316L Stainless Steel

Hastelloy C22

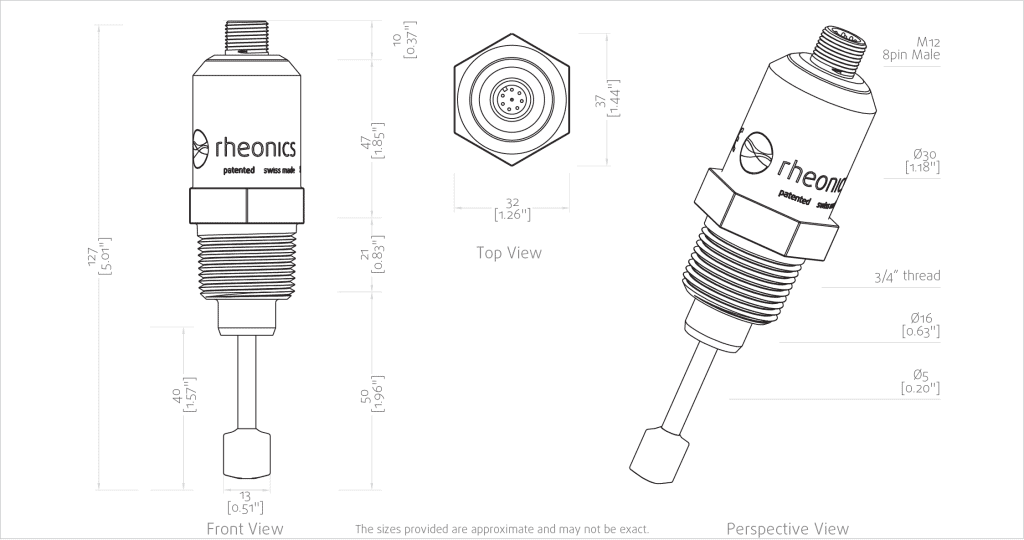

| Density Range | 0.0 - 4.0 g/cc 0.0 - 4000 kg/m3 0.0 - 33.38 lb/gal |

| Density Accuracy | 0.01 g/cc (0.001 g/cc & higher accuracy available) |

| Viscosity Range | 1 to 3,000 cP (standard) Wider range available |

| Viscosity Accuracy | 5% of reading (standard) 1% & higher accuracy available |

| Reproducibility | Better than 1% of reading |

| Temperature | Pt1000 (DIN EN 60751) |

| Process Fluid Temperature | -40 up to 300 °C (575°F) |

| Ambient Temperature | -40 up to 150 °C |

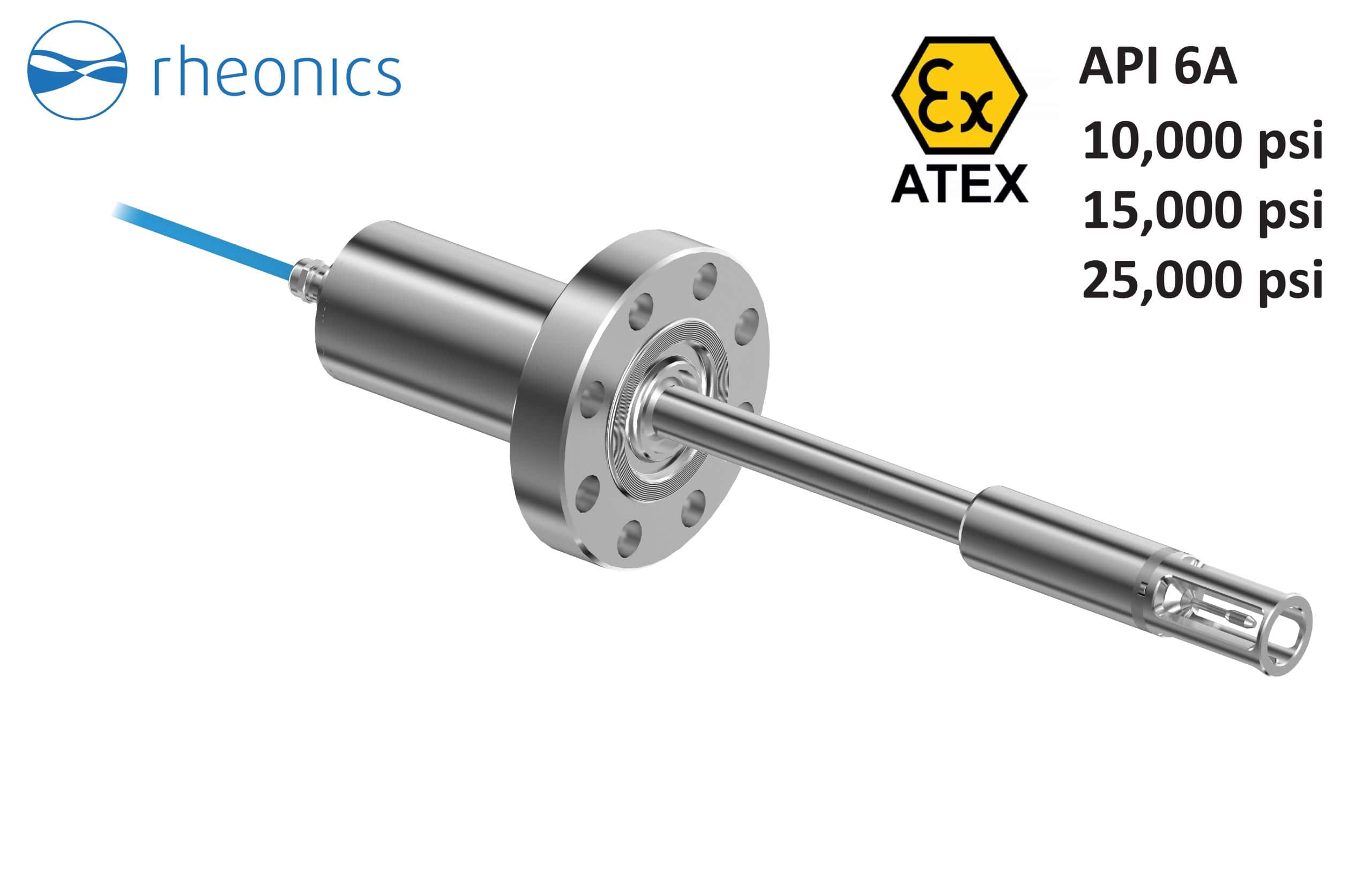

| Pressure Range | up to 7,500 psi (500 bar) |

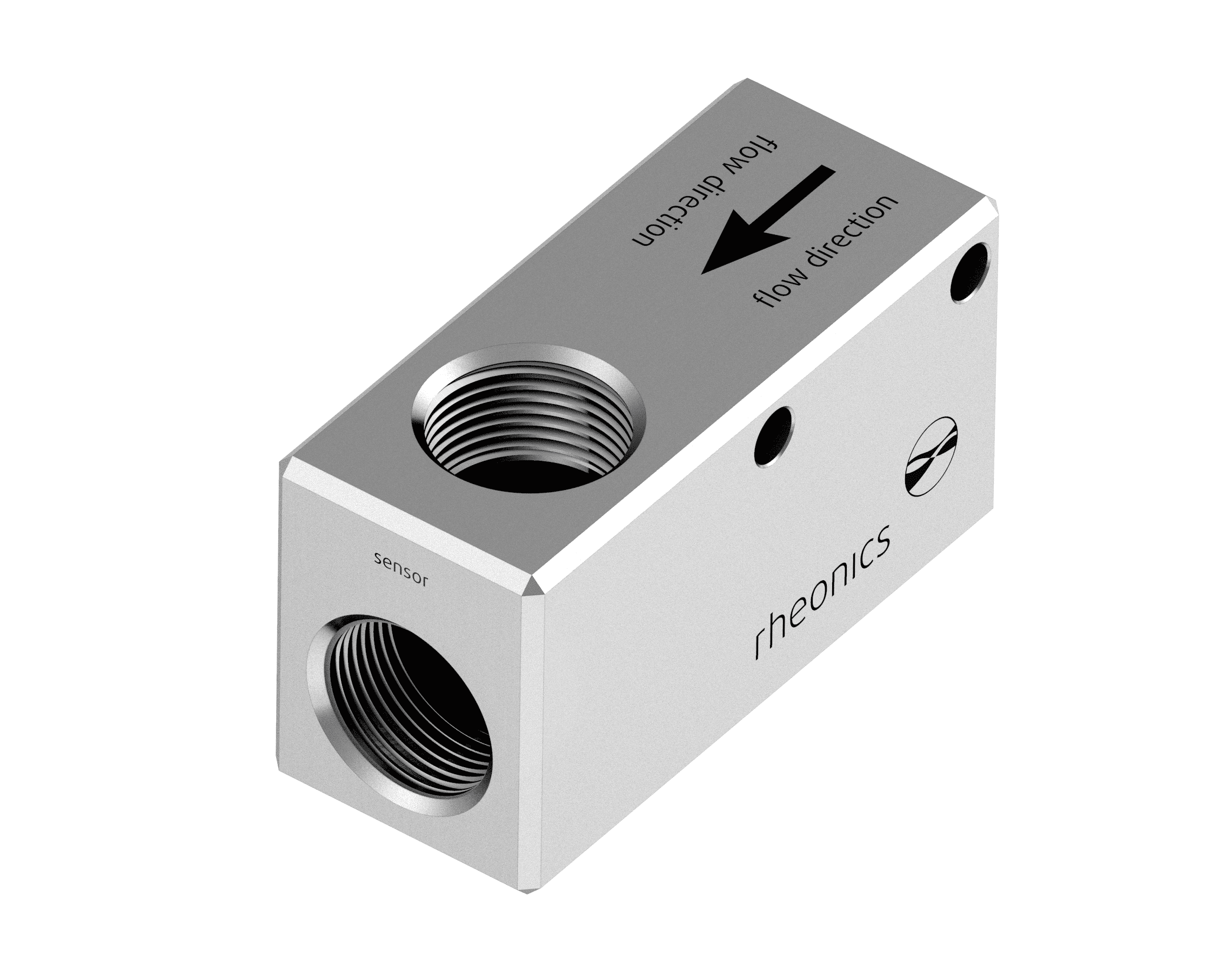

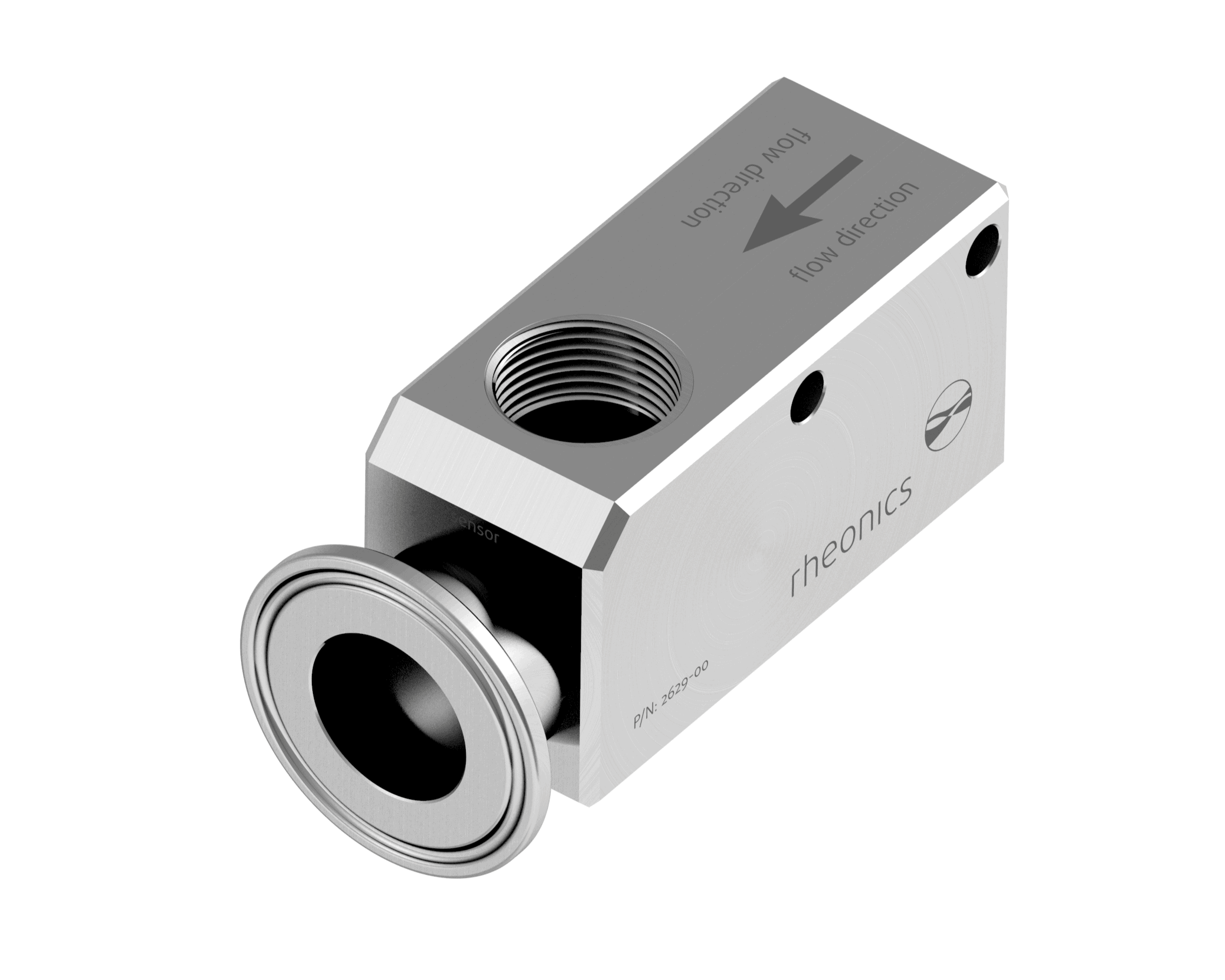

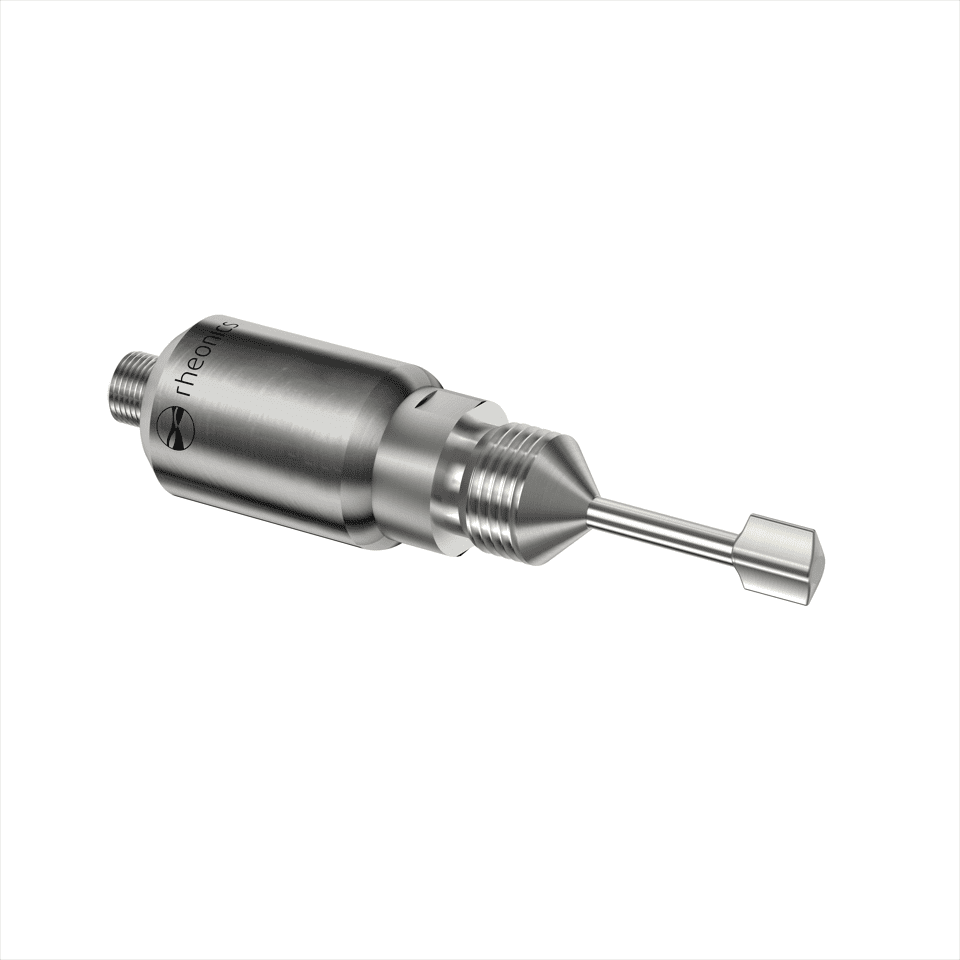

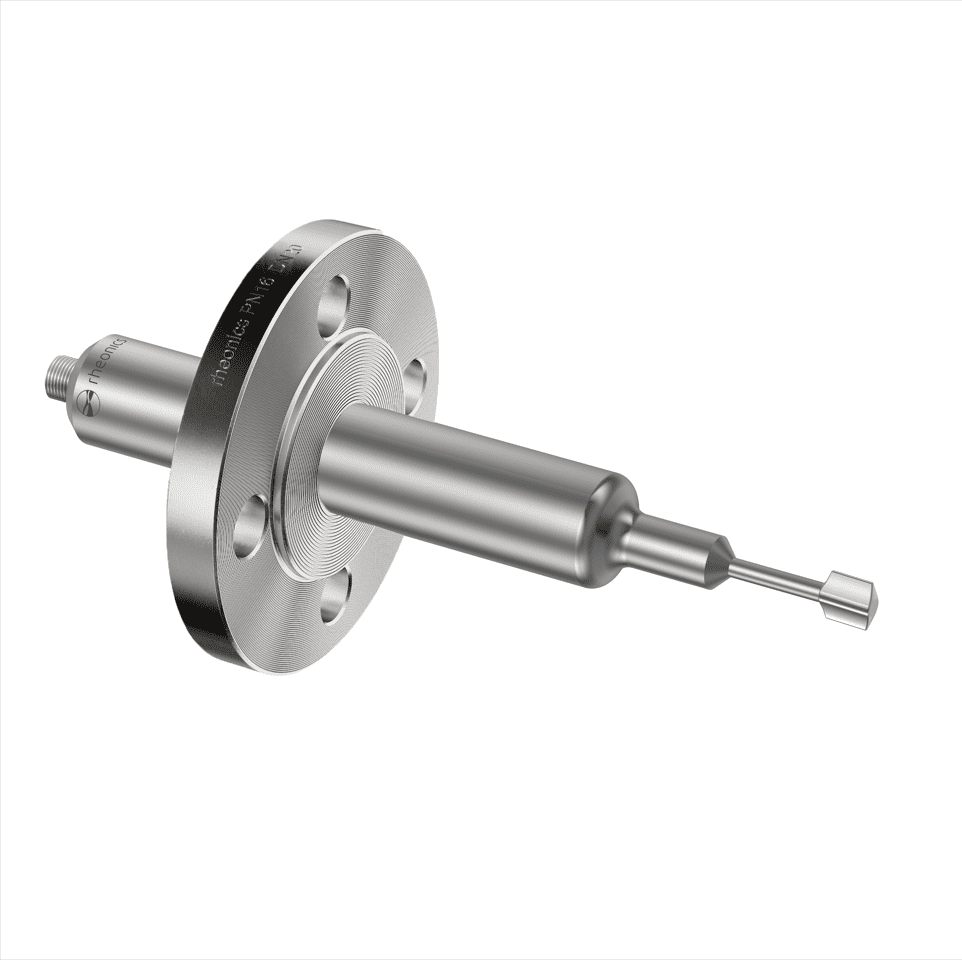

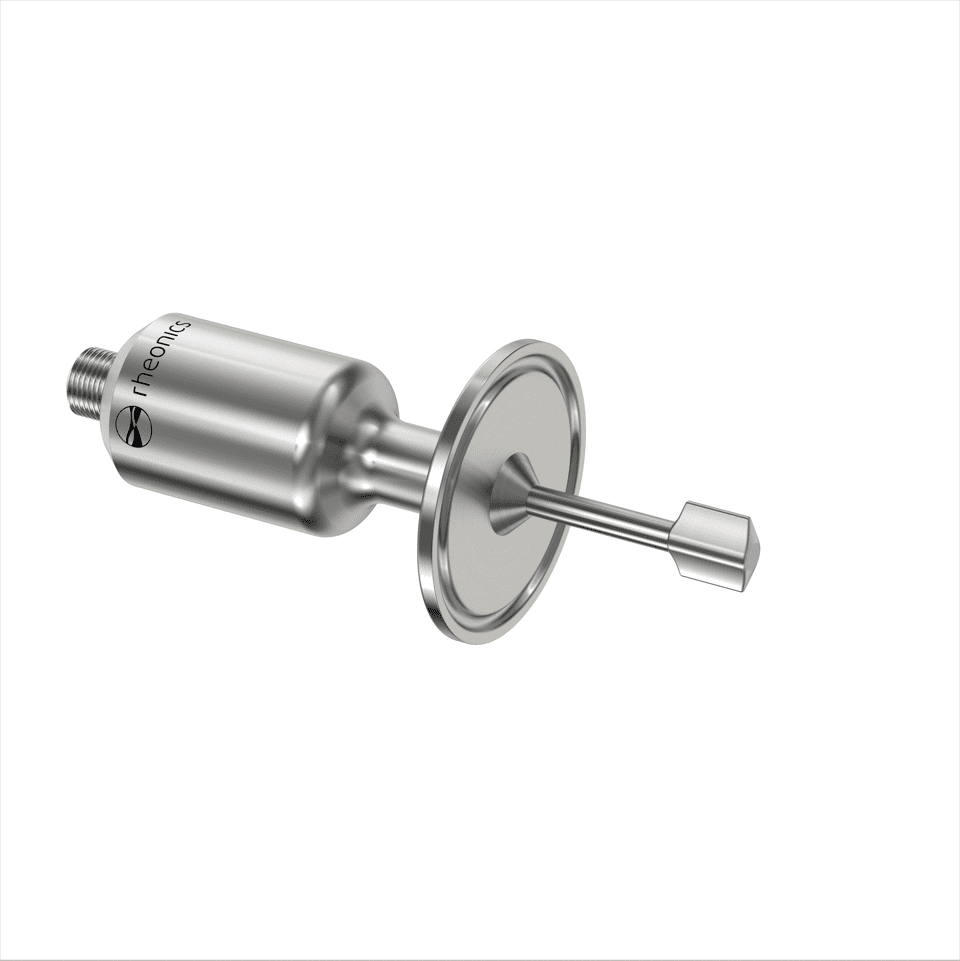

| Fluid Wetted Materials | 316L Stainless steel Hastelloy C22 |

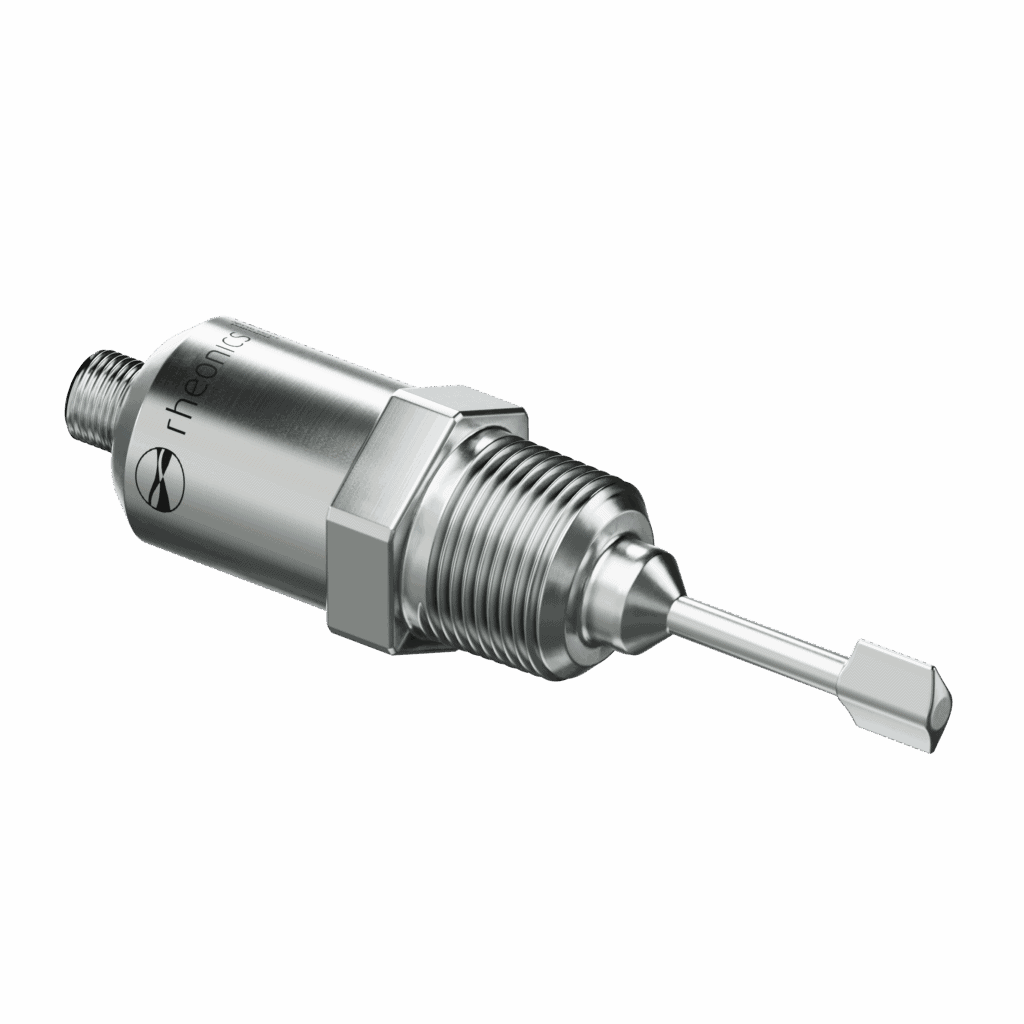

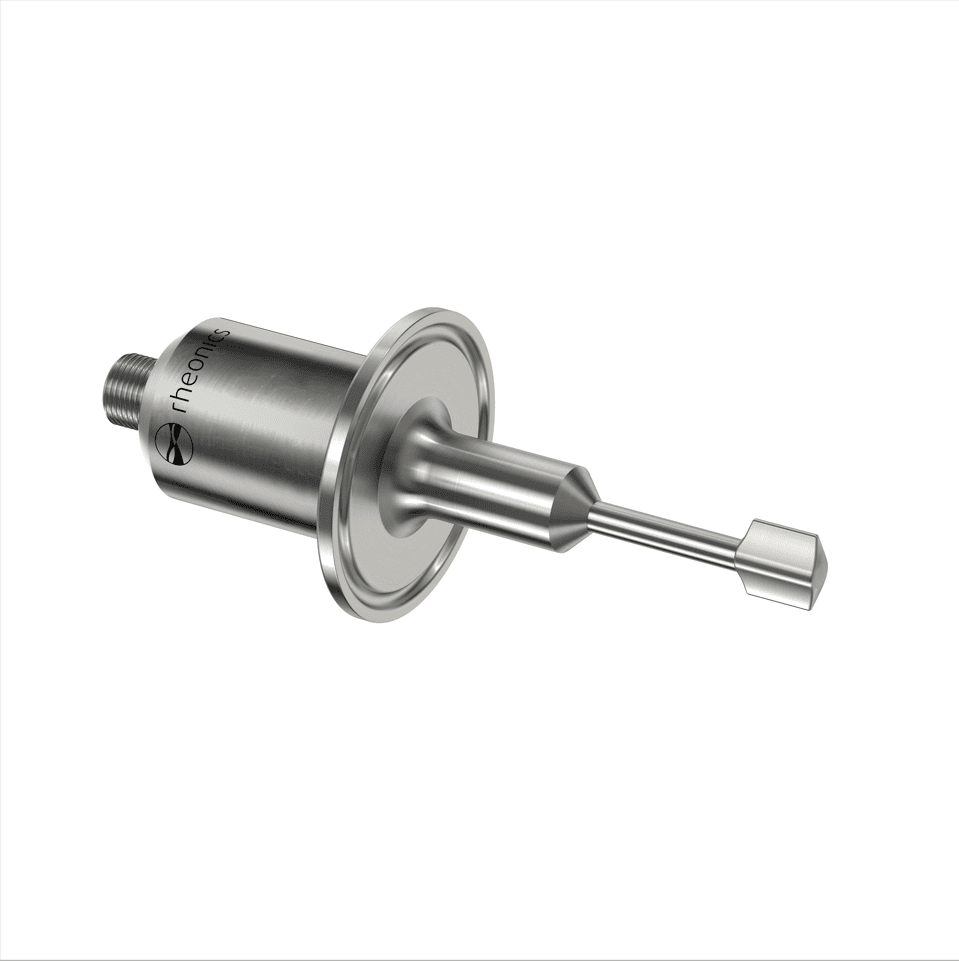

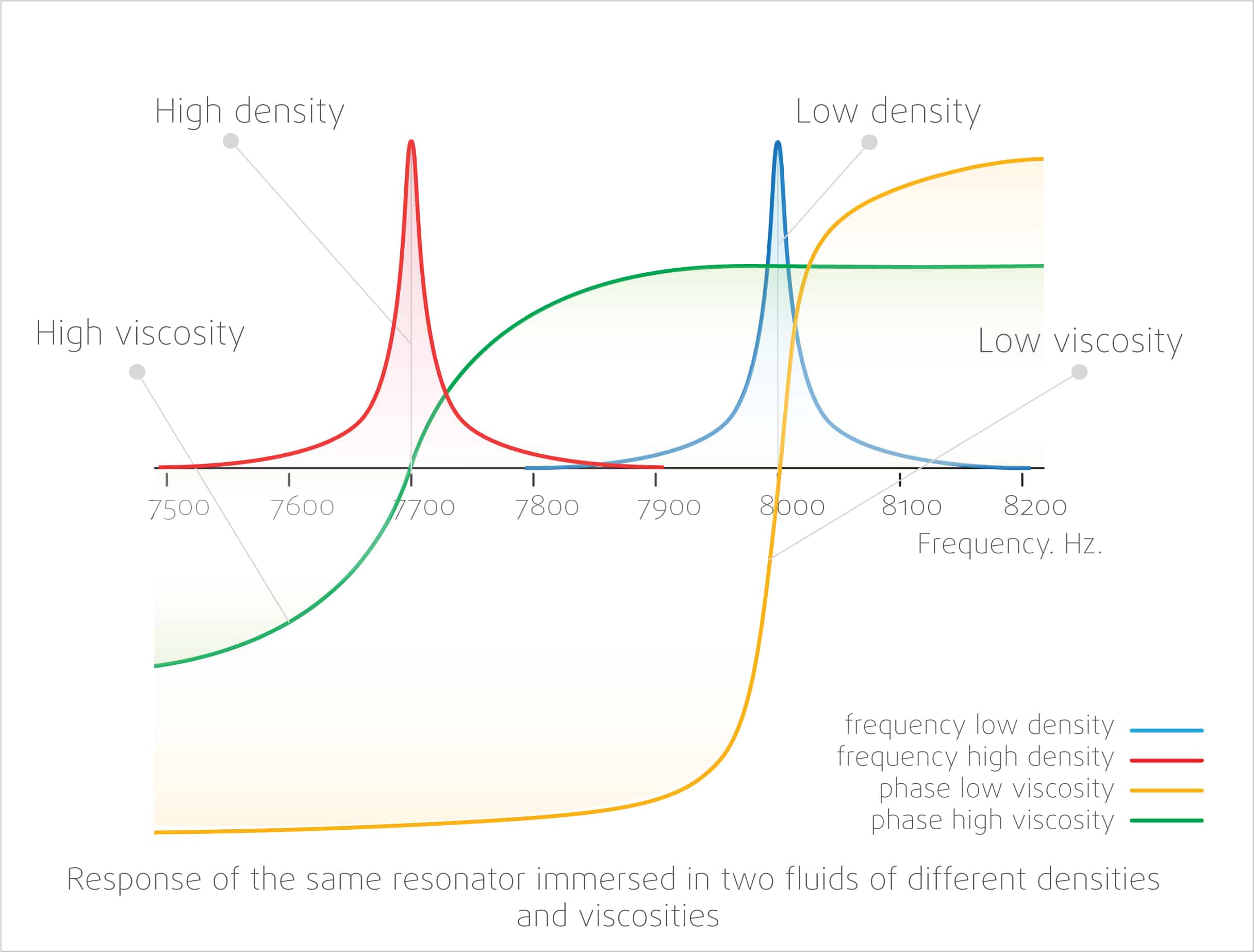

- The rheonics density meter SRD measures viscosity and density by means of a balanced torsional resonator, one end of which is immersed in the fluid under test.

- Density of fluid is measured through the shift in resonant frequency of the resonator.

- The more viscous the fluid, the higher the mechanical damping of the resonator. By measuring the damping, the product of viscosity and density is calculated by rheonics’ proprietary algorithms.

- Density and viscosity of fluid is measured by the rheonics patented sensing and evaluation electronics and stable, high accuracy and repeatable readings are obtained based on rheonics’ proven gated phase-locked loop technology.

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. Ultra-fast and robust electronics, combined with comprehensive computational models, make SRDs one of the fastest and most accurate in the industry. SRD gives real time, accurate density measurements every second and is not affected by flow variations! In addition, you get real-time viscosity measurement of the fluids as well.

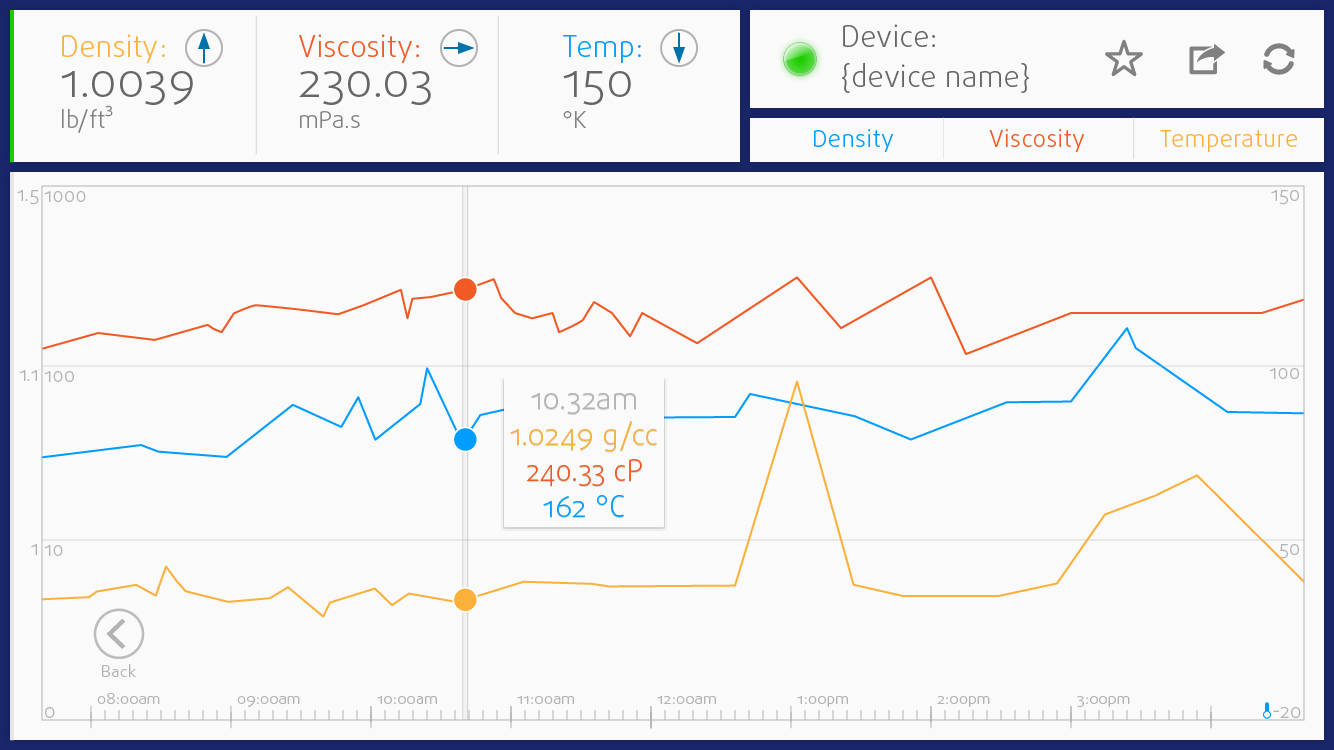

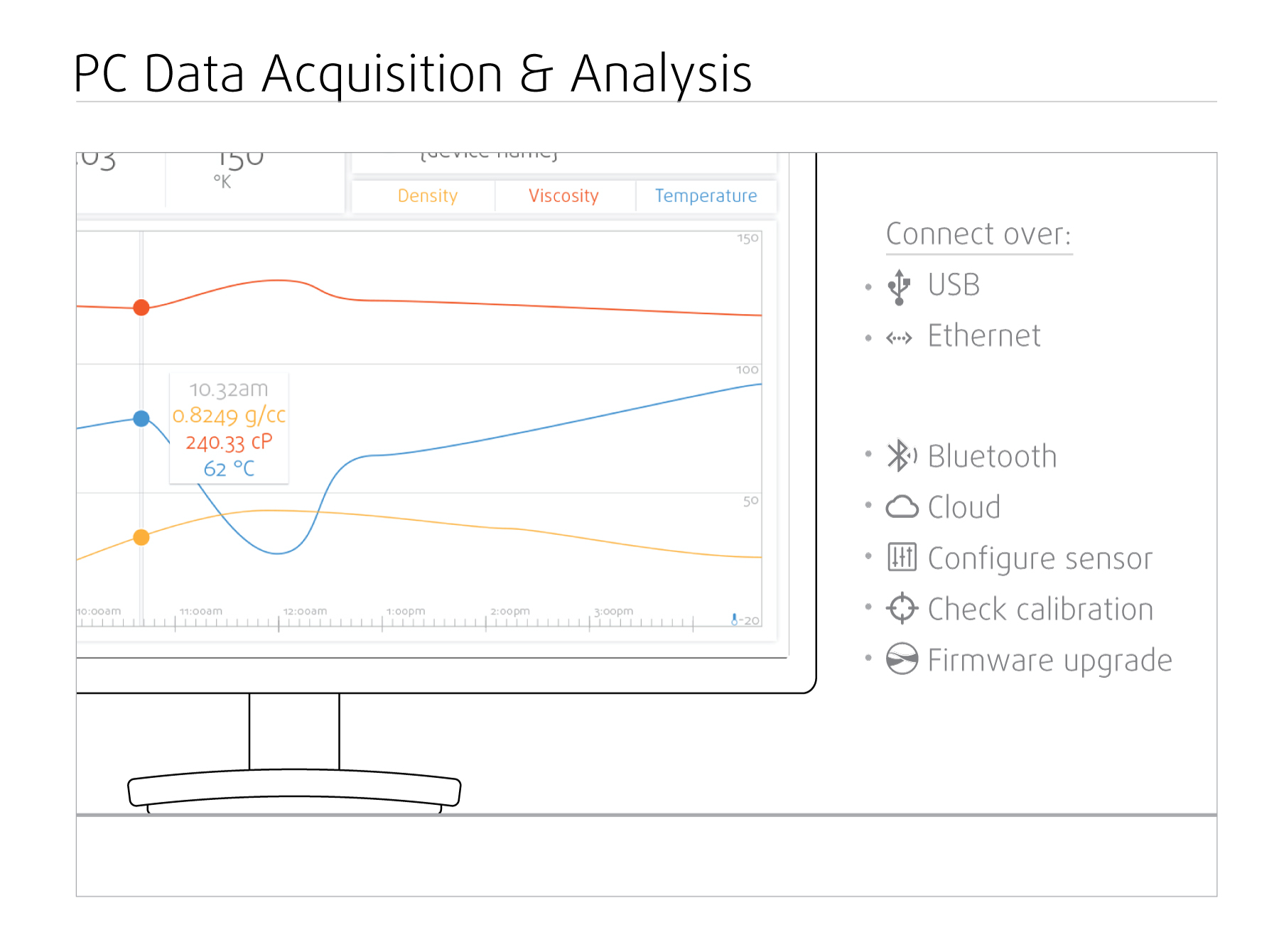

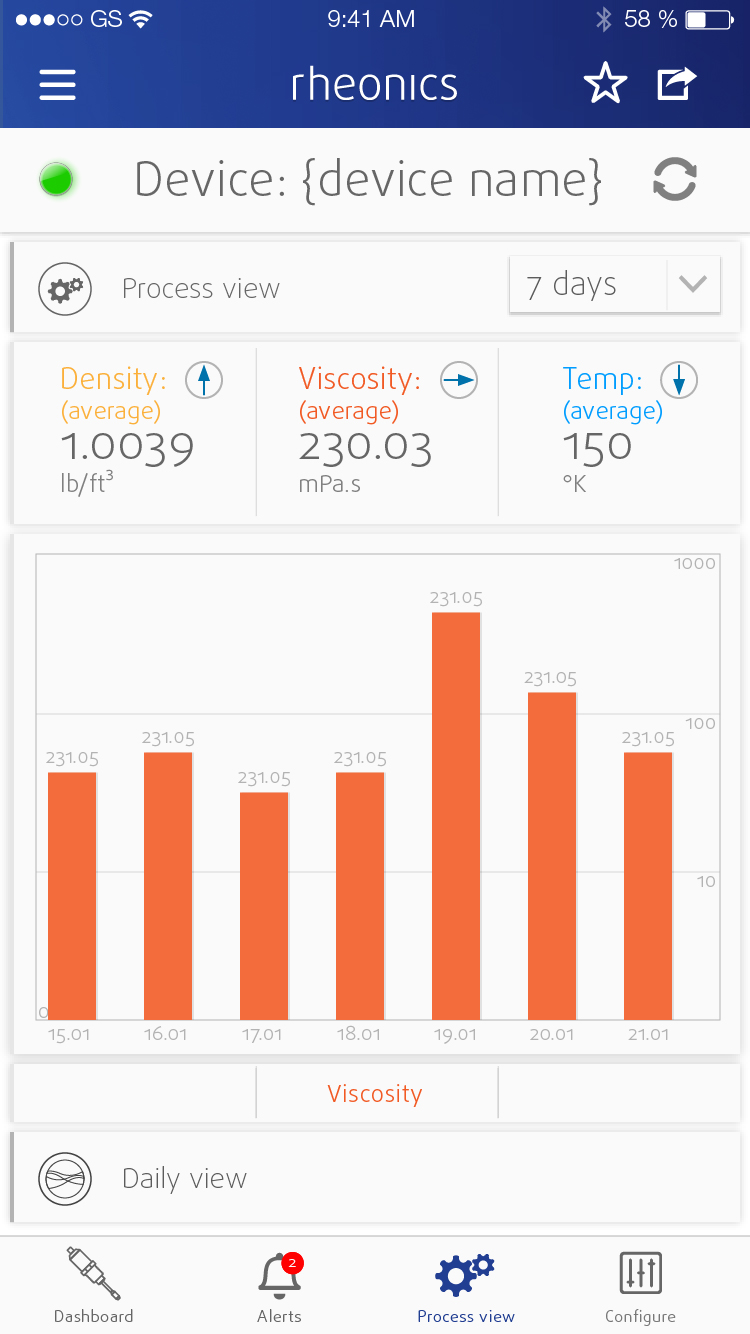

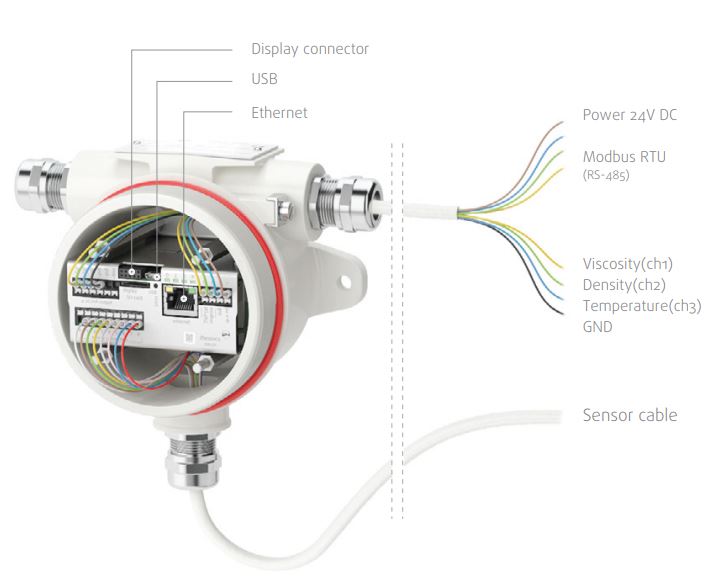

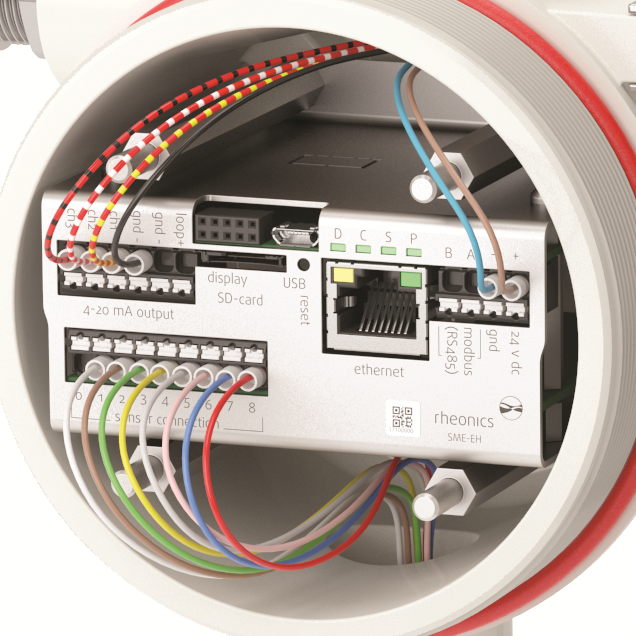

Communication

Acquire data in real-time. Transfer it to your computer, PLC or upload to the cloud

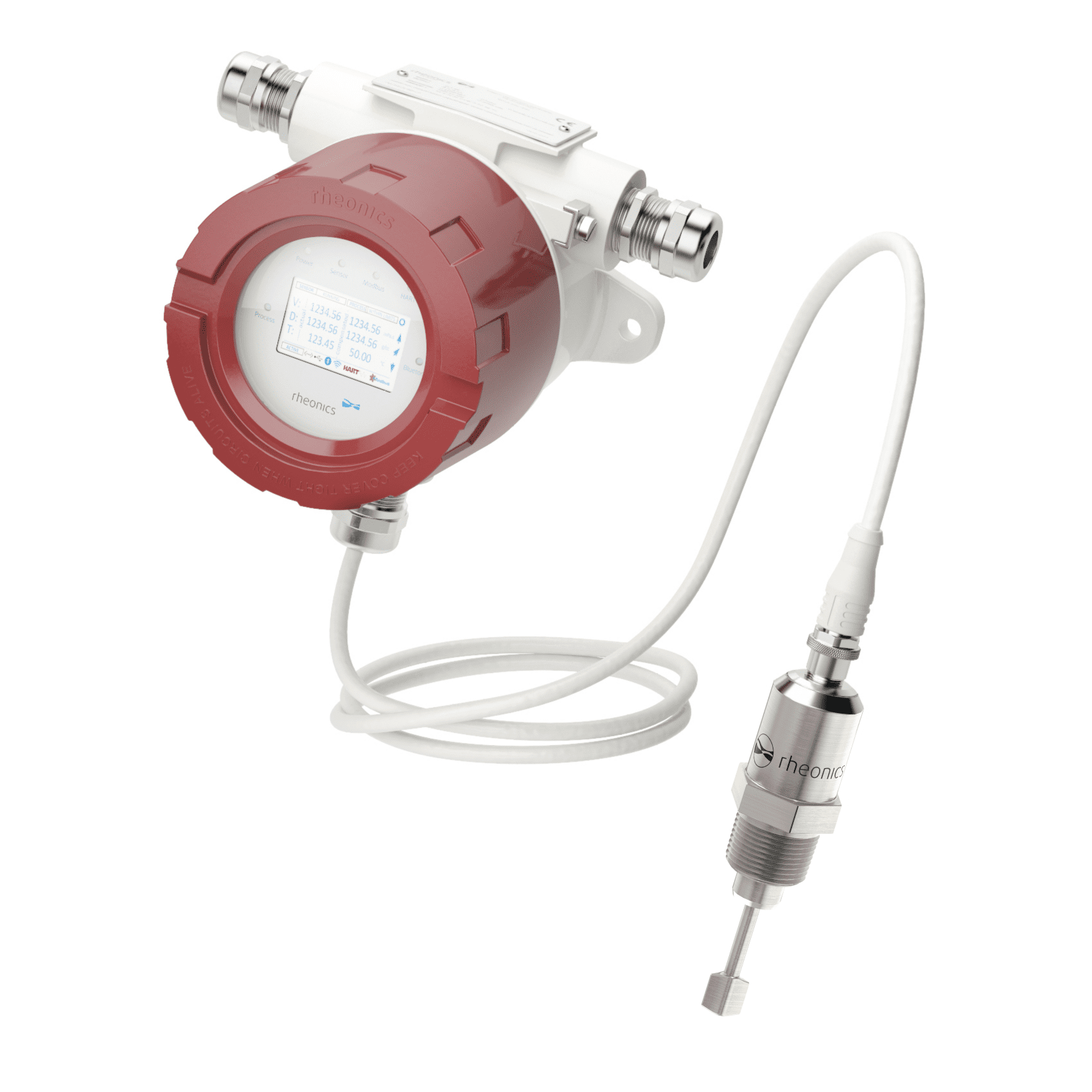

Standalone IP66 rated boxes to integrate into your system.

Standard PCB to integrate in your equipment panel box.

Next generation electronics in sensor head.

Ethernet, 4-20 mA, RS232 over USB.

CAN, Profinet, HART available.

| Title | Description | Link | File Category | Products | Tags | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|

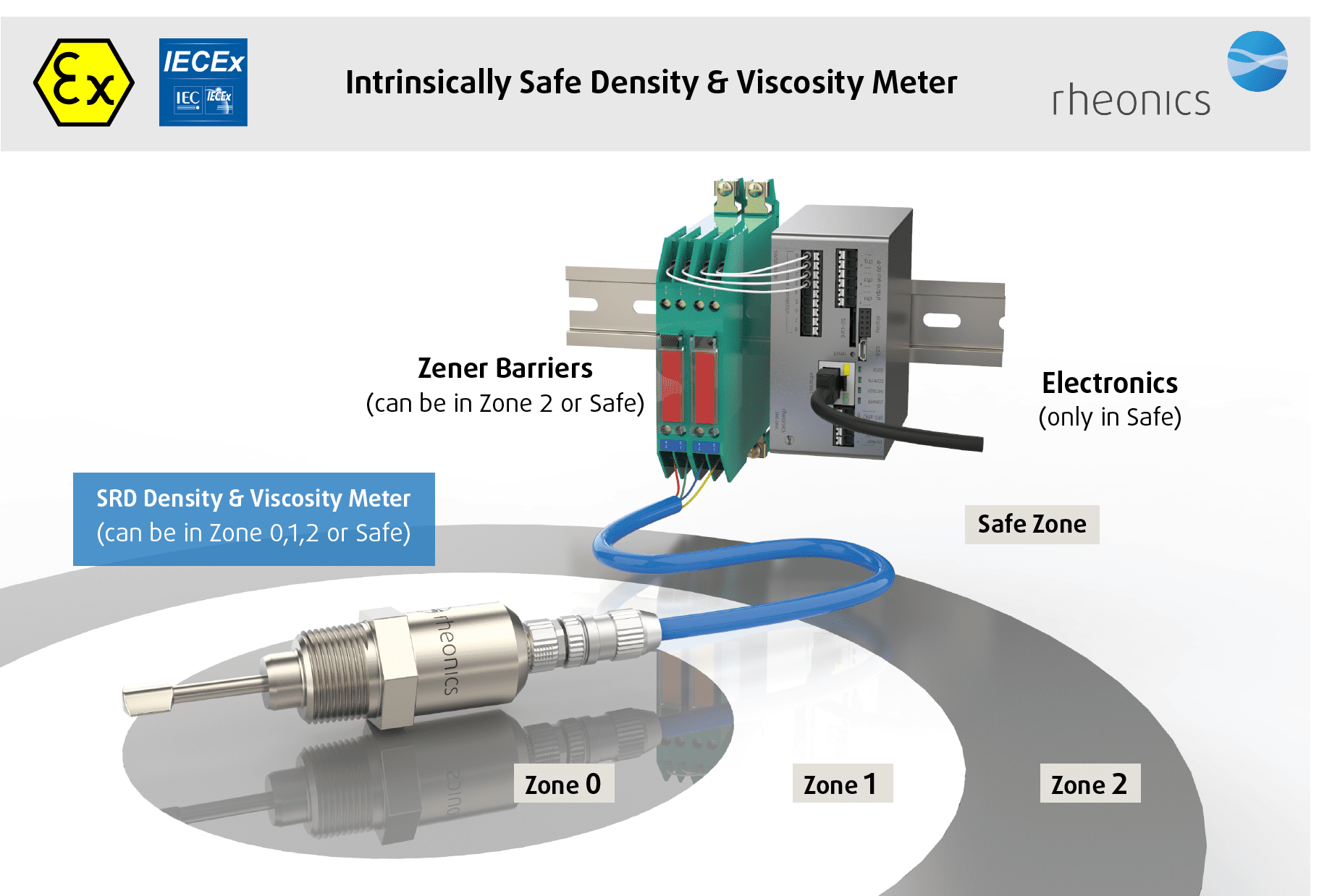

| Certificate – IECEx Certificate of Conformity for SRV & SRD – Issue 05 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standards listed in the Certificate Issue 05 | EX Certificates, Certificates | SRV, SRD, DVM, DVP | ex-certificates certificates | |||

| Training Deck – Integration to Ignition | Training deck on Type-SR sensor UDT Configuration in Ignition | Information and Training Decks | SRV, SRD, Communication | training-deck | |||

| Certificate – RoHS 3 Conformance | This certificate is issued as verification of compliance with directive RoHS 3 | Certificates | SRD, DVM, DVP, Standard Products, SRV | certificates | |||

| Certificate – IECEx Certificate of Conformity for SRV & SRD – Issue 04 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standards listed in the Certificate Issue 04 | EX Certificates, Certificates | SRD, SRV | ex-certificates certificates | |||

| Certificate – ATEX Certificate for SRV & SRD – Issue 04 | Certificate for Equipment and Protective Systems intended for use in Potentially Explosive Atmosphere – Directive 2014/34/EU – Issue 04 | Certificates, EX Certificates | SRD, SRV | certificates ex-certificates | |||

| Certificate – ATEX Certificate for SRV & SRD – Issue 03 | Certificate for Equipment and Protective Systems intended for use in Potentially Explosive Atmosphere – Directive 2014/34/EU – Issue 03 | Certificates, EX Certificates | SRD, SRV | certificates ex-certificates | |||

| Certificate – JPEx Certificate for SRV & SRD – Issue 01 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the JPEx Standards – Issue 01 | Certificates, EX Certificates | SRV, SRD | certificates ex-certificates | |||

| CAD Model – SRD-X5 Flange | CAD Model (STEP File), 2D PDF Drawing, DXF File of SRD-X5 with custom Flange connection | CAD Models | SRD | cad-models | |||

| Certificate – JPEx Certificate for SRV & SRD – Issue 00 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the JPEx Standards – Issue 00 | Certificates, EX Certificates | SRV, SRD | certificates ex-certificates | |||

| Drawing – SRD-HS-X5 – Hygienic long insertion – Flange | 2D drawing of SRD-HS-X5, 3-A EHEDG, Process Connection: Flange |

| Drawings | SRD | drawings | ||

| Manual – Ex Installation and Intrinsic Safety V3.1 | Installation and Intrinsic Safety Installation and intrinsic safety manual V3.1 for Rheonics sensors types SRV, SRV-FPC, SRD and SRD-FPC. Valid only for Issue 2 of Ex certificate. | Manuals | SRV, SRD | manuals | |||

| Certificate – 3-A viscosity and density meter and weld-in accessories | Certificate for 3-A Sanitary Standards for SRV and SRD probes and weld-in accessories | Certificates | SRV, Accessories, SRD | certificates | |||

| Teletube sensor probe parts list and assembly guide | Assembly manual for Rheonics Teletube ultra-long probe SRV and SRD | Manuals | SRV, SRD | manuals | |||

| Drawing – SR RP Reactor Probes | SRV and SRD Reactor Probes Configuration Order Drawing | Drawings | SRV, SRD | drawings | |||

| Drawing – SR SLP Slimline Probes | SRV and SRD Slimline Probes Configuration Order Drawing | Drawings | SRV, SRD | drawings | |||

| Drawing – SRD-SLP-A117-BH40 | Drawing for SRD-SLP: Density and viscosity meter Slimline Probe design with Hygienic DN40 connection. | Drawings | SRD | Technical Information | drawings | technical-information | |

| CAD Model – SRD-SLP-A117-BH40 | CAD Model (pdf, dxf, 3D step) for SRD-SLP: Density and viscosity meter Slimline Probe design. | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| Drawing – SRD-SLP in elbow DN40 | Drawing for SRD-SLP: Density and viscosity meter Slimline Probe design in a jacketed elbow DN40. | Drawings | SRD | Technical Information | drawings | technical-information | |

| CAD Model – SRD-SLP in elbow DN40 | CAD Model (pdf, dxf, 3D step) for SRD-SLP: Density and viscosity meter Slimline Probe design in a jacketed elbow DN40. | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| Rheonics EHEDG density meter and viscometer – Installation guide | Installation guidelines for EHEDG certified hygienic process density meter and viscometer – SRD and SRV | Manuals | SRD, SRV | Technical Information | manuals | technical-information | |

| Certificate – EHEDG SRD inline density and viscosity meter | Certificate for Hygienic EHEDG certified design for SRD probe | Certificates | SRD | Technical Information | certificates | technical-information | |

| CAD Model – SRD Flush Tri-Clamp | CAD Model (STEP File), 2D PDF Drawing, DXF File of SRD – Flush Tri-Clamp | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| Drawing – SME-TR Electronics option: E2 | Drawing for SME-TR: Sensor electronics in Transmitter Housing | Drawings | Electronics, DVM, DVP, SRD, SRV | Technical Information | drawings | technical-information | |

| CAD Model – SRD G1/2″ | CAD Model (STEP File), 2D PDF Drawing, DXF File of SRD – G1/2″ | CAD Models | SRD | cad-models | |||

| RFQ Request for quotation SRD density and viscosity meter | Fill out this PDF file and send it to to request a quote for the SRD. We recommend using the online RFQ form | Sales Document | SRD | Sales Information | sales-document | sales-information | |

| CAD Model- SME-TRD Electronics option: E1 | CAD Model (pdf, dxf, 3D step) for SME-TRD: Sensor electronics in Transmitter Housing with Display | CAD Models | SRD, Electronics, DVM, DVP, SRV | Technical Information | cad-models | technical-information | |

| Drawing – SME-TRD Electronics option: E1 | Drawing for SME-TRD: Sensor electronics in Transmitter Housing with Display | Drawings | SRD, Electronics, DVM, DVP, SRV | Technical Information | drawings | technical-information | |

| CAD Model – SME-TR Electronics option: E2 | CAD Model (pdf, dxf, 3D step) for SME-TR: Sensor electronics in Transmitter Housing | CAD Models | Electronics, DVM, DVP, SRV, SRD | Technical Information | cad-models | technical-information | |

| CAD Model – SME-DRM Electronics option: E3 | CAD Model (pdf, dxf, 3D step) for SME-DRM: DIN rail mount Sensor electronics | CAD Models | SRV, SRD, Electronics, DVM, DVP | Technical Information | cad-models | technical-information | |

| Drawing – SME-DRM Electronics option: E3 | Drawing for SME-DRM: DIN rail mount Sensor electronics | Drawings | SRV, SRD, Electronics, DVM, DVP | Technical Information | drawings | technical-information | |

| CAD Model – SRD Tri-Clamp | CAD Model (STEP File), 2D PDF Drawing, DXF & DWG files of SRD – Tri-Clamp | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| CAD Model – SRD Long Flange | CAD Model (STEP File), 2D PDF Drawing, DXF & DWG files of SRD – Long Flange | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| CAD Model – SRD Flange | CAD Model (STEP File), 2D PDF Drawing, DXF & DWG files of SRD – Flange | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| CAD Model – SRD NPT | CAD Model (STEP File), 2D PDF Drawing, DXF & DWG files of SRD – NPT | CAD Models | SRD | Technical Information | cad-models | technical-information | |

| Drawings – SRD – EHEDG | SRD – EHEDG (European Hygienic Engineering and Design Group) certified variants | Drawings | SRD | pharmaceutical, food, EHEDG | drawings | pharmaceutical food ehedg | |

| Drawing – SRD – Long insertion – VARINLINE | 2D drawing of SRD – FPC, Process Connection: VARINLINE |

| Drawings | SRD | Technical Information, FPC | drawings | technical-information fpc |

| Drawing – SRD – Long insertion – Triclamp | 2D drawing of SRD – FPC, Process Connection: Triclamp | Drawings | SRD | Technical Information, FPC | drawings | technical-information fpc | |

| Drawing – SRD – Long insertion – Threaded | 2D drawing of SRD – FPC, Process Connection: Threaded (G, NPT, others) | Drawings | SRD | Technical Information, FPC | drawings | technical-information fpc | |

| Drawing – SRD-X5 – Long insertion – Flange | 2D drawing of SRD-X5, Process Connection: Flange | Drawings | SRD | Technical Information, FPC | drawings | technical-information fpc | |

| Drawing – SRD – Long insertion – DIN11851 | 2D drawing of SRD – FPC, Process Connection: DIN11851 | Drawings | SRD | Technical Information, FPC | drawings | technical-information fpc | |

| Drawing – SRD – Sanitary | 2D drawing of SRD – Sanitary Process Connection |

| Drawings | SRD | Technical Information | drawings | technical-information |

| Drawing – SRD – Triclamp | 2D drawing of SRD – Triclamp Process Connection |

| Drawings | SRD | Technical Information | drawings | technical-information |

| Drawing – SRD – Flange | 2D drawing of SRD – Flange Process Connection |

| Drawings | SRD | Technical Information | drawings | technical-information |

| Drawing – SRD – NPT | 2D drawing of SRD – NPT Process Connection |

| Drawings | SRD | Technical Information | drawings | technical-information |

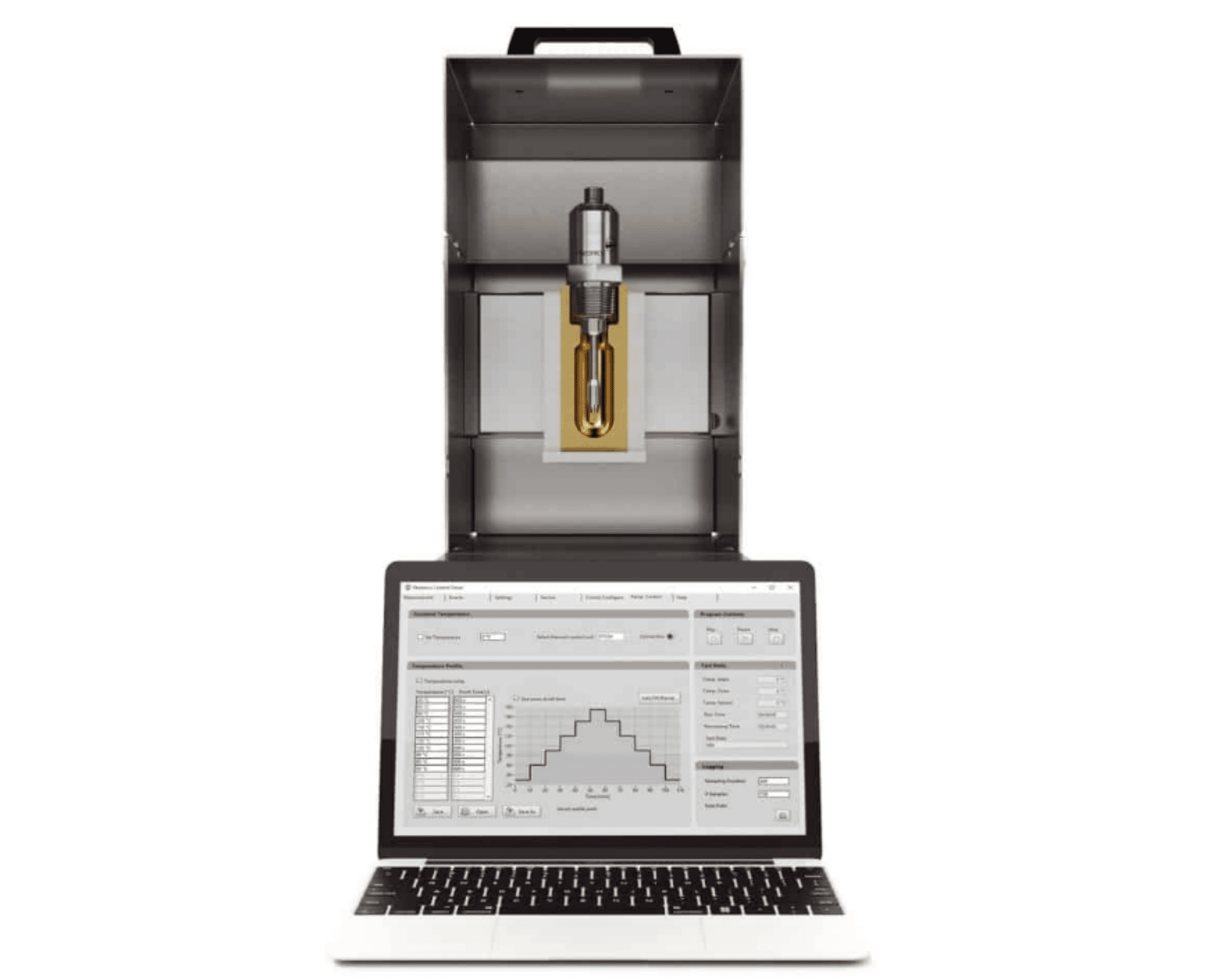

| Datasheet – STCM | Information and specifications about SRV and SRD Smart Thermal Control Module | Datasheets & Brochures | SRV, SRD, STCM | Technical Information | datasheets | technical-information | |

| Certificate – IECEx Quality Assessment Report for SRV & SRD | IECEx Quality Assessment Report Summary | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Declaration of Conformity – Food Contact Compliance as per US FDA and EU Compliance for SRV & SRD | Rheonics’ Declaration of Conformity for Food Contact Compliance as per US FDA and EU Compliance for SRV & SRD | Certificates | SRV, SRD | Technical Information, Application | certificates | technical-information application | |

| Declaration of Conformity – CE Declaration of Conformity as per EN 61326-1:2013, EN 61326-2-3:2013 & EN 50581:2012 | Declaration of Conformity for SME-TRD, SME-TR & SME-DRM as per directives – Electromagnetic compatibility (EMC) Directive 2014/30/EU & Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS2) Directive 2011/65/EU | Certificates | SRD, Electronics, DVM, DVP, SRV | Technical Information | certificates | technical-information | |

| Certificate – ATEX Quality Assurance Notification (QAN) – German | ATEX-QAN (Quality Assurance Notification) in German – Requirements according to directive 2014/34/EU have been fulfilled | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Certificate – ATEX Quality Assurance Notification (QAN) – English | ATEX-QAN (Quality Assurance Notification) in English – Requirements according to directive 2014/34/EU have been fulfilled. | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Declaration of Conformity – CE Declaration of Conformity according to directive 2014/34/EU (ATEX) for SRV & SRD | Rheonics’ EU Declaration of Conformity according to directive 2014/34/EU (ATEX) and relevant standards for SRV, SRV-FPC, SRD & SRD-FPC | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Certificate – ATEX Certificate for SRV & SRD – Issue 02 | Certificate for Equipment and Protective Systems intended for use in Potentially Explosive Atmosphere – Directive 2014/34/EU – Issue 02 | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Certificate – IECEx Certificate of Conformity for SRV & SRD – Issue 02 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standards listed in the Certificate Issue 02 | EX Certificates, Certificates | SRV, SRD | Technical Information | ex-certificates certificates | technical-information | |

| Article – Laboratory for Mechanics and Experimental Dynamics, ETH Zurich | ETH Zurich, Laboratory for Mechanics and Experimental Dynamics – Article on Dynamic viscosity and density sensing featuring Rheonics (previously Viscoteers) | Publications | SRV, SRD, DVM, DVP | Technical Information | publications | technical-information | |

| Manual – SRD | SRD Installation and Operating Instructions | Manuals | SRD | Training | manuals | training | |

| Product Portfolio – SRV, SRD, DVM, DVP | Overview of the Standard Products – Information on Specifications, Electronics, Communication, Mechanical, Dimensions, Software and installation. | Datasheets & Brochures | SRV, SRD, DVM, DVP | Marketing, Technical Information | datasheets | marketing technical-information | |

| Datasheet – SRD | Information on Specifications, Electronics, Communication, Mechanical, Dimensions, Software and installation. | Datasheets & Brochures | SRD | Technical Information | datasheets | technical-information |

- All

- Adhesive

- Cosmetics

- Printing and Coating

- Industrial Mixing and Grinding

- Food and Beverages

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

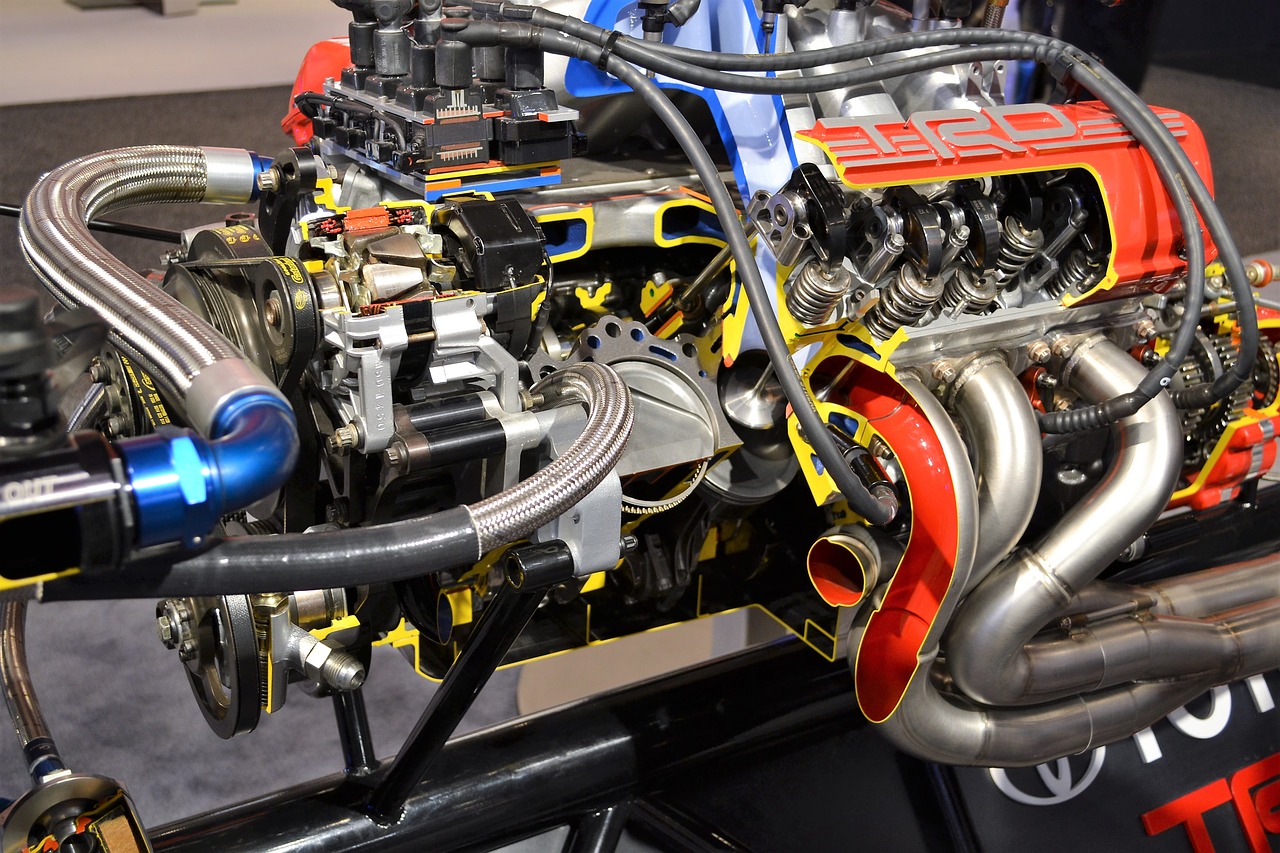

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Enhancing Safety and Process Control in Combustible Dust Environments with EX Certified Rheonics Density Meters and Viscometers

Combustible dust poses a significant explosion risk across industries such as food processing, chemicals, mining, and metal powders. This application…

Viscosity Management in Medical Device Coatings: Enhancing Performance and Compliance

Viscosity and density play a crucial role in medical device coatings, directly impacting product cohesion, surface quality, and therapeutic effectiveness…

Optimizing Hotmelt Adhesive (HMA) Processes with Advanced Viscosity Control

Adhesive hotmelt’s viscosity is a critical property, as it directly impacts its ability to be applied and form a strong…

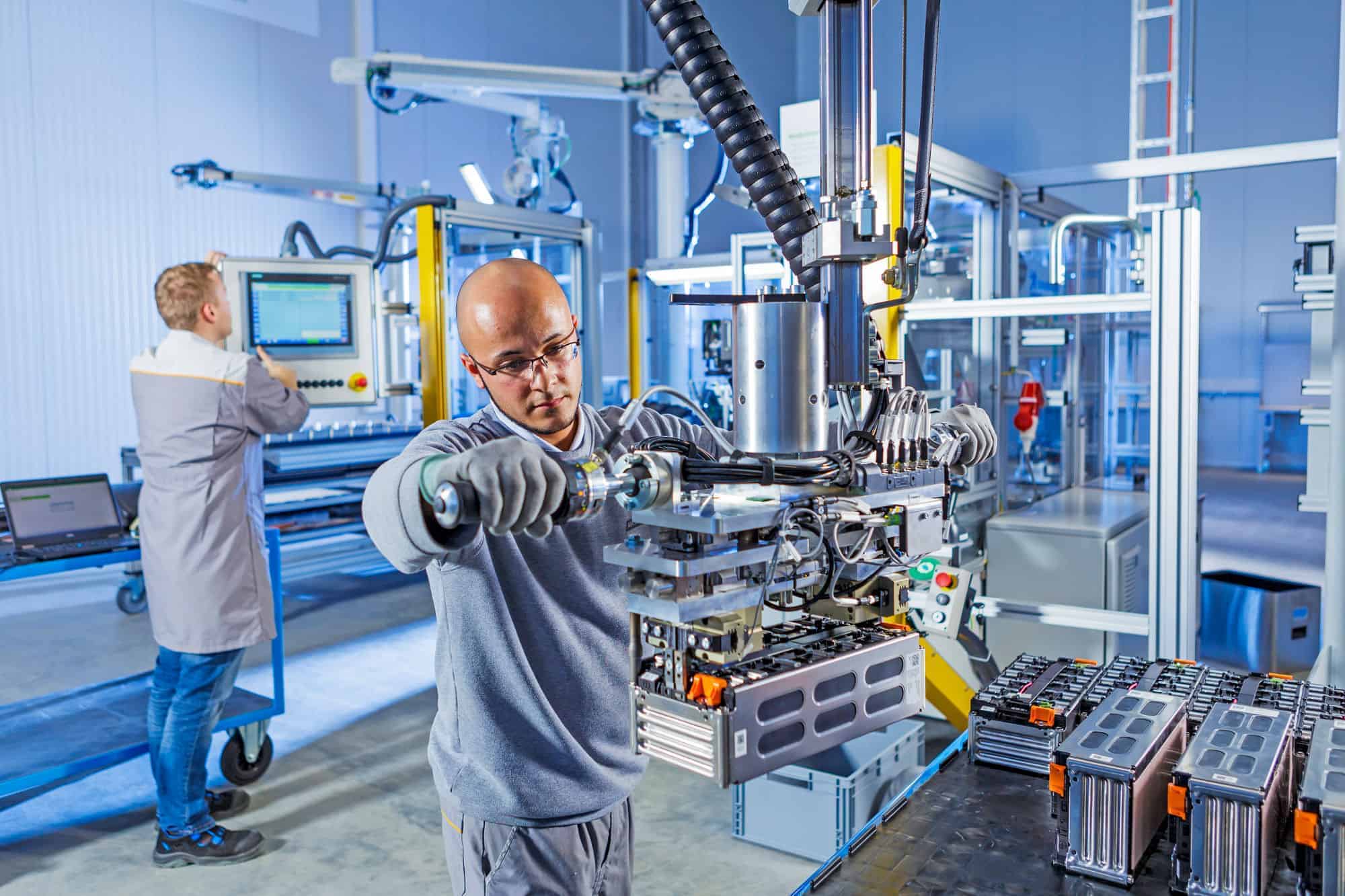

Monitoring Battery Slurry Production with Inline Viscometers and Density Meters

In battery manufacturing, viscosity and density play a critical role in achieving consistent slurry quality, optimizing performance, and improving the…

Inline Viscosity and Density Monitoring for Gelatin Capsule Production

Capsules are a solid oral dosage form used for the delivery of medical drugs, vitamins, minerals, and other health-related ingredients…

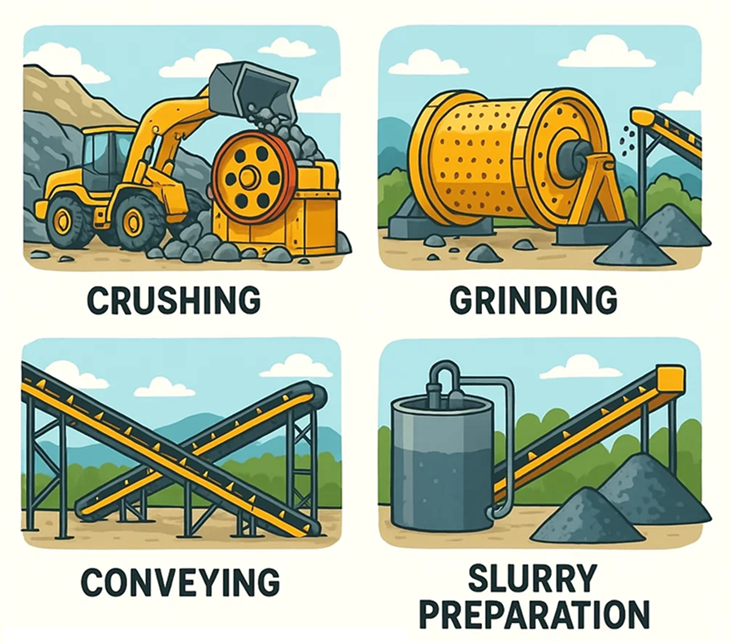

Automating and optimizing mining operations with Rheonics Sensors and Solutions

The mining industry has always been known for its complexity and hard environments. From ore extraction to final product recovery,…

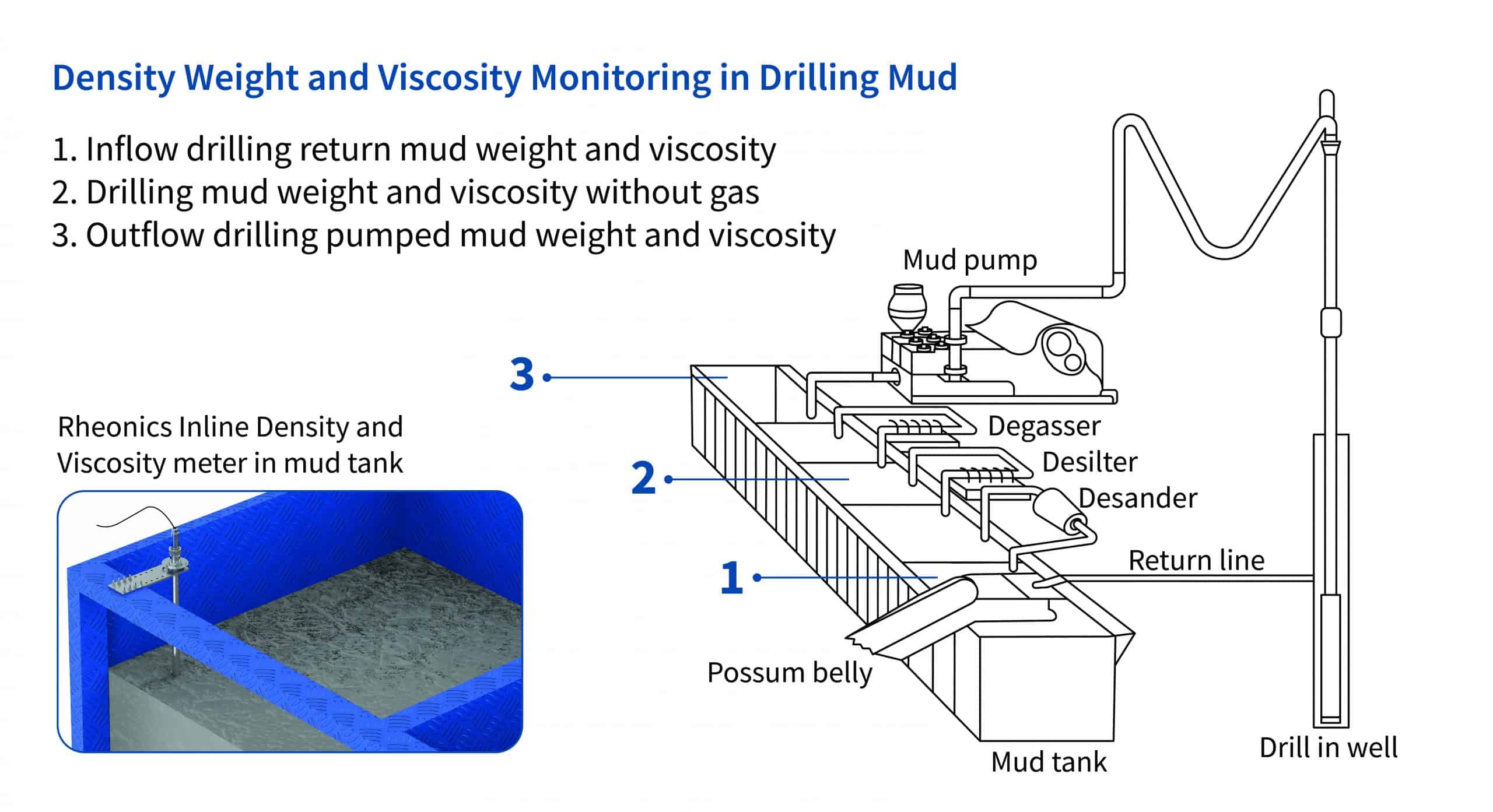

Drilling Mud Weight and Viscosity Monitoring to Optimize Well Performance

Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or…

Adhesives and Sealants Industry Overview and Rheonics Sensors Use

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Density and Concentration Brine pond monitoring in lithium extraction process

Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process…

Monitoring Density and Viscosity in 3D Cement Printing

Density and viscosity are critical parameters in 3D cement printing as they directly affect the printability, structural integrity, and layer…

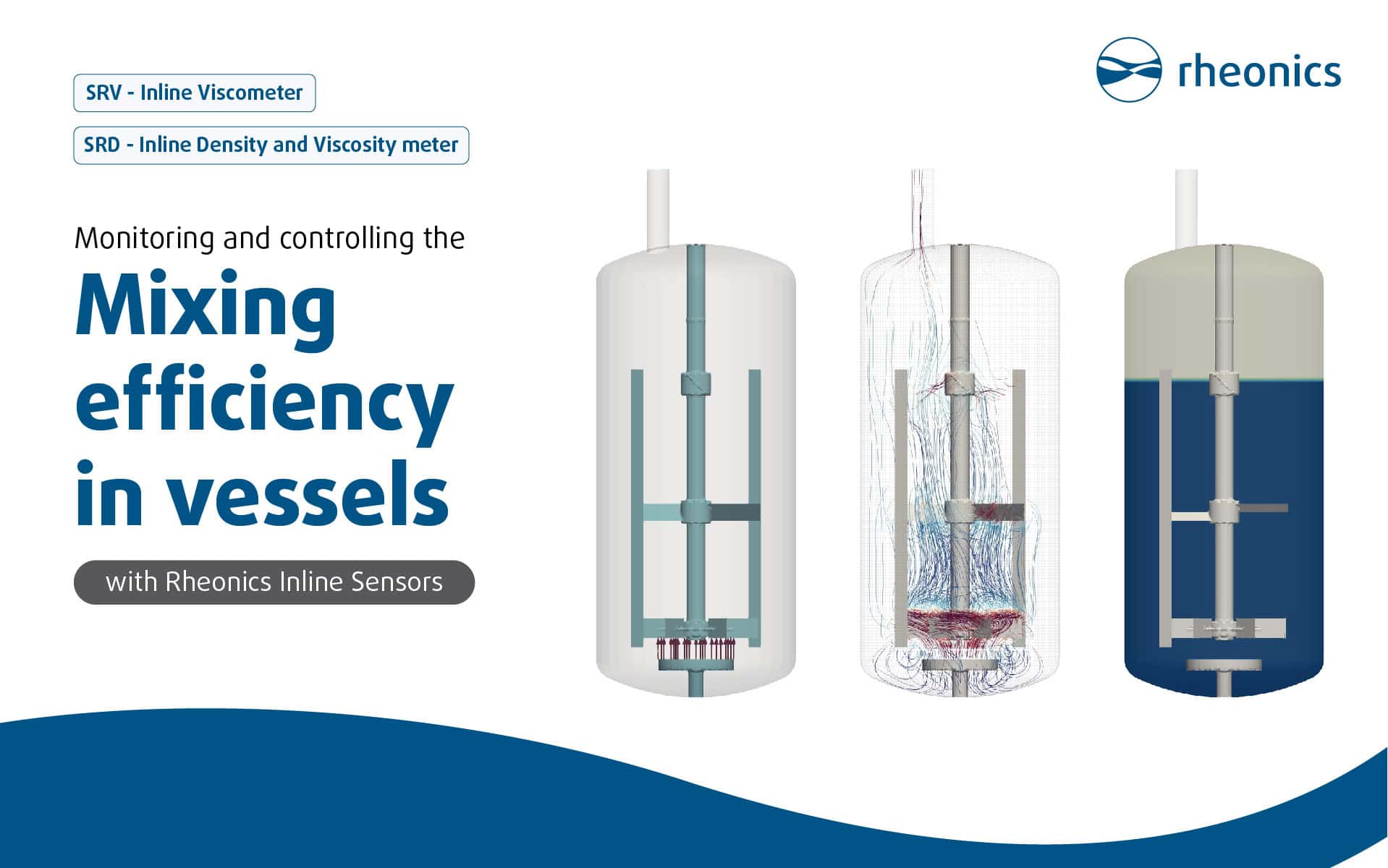

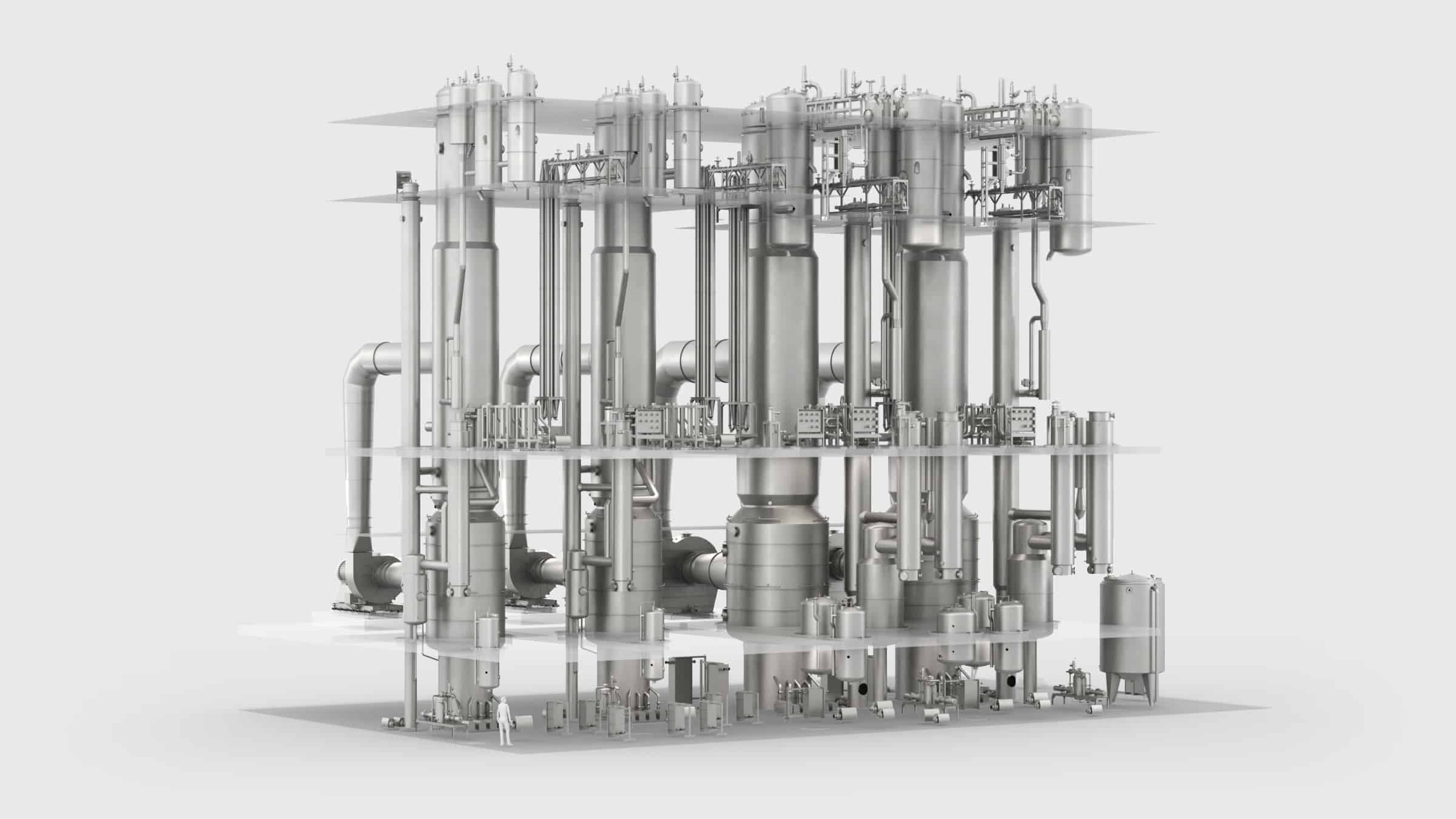

Mixing vessels – monitoring and controlling the mixing efficiency

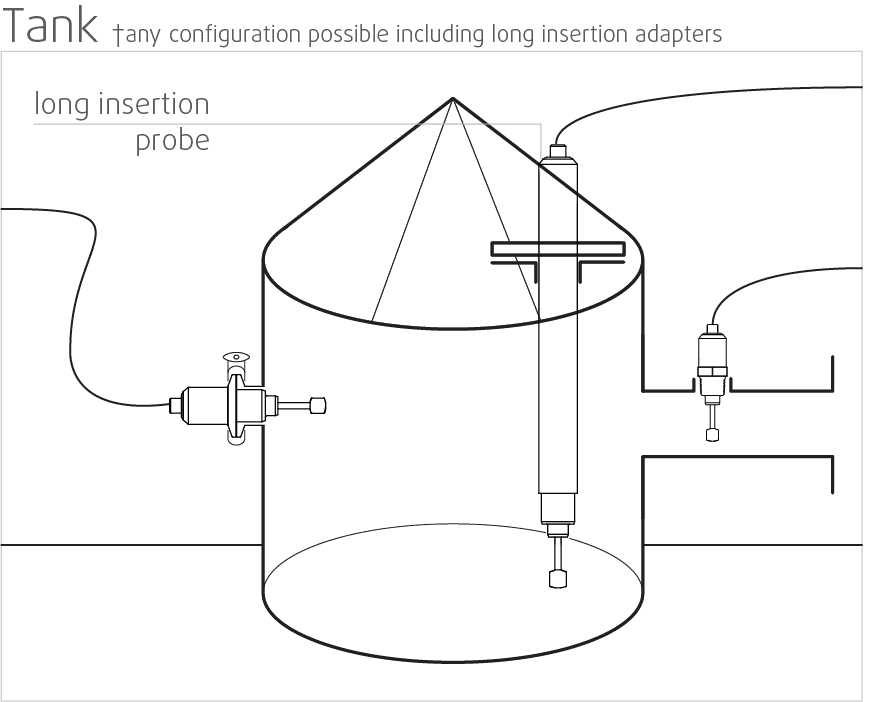

Rheonics process viscometer SRV or Rheonics process density and viscometer SRD can be installed in a variety of locations in…

DeSander and Separator sand level realtime monitoring for automatic removal

The ability to monitor the level of sand in desanders, separators, and flowback systems allows for automation and higher efficiency…

Real-time quality control of paint, ink, coating manufacturing using process viscometer and density meter

Paint, ink and coating manufacturing processes follow similar steps, from initial mixing, until final packaging or storage, requiring a grinding…

Inline viscometers boost efficiencies of spray drying processes in milk powder manufacturing

The process of converting liquid milk into dry powder involves removing most of the water. The amount of water removed…

Glaze slurry viscosity monitoring and control for preventing defects in coating

Defects in glaze coating are driven by variation in glazing causing color differences, coating thickness variation, cracks. Monitoring and controlling…

Polyelectrolyte preparation and dosing equipment deploy inline viscosity automation systems

Treatment plants are faced with the challenge of stricter regulations and higher standards for finished water quality. New developments in…

Meeting rigorous quality control of asphalt for every load at the terminal with real-time viscosity measurements

Asphalt has proven itself to be one of the most versatile and effective materials for paving – be it road…

Inline viscosity measurement of starch glue for the production of corrugated cardboard

Real-time inline viscosity measurement in cardboard production is essential for continuous quality control, avoid waste and optimize energy consumption. Starch…

Cheese coagulation monitoring and cutting automation with inline viscosity measurements

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure…

Optimizing non-Newtonian mixing applications with viscosity management

Key advantages of viscosity management in mixing applications: Accurate and efficient mixing operations – significant savings in material costs and…

Semiconductor CMP (chemical mechanical polishing) slurry quality control through density and viscosity monitoring

Optimum process performance can be ensured by monitoring slurry health continuously. It helps to accommodate tighter purity and blend accuracy…

Vaccine production quality control with inline viscosity monitoring

Innovate vaccine production and release, to address the global shortage of almost all vaccines Increase production capacity and shorten cycle…

Continuous monitoring of frying oil degradation in industrial food fryers

Summary: a single sensor to monitor effects of oxidation (TOTOX), fatty acid (TBA), and Polar compounds (TPC) on frying oil…

Lubricants manufacturing process control & QC testing with inline viscosity measurements

Key ways in viscosity & density measurements and management play central role in lube oil manufacturing steps are the following:…

Optimizing liquid packaging, filling operations with inline viscosity management

Challenge Fluctuations in liquid products consistency in packaging, filling, dispensing operations means companies run risk of underfilling (which can be…

Using real-time viscosity measurements in refinery operations for greater efficiency, agility and profitability

Processes in refineries where viscosity & density measurements and management play central role in refinery operations are the following: Accurate…

Controlling the rheological behaviour of dairy food items to create consistent products – cheese, cream, ice-cream, milk, butter, yogurt

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure…

Online viscosity monitoring for quality control in emulsions formulation, testing and processing

Emulsions are used in almost every aspect of daily lives. Their processing and development expands across many industries – chemicals,…

Wastewater management in beverage and food processing with inline viscosity monitoring

Food and beverage industry is one of the key industrial segments and major contributor to global economic and societal growth…

Achieve high quality cosmetic products through real-time in-line viscosity control during manufacturing – improve consistency, texture and sensorial attributes

Viscosity testing of cosmetics and personal care products is extremely important for quality control in their production. Analyzing the viscosity…

High quality Swiss chocolates rely on in-line viscosity monitoring for consistent rheology & texture

The chocolate confectionery industry is a sector that is not restricted by age or nationality; therefore, the growth of this…

Sealants and adhesives viscosity & rheology in formulation, testing and application

Adhesives and sealants are used widely for joining , protecting and sealing systems in construction, manufacturing and maintenance. This industry…

Monitoring and controlling viscosity of ceramic slurries in investment casting

Investment castings are one of the most popular production methods for metal parts today. Investment casting process, also termed as…

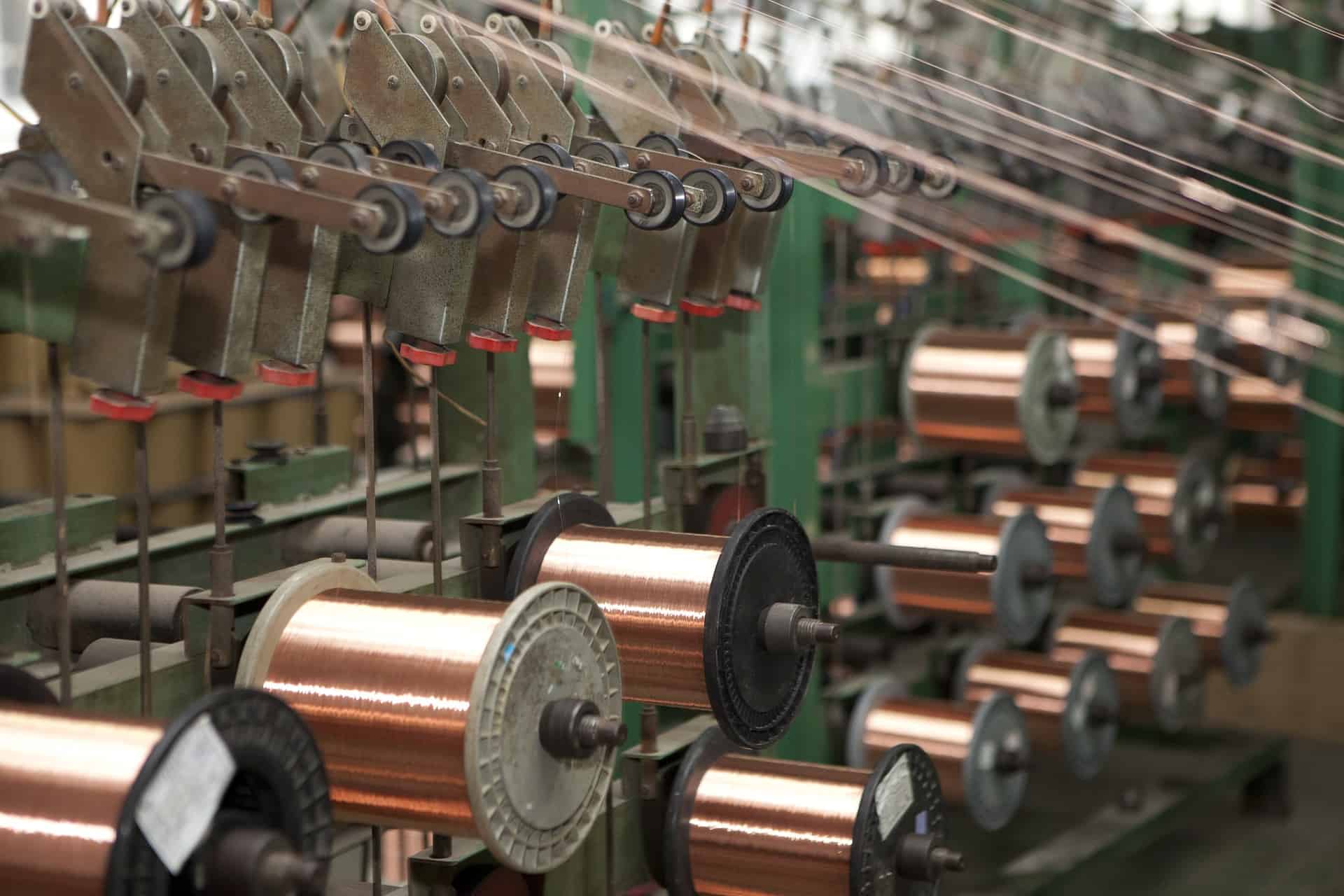

Monitoring and controlling viscosity of wire enamel in coating process

The global electrical insulation coatings market size in 2015 was USD 2 billion and is expected to grow significantly in…

Monitoring enteric coating for pharmaceutical products and livestock feed

An enteric (delayed-release) coating is a barrier applied to oral medication that controls the location in the digestive tract where…

Real-time rheology measurements of polymer melts

Polymers have gone from being cheap substitutes for natural products to providing high-quality options for a variety of industrial applications…

Inline viscosity measurements in polymerisation reactions

Polymer production is one of the most important areas of applied chemistry due to its significant number of applications industry…

Tablet coating process control

Film coating of solid oral dosage forms is a well-established process in the pharmaceutical industry. Most tablets dosage forms undergo…

Pharmaceutical printing process control

Product marking has come under increased scrutiny in the pharmaceutical industry due to pressure from three factors: regulations, aesthetics, and…

Mixing Process Management

Mixing is the fundamental step in the manufacture of many products. Even though it may not have strict precision requirements,…

Batter preparation and coating process control

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts,…

Optimizing flexographic, gravure and corrugated printing applications through inline viscosity monitoring and control

Printing presses have numerous applications – newspapers, magazines, catalogues, packaging and labels. The global printing industry is forecast to reach…

Monitoring concrete mixing process

Being one of the most versatile building materials, concrete is used in many forms of construction. Concrete is often used…

Mud Weight Monitoring

As a part of the industry’s drive for continuous cost-effectiveness, drilling fluid performance and management have come under closer scrutiny…

Real-time engine oil condition monitoring

One of the largest areas of innovation and R&D in the automobile industry is the engine oil condition monitoring. Rapid…

Automotive painting and coating quality control and optimization

Through all the advancement in automotive design and manufacturing over the years, there has been one constant – vehicle’s aesthetics…

Battery production – Slurry Mixing and Coating

Lithium batteries keep both essentials and comfort of modern life running with safety and reliability. They have a long list…