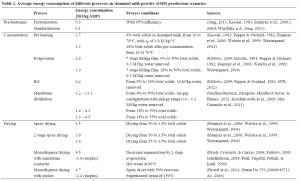

Milk powder manufacture includes many heating procedures, which consume a lot of energy. The present manufacturing process has been greatly optimised during the last few decades. The adoption of new milk powder technologies will be critical. Upstream and downstream process units will be influenced by the optimization of single process units. As a result, it is critical to consider the entire manufacturing chain. Engineers’ objective is to create an optimization routine that considers energy and water usage, Lifecycle assessment (LCA), and economic elements, resulting in a sustainable milk powder manufacturing chain.

Milk Powder Production Process

Milk powder production is a simple process that can be done on a large scale. The gentle removal of water at the lowest possible cost under stringent hygiene conditions while retaining all of the desirable natural properties of the milk such as colour, flavour, solubility, and nutritional value is involved in production.

Whole (full cream) milk is approximately 87 percent water. Skim milk is made up of roughly 91 percent water. Water is removed from milk powder during the manufacturing process by boiling the milk under reduced pressure at a low temperature, a process known as evaporation. The resulting concentrated milk is then sprayed in a fine mist into hot air to remove any remaining moisture, resulting in the formation of a powder.

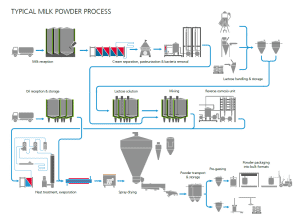

The key steps in the milk powder production process are:

Separation

The traditional method of producing milk powders begins with pasteurising raw milk received from the dairy factory and separating it into skim milk and cream using a centrifugal cream separator.

Pre-heating

The next step in the process is “preheating,” which involves heating the standardised milk to temperatures ranging from 75 to 120 ° C. The milk is kept in this state for a set amount of time, which can range from a few seconds to several minutes (pasteurisation: 72 ° C for 15 seconds). Preheating causes a controlled denaturation of the whey proteins in milk, as well as the destruction of bacteria, the inactivation of enzymes, the production of natural antioxidants, and the imparting of heat stability. Preheating can be done indirectly (via heat exchangers), directly (via steam injection or infusion into the product), or a combination of the two. In order to reduce energy costs, indirect heaters typically use waste heat from other parts of the process.

Evaporation

The preheated milk is concentrated in stages or “effects” in the evaporator, starting at around 9.0 percent total solids for skim milk and 13 percent for whole milk and increasing to 45-52 percent total solids. This is accomplished by boiling the milk in a falling film on the interior of vertical tubes at temperatures below 72 °C and extracting the water as vapour. This vapour, which can be compressed mechanically or thermally, is then used to heat the milk in the evaporator’s next effect, which can be operated at a lower pressure and temperature than the previous effect. For maximum energy efficiency, modern plants can have up to seven effects. In the evaporator, more than 85 percent of the water in the milk can be removed.

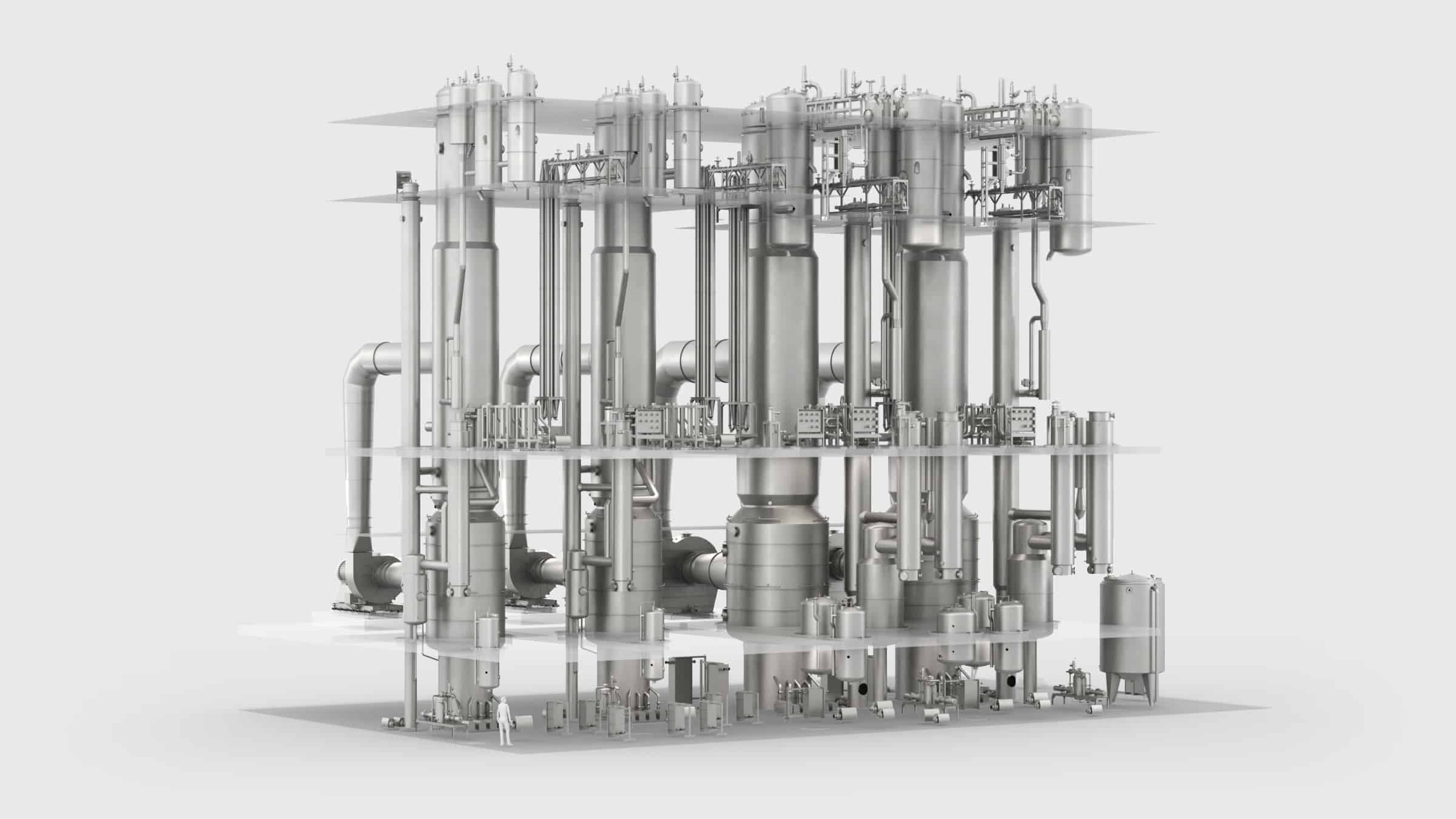

Overview of basic production processes | Source: GEA (https://www.gea.com/en/products/dryers-particle-processing/spray-dryers/msd-spray-dryer)

Spray Drying

The milk concentrate from the evaporator is atomized into thin droplets before being spray dried. This is done with either a spinning disc atomizer or a series of high-pressure nozzles inside a huge drying chamber in a flow of hot air (up to 200 °C). Evaporation cools the milk droplets, and they never reach the temperature of the air. Prior to atomization, the concentrate can be heated to reduce viscosity and increase the energy available for drying. Much of the remaining water evaporates in the drying chamber, leaving a fine powder with a moisture content of around 6% and a mean particle size of typically 0.1 mm diameter. Final or “secondary” drying occurs in a fluid bed, or a series of such beds, in which hot air is blown through a layer of fluidized powder, removing water to a moisture content of 2-4 percent.

Source: GEA

Packaging and Storage

Milk powders are far more stable than fresh milk, but they must be protected from moisture, air, light, and heat to retain their quality and shelf life. Milk powders easily absorb moisture from the air, resulting in fast deterioration of quality and caking or lumping.

The fat in WMPs can react with oxygen in the air to produce off-flavors, especially at higher storage temperatures (> 30 °C), such as those found in the Tropics’ lower latitudes. Milk powder is packaged in either multi-wall plastic-lined bags (25 kg) or bulk bins (600 kg).

Energy and environmental considerations

Large amounts of energy are expended in the process of removing water and so plants developed over the years have become increasingly more energy efficient. Evaporators are much more energy efficient than driers, using only a fraction of a kilogram of steam (or the energy equivalent) per kilogram of water removed.

Drying process contributes to a major chunk of overall energy consumption

On the other hand, dryers use several kilograms of steam (or steam equivalent) per kilogram of water evaporated. Drying with a spray can remove the bulk of the remaining water cleanly and rapidly, but spray driers must be short-term residences. Fluid beds are therefore used for the final stages of drying. The powder remains for several minutes in fluid beds allowing time for the last of the water to be removed. It is common for milk powder manufacturing plants to be very large, few in number, and located in rural areas. Modern and well-managed plants have relatively little impact on the environment. Their energy requirements are moderate, as they burn coal or gas and consume substantial amounts of electricity. Energy consumption is under strong economic pressure to be reduced, but major improvements are unlikely.

The silos, cream separators, and evaporators and associated equipment must be cleaned every day, while dryers need only be cleaned occasionally. As cleaning agents, sodium hydroxide and nitric acid are used. Suitable disposal methods need to be used with used cleaning fluids. Milk powder dust can be released into the local environment when the plant malfunctions, but this is rare.

Source: Moejes, S. N. (2019). Redesign of the milk powder production chain: assessment of innovative technologies. Wageningen University. https://doi.org/10.18174/498246

Value of viscosity measurements in spray drying step of milk powder manufacturing

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, slurry or liquid. This process is often used as a final production step before selling or packaging products. A source of heat and a medium to remove the vapour produced by the process are often involved. In bio-products like food, grains, and pharmaceuticals, the solvent to be removed is almost invariably water.

This process is widely used in the food and chemicals industries for making products as diverse as baby foods, coffee, soup mixes and dyestuffs. The efficiency of drying is largely determined by the degree of atomisation, which is directly proportional to the viscosity of the feed solution. Control of milk concentrate viscosity and total solids (TS) content prior to spray drying can improve dairy ingredient manufacture.

Thus, the viscosity of the milk at the atomisation step has a crucial effect on the characteristics of the resulting milk powder. Installed at the pre-atomiser point, a viscometer offers significantly better control of the atomisation process, leading to reductions in wastage, lower energy consumption and better control of product texture, bulk density and moisture content.

Consequences of inadequate viscosity management during spray drying

It is often because of the recipe complexity, the development time, and the costs of development that spray-drying in powder form is inefficient. Viscosity parameter failure during spray drying affects production efficiency in various ways, including:

- End product quality is unstable: consistency problems, ingredient variations, poor dry extract

- Moisture content not according to specifications

- Loss of nutritional value

- Less or bad taste

- Riveted batches

- Short shelf life

- Inefficiencies in the production process: loss of productivity and profits

- Waste of energy: drying towers use a lot of energy and increase overhead costs

Viscosity measurements of concentrated milk are challenging due to its non-Newtonian properties, suspended solids and gases, heavy processing (pressure, vibration, contamination) and cleaning procedures.

Measurement challenges

Because of its non-Newtonian flow properties, age-thickening characteristics, and the presence of suspended solids and gases, measuring the viscosity of concentrated milk is a difficult task. Exposure to hostile process conditions, such as plant vibrations, fouling, cleaning agents, dust, and so on, presents additional challenges in the design of on-line probes in food processing plants.

Many laboratory viscometers currently available have limitations, i.e., measurements are time-consuming, not suitable for rapid real-time monitoring of concentrate viscosity and may not be suitable for characterising samples with complex rheological properties (e.g., materials which are time, temperature and shear dependent). Research with rotational-type viscometers showed that the latter have some limitations in a dairy processing context which partly explains their poor uptake in milk powder plants. Some limitations of conventional viscometers can be overcome by inline viscosity measurements that monitors concentrate viscosity in real-time for improved process control.

Requirements from an inline process monitoring equipment

The ideal PAT (Process Analytical Technologies) tool is an inline instrument that can monitor and measure process parameters simultaneously in real time while operating in a highly automated environment. Instruments must be of sanitary design, operate robustly within the full process cycle (production and cleaning). Inline determination of the rheological properties of moving fluids (i.e. dairy concentrates) is one of the process parameters where PAT tools can be add real value in terms of optimising process control. Measurement of process viscosity is crucial in the monitoring and control of a variety of concentration processes in the dairy industry. Continuous monitoring of the rheological behaviour of the fluid can allow for optimisation of the process e.g. pumping (avoid pump blockage and failure), evaporation (limit fouling and maximise water removal) and spray drying (avoidance of nozzle fouling).

To guarantee that any measurement acquired is representative, the optimum design should allow for cleaning-in-place with little fouling, rapid reaction time, and good sample renewal or even better, if there are no sampling needs. A probe must meet sanitary regulations, such as the elimination of dead spots where germs could multiply. Because certain atomisation systems use high-pressure nozzles, the optimal viscosity measuring technique may be determined by the atomisation type.

Studies have revealed that torsional vibration gave the most trouble-free performance of those systems evaluated for monitoring viscosity. Its advantages include high immunity to plant vibration, ease of cleaning and low maintenance requirement, having no moving parts.

Importantly, measurements are unaffected by changes in flow rate or the presence of suspended solids or gases. Installed at the pre-atomiser point, the viscometer offered significantly better control of the atomisation process, leading to reductions in wastage, lower energy consumption and better control of product texture, bulk density and moisture content. Inline viscosity monitoring of powdered milk improves manufacturing by optimizing the homogeneity of dehydrated milk, creating consistent reconstituted products, increasing yields and reducing losses.

Rheonics' Advantage

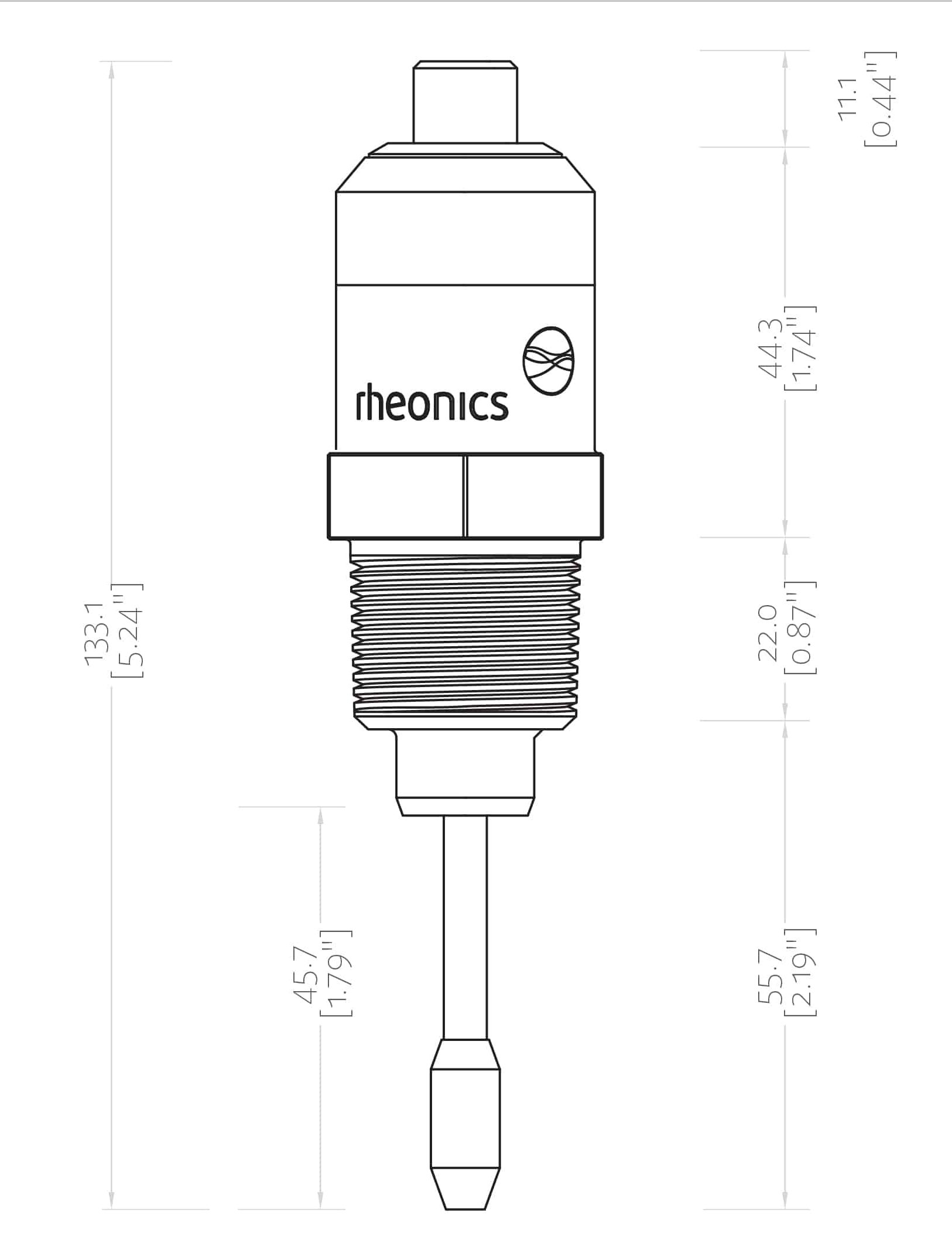

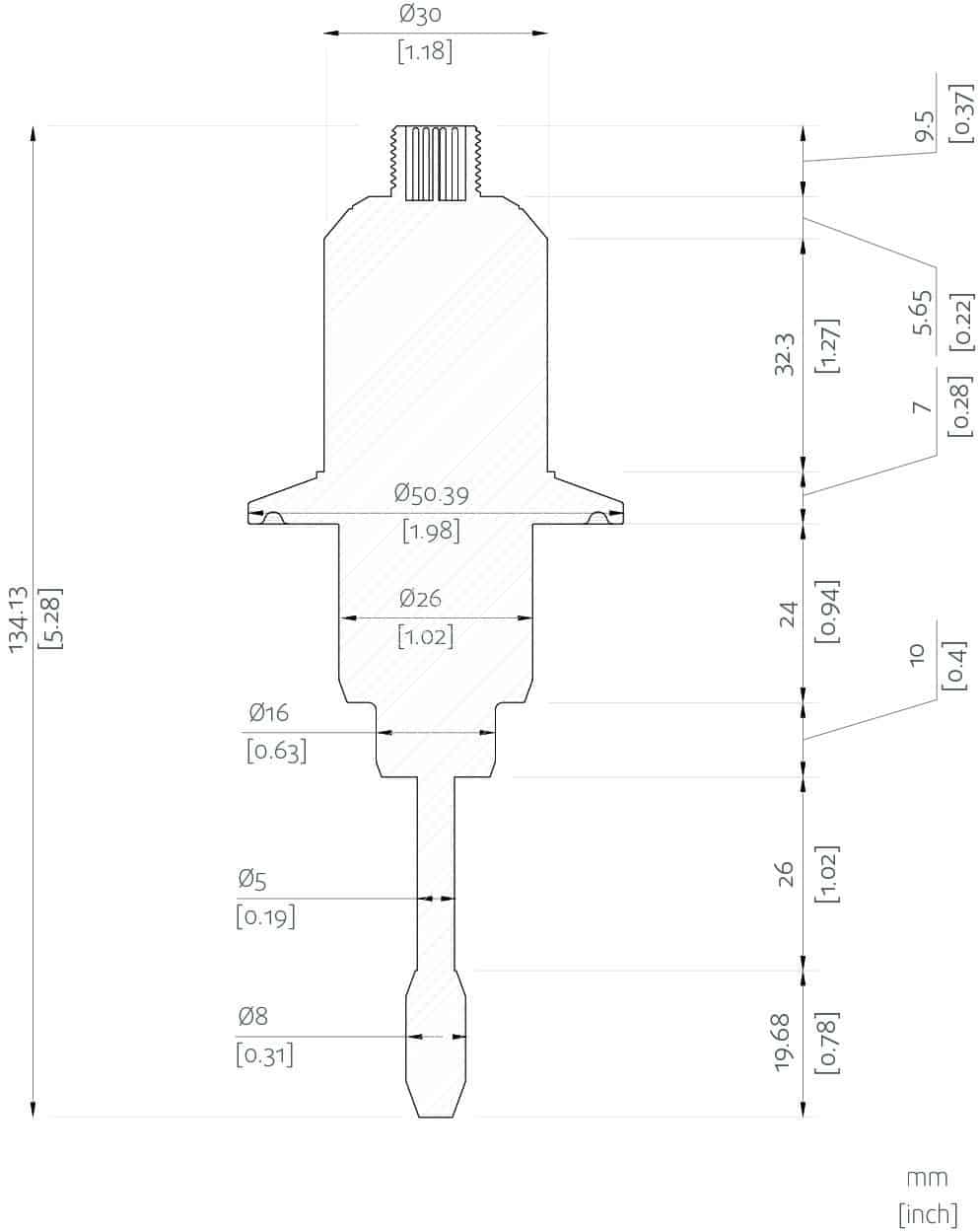

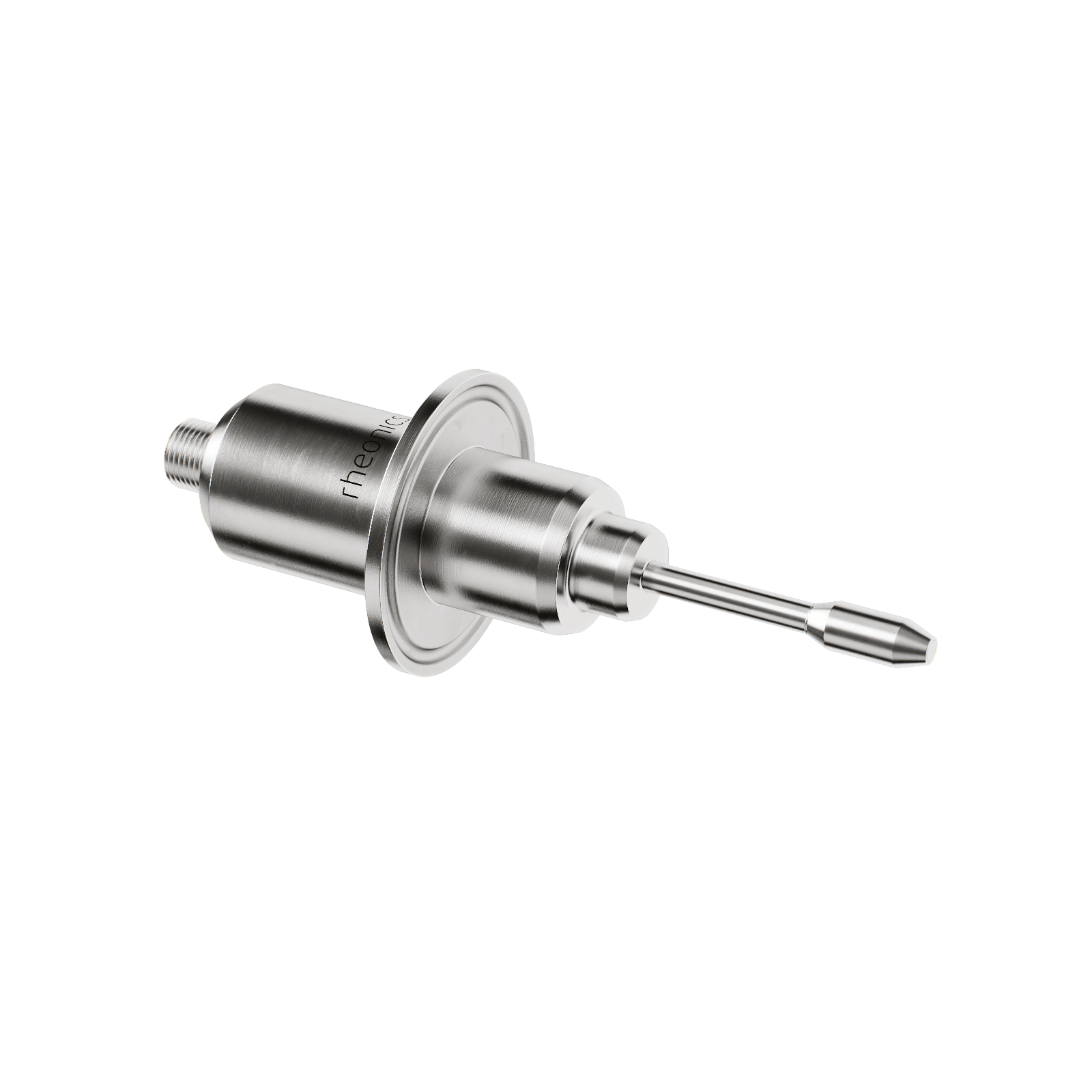

Compact form factor, no moving parts and require no maintenance

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations. They have a small footprint enabling Inline installation in any process line, avoiding any additional space or adapter requirement.

Hygienic, sanitary design

Rheonics SRV and SRD are available in tri-clamp and DIN 11851 connections besides custom process connections.

Both SRV & SRD conform to Food Contact Compliance requirements according to US FDA and EU regulations.

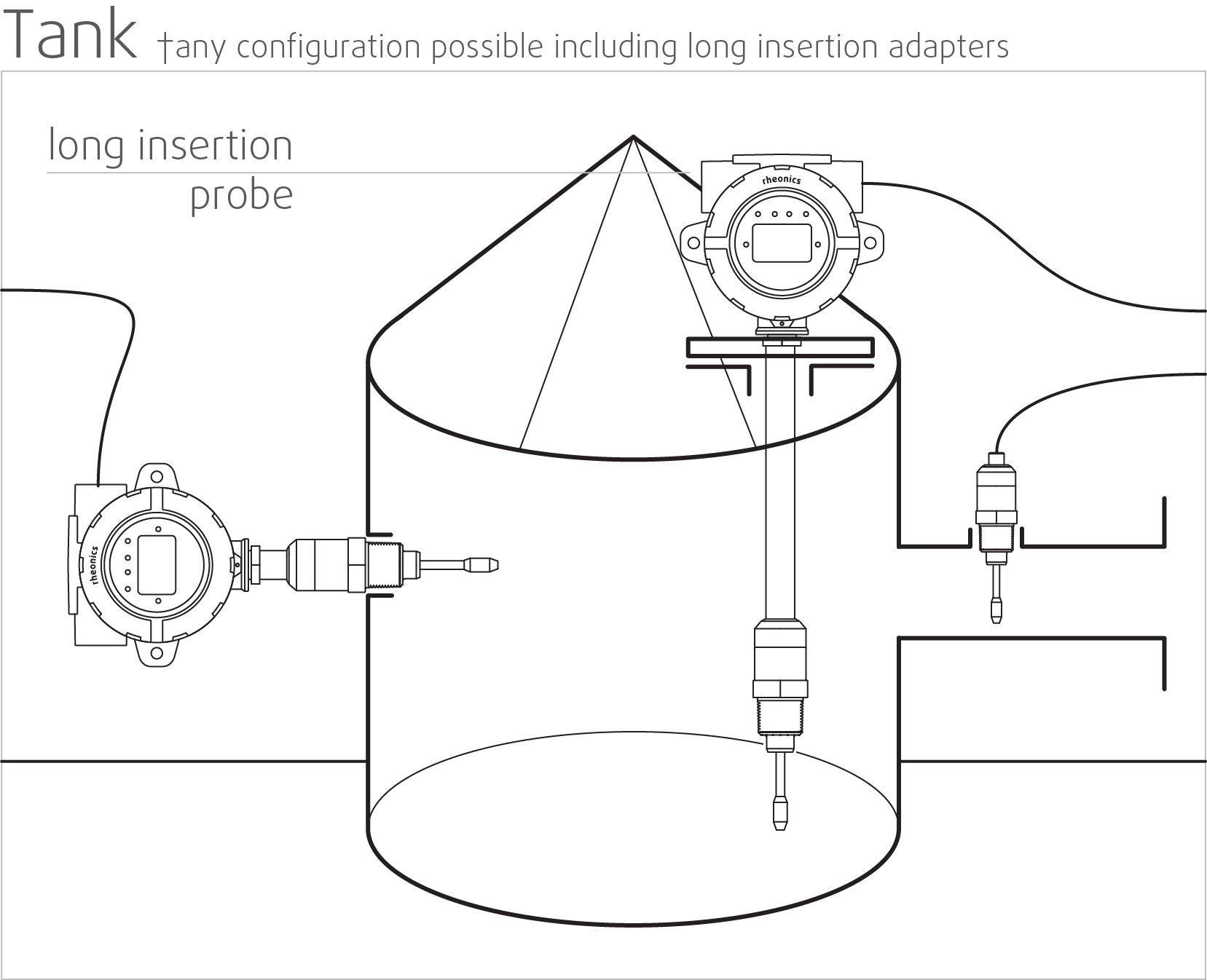

High stability and insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions and flow rates. Sensor element sits directly in the fluid, with no special housing or protective cage requirements.

Instant accurate readouts on quality – Complete system overview and predictive control

Rheonics’ software is powerful, intuitive and convenient to use. Real-time process fluid can be monitored on the integrated IPC or an external computer. Multiple sensors spread across the plant are managed from a single dashboard. No effect of pressure pulsation from pumping on sensor operation or measurement accuracy. No effect of vibration.

Easy installation and no reconfigurations/recalibrations needed – zero maintenance/down-times

In the unlikely event of a damaged sensor, replace sensors without replacing or re-programming electronics. Drop-in replacements for both sensor and electronics without any firmware updates or calibration changes. Easy mounting. Available with standard and custom process connections like NPT, Tri-Clamp, DIN 11851, Flange, Varinline and other sanitary and hygienic connections. No special chambers. Easily removed for cleaning or inspection. SRV is also available with DIN11851 and tri-clamp connection for easy mounting and dis-mounting. SRV probes are hermetically sealed for Clean-in-place (CIP) and supports high pressure wash with IP69K M12 connectors.

Rheonics instruments have stainless steel probes, and optionally provide protective coatings for special situations.

Low power consumption

24V DC power supply with less than 0.1 A current draw during normal operation.

Fast response time and temperature compensated viscosity

Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest, versatile and most accurate in the industry. SRV and SRD give real-time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions.

SRV is available with the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi

- Temperature range from -40 up to 200°C

- Viscosity range: 0.5 cP up to 50,000 cP (and higher)

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Clean in place (CIP) and Sterilization in place (SIP)

SRV (and SRD) monitors the cleanup of the fluid lines by monitoring the viscosity (and density) of the cleaner/solvent during the cleaning phase. Any small residue is detected by the sensor, enabling the operator to decide when the line is clean/fit for purpose. Alternatively, SRV (and SRD) provides information to the automated cleaning system to ensure full and repeatable cleaning between runs, thus ensuring full compliance to sanitary standards of food manufacturing facilities.

Superior sensor design and technology

Sophisticated, patented electronics is the brain of these sensors. SRV and SRD are available with industry standard process connections like ¾” NPT, DIN 11851, Flange and Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV/SRD giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Electronics built to fit your needs

Available in both a transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process lines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

Analog and Digital Communication Options

Optional Digital Communication Options

ATEX & IECEx Compliance

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Implementation

Directly install the sensor in your vat to do real-time viscosity and density measurements. No bypass line is required: the sensor can be immersed in-line; flow rate and vibrations do not affect the measurement stability and accuracy. Optimize mixing performance by providing repeated, consecutive, and consistent tests on the fluid.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers and density meters have the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed