Our blogs offer insights into current topics, new products, applications, case studies and latest news.

RHEONICS BLOG

Table of Content Problem Solution PROFINET’s Role Key Benefits Conclusion Investment castings are one…

Rheonics Type-SR, Type-DV, and Type-BT sensor probes are now available with Korean KCs Ex certification…

In a recent issue E-Mobility Engineering the leading independent magazine for EV engineers, published a…

We are excited to share that our latest work is featured in the February issue…

At Rheonics, we understand that accurate sensor data is only valuable if it can be…

Ever wondered what gives chocolate its irresistible smooth texture? The secret lies in viscosity, but…

Different processes require different installation setups for viscosity measurement. Rheonics addresses this with a range…

Our sensors now feature extended EX certification, ensuring top-tier safety and performance across a wide…

Rheonics inline density and viscosity sensors were used in the EMPIR EURAMET Safest project [1]…

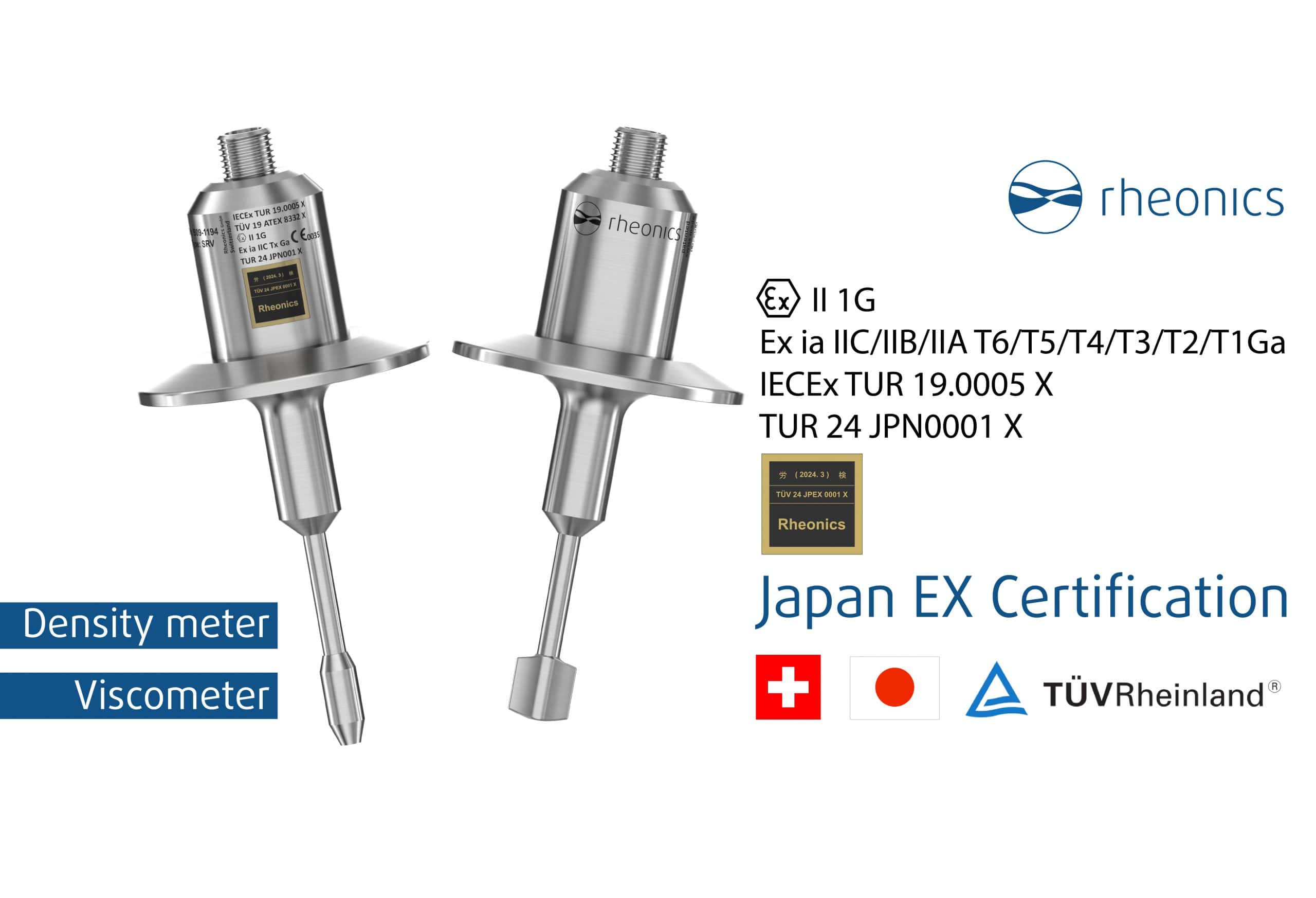

Rheonics SRV and SRD sensors are now available with Japanese Ex certification Rheonics inline process…

Rheonics is a member of the Modbus Organization as a vendor of hardware, software, and…

Rheonics SRV and SRD sensors and hygienic accessories are now available with 3-A Sanitary Standards…

Rheonics density and viscosity meter SRD can be specially designed for installation with API hubs…

Rheonics is proud to announce its partnership with FieldComm Group. FieldComm Group owns the HART…

Topic Ink viscosity optimization and automation for quality, efficiency and sustainability benefits in printing and…

Topic Viscosity control for consistent casting shell building Date & Time August 22, 2022 @…

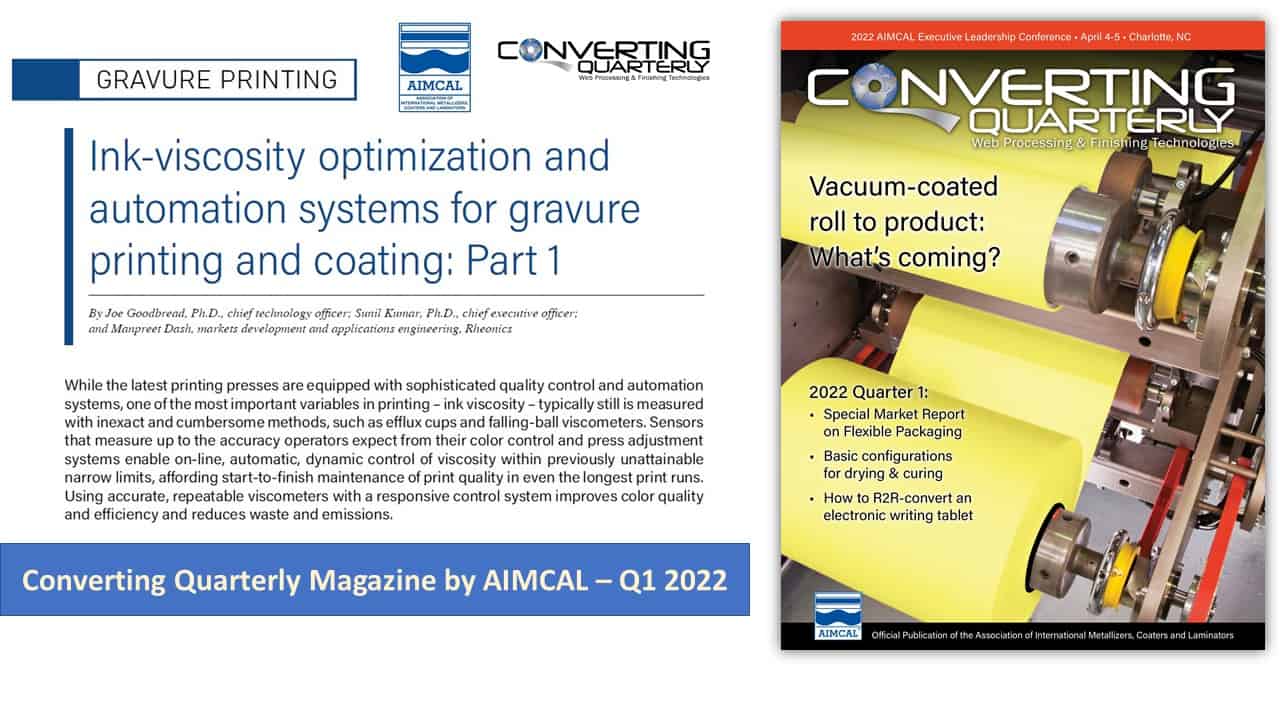

Web processing & finishing focused magazine - Converting Quarterly (https://www.convertingquarterly.com/) publishes an in depth article…

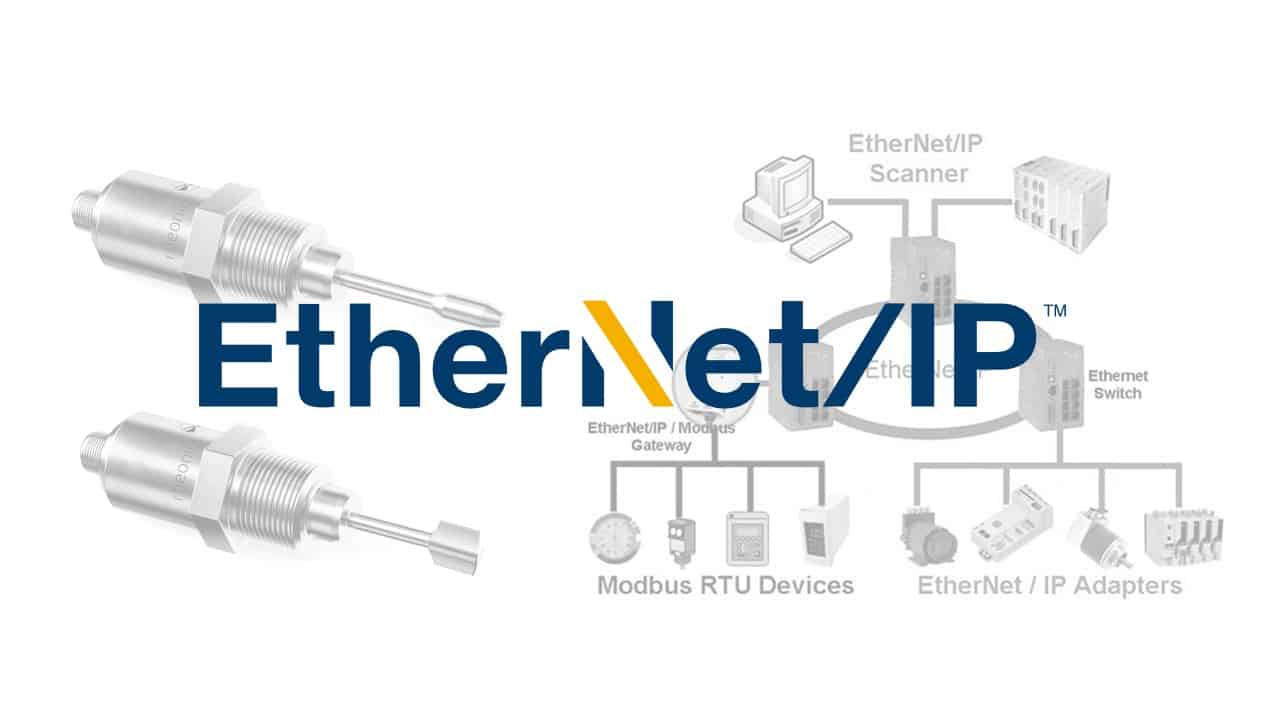

EtherNet/IP: The standard protocol for communication in industrial networks EtherNet/IP is a widely used Ethernet-based…

Association of International Metallizers, Coaters and Laminators (AIMCAL), founded in 1970, is a global nonprofit…

A leading business-to-business media brand covering the transportation construction and maintenance marketplace Roads & Bridges…

EHEDG certified inline viscosity and density sensors: SRV & SRD The sensors available from Rheonics continuously…

Topic Online viscosity monitoring for consistent asphalt quality Date & Time March 30, 2022 @…

Web processing & finishing focused magazine - Converting Quarterly (https://www.convertingquarterly.com/) publishes an in depth article…

Concerns about the economy, technological threats, and unclear futures have all contributed to a print…

“The product is suitable for use in Zone 1, as well as for use in…

We are pleased to announce that Rheonics has been awarded ISO 9001 Certification. ISO 9001…

Rheonics wins a Sustainable Packaging Innovation Award by the European Rotogravure Association. Dr. Sunil Kumar…

Novel insruments for inline and production applications

It’s an incredibly proud moment for all to announce that the Rheonics has been awarded…

Topic High Quality and ‘Greener’ Coatings with Automated Viscosity Monitoring and Control Date & Time…

Topic Color Excellence Through Tight Viscosity Control, a 2021 FTA Technical Innovation Award Winner Date…

It’s an incredibly proud moment for all of us here at Rheonics to announce that…

Flexographic printing focused magazine - Flexo (https://www.flexography.org/flexo-magazine/) publishes an in depth article showcasing the Rheonics…

Topic Foundry 4.0 – High quality, defects-free, effective shell building needs real-time viscosity monitoring and…

Challenge Fluctuations in material throughput related to market demand can also be seen as a…

Challenge Fluctuations in material throughput related to market demand can also be seen as a…

Flexographic printing focused magazine - Flexo (https://www.flexography.org/flexo-magazine/) publishes brief synopses of the 2021 Technical Innovation…

It’s an incredibly proud moment for all of us here at Rheonics to announce that…

Rheonics SensorView is now live on both google play and apple store! As a long…

Challenge Fluctuations in material throughput related to market demand can also be seen as a…

Flexographic printing focused magazine - Flexo (https://www.flexography.org/flexo-magazine/) publishes an in depth article showcasing the Rheonics…

Flexographic printing has a number of advantages over traditional printing presses. It has a faster…

A paper was published for presentation at the SPE (Society of Petroleum Engineers) Improved Oil…

Abstract The challenge in the coatings industry for existing and emerging markets is to lower…

About INA Grupa INA-Industrija nafte, d.d. (INA, d.d.) is a medium-sized European oil company. INA…

Food industry focused magazine - Food Engineering Mag (https://www.foodengineeringmag.com/) publishes a feature article covering the…

Rheonics - Switzerland division recently relocated to a new facility in order to expand and…

Investment casting industry focused magazine - INCAST Mag (https://www.investmentcasting.org/current-issue.html) publishes a feature article covering the…

What is CIP? In CIP systems, cleaning takes place without dismantling the system. CIP refers…

States Foods and Drug Administration (FDA or USFDA) is a federal agency of the Department…

Temperature fluctuations, mixing equipment condition, type and conditions of substrates, formulations, process step interactions and…

Viscosity and density measurements in the oil and gas sector are among the most essential,…

Through all the advancement in automotive design and manufacturing over the years, there has been…

Many parameters can alter the ceramic slurry quality in investment casting across batches - Temperature…

Coupled with Industry 4.0 technology, inline sensing means no more rushing grab-samples to the lab,…

Food industry focused magazine - Food Engineering Mag (https://www.foodengineeringmag.com/) publishes a feature article covering the…

Temperature fluctuations, mixing equipment condition, type and conditions of substrates, batter formulations, process step interactions…

Paint & Coatings industry focused magazine - PCI publishes a feature article covering the Rheonics…

“Tired of the expense, bulk and issues with measurement accuracy of the Coriolis meter for…

Gelation/gel-transition is the formation of a gel from a system with polymers. Branched polymers can form links…

Emulsions are dispersions of two immiscible liquids. They are of interest in many important practical…

We are pleased to inform you that we are now members of the Investment Casting Institute!…

A versatile material, asphalt creates a smooth, durable surface for driveways, walking paths, roads and…

Many, if not most, fluids exhibit non-Newtonian behavior. A fluid is said to be non-Newtonian…

Packaging industry focused publication - Flexo+Tief Druck publishes a feature article covering the revolutionary Rheonics…

Adhesives and Sealants industry focused magazine - ASI publishes a feature article covering the Rheonics…

Packaging industry focused publication - Flexo+Tief Druck publishes a feature article covering the revolutionary Rheonics…

Hydraulic fracturing (also called as fracking, fracing, hydrofracturing) involves high-pressure injection of ‘fracing fluid’ (primarily…

Robust, maintenance free viscosity sensor eliminates need for re-calibration Agile viscosity controller reduces viscosity variation…

In the history of our company we have applied every type of viscosity sensor: rotational,…

Rheonics is pleased to announce the release of its ATEX & IECEx certifications. The new certifications project…

Automotive companies and coaters recognize the need to monitor viscosity, but making that measurement outside…

The Journal of Petroleum Technology, the Society of Petroleum Engineers’ flagship magazine, presents authoritative briefs and features…

Oil industry industry focused magazine - WorldOil publishes a feature article covering the Rheonics' New…

The International Symposium on Food Rheology and Structure (ISFRS) was hosted by the Institute of…

A conference paper was published and a talk was delivered in Sensors and Measuring Systems…

Stay in touch.

Subscribe to our newsletters.

With Rheonics’ opt-in newsletter, we provide you with exactly the information you need. Our newsletters offer insights into current topics, new products, applications, case studies and latest news.