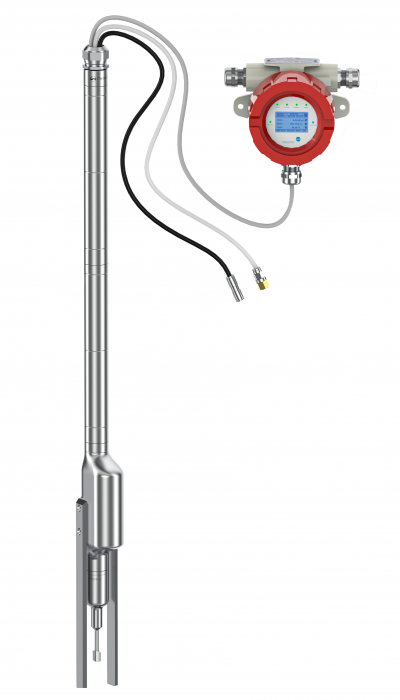

in-line, online, real-time viscosity & density meter for viscous, abrasive, sticky slurry

- Sensor probe with self-cleaning harmonics

- Eliminates need for removal and cleaning

- Continuous monitoring without concern for deposits

- Measures reliably in the most deposition prone slurries

- Major step towards Industry 4.0 compliance

- Eliminates manual plate-weight or efflux cup measurements

| Density Range (SRD only) | 0.0 - 4.0 g/cc 0.0 - 4000 kg/m3 0.0 - 33.38 lb/gal |

| Density Accuracy (SRD only) | 0.01 g/cc (0.001 g/cc & higher accuracy available) |

| Viscosity Range | 1 to 3,000 cP (SRD) 1 to 200,000cP (SRV) Wider range available |

| Viscosity Accuracy | 5% of reading (standard) 1% & higher accuracy available |

| Reproducibility | Better than 1% of reading |

| Temperature | -20 to 65 °C (-5 to 150 °F) |

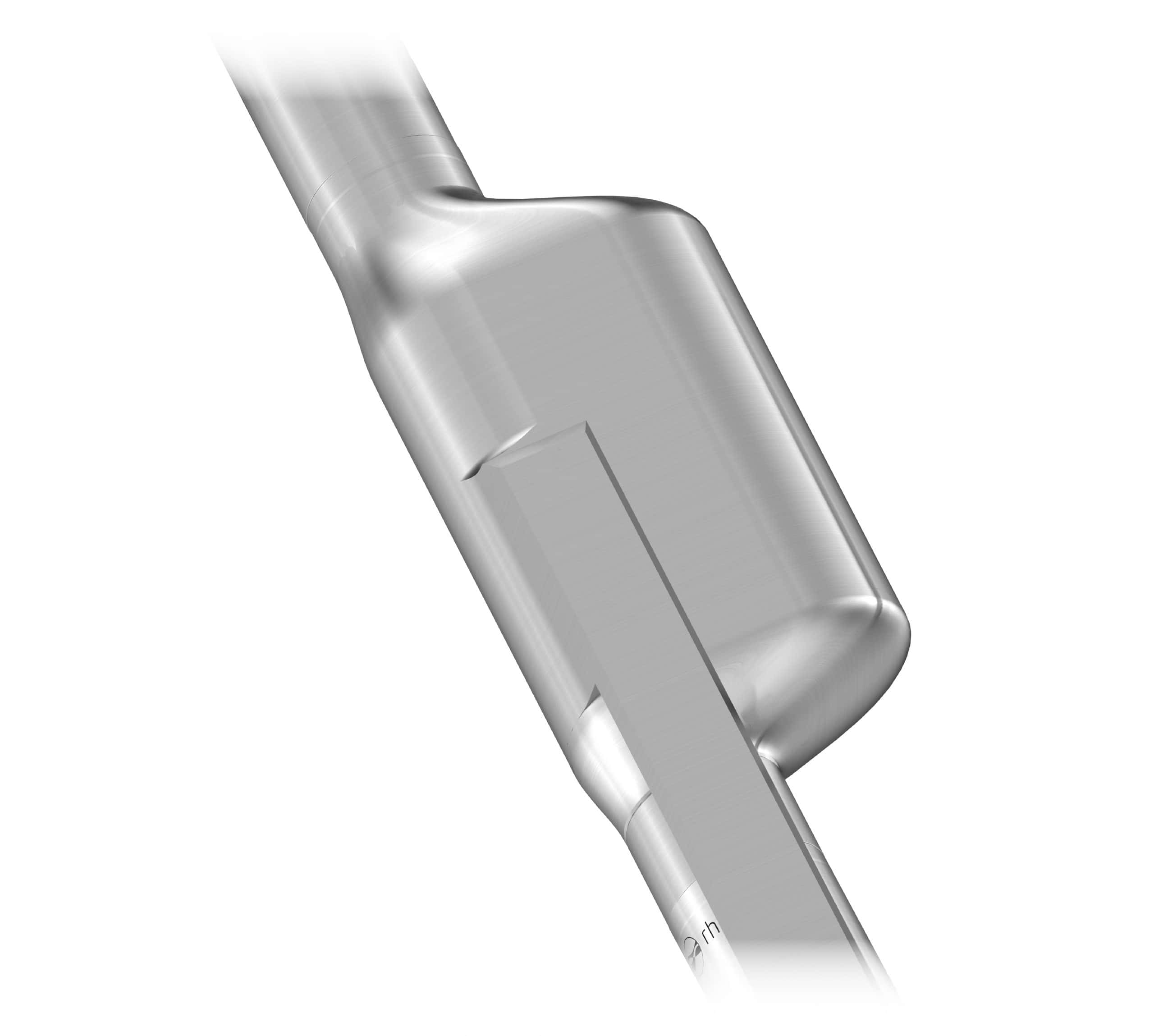

| Material | Stainless Steel 316L |

| Sealing Material | Cleanwave - Sensor FKM (Fluoroelastomer, FPM, and Viton) |

| Total Length | Customizable |

| Installation Accessories | Mounting Base Installation Connection Adapters |

| Air Line Size | 6 mm |

| Air Line Pressure | 2-6 bar (30-90 psi) |

CleanWaveTM technology is integrated with Rheonics inline viscometer or Rheonics inline density meter and viscometer to create SlurrySense, a measurement probe that prevents deposits from forming using an inbuilt vibrator. The CleanWaveTM vibrations can be used continuously or intermittently to, respectively, prevent or slough off deposits. With the sensor probe cleanness maintained, the Rheonics inline viscometer or Rheonics inline density meter and viscometer can continuously provide reliable consistency readings without the need for operator cleaning interventions.

English Video Explanation:

Japanese Video Explanation:

Chinese Video Explanation:

| Title | Summary | Link | File Category | Products | Tags | Type | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|---|

| Article – Rheonics SlurrySense – INCAST 2025 | SlurrySense product article, presented in INCAST 2025 | Publications | SlurrySense | publications | ||||

| Presentation Deck – Rheonics SlurrySense – EICF 2025 | SlurrySense product deck describing operation and data examples, presented in EICF 2025 | Information and Training Decks | SlurrySense | training-deck | ||||

| Flyer – Rheonics SlurrySense Product Launch | Rheonics SlurrySense Product Launch Flyer | Datasheets & Brochures | SlurrySense | datasheets | ||||

| Flyer – Rheonics SlurrySense Technical Information | Rheonics SlurrySense Product Technical Flyer |

| Datasheets & Brochures | SlurrySense | datasheets | |||

| Drawing – Rheonics SlurrySense SRD | 2D drawing of Rheonics SlurrySense SRD and mounting adapter | Drawings | SlurrySense | drawings |

- All

- Adhesive

- Cosmetics

- Printing and Coating

- Industrial Mixing and Grinding

- Food and Beverages

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Mining, minerals and metals

Optimizing liquid packaging, filling operations with inline viscosity management

Challenge Fluctuations in liquid products consistency in packaging, filling, dispensing operations means companies run risk of underfilling (which can be…

Using real-time viscosity measurements in refinery operations for greater efficiency, agility and profitability

Processes in refineries where viscosity & density measurements and management play central role in refinery operations are the following: Accurate…

Controlling the rheological behaviour of dairy food items to create consistent products – cheese, cream, ice-cream, milk, butter, yogurt

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure…

Online viscosity monitoring for quality control in emulsions formulation, testing and processing

Emulsions are used in almost every aspect of daily lives. Their processing and development expands across many industries – chemicals,…

Wastewater management in beverage and food processing with inline viscosity monitoring

Food and beverage industry is one of the key industrial segments and major contributor to global economic and societal growth…

Achieve high quality cosmetic products through real-time in-line viscosity control during manufacturing – improve consistency, texture and sensorial attributes

Viscosity testing of cosmetics and personal care products is extremely important for quality control in their production. Analyzing the viscosity…

High quality Swiss chocolates rely on in-line viscosity monitoring for consistent rheology & texture

The chocolate confectionery industry is a sector that is not restricted by age or nationality; therefore, the growth of this…

Sealants and adhesives viscosity & rheology in formulation, testing and application

Adhesives and sealants are used widely for joining , protecting and sealing systems in construction, manufacturing and maintenance. This industry…

Monitoring and controlling viscosity of ceramic slurries in investment casting

Investment castings are one of the most popular production methods for metal parts today. Investment casting process, also termed as…

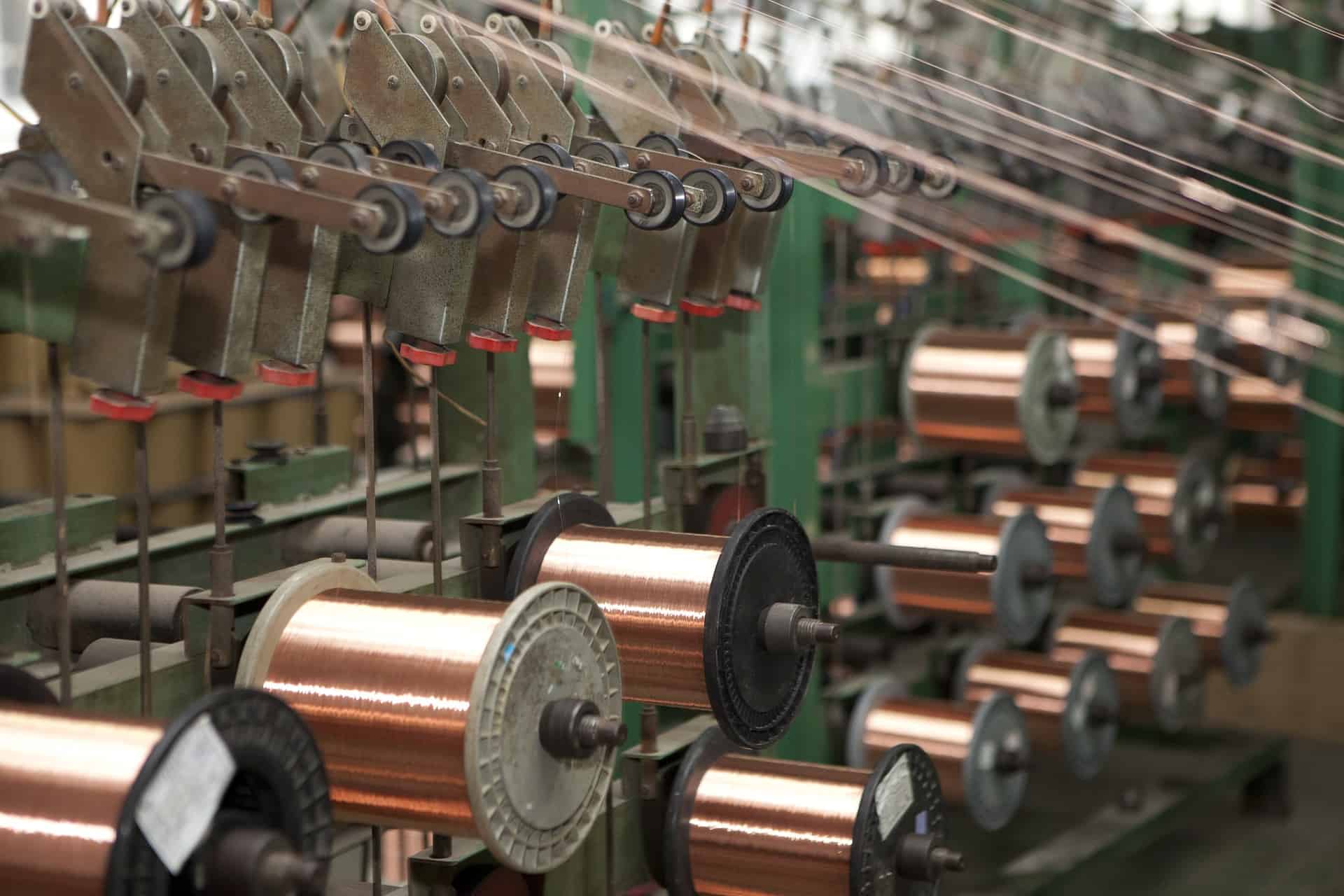

Monitoring and controlling viscosity of wire enamel in coating process

The global electrical insulation coatings market size in 2015 was USD 2 billion and is expected to grow significantly in…

Monitoring enteric coating for pharmaceutical products and livestock feed

An enteric (delayed-release) coating is a barrier applied to oral medication that controls the location in the digestive tract where…

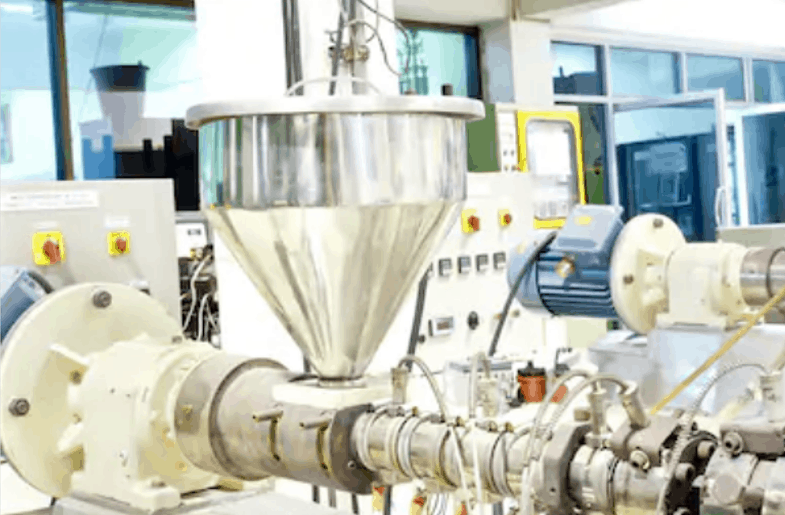

Real-time rheology measurements of polymer melts

Polymers have gone from being cheap substitutes for natural products to providing high-quality options for a variety of industrial applications…