Introduction

Mixing is the fundamental step in the manufacture of many products. Even though it may not have strict precision requirements, over-mixing still is an unnecessary waste of energy and time. In most cases however, mixing is more of an exact science. Under mixing will leave various components unevenly distributed whereas over mixing might change the state of the end product.

Application

The intent of virtually every mixing process is the same – to achieve required level of homogeneity. Mixing and grinding are common steps throughout the process industries:

- Food

- Pharmaceuticals

- Chemicals

- Cosmetics

- Inks, Paints and coating

- Battery

- Adhesives and Sealants

Not only does the mixture require the correct composition and percent solids, the viscosity should be maintained so that consistent product is produced. Degree of variability of viscosity of various parts of the sample is a true indicator of degree of homogeneity of the mixture. Continuous viscosity monitoring throughout the mixing process is an accurate method to measure and eventually control the key parameters (like % solids) to achieve target properties.

Why is viscosity management critical in mixing applications?

The broad and significant factors which make viscosity management important in virtually every mixing application:

- Quality: Viscosity of the mixture is an indicator of key target properties, thus making it critical to the quality. Depending upon the application, the viscosity essentially determines key properties of the produced mixture. Under mixing will give rise to non-homogeneity and over mixing will affect the end product quality, thus making continuous viscosity monitoring indispensable to desired quality.

- Waste: Over-mixing can not only change the state of end product but is a waste of time and energy. Viscosity management in the mixing process can enable identifying the endpoint reliably and accurately, thus leading to significant reduction in rejects and wastes.

- Efficiency: Hassle free, real time monitoring of mix viscosity can save a lot of time and effort which is involved in offline analysis of the sample and making process decisions based on that analysis.

- Environment: Lowering the amount of wastes is good for the environment.

Challenges

Mixing operators recognize the need to monitor viscosity but making that measurement has challenged process engineers and quality departments over the years.

Challenges with Off-line viscosity measurements

Existing laboratory viscometers are of little value in process environments because viscosity is directly affected by temperature, shear rate and other variables that are very different off-line from what they are in-line. The condition of the off-line viscosity measurement is often a non-agitated sample that may not give a true representation of the coatings resistance to flow, viscosity. Collecting samples to be tested in the laboratory and making process decisions based on the findings in the laboratory can be highly cumbersome, time-consuming and extremely inefficient. It is pretty inaccurate, inconsistent and non-repeatable even with an experienced operator.

Challenges with Rotational viscometers

Rotational viscometer measures mix viscosity by monitoring the torque required to rotate a spindle at a constant speed within the fluid. The viscosity measurement principle is as follows – the torque, generally measured by determining the reaction torque on the motor, is proportional to the viscous drag on the spindle, and thus to the viscosity of the fluid. This technique however poses more problems than it solves:

- Torque monitoring is carried out by measuring the supply current during the mixing process. Fluctuations in supplied power to the motor renders the measurements completely unreliable, making is difficult to keep costs at a controllable level and generates higher quantities of waste concrete. Controlling power fluctuations by switching to a more reliable power supply in form of a generator can be a very expensive option.

- Because the spindle is rotating, the wires attached to the torque sensor on the shaft would wind up and snap. Slip rings can be alternatives, but not ideal because of set-up times, costs and inevitable wear and tear.

Rheonics' Solutions

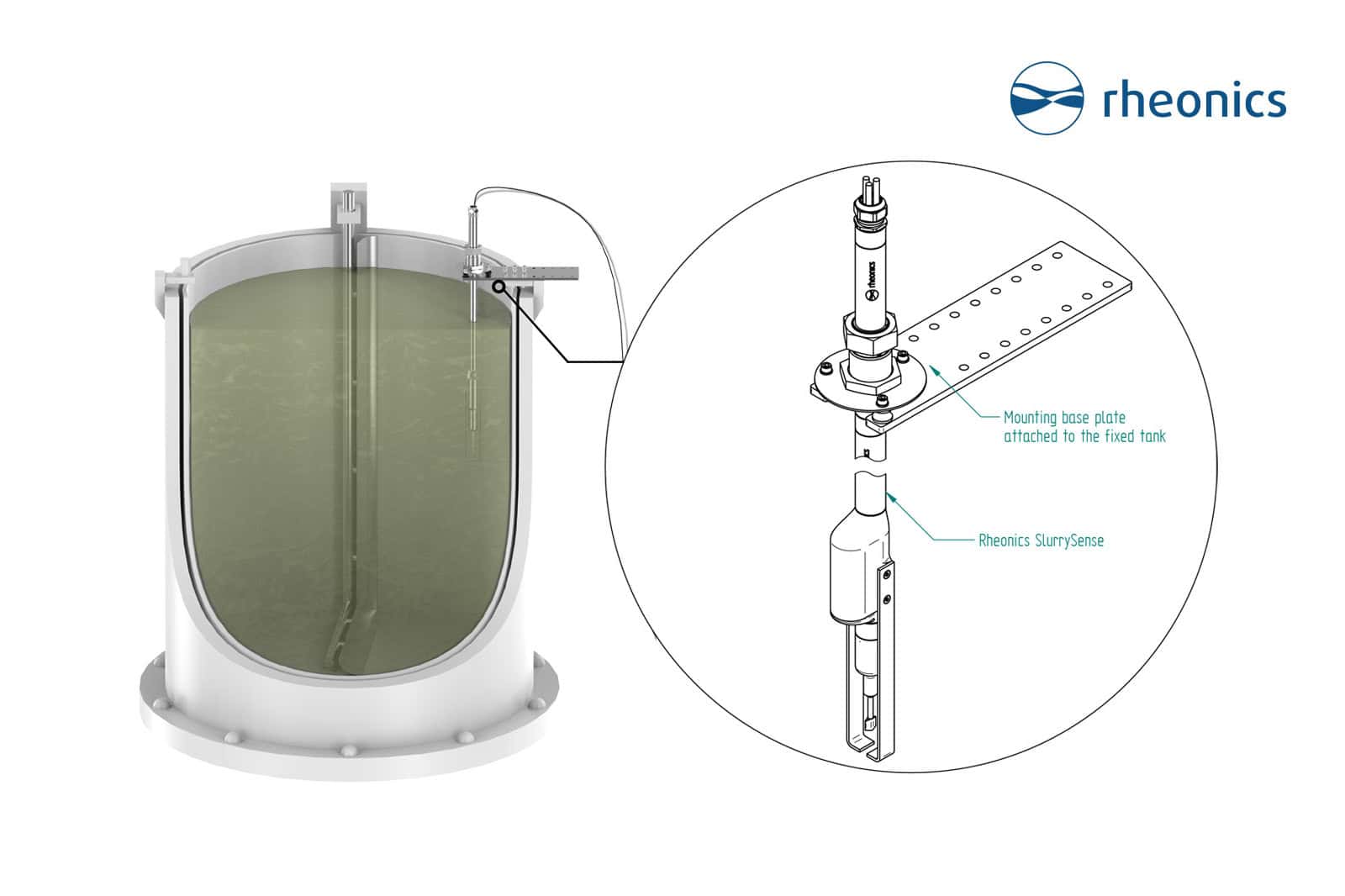

Automated and continuous in-line viscosity measurement is crucial to concrete mix. Rheonics offers the following solutions for the concrete mixing process:

- In-line Viscosity measurements: Rheonics’ SRV is a is a wide range, in-line viscosity measurement device with inbuilt fluid temperature measurement and is capable of detecting viscosity changes within any process stream in real time.

- In-line Viscosity and Density measurements: Rheonics’ SRD is an in-line simultaneous density and viscosity measurement instrument with inbuilt fluid temperature measurement. If density measurement is important for your operations, SRD is the best sensor to cater to your needs, with operational capabilities similar to the SRV along with accurate density measurements.

Automated in-line viscosity measurement through SRV or an SRD eliminates the variations in sample taking and lab techniques which are used for viscosity measurement by the traditional methods. Rheonics’ sensors are driven by patented torsional resonators. Rheonics balanced torsional resonators together with proprietary 3rd generation electronics and algorithms make these sensors accurate, reliable and repeatable under the harshest operating conditions. The sensor is located in-line so that it continuously measures the mix viscosity. The consistency of the concrete mix can be ensured by automation of the dosing system through a controller using continuous real-time viscosity measurements. Both the sensors have a compact form factor for simple OEM and retrofit installation. They require no maintenance or re-configurations. Using no consumables, SRV and SRD are extremely easy to operate.

Rheonics' Advantage

Compact form factor, no moving parts and require no maintenance

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations.

Insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions. Hook up the sensor in different parts of the mixing tank and check the consistency of the mix throughout the process. These sensors can easily cope up with regular relocation.

Complete system overview and predictive control – monitor the mixing process with extreme ease

Rheonics’ software is powerful, intuitive and convenient to use. Real-time ink viscosity can be monitored on a computer. Multiple sensors are managed from a single dashboard spread across the factory floor.

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions. SRV has the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi

- Temperature range from -40 up to 200°C

- Viscosity range: 0.5 cP up to 50,000 cP

Achieve the right mix properties, cut down costs and enhance productivity

Rheonics’ closed loop process systems cater to the needs of today’s environmental and safety concerns. Integrate an SRV/SRD in the mixing tank and monitor the viscosity of the mixture all the way till it achieves the desired viscosity SRV (and SRD) constantly monitors and controls viscosity (and density in case of SRD) and prevents overuse of resources. Optimise the mixing process with an SRV and experience lesser reject rates, lesser wastes, fewer customer complaints, fewer press shut downs and material cost savings– produce exacting results safely and profitably. Avoid future liabilities and litigation costs, achieve a better bottom line.

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Superior sensor design and technology

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest and most accurate in the industry. SRV and SRD give real time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

SRV is available with industry standard process connections like ¾” NPT and 1” Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Electronics built to fit your needs

Available in both an explosion-proof transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process pipelines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

ATEX & IECEx Compliance

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers has the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed