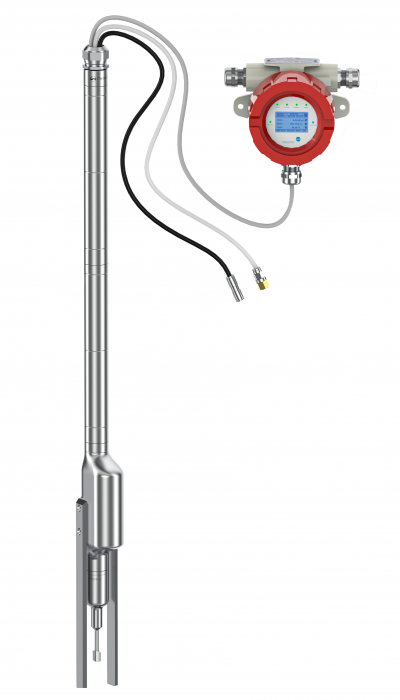

in-line, online, real-time viscosity & density meter for viscous, abrasive, sticky slurry

- Sensor probe with self-cleaning harmonics

- Eliminates need for removal and cleaning

- Continuous monitoring without concern for deposits

- Measures reliably in the most deposition prone slurries

- Major step towards Industry 4.0 compliance

- Eliminates manual plate-weight or efflux cup measurements

| Density Range (SRD only) | 0.0 - 4.0 g/cc 0.0 - 4000 kg/m3 0.0 - 33.38 lb/gal |

| Density Accuracy (SRD only) | 0.01 g/cc (0.001 g/cc & higher accuracy available) |

| Viscosity Range | 1 to 3,000 cP (SRD) 1 to 200,000cP (SRV) Wider range available |

| Viscosity Accuracy | 5% of reading (standard) 1% & higher accuracy available |

| Reproducibility | Better than 1% of reading |

| Temperature | -20 to 65 °C (-5 to 150 °F) |

| Material | Stainless Steel 316L |

| Sealing Material | Cleanwave - Sensor FKM (Fluoroelastomer, FPM, and Viton) |

| Total Length | Customizable |

| Installation Accessories | Mounting Base Installation Connection Adapters |

| Air Line Size | 6 mm |

| Air Line Pressure | 2-6 bar (30-90 psi) |

CleanWaveTM technology is integrated with Rheonics inline viscometer or Rheonics inline density meter and viscometer to create SlurrySense, a measurement probe that prevents deposits from forming using an inbuilt vibrator. The CleanWaveTM vibrations can be used continuously or intermittently to, respectively, prevent or slough off deposits. With the sensor probe cleanness maintained, the Rheonics inline viscometer or Rheonics inline density meter and viscometer can continuously provide reliable consistency readings without the need for operator cleaning interventions.

English Video Explanation:

Japanese Video Explanation:

Chinese Video Explanation:

| Title | Summary | Link | File Category | Products | Tags | Type | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|---|

| Article – Rheonics SlurrySense – INCAST 2025 | SlurrySense product article, presented in INCAST 2025 | Publications | SlurrySense | publications | ||||

| Presentation Deck – Rheonics SlurrySense – EICF 2025 | SlurrySense product deck describing operation and data examples, presented in EICF 2025 | Information and Training Decks | SlurrySense | training-deck | ||||

| Flyer – Rheonics SlurrySense Product Launch | Rheonics SlurrySense Product Launch Flyer | Datasheets & Brochures | SlurrySense | datasheets | ||||

| Flyer – Rheonics SlurrySense Technical Information | Rheonics SlurrySense Product Technical Flyer |

| Datasheets & Brochures | SlurrySense | datasheets | |||

| Drawing – Rheonics SlurrySense SRD | 2D drawing of Rheonics SlurrySense SRD and mounting adapter | Drawings | SlurrySense | drawings |

- All

- Printing and Coating

- Industrial Mixing and Grinding

- Food and Beverages

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Inline viscosity measurements in polymerisation reactions

Polymer production is one of the most important areas of applied chemistry due to its significant number of applications industry…

Tablet coating process control

Film coating of solid oral dosage forms is a well-established process in the pharmaceutical industry. Most tablets dosage forms undergo…

Pharmaceutical printing process control

Product marking has come under increased scrutiny in the pharmaceutical industry due to pressure from three factors: regulations, aesthetics, and…

Mixing Process Management

Mixing is the fundamental step in the manufacture of many products. Even though it may not have strict precision requirements,…

Batter preparation and coating process control

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts,…

Optimizing flexographic, gravure and corrugated printing applications through inline viscosity monitoring and control

Printing presses have numerous applications – newspapers, magazines, catalogues, packaging and labels. The global printing industry is forecast to reach…

Monitoring concrete mixing process

Being one of the most versatile building materials, concrete is used in many forms of construction. Concrete is often used…

Mud Weight Monitoring

As a part of the industry’s drive for continuous cost-effectiveness, drilling fluid performance and management have come under closer scrutiny…

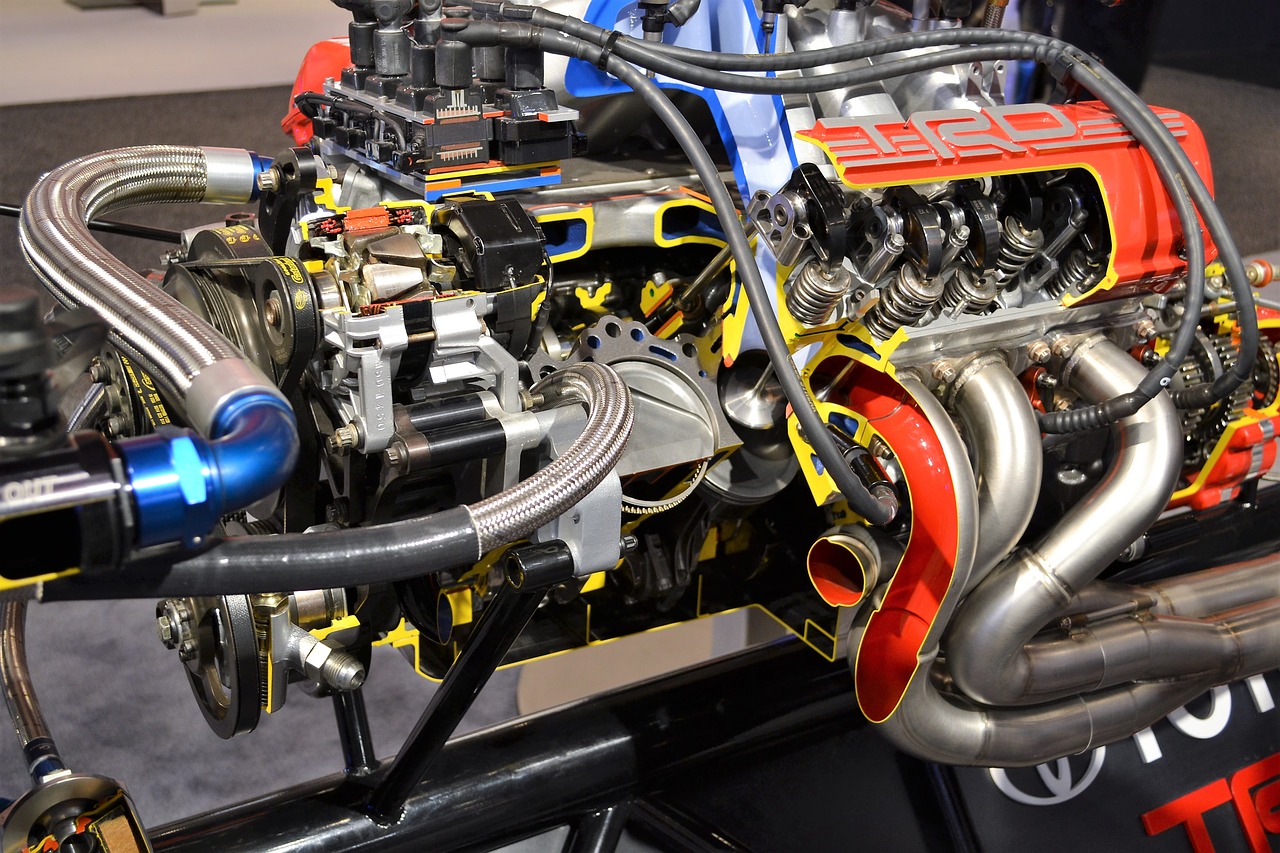

Real-time engine oil condition monitoring

One of the largest areas of innovation and R&D in the automobile industry is the engine oil condition monitoring. Rapid…

Automotive painting and coating quality control and optimization

Through all the advancement in automotive design and manufacturing over the years, there has been one constant – vehicle’s aesthetics…

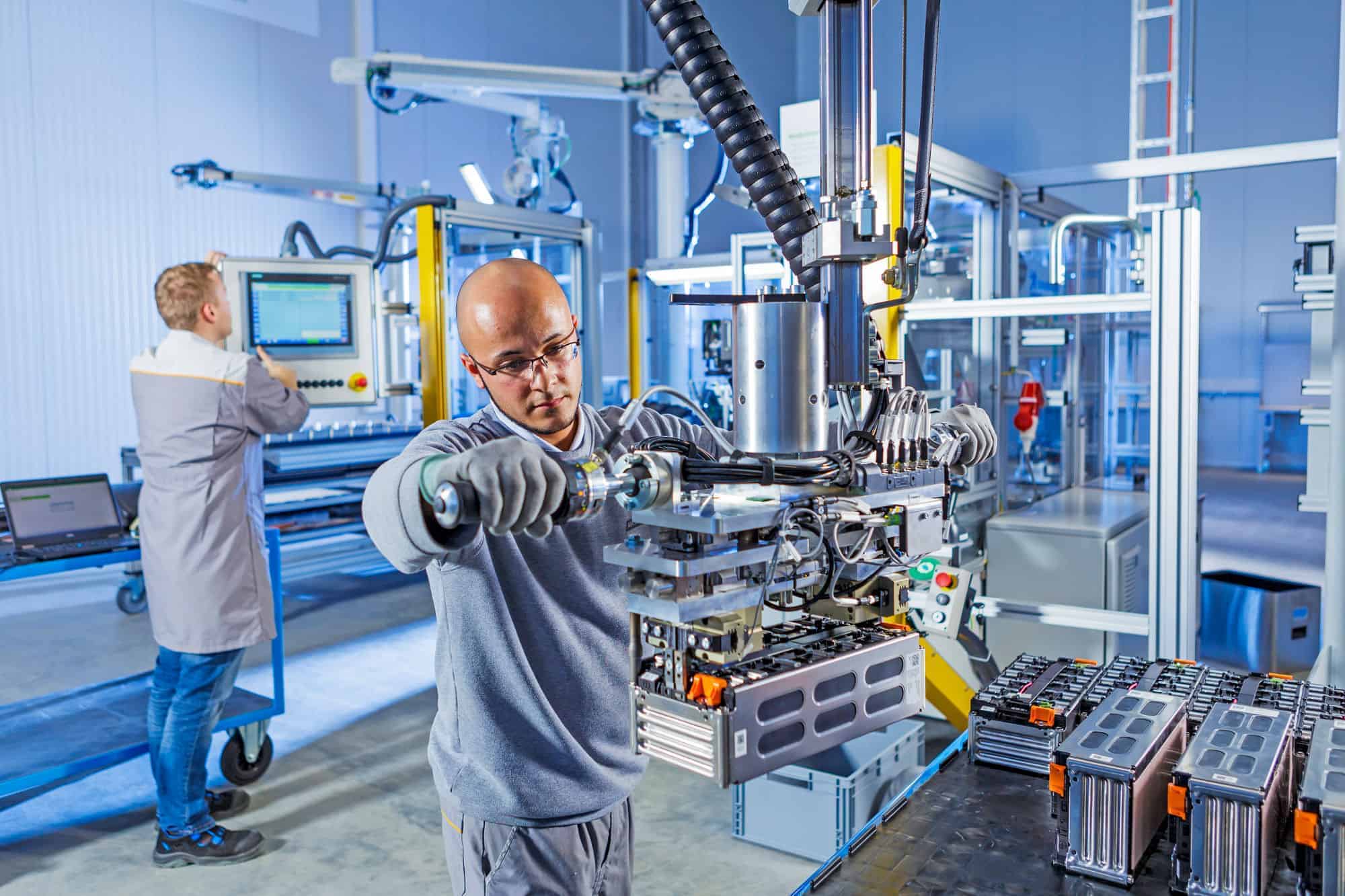

Battery production – Slurry Mixing and Coating

Lithium batteries keep both essentials and comfort of modern life running with safety and reliability. They have a long list…