Fluid viscosity and density monitoring and control

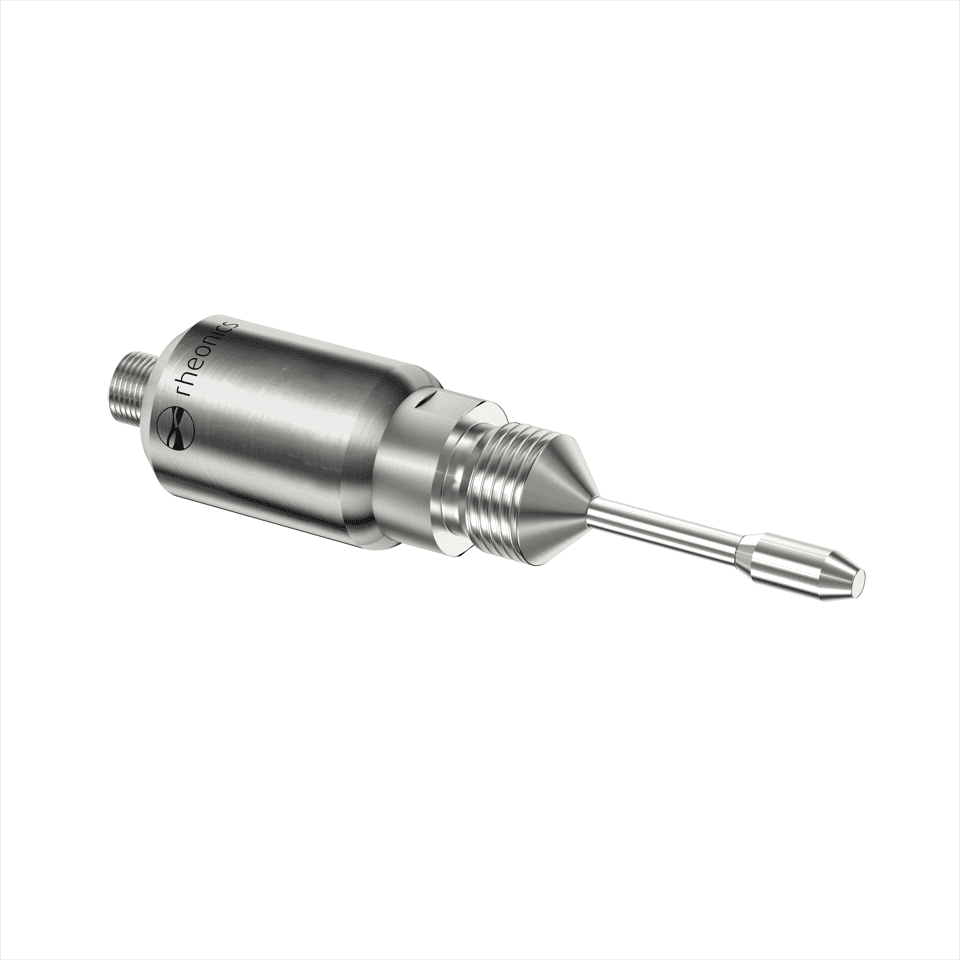

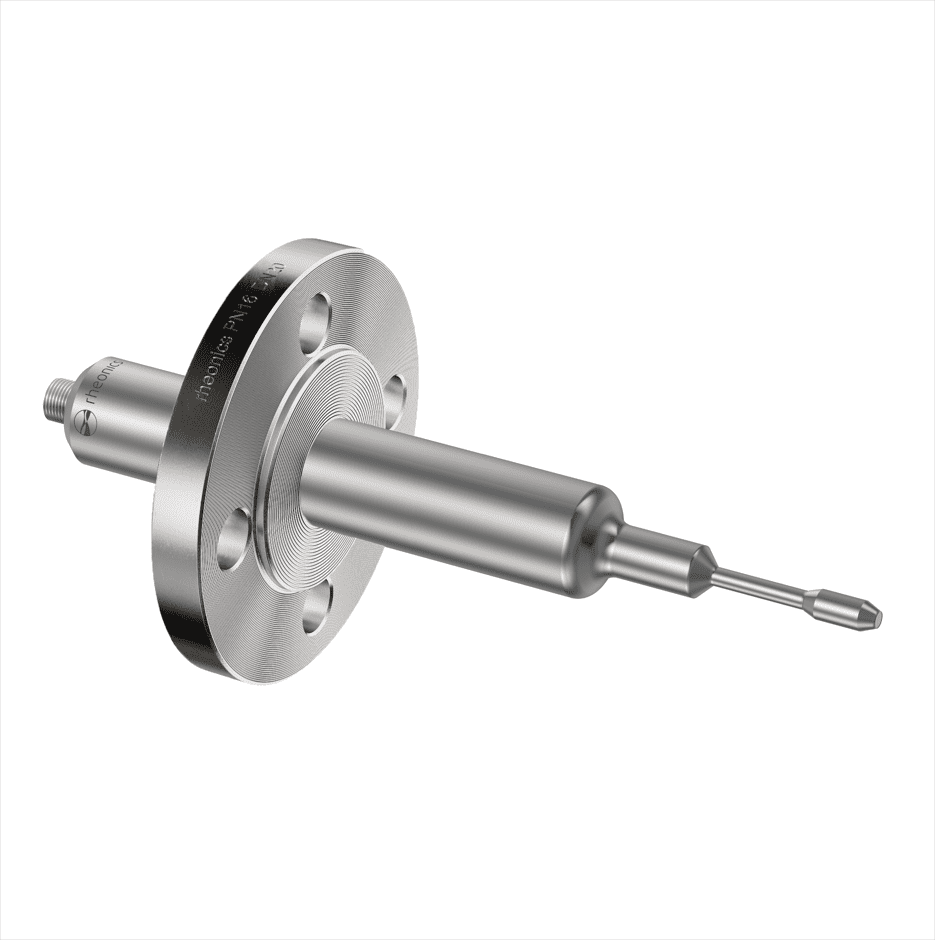

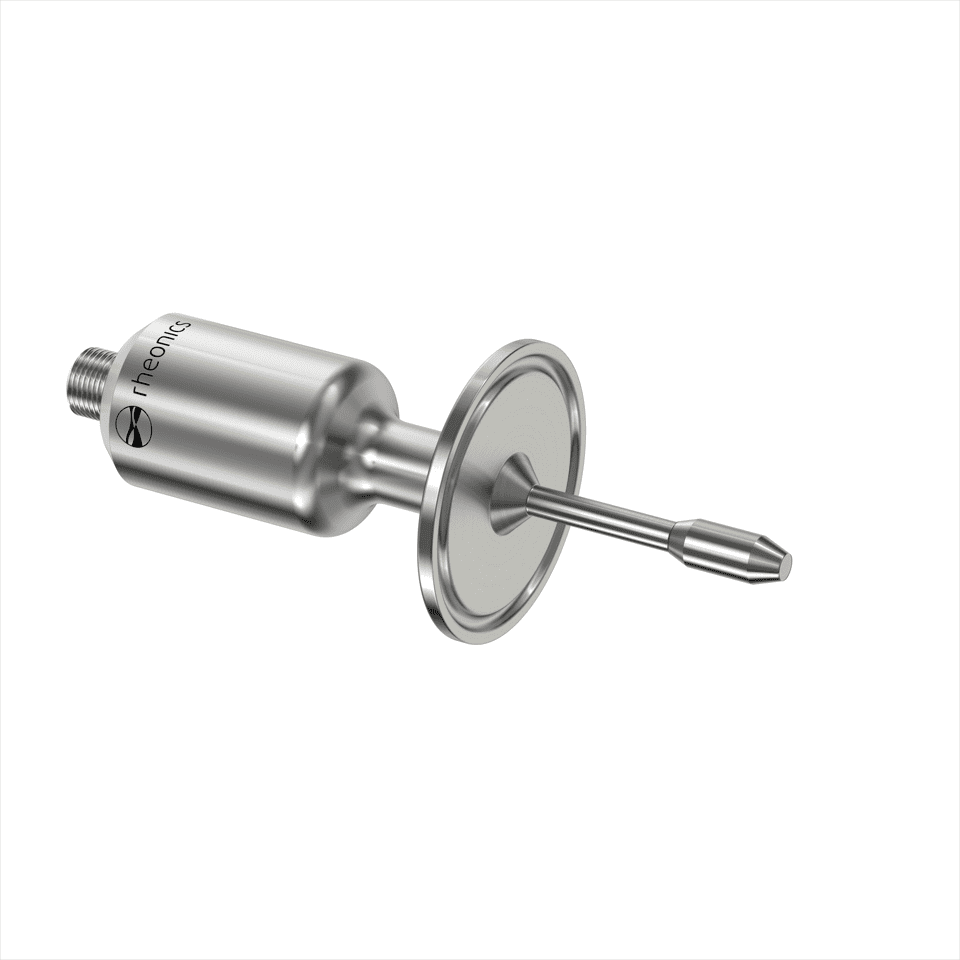

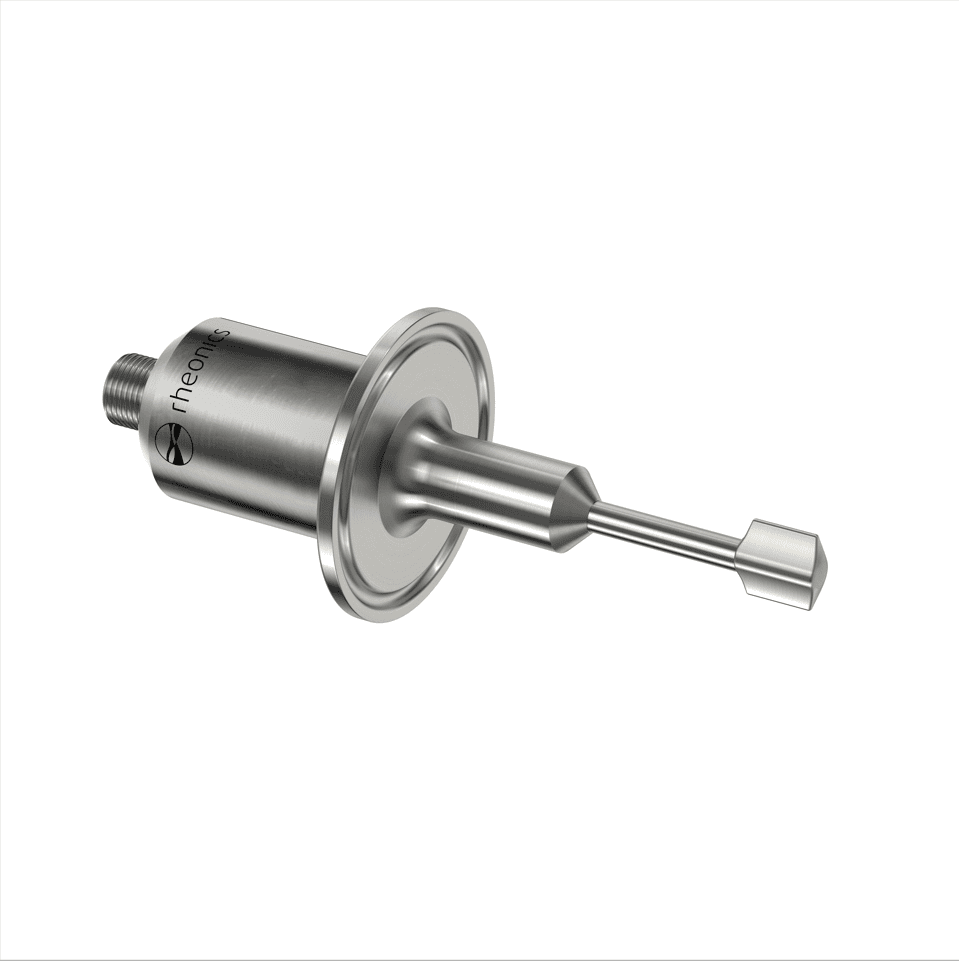

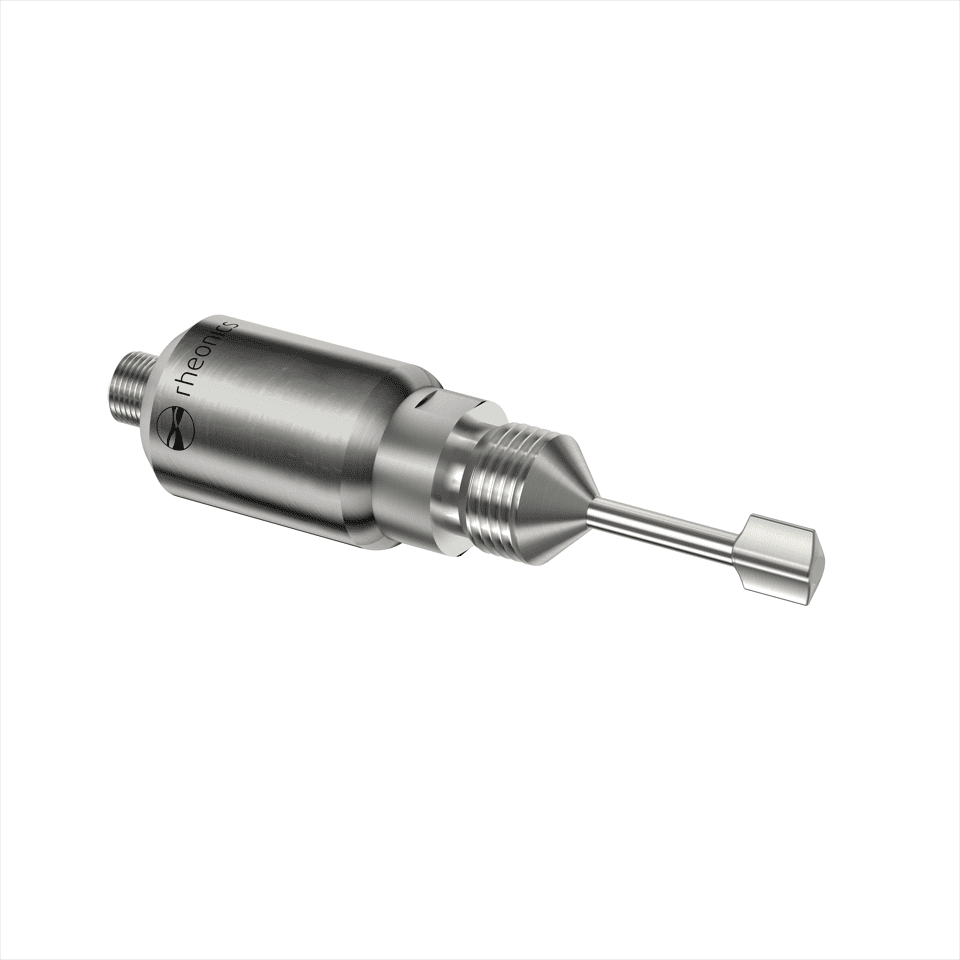

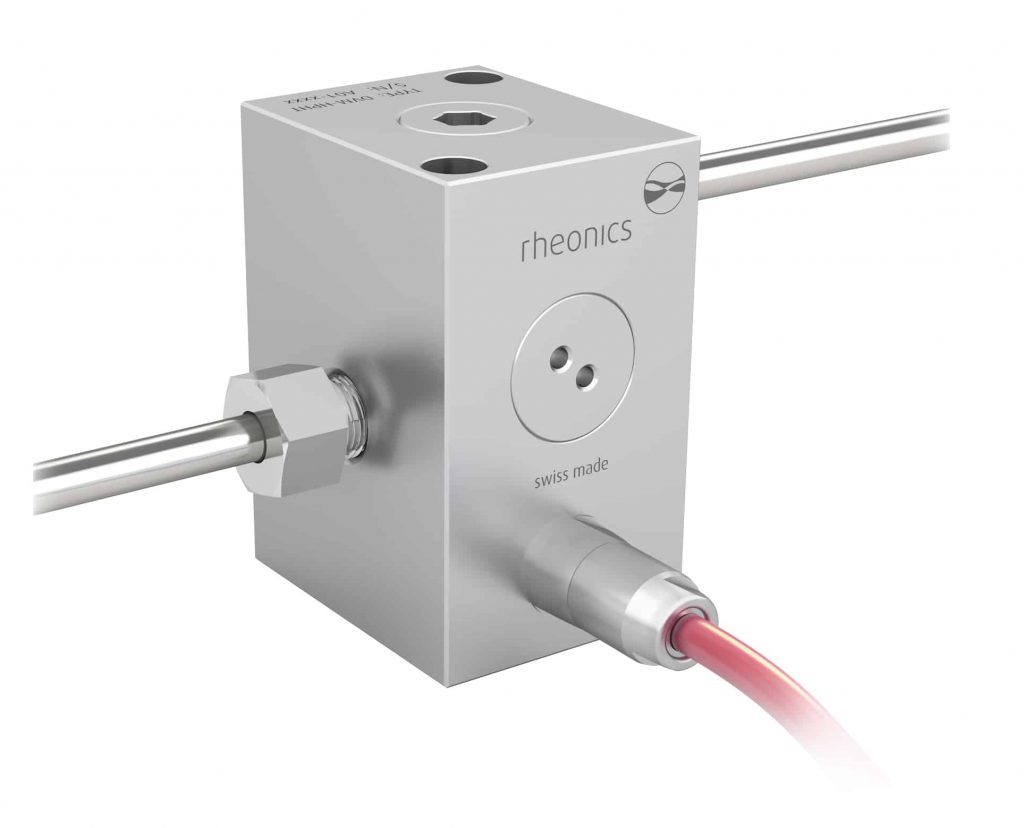

Rheonics online density meters and viscometers are available as probes and flow-through systems for installation in tanks, process lines and reactors.

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Rock-solid, intelligent, plug and play process monitoring

Whether you are manufacturing soap or doing PVT analysis on live oil samples, one of our sensor families will fit your needs.

International Innovation meets Swiss Precision

Rheonics density meters and viscometers are based on a large and growing portfolio of intellectual property and manufactured in Switzerland.

Our solid foundation of technology and products is your assurance of stable and sustainable solutions for your process needs.

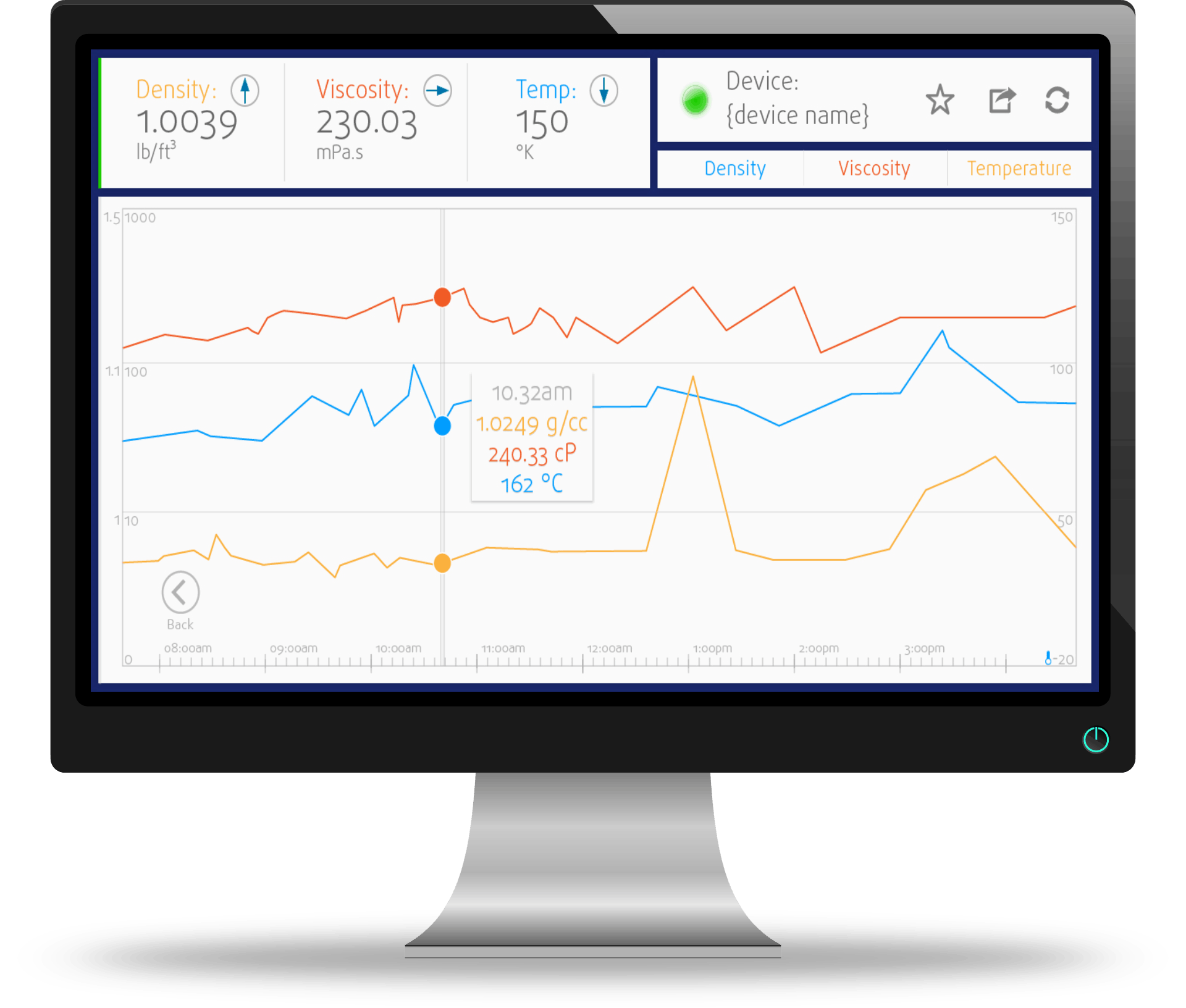

Software

Acquire data in real-time. Analyze, Optimize and Control

Standalone software and modules to integrate into your system.

Labview VI to integrate and configure.

Log data, detect events, configure logging.

Intelligent process control & optimization.

Remote data acquisition & analysis.

Communication

Acquire data in real-time. Transfer it to your computer or upload to the cloud

Standalone IP65 rated boxes to integrate into your system.

Standard PCB to integrate in your equipment panel box.

Next generation electronics in sensor head.

Ethernet, 4-20 mA, RS232 over USB.

CAN, Profinet, HART available for custom applications.