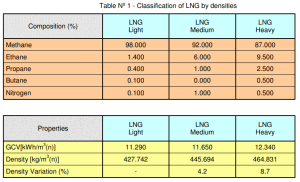

Globally, the LNG market has expanded at a significant rate in the last decade, and LNG has considerable environmental benefits as a transport fuel. Traders trade LNG on the basis of energy transferred, which is based on volume, density, and gross calorific value. High-speed, accurate density measurements, therefore, are important for trading, shipping and transporting LNG.

Application

The only alternative to diesel fuel for heavy duty transport is liquefied natural gas (LNG), which emits less noise and has a lower CO2 footprint than diesel. Natural gas is expected to be transported by pipeline and by ship in equal amounts in the future.

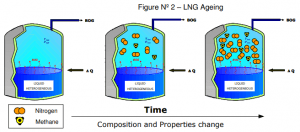

However, LNG, being a liquefied mixture of hydrocarbons that is usually stored and used at -162 C, undergoes a change in composition during transportation. A lengthy ballast voyage significantly changes the composition and density of LNG quantities (Heel) retained after the discharging operation. Liquids like methane, which are light, can evaporate. Only the heavy fractions Propane, Butane, and Ethane will remain after removing the CH4 content. As a result, the liquid mass will have relatively high saturation temperatures and densities, which may prevent pumping due to the low amperage loads induced in the pump motor. Heel ageing is a factor to be considered on long-duration ballast voyages.

LNG Classification by densities | Source: Accurate determination of LNG quality unloaded in Receiving Terminals: An Innovative Approach by Angel Benito

Therefore, the quality and all related physical and chemical properties also change. For this reason, LNG is much more challenging to metrologically examine than natural gas. Moreover, the composition of LNG in LNG carriers and storage tanks generally changes over time by a process known as “aging,” which translates into the LNG becoming richer in heavier components over time. It is critical that accurate measurements be taken from the source to the engine in order to enable the wide scale use of LNG.

Composition and properties of LNG changes due to ageing | Source: Accurate determination of LNG quality unloaded in Receiving Terminals: An Innovative Approach by Angel Benito

Need for continuous density monitoring

- Density stratification causes instability issue in tanks

- Density changes due to evaporation on long journey leads to change of load making pumping inefficient

- Safety is severely compromised if density is not closely monitored.

Having the LNG density, the age, and the GCV information can be very useful to LNG carriers preparing for the Custody Transfer operation, and a convenient way to check the composition report. In LNG FSRU tanks, the density profile monitoring and trend function are helpful tools for monitoring the boil-off process and density and temperature profiles in the tanks in order to prevent roll-over accidents.

Density values to be used could be one of the following: (a) on-board measurement systems; (b) the density measured by the fuel supplier at fuel bunkering and recorded on BDN; (c) the density measured in a test analysis conducted in an accredited fuel test laboratory, where available.

Continuous monitoring of variation in LNG density during dynamic LNG flow measurement gives a good indication of change in fluid quality and thus onset of boiling, which is known to affect measurement accuracy.

Measurement challenges

Custody transfer of LNG is based on energy measurements of the transferred LNG. The energy is determined by volume, density and the gross calorific value of the LNG. The volume of ship tanks is measured using tank level gauging. This method is currently the only established procedure to measure the LNG volume transferred.

Pipelines leading the LNG terminal and the LNG tanker

The alternative is use of flow meters, used often as secondary standards at LNG terminals. These flow meters are commercially available, but hardly used for custody transfer purposes, due to lack of direct traceability to an LNG flow standard at this scale and the lack of an ISO standard.

LNG Sampling Equipment | Source: 360° KAS

For fiscal measurements, the physical and chemical properties of LNG are defined through sophisticated LNG sampling and analysis procedures. These processes involve several careful steps including sample collection, conditioning, vaporizing, analyzing, reporting LNG composition and, finally, calculation of LNG properties and energy content. However, for monitoring and control purposes, it may not be practical or cost-effective to use such equipment. Development of cost-effective sensors that can be easily installed in-line and provide acceptable measurement accuracy are required.

Rheonics inline LNG Density Meter

With Rheonics DVP sensor, the density of the LNG is monitored continuously as long as the sensing part of the pipe is immersed in LNG. This is done at each immersed segment in the tanks or pipelines. By knowing the N2 content to certain accuracy, the uncertainty of the density measurement is reduced to a level well below the uncertainty of today’s accepted standards. Accurate density measurement is possible regardless of the tank or pipeline atmospheric conditions. High instrument accuracy and flexible software ensure continuously monitoring of the density and its change both in cases with natural and forced boil-off and re-liquefaction.

Rheonics DVP (Ultra high accuracy simultaneous density and viscosity metering for gas, fluids)

DVP Applications in oil & natural gas industries

The DVP’s high sensitivity and low-density capabilities make it ideal for measurements in oil and gas installations.

Rheonics SRD (Inline density meter and viscosity meter)

The Rheonics SRD can be used in all stages of natural gas processing, from production, through liquefaction, to storage and transport. It can also be used in petroleum production, refining, storage and transportation, especially for less-viscous products like light lubricating oils, naptha, and gasoline.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers and density meters have the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Single instrument for simultaneous process density, viscosity and temperature

- Monitor even gas density and viscosity

- Accurate measurement in the harshest of conditions

- Operational to 1000 bar and 200°C (15000 psi, 400°F)

- Full Titanium construction

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed