Introduction

In the food processing industry, manufacturers are looking for two things – taste and texture. Texture is the “feeling” in the mouth when the product is eaten, and it is usually assessed by measuring the product’s viscosity. In this area, companies are looking for consistency above all else. Texture can ‘make or break’ a product’s reception. Adding to texture’s importance is the intricate manner in which it interacts with its higher profile teammates: taste, aroma and flavor.

Application

Yogurt is the result of milk fermentation by two lactic thermophilic bacteria. The milk solidification formed by fermentation is referred to as the ‘white mass’. It can be consumed in this form (the firm state) or after brewing, which provides a creamy or liquid consistency. Yogurt manufacturing process includes various steps: milk preparation, concentration, thermal treatment which will lead to serum expulsion, homogenization and culture. Culture is done in tanks and agitation is required to have good homogeneity of the mix milk/ferments. At this step, process differs for firm or stirred yogurt productions. Texture management is crucial in various stages of yogurt manufacturing.

Yogurt is typically eaten in a semi-solid state using a spoon. In recent years, however, demand has increased for lower viscosity yogurt beverages that customers can drink using a straw. Since texture and sensation when swallowing are extremely important characteristics of yogurt, texture evaluations for viscosity is indispensable.

Key points:

- Texture and product consistency are of utmost importance in yogurt manufacturing, for which viscosity is the correlated parameter

- Not controlling excessive whey in final yogurt manufacturing results in diluted yogurts, abysmal sensation in mouth

- Texture interacts in an intricate manner with its higher profile teammates: taste, aroma and flavor

Challenges

Process-related

The quality of white mass yogurt is not as stable as expected due to its complexity, particularly after the maturation and the cooling processes. Moreover, the time is crucial: it is important to reduce the time at the maximum between preparation phase and packaging phase, because this is when lactoserum pockets are created.

At the end of fermentation, the tanks may contain pockets of milk plasma- called as whey, apart from yogurt. These pockets of whey should not enter in the mixing step, neither they should be excessive in the pot. Possible consequences of not controlling excessive whey in final yogurt manufacturing results in diluted yogurts, abysmal sensation in mouth and hits the products’ reception badly by customers.

Viscosity measurement related

The offline measurements of viscosity lack accuracy and repeatability, more so for non-newtonian fluids. The very act of taking a sample out of the line affects the product. Processing temperatures, shear forces and cooling times all can have a big impact on offline viscosity measurements. The time needed to get the product to the laboratory and conduct an analysis also has an impact on the results. Offline viscosity measurement data at yogurt manufacturing plants show that the texture unexpectedly varied by plus or minus 25% for the same product produced in one month, which is a serious concern.

Clearly, the quality control groups at yogurt manufacturing set-ups seek accurate and real-time, in-line viscosity measurements to analyze factors generating the defects and inconsistencies. To ensure consistency in texture of yogurt, the change in viscosity through-out the process stream has to be monitored in real time and viscosity adjustments have to be made accordingly at various stages of the yogurt production process.

Rheonics' Solutions

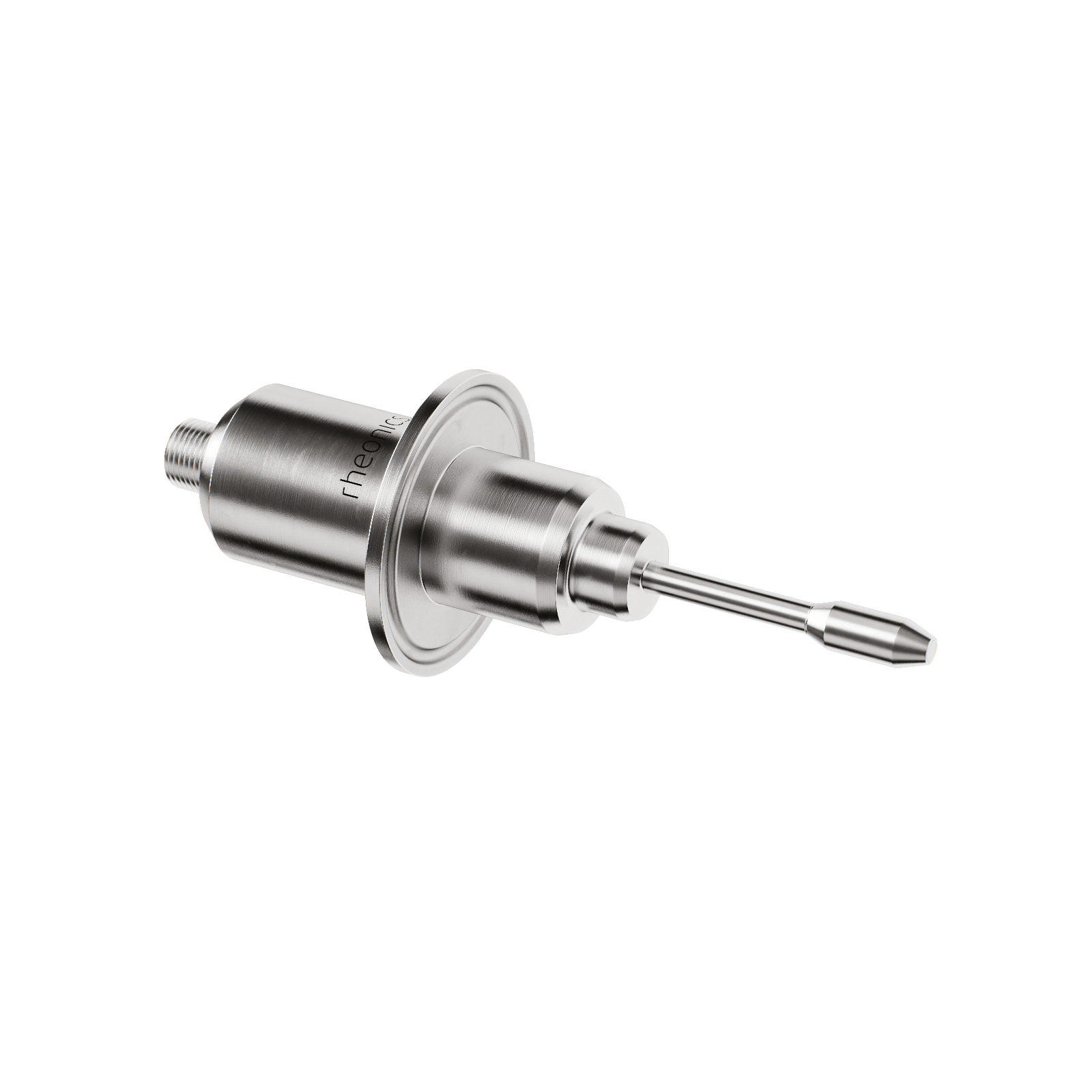

Automated in-line process viscosity measurements enable continuous monitoring of the yogurt viscosity through the various production stages and assure the desirable ‘texture’ of the produced yogurt. Rheonics’ SRV is a wide-range in-line process viscometer with inbuilt fluid temperature measurement and is capable of detecting viscosity changes within any process stream in real time.

The sensor is located in-line so that it continuously measures the yogurt viscosity and simultaneously delivers the information to the processor at critical stages of production. Whey has a lower viscosity than yogurt and can be detected by the SRV just before mixing step. The inline viscometer correlated to texture and concentration values, can assure yogurt texture consistency thus improving productivity, profit margins and environmental goals.

Rheonics' Advantage

Hygienic, sanitary design

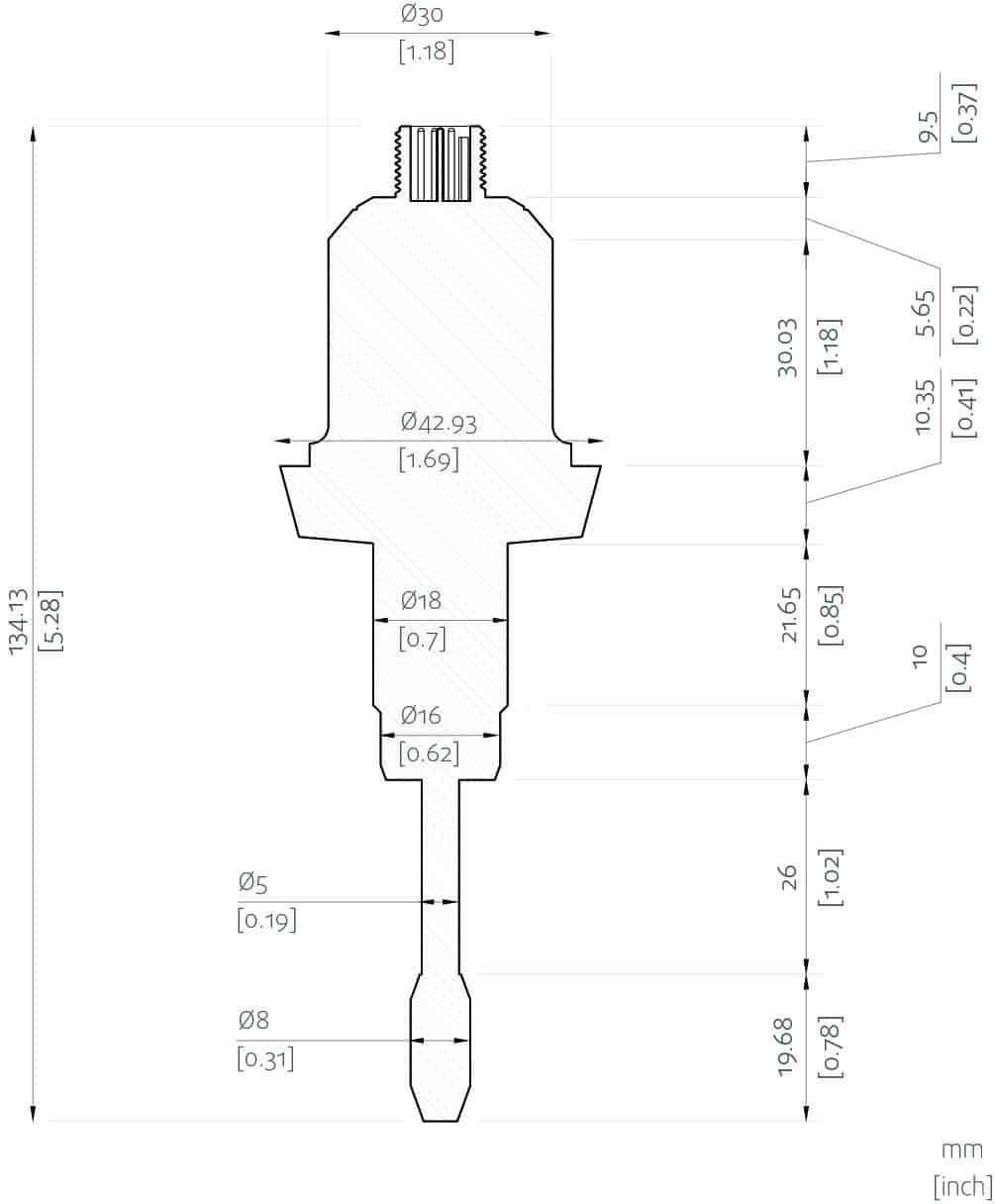

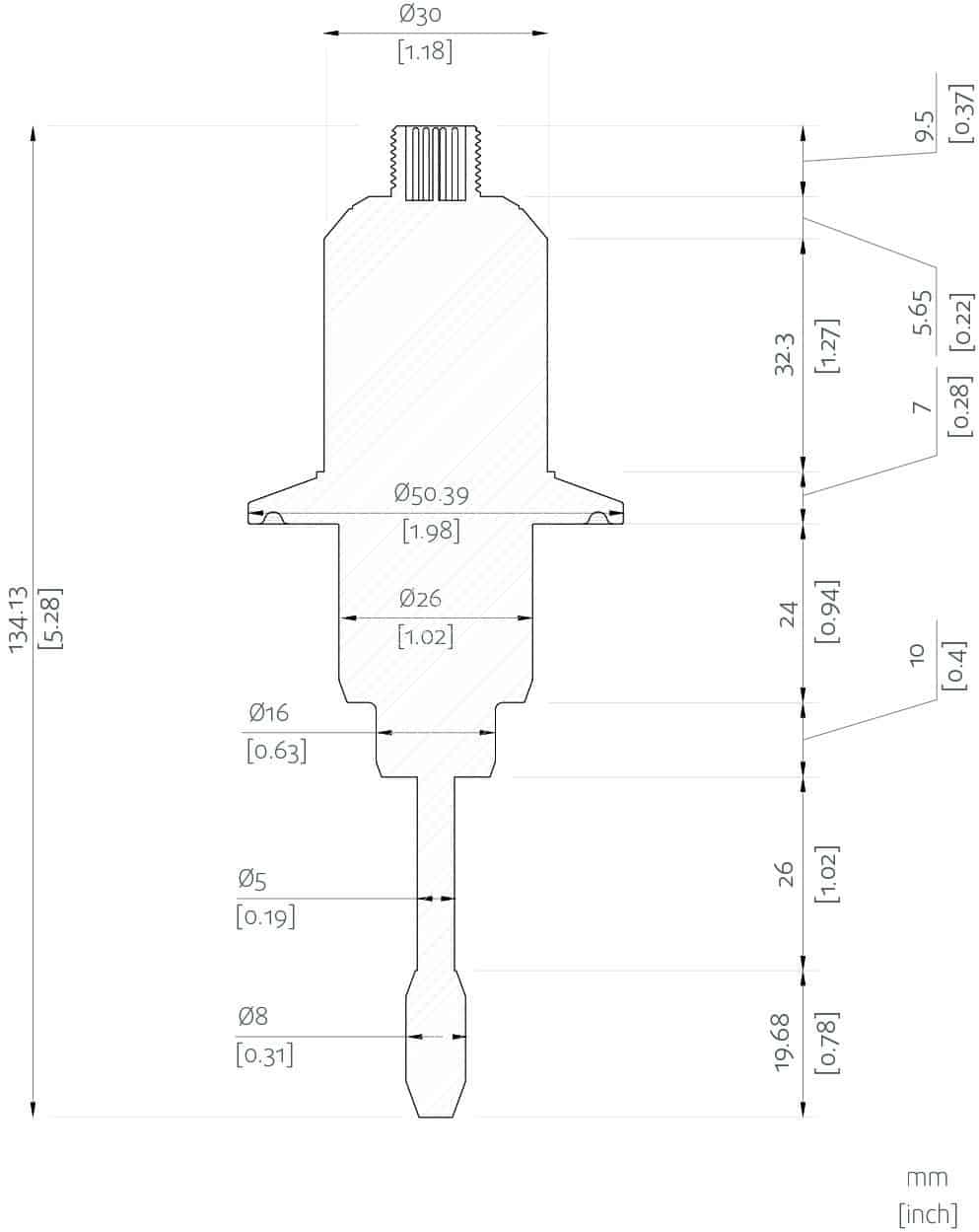

Rheonics SRV and SRD are available in tri-clamp and DIN 11851 connections besides custom process connections.

Both SRV & SRD conform to Food Contact Compliance requirements according to US FDA and EU regulations.

Compact form factor, no moving parts and require no maintenance

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations. They have a small footprint enabling in-line installation, avoiding any additional space or adapter requirement on the press/systems.

High stability and insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions and ink flow rates. These sensors can easily cope up with regular relocation. Sensor element sits directly in the fluid, with no special housing or protective cage required.

Instant accurate readouts on printing conditions – Complete system overview and predictive control

Rheonics’ software is powerful, intuitive and convenient to use. Real-time viscosity can be monitored on a computer. Multiple sensors spread across the factory floor are managed from a single dashboard. There is no effect of pressure pulsation from pumping on sensor operation or measurement accuracy. In addition, the sensor is insensitive to any vibrations or electrical noise from external machinery.

Easy installation and no reconfigurations/recalibrations needed

Replace sensors without replacing or re-programming electronics

Drop-in replacements for both sensor and electronics without any firmware updates or calibration coefficient changes.

Easy mounting. Screws into ¾” NPT threaded in-line fittings, or Flanged connections.

No chambers, O-ring seals or gaskets.

Easily removed for cleaning or inspection.

SRV available with flange, DIN 11851 hygienic and tri-clamp connection for easy mounting and dis-mounting.

Low power consumption

24V DC power supply with less than 0.1 A current draw during normal operation (less than 3W)

Fast response time and temperature compensated viscosity

Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest and most accurate in the industry. SRV and SRD give real-time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions. SRV has the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi and higher

- Temperature range from -40 up to 300°C

- Viscosity range: 0.5 cP up to 50,000+ cP

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Clean in place (CIP)

SRV (and SRD) monitors the cleanup of the ink lines by monitoring the viscosity (and density) of the solvent during the cleaning phase. Any small residue is detected by the sensor, enabling the operator to decide when the line is clean for purpose. Alternatively, SRV provides information to the automated cleaning system to ensure full and repeatable cleaning between runs.

Superior sensor design and technology

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. SRV and SRD are available with industry standard process connections like ¾” NPT and 1” Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV/SRD giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Environment friendly

Reduce the use of VOC (volatile organic compounds) in your process reducing the energy required to recover it or disposal costs. Manufacture smart while saving costs, ensuring high quality and protecting the environment.

Electronics built to fit your needs

Available in both an explosion-proof transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process pipelines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

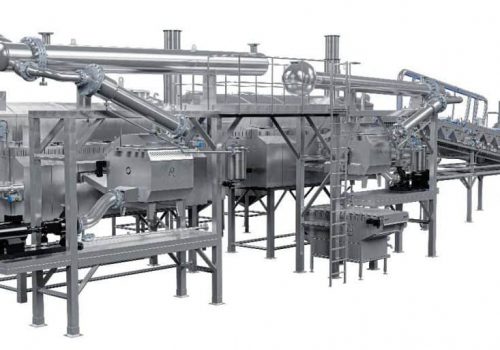

Implementation

According to the yogurt type, SRV can be fitted after the homogenization tank for firm yogurt or on the conditioning line for stirred or liquid yogurt, before filling the pots to do real time viscosity measurements and adjustments. No bypass line is required: the sensor can be immersed directly in the process line; flow rate and production vibrations do not affect the measurement stability and accuracy. By automating a mixing system through a controller, the texture of yogurt can be controlled precisely.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers has the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory.

Suggested product(s) for the Application

• Wide viscosity range – monitor the complete process

• Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

• Hermetically sealed, all Titanium Grade 5 wetted parts

• Built in fluid temperature measurement

• Compact form-factor for simple installation in existing process lines

• Hermetically sealed, all Titanium Grade 5 wetted parts

• Easy to clean, no maintenance or re-configurations needed