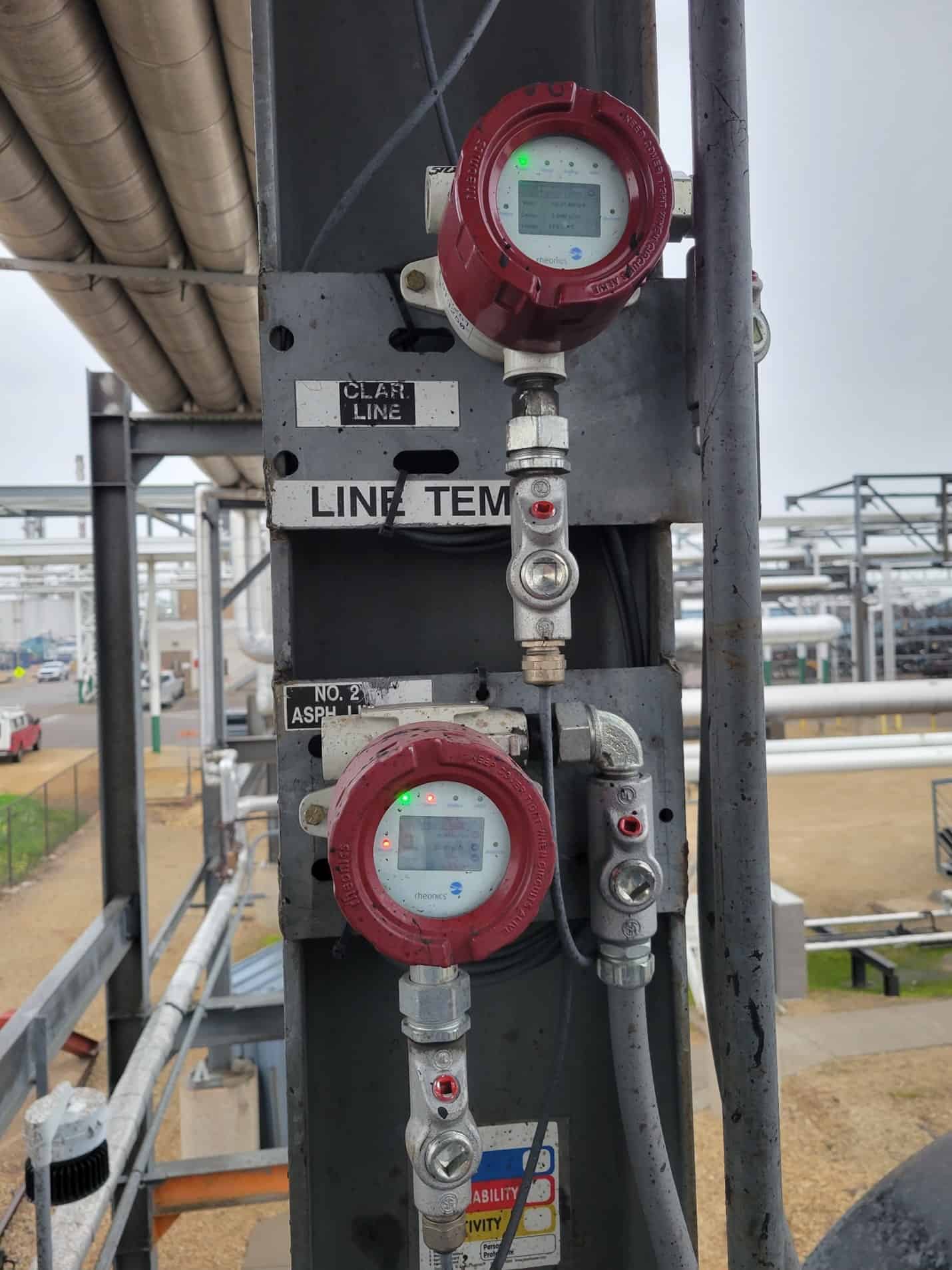

Roads & Bridges Magazine, March 2022 Issue features Rheonics Technology – “Asphalt 4.0: Meeting rigorous quality control of asphalt for every load at the terminal with real-time viscosity measurements”

Overview

A leading business-to-business media brand covering the transportation construction and maintenance marketplace Roads & Bridges magazine (https://www.roadsbridges.com/march-2022) publishes an in depth article about how SRV and SRD revolutionizes asphalt viscosity management. Real-time viscosity management supports engineers in asphalt production and handling to utilize Industry 4.0 and latest automation technologies for more robust, reliable and safer operations. It helps them meet quality control needs across the life cycle while reducing the carbon footprint and emissions.

Find the link to the publication.

To download the pdf copy of the article, please use the link below.

Introduction

Asphalt has proven itself to be one of the most versatile and effective materials for paving – be it road or roof. Ensuring that asphalt meets regulatory norms like ASTM, AASHTO, DIN, EN while reducing emissions related to its production and use is a win-win. Real-time inline viscosity monitoring and control of asphalt from production in refineries to final loading at terminal for transport to paving site improves bottom-line and protects personnel. Cost reduction and safety improvements are achieved through optimizing the use of solvents & modifiers to achieve fit-for-purpose asphalt mixture. The measuring process creates zero emissions and can be done completely inline without need for offline grab samples. A resonant sensor based inline viscometer takes viscosity measurements into the digital world in tune with modern road design and enables real-time management of bitumen properties across the complete asphalt life cycle.

Topics Covered in the article

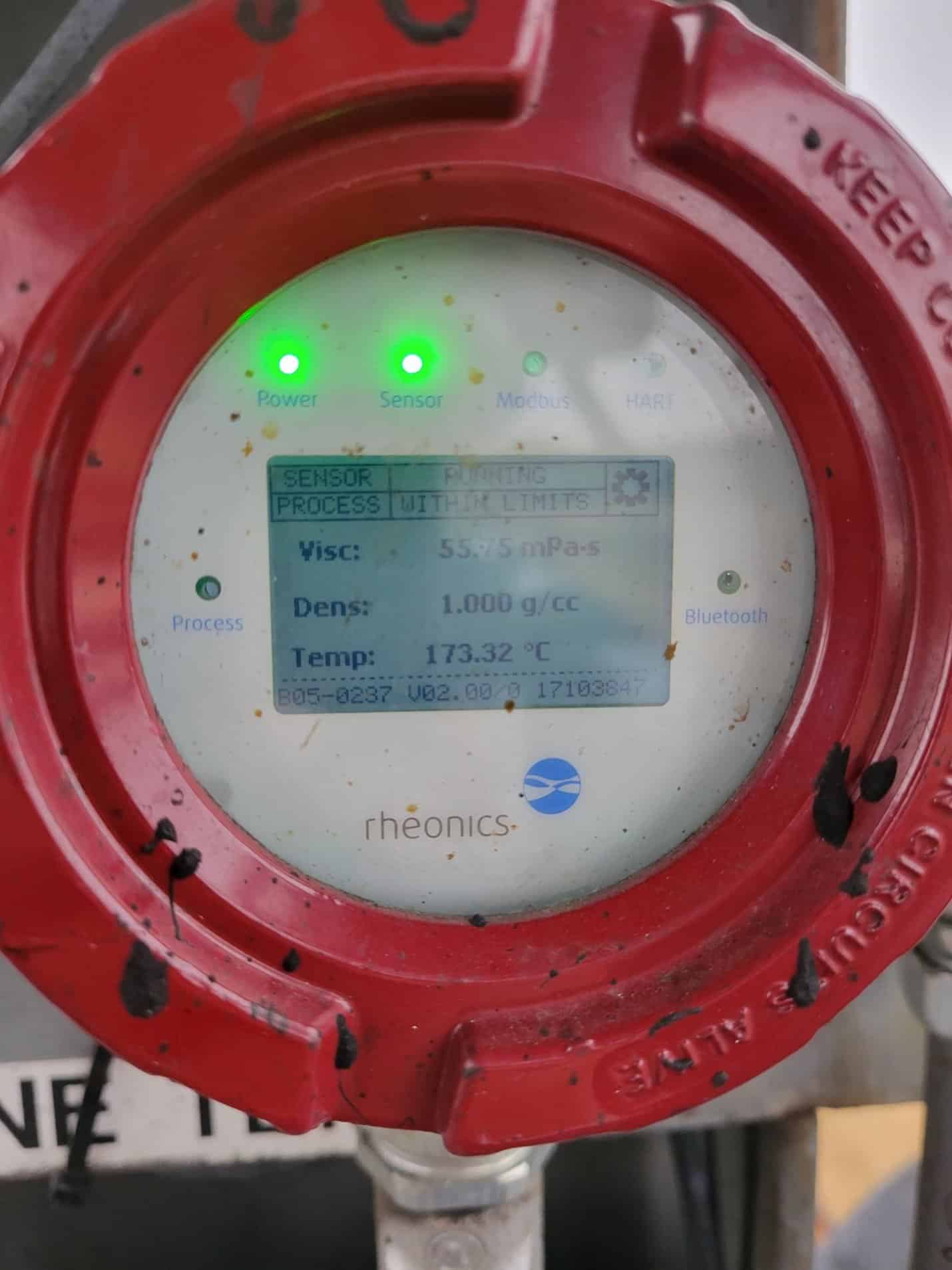

The two main parameters of polymer blended bitumen for the production of Hot Mix Asphalt (HMA) are viscosity and temperature. Asphalt-cement viscosity describes resistance to compaction of paving mixture. Using viscosity measurements in pipes and tanks, engineers can ensure that the quality control parameters are adhered to and the product is within specifications. An inline viscosity measurement could be used as a process feedback variable in an automatic blending control system to regulate the temperature, mixing time, and addition of performance enhancing additives.

For asphalt mixing and transportation operations, viscosity data provides more meaningful insights when collected and analysed over time. Data analysis helps process engineers diagnose quality issues. Operators can schedule maintenance and make necessary upgrades to their equipment to improve reliability and efficiency.

- Stages in the asphalt ecosystem where viscosity measurements bring value

- Typical test methods for characterizing bitumen relevant properties and impact on resistance to rutting

- How viscosity measurements can be made and reliably put to use?

- Asphalt 4.0 – Staying ahead of problems by using data and digitalization

- Accurate and responsive in-line viscosity measurement and control

- Value proposition for refineries

Some figures from the article

Unique advantages with the Rheonics SRV sensors

In addition to meeting the customer’s need for high temperature viscosity measurement and real-time data collection, the viscometer system’s self-cleaning design enables the asphalt manufacturer to maintain the systems more efficiently, without constant maintenance and re-calibration.

Unique benefits with Rheonics SRV for bitumen applications:

- Rugged, hermetically-sealed sensor head. The SRV can be cleaned with a solvent wetted rag, no need for disassembly or re-calibration.

- No moving parts to age or foul with sediments.

- Unaffected by mounting conditions – can be mounted in any part of the painting system.

- Insensitive to particulate matter; no problem of fouling of narrow gaps by large particles

- All wetted parts 316L stainless steel – no corrosion problems with commercial coatings, additives, or solvents.

- Certified under ATEX and IECEx as intrinsically safe

- Wide operational range and simple integration – Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

- Powerful software – Rheonics ViscoLock software is convenient and intuitive. It is designed for automated instrument control and data acquisition in factory environment.

Related Articles

Rheonics Technical Webinar – Infrastructure Insider, Roads & Bridges – Online viscosity monitoring for consistent asphalt quality

Topic Online viscosity monitoring for consistent asphalt quality Date & Time March 30, 2022 @ 6 p.m. Central European Standard Time Speaker Dr. Joe Goodbread, CTO, Rheonics Dr. Sunil Kumar, CEO, Rheonics

Meeting rigorous quality control of asphalt for every load at the terminal with real-time viscosity measurements

Asphalt has proven itself to be one of the most versatile and effective materials for paving – be it road or roof. Ensuring that asphalt meets regulatory norms like ASTM, AASHTO, DIN, EN while reducing emissions related to its production and use is a win-win. Real-time inline viscosity monitoring and control of asphalt from production in refineries to final loading…

Monitoring Asphalt & Bitumen quality from refinery to pavements

A versatile material, asphalt creates a smooth, durable surface for driveways, walking paths, roads and parking lots. It is used mostly in construction and outdoor areas. In its fluid-like form, asphalt is used to waterproof walls and surfaces, as well as in shingles for residential roofing. A variety of industrial and recreational uses of asphalt make it an ideal choice…

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Conclusion

Since the beginning of asphalt technology, viscosity has been used to classify bitumen and predict asphalt properties. The measuring methods, however, have not kept up with the times. They’re slow, laborious, and solvent dependent. Modern viscometers excel from a practical and environmental perspective, as well as from a cost perspective. Due to the complexity of asphalt melts and asphalt emulsions as fluids, typical lab instruments are expensive and cumbersome. So, there is a need for better, simpler instrumentation in industry.

In addition to meeting the customer’s need for high temperature viscosity measurement and real-time data collection, the inline viscometer system’s self-cleaning design enables the asphalt manufacturer to maintain the systems more efficiently, without constant maintenance and re-calibration. Road pavement industries highlight huge CO2 savings which can be potentially achieved with top built quality of roads.