Summary: a single sensor to monitor effects of oxidation (TOTOX), fatty acid (TBA), and Polar compounds (TPC) on frying oil health and performance. Don’t just test or sample, monitor throughout the frying process.

Overview

Frying is one of the oldest and most popular cooking methods. Frying oil is expensive and heating it consumes significant energy so frying economics demands reuse of the oil in the fryer for multiple batches. The repeated usage of frying oil has been proven hazardous due to chemical degradation which also degrades frying performance of the oil (Liu, M. et al., 2016). The assessment and proper management of used frying oil is a subject of great concern for health agencies, food manufacturers and consumers. Ensuring safe and healthy fried products while controlling costs is the route to sustainable business for food companies.

Application

Why does frying oil degrade?

The most frequent chemical reactions occurring in the frying process are hydrolysis, polymerization and oxidation, thermal alteration. These reactions produce a considerable number of harmful compounds such as polymer and ketones, which significantly change the quality of frying oil. The generated thermoxidation compounds deserve attention as the oxidative stress is associated with various degenerative processes and diseases, for example, mutagenesis, cell transformation and cancer, atherosclerosis, heart attacks and chronic inflammatory diseases (Liu, M. et al., 2016).

In most cases frying oil degradation is evaluated based on visual inspection. For example, the chefs/factory engineers use their experience to decide when to discard the oil based on excessive foaming, odour, smoking, color changes, and by tasting the food products. However, these methods are not reliable due to their subjective nature and these parameters may manifest only when the oil has already become unsafe to be reused.

How do industrial fryers monitor and manage frying oil?

In industrial frying, quality staff may monitor several chemical parameters during the frying operation in an effort to maintain optimum quality. In fact, monitoring frying oil is essential to avoid unpleasant effects on finished snacks products that can not only affect taste but also health of consumers.

Manufacturing plants usually have a filtering system that is designed to extend the life of the oil, while drastically reducing costs. However, it is still important to identify the parameters that indicate a progressive degradation of oil, as a result of the fact that physical and chemical properties of fried oil and fat tend to change significantly after extensive use.

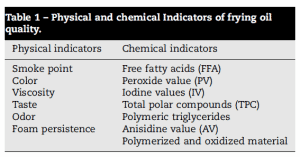

What quality index do fryers use to optimize frying?

Engineers in these food processing plants are posed with the question – what is the best chemical index for the frying oil to use when developing and implementing a program to ensure the quality of the food being fried? There are many different indices that are used like:

- Free fatty acid (acid value)

- Total polar materials (TPM)

- Polymerized triglyceride

- Soaps

- Lovibond color

- Anisidine value

- Peroxide value

- Oil stability index (OSI)

Physical indicators such as smoke point, color, taste, odour, foam persistence and viscosity are used to evaluate quality of frying oil.

Source: “Capacitive sensor probe to assess frying oil degradation” – https://doi.org/10.1016/j.inpa.2015.07.002

Major multinationals in the restaurant and industrial frying industry have invested a lot of money to establish a direct link between the chemical parameters of the oil in fryers and the quality of the food being fried. This means operators must not only monitor different parameters of the degrading oil, they have to relate those parameters to the sensory quality of the food.

Equipment manufacturers work with their customers to establish endpoints for discarding oil. Many different test systems have been introduced over the years, but very few have taken hold with foodservice and industrial fryers, because few potential users would make the commitment to determine food quality endpoints. To do this entails a frying study, which is expensive, time consuming and often needs outside expertise to conduct sensory studies and properly analyze the data.

Why is viscosity data a reliable indicator of the frying oil quality?

Iodine value (IV) is used for the assessment of the suitability of the oils. Garba et al. reported that oil with high IV exhibited poor performance due to the oxidation reactions of lipids and the hydroperoxide formation between the unsaturated fatty acids and oxygen. Also, free fatty acid (FFA), polymeric triglycerides, anisidine value (AV), and polymerized and oxidized material (POM) are broadly used as the pointers of the frying oil quality, but are not conclusive in themselves.

In particular, the increase in viscosity during repeated frying has been identified by some researchers as the factor responsible for an increase in oil uptake of fried foods (Guillaumin, 1988; Moreira et al., 1997). Furthermore, changes in the viscosity and density of the frying medium during repeated frying can be expected to affect buoyant bubble removal from the food surface and, consequently, the convective heat transfer from the oil to the food that undergoes frying.

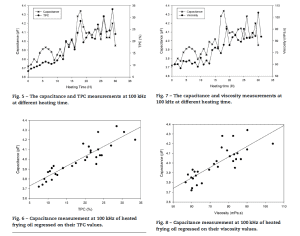

Viscosity correlates very well with other chemical indicators such as FFA, POM, TPC, Lovibond Color Value as has been demonstrated by various studies, some of which are shown below.

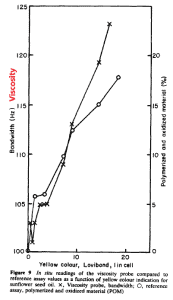

Viscosity and TPC

Figure 1 – Showing the trend of TPC and viscosity measurements (also capacitive measurements) with increase in heating time. Source: “Capacitive sensor probe to assess frying oil degradation” – https://doi.org/10.1016/j.inpa.2015.07.002

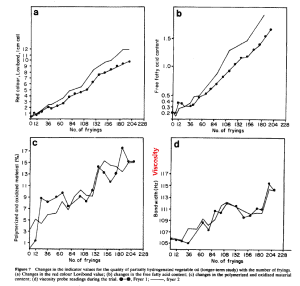

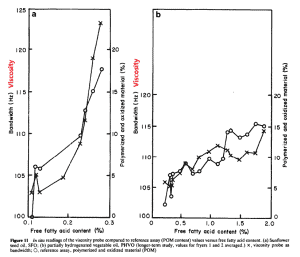

Viscosity and correlation with Color Lovibond value, Free Fatty Acid (FFA), Polymerized and Oxidised Material (POM)

Figure 2 – Measurements with (a) Red color Lovibond value (b) FFA (c) POM (d) Viscosity (Bandwidth) with increase in heating time. Source: “Development and evaluation of a novel sensor for the In-situ assessment of frying oil quality” – https://doi.org/10.1016/0956-7135(90)90008-Z

Figure 3 – Viscosity (Bandwidth) and Color Lovibond trends. Source: “Development and evaluation of a novel sensor for the In-situ assessment of frying oil quality” – https://doi.org/10.1016/0956-7135(90)90008-Z

Figure 4 – Viscosity (Bandwidth) and FFA trends. Source: “Development and evaluation of a novel sensor for the In-situ assessment of frying oil quality” – https://doi.org/10.1016/0956-7135(90)90008-Z

Studies showing how the viscosity evolves with heating time

Researchers have performed regression analysis (https://doi.org/10.1016/j.jfoodeng.2011.02.021) in order to examine the dependence of viscosity on the number of frying batches. The analysis showed that, for the high frying load viscosity was related to the frying batch number following a second order polynomial equation.

Linear regression analysis for oil types (Palm and olive oil) showed that oil viscosity during frying and heating is a function of fresh oil viscosity and the concentration of different polymer compound classes generated during the frying and heating process. This equation is valid also for other oil types provided that the same compound classes are generated during frying and heating.

Figure 5 – Viscosity evolution with heating time, followed a second order polynomial function as per the study. Source: “Effect of repeated frying on the viscosity, density and dynamic interfacial tension of palm and olive oil” – https://doi.org/10.1016/j.jfoodeng.2011.02.021

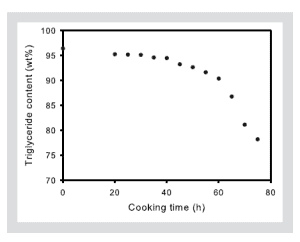

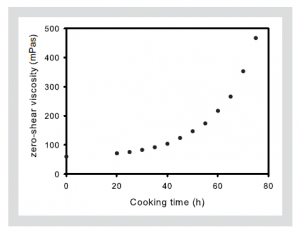

Viscosity and Triglycerides content

Studies and experimental data (Olivares-Carrillo et al., 2014) reveal that the main chemical reactions that take place during deep frying are the rupture of some triglycerides and the addition polymerization of triglycerides containing C18:2 and C18:3 fatty acid chains, the latter reaction being responsible for the observed abrupt viscosity increment.

Viscosity provides an excellent index to follow the loss in triglycerides content caused by deep frying processes. Quantitative relation between the triglycerides content and the (specific) viscosity of soybean oil has been established by the researchers.

Figure 6 – Evolution of triglyceride content and zero-shear viscosity of soybean oil with cooking time and established. Source: “Viscosity as a Measure of Oil Composition Changes due to Thermal Degradation, Applied rheology” – http://dx.doi.org/10.3933/APPLRHEOL-24-53667

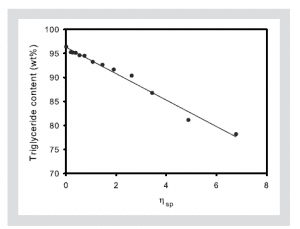

Figure 7 – Correlation between specific viscosity and weight % of triglyceride. Source: “Viscosity as a Measure of Oil Composition Changes due to Thermal Degradation, Applied rheology” – http://dx.doi.org/10.3933/APPLRHEOL-24-53667

Specific viscosity nsp = (n – n0)/n0, where the reference viscosity n0 is that corresponding to the original oil sample at “zero cooking time”. Established correlation weight %(triglyceride) = 96.28 – 2.75 nsp

The need for a simple, inline sensing system to monitor frying oil in real time

To date various methods have been developed and introduced to measure the different chemical and physical parameters of frying oil. For example, chemosensory system for controlling the quality of oil in food industries, Fourier transforms infrared (FTIR) to differentiate between good and inadmissible oils, chromatography to measure dielectric constant, smoke point and viscosity and image analysis to determine the TPC rate in frying oil. However, these methods are predominantly based on sampling and are complicated, time consuming, and expensive. Thus, developing a simple sensing system to help in appraising the quality of frying oil is required.

There are instruments which measure quality of frying oil by testing the total polar materials (TPM) based on changes in the dielectric constant of the oil. FFA and TPC test kits are based on color reaction of the oil. However, there are some limitations with these devices such as complex calibration requirement, suitability for different type of oil as well as distinct temperature dependencies.

Sensor must be reliable in the ‘difficult’ frying conditions

In the frying oil application, there’s one factor which is of paramount importance – cleanliness. Frying oils are a dynamic environment. Polymers (brown build-up) begin to form on heating surfaces of the fryer and are deposited at various sections of the fryer. These polymers are removed by using strong caustic cleaners and scrubbing. Many of the sensors themselves are prone to polymer deposits, making the instrument less sensitive, which could adversely affect its performance.

So, the sensor deployed for measurements should be easily cleanable and must be able to produce measurements in such environments. Even better, if the sensor assists in the cleaning cycles and helps detect end points for the cleaning phase.

An inline viscometer for continuous oil tracking

Various studies establish that viscosity is a reliable indicator of oil quality in frying processes. It shows reasonable correlations with the other important chemical indicators such as POM, FFA, TPM, triglycerides content and color values.

Measuring the viscosity of oil is a rapid method of determining oil condition, and is considered an important parameter in assessing asset readiness. The viscosity sensor which can complement infrared (IR) spectroscopy and other bulk property sensors provides instantaneous on-line viscosity and temperature data, has no moving parts and a wide operating range and offers universal plug-and-play connectivity for integration with and into other handheld products.

An inline viscometer such as the SRV ensures that engineers on the floor can monitor and act on the continuous viscosity data from the sensor. In addition to the automation possibilities from this data, it also is extremely efficient as compared to traditional methods which involve sampling and other manual interventions.

Figure 8 – (a) Hand held TPM measuring device (on left) (b) Measuring free fatty acids using test rod (on right) – both need regular, periodic manual measurements from engineers/operators on the factory floor

Balanced torsional resonator – The gamechanger in viscometer technology

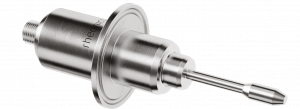

Figure 9 – Rheonics SRV Viscometer – For continuous oil degradation tracking

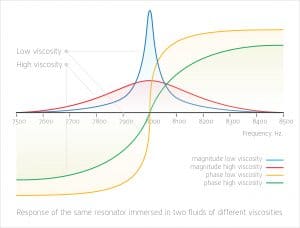

Figure 10 – Sensor Operating Principle, Read more: https://rheonics.com/whitepapers/

- Rheonics SRV viscosity technology makes use of an ultra-stable torsionally balanced mechanical resonator (US patent 9,267,872) whose oscillations are damped by the viscosity of the

- The more viscous the fluid, the higher the mechanical damping of the resonator. By measuring the damping, the product of viscosity and density is estimated.

- The resonator is excited and sensed by means of an electromagnetic transducer mounted in the sensor’s body.

- Damping is measured by Rheonics patented proven and patented gated phase-locked loop technology

- Based on these two key technologies, the SRV viscosity sensor delivers stable, repeatable and highly accurate measurements of the oil viscosity while being small enough to fit in the palm of your hand.

Rheonics SRV Sensor is a small form-factor sensor built to insert directly in the oil frying containers. Extremely high accuracy and stability of viscosity measurement enables quick detection of the smallest variation and build up of unwanted substances/compounds in the frying oil.

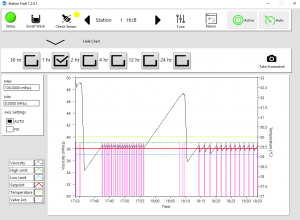

How is Rheonics SRV inline viscometer used for real time frying oil quality monitor?

An inline viscometer making measurements continuously enables the engineers in the factory to achieve the following:

- For automated monitoring, dosing of fresh oil and modifiers to maintain desired oil quality

- To check sampling periodicity – determine when a lab sample should be taken to perform an in-depth measurement of various parameters

- Detect any anomaly or unexpected behaviours and take corrective actions

- Act on oil or product being fried if the trend is off

- Track and trace every batch of fried products all the way to the exact pack of chips!

Figure 11 – Overview of the Rheonics Software Interface

Rheonics inline viscometer SRV, makes life easier for the fryer operator even further by characteristics that makes it well suited for food processes.

- Sanitary and hygienic connections

- Complete sensor is CIP (clean-in-place) compatible

- Measurements are extremely repeatable giving accurate results

- With on-board temperature compensation

- Requiring no re-calibrations but supporting quick in-field calibration verification (FDA conformance)

- Having inter-sensor reproducibility that allows reuse of the same correlation across multiple plants and interchange/replacement of probes without any re-programming

- Underlying technology operated on sub-micron vibration amplitudes that do not affect fluid structure giving you accurate measurement of the fluid itself

- Enabling easy installation directly in process line, no need of by-pass, no disruption to flow

- A robust sensor made of 316L stainless steel with sealed connections (IP69K) to support high temperature, high pressure, acidic and alkaline cleaning

- Low lifetime operating costs with zero maintenance

- Very high ROI (return-on-investment)

Ensure safety of your frying operation while delighting your customers!

Finally, a truly inline online frying oil sensor that does not need operator attention and helps operators focus on getting maximum throughput through the fryers.

References

- Guillaumin, R., 1988. Kinetics of fat penetration in food. In: Varela, G., Bender, A.E., Morton, I.D. (Eds.), Frying of Food: Principles, Changes, New Approaches. Ellis Horwood Ltd., Chichester, pp. 82–90.

- Moreira, R.G., Sun, X., Chen, Y., 1997. Factors affecting oil uptake in tortilla chips in deep-fat frying. Journal of Food Engineering 31 (4), 485–498.

- Matthaus B. Use of palm oil for frying in comparison with other high-stability oils. Eur J Lipid Sci Technol 2007;109 (4):400–9.

- Garba ZN, Gimba CE, Emmanuel P. Production and characterisation of biobased transformer oil from Jatropha Curcas Seed. J Phys Sci 2013;24(2):49–61.

- Kress-Rogers E, Gillatt PN, Rossell JB. Development and evaluation of a novel sensor for the in-situ assessment of frying oil quality. Food Control 1990;1(3):163–78.

- Kalogianni, E. P.; Karapantsios, T. D.; Miller, R. Effect of Repeated Frying on the Viscosity, Density and Dynamic Interfacial Tension of Palm and Olive Oil. Journal of Food Engineering 2011, 105(1), 169–179.

- Liu, M. et al. Microfluidic Assessment of Frying Oil Degradation. Sci. Rep. 6, 27970; doi: 10.1038/srep27970 (2016).

- Olivares-Carrillo P, de los Rias AP, Quesada-Medina J, Hernandez Cifre JG, Diaz Banos FG: Viscosity as a measure of oil composition changes due to thermal degradation, Appl. Rheol. 24 (2014) 53667.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed