| Viscosity Range | 0.2 to 300 cP lower than 0.2 available |

| Viscosity Accuracy | 0.1 cP below 1 cP 5% of reading (standard) |

| Density Range | 0 – 1.5 g/cc |

| Density Accuracy | 0.001 g/cc |

| Reproducibility | Better than 1% of reading |

| Temperature | Pt1000 (cIass AA) |

| Process Fluid Temperature | -40 up to 200 °C (400 °F) |

| Ambient Temperature | -40 up to 200 °C |

| Pressure Range | up to 30,000 psi (2000 bar) |

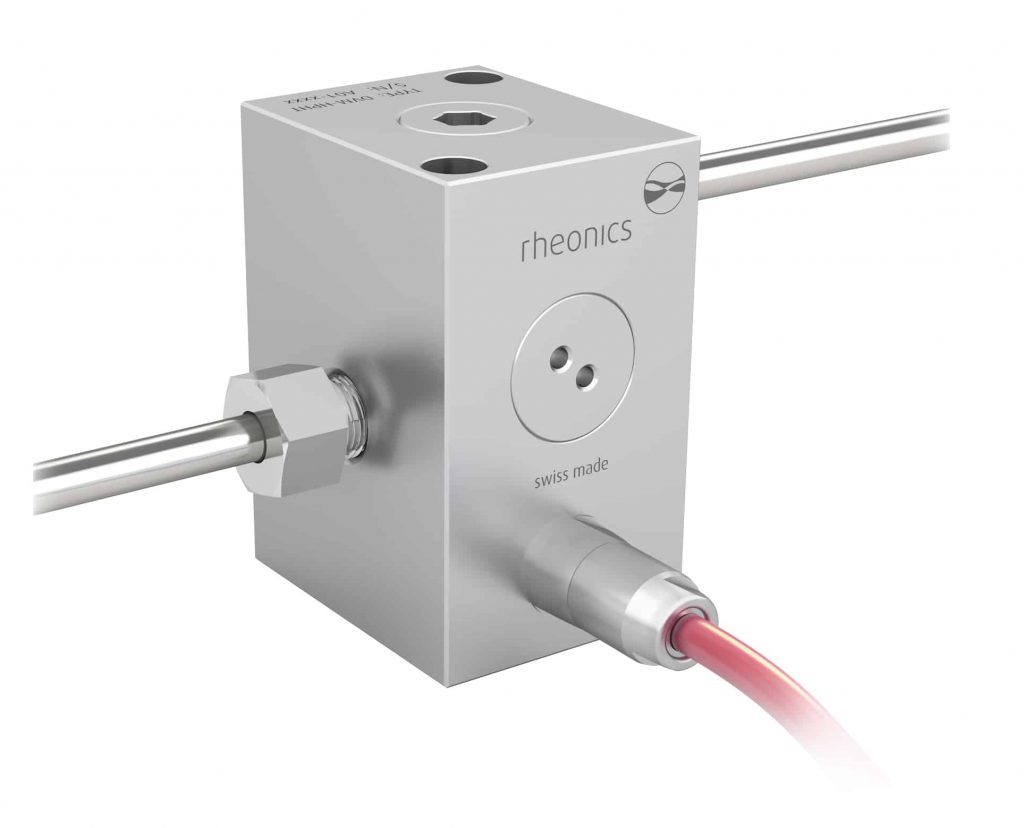

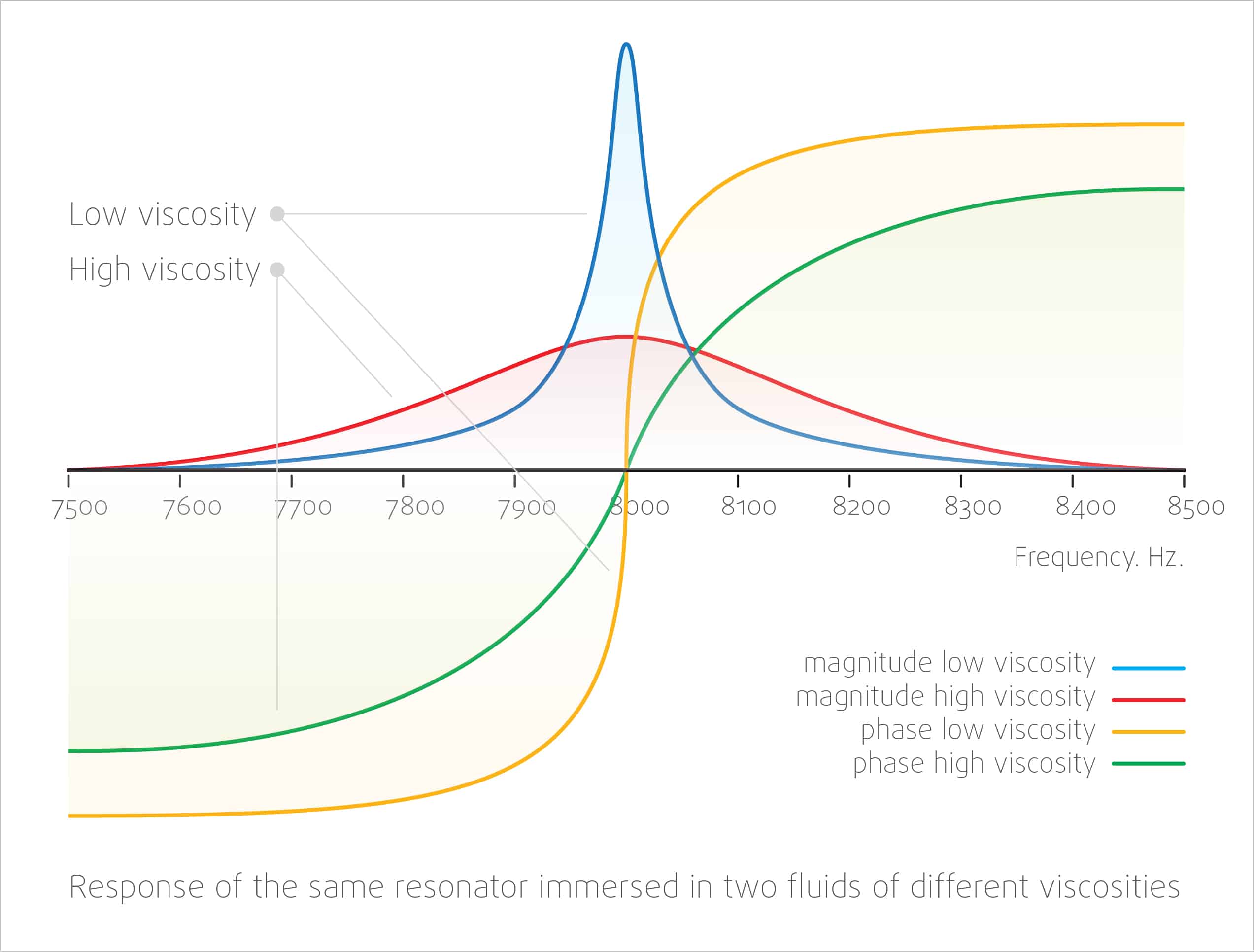

- The rheonics DVM measures viscosity and density by means of a torsional resonator, which is fully immersed in the fluid under test.

- The more viscous the fluid, the higher the mechanical damping of the resonator. By measuring the damping, the product of viscosity and density may be calculated by rheonics’ proprietary algorithms.

- The denser the fluid, the lower the resonant frequency. A denser fluid increases the mass loading of the resonator.

- The resonator is both excited and sensed by means of an electromagnetic transducer mounted in the sensor’s body.

- Damping is measured by the rheonics patented sensing and evaluation electronics and stable, high accuracy and repeatable readings are obtained based on rheonics’ proven gated phase-locked loop technology.

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. Ultra-fast and robust electronics, combined with comprehensive computational models, make SRVs one of the fastest and most accurate in the industry. SRV gives real time, accurate viscosity measurements every second and are not affected by flow variations!

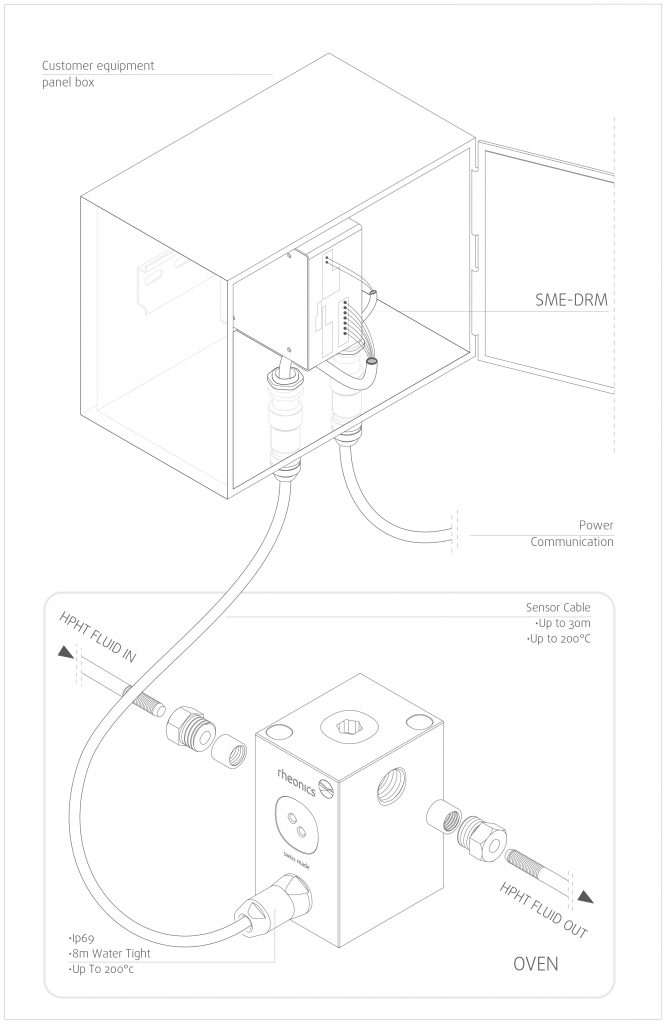

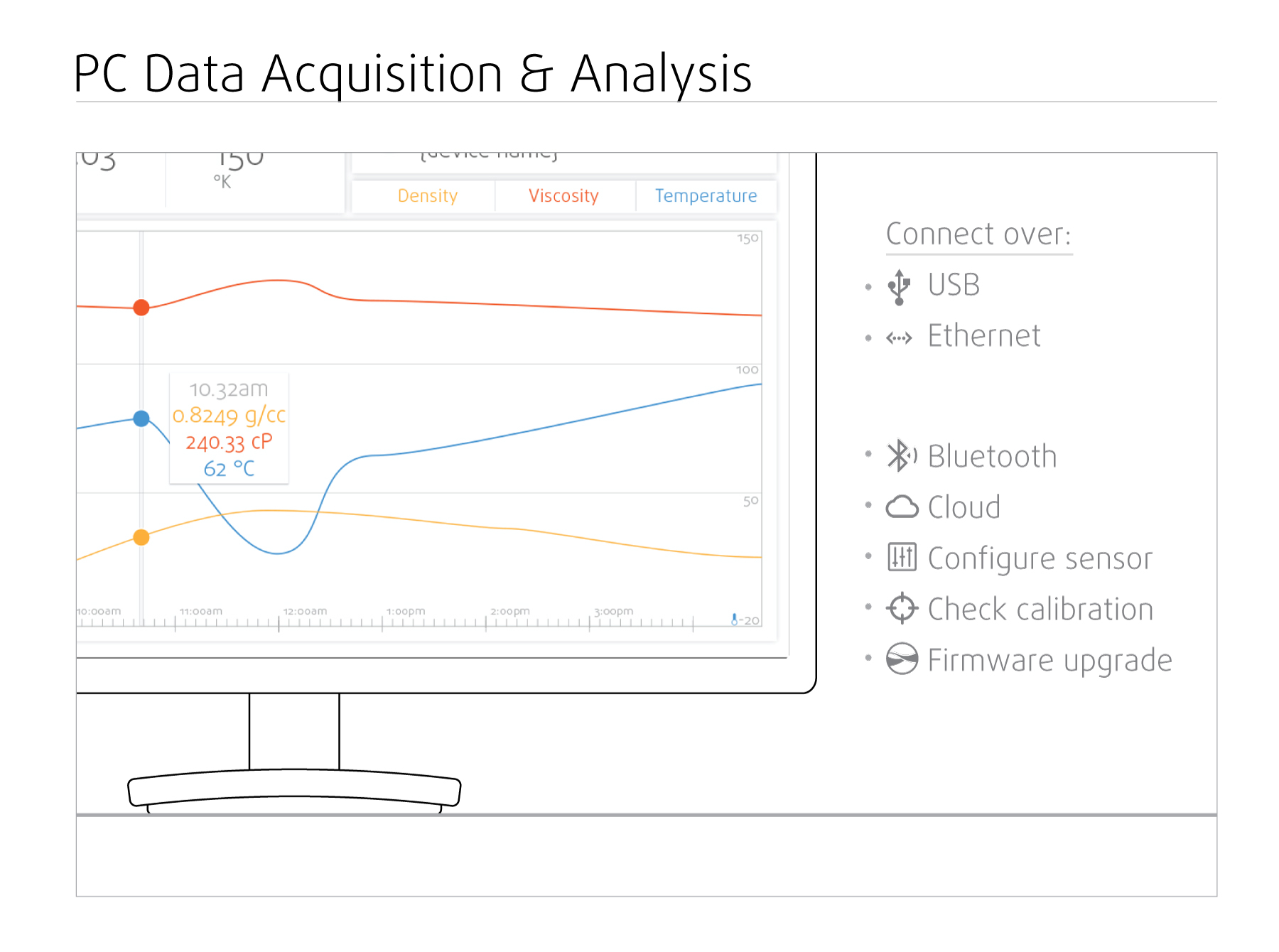

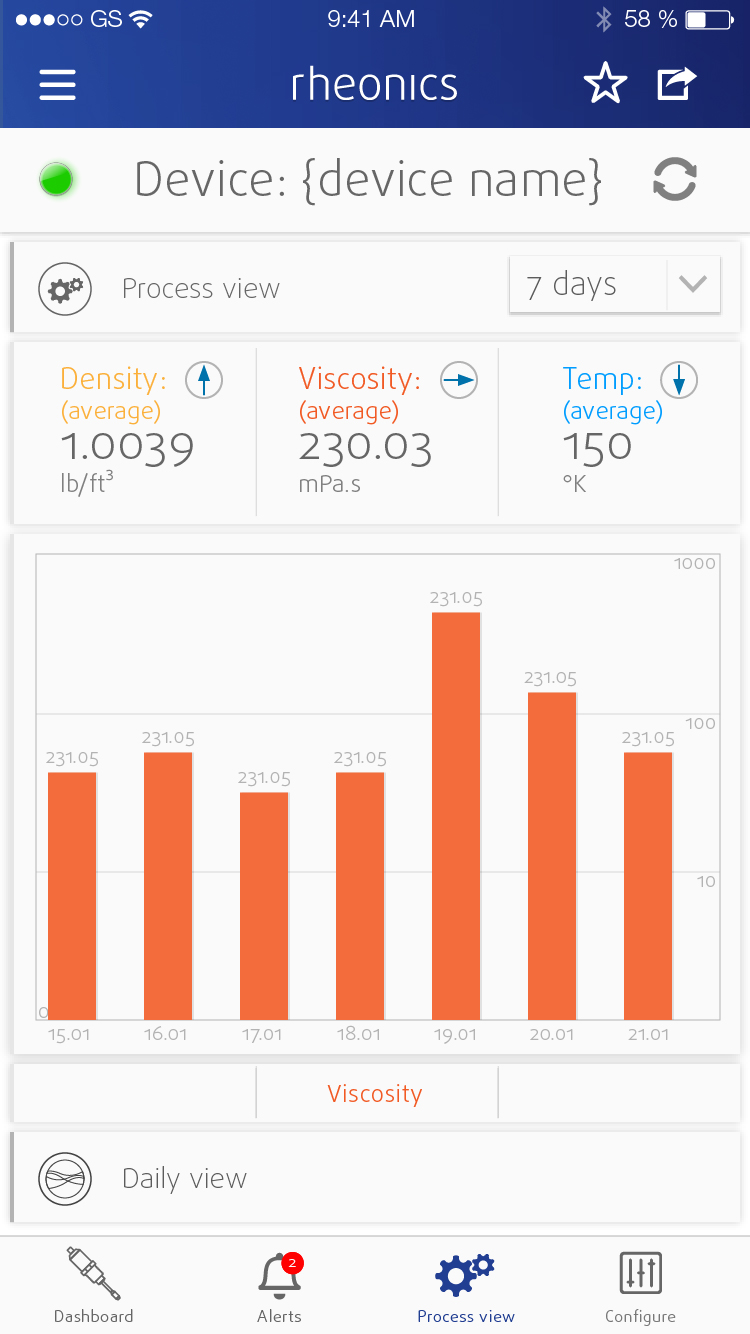

Communication

Acquire data in real-time. Transfer it to your computer or upload to the cloud

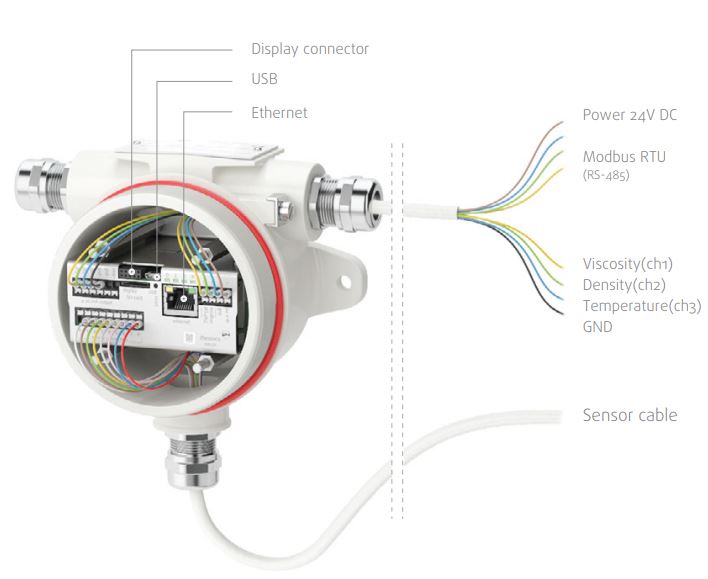

Standalone IP65 rated boxes to integrate into your system.

Standard PCB to integrate in your equipment panel box.

Next generation electronics in sensor head.

Ethernet, 4-20 mA, RS232 over USB.

CAN, Profinet, HART available for custom applications.

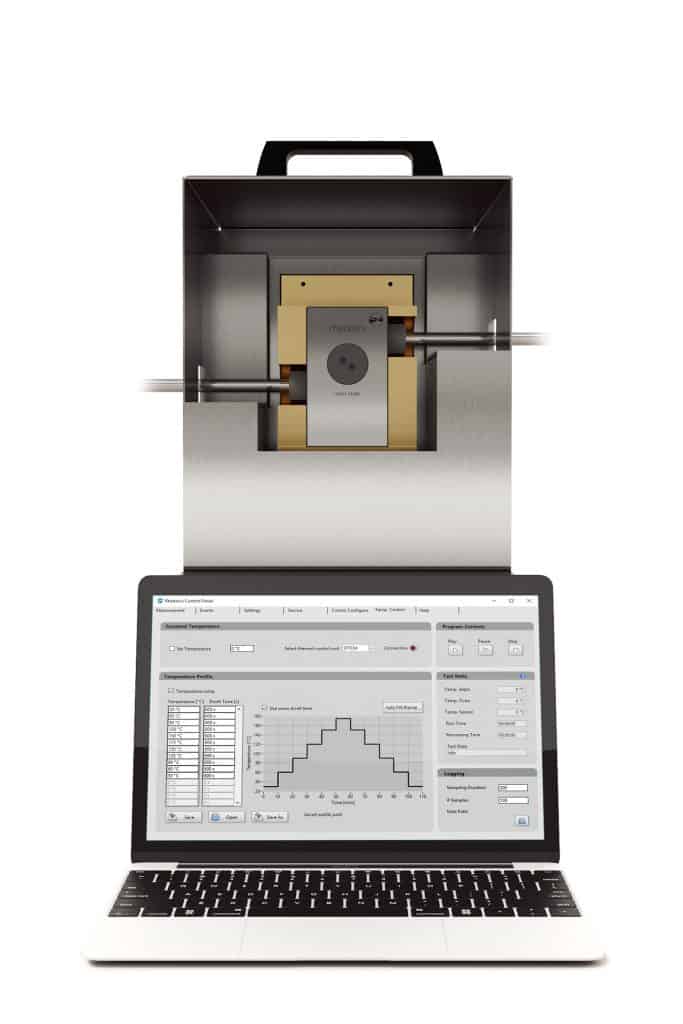

DTCM eliminates the need for bulky and expensive thermal test chambers (climate chambers) for temperature control. It reduces the foot print to the same size as a typical small coffee machine (Nespresso) while achieving 10x better stability and uniformity compared to a typical 100L commercial thermal chamber.

DVM Thermal Control Module

- DVM thermal chamber

- 10 °C to 180 °C

- 0.005 °C temperature stability

- 0.05 °C temperature accuracy

- Integrated temperature controller

- PC built-in for standalone operation

- Ethernet, Wi-fi, RS485 ports for direct integration

- 7.5kg (16.5 lb) with DVM

| Title | Description | Link | File Category | Products | Tags | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|

| DTCM-G2 Drawing | Drawing for DTCM G2: DVM Thermal Control Module | Drawings | DVM, DTCM | drawings | |||

| Drawing – SME-TR Electronics option: E2 | Drawing for SME-TR: Sensor electronics in Transmitter Housing | Drawings | Electronics, SRV, SRD, DVM, DVP | Technical Information | drawings | technical-information | |

| CAD Model- SME-TRD Electronics option: E1 | CAD Model (pdf, dxf, 3D step) for SME-TRD: Sensor electronics in Transmitter Housing with Display | CAD Models | Electronics, SRV, SRD, DVM, DVP | Technical Information | cad-models | technical-information | |

| Drawing – SME-TRD Electronics option: E1 | Drawing for SME-TRD: Sensor electronics in Transmitter Housing with Display | Drawings | DVP, Electronics, SRV, SRD, DVM | Technical Information | drawings | technical-information | |

| CAD Model – SME-TR Electronics option: E2 | CAD Model (pdf, dxf, 3D step) for SME-TR: Sensor electronics in Transmitter Housing | CAD Models | DVP, Electronics, SRV, SRD, DVM | Technical Information | cad-models | technical-information | |

| CAD Model – SME-DRM Electronics option: E3 | CAD Model (pdf, dxf, 3D step) for SME-DRM: DIN rail mount Sensor electronics | CAD Models | DVM, DVP, Electronics, SRV, SRD | Technical Information | cad-models | technical-information | |

| Drawing – SME-DRM Electronics option: E3 | Drawing for SME-DRM: DIN rail mount Sensor electronics | Drawings | DVM, DVP, Electronics, SRV, SRD | Technical Information | drawings | technical-information | |

| Drawing – DVM | 2D drawing of DVM | Drawings | DVM | Technical Information | drawings | technical-information | |

| Datasheet – DTCM | Information and specifications about DVM Thermal Control Module | Datasheets & Brochures | DTCM, DVM | Technical Information | datasheets | technical-information | |

| Declaration of Conformity – CE Declaration of Conformity as per EN 61326-1:2013, EN 61326-2-3:2013 & EN 50581:2012 | Declaration of Conformity for SME-TRD, SME-TR & SME-DRM as per directives – Electromagnetic compatibility (EMC) Directive 2014/30/EU & Restriction of Hazardous Substances in Electrical and Electronic Equipment (RoHS2) Directive 2011/65/EU | Certificates | SRV, SRD, DVM, DVP, Electronics | Technical Information | certificates | technical-information | |

| Conference Paper – A New Sensor for Viscosity and Fluid Density Measurement for Oil Well Drilling Applications | Viscosity and Fluid Density Measurement for Oil Well Drilling Applications, Published in Sensors and Measuring Systems 2014; 17. ITG/GMA Symposium | Publications | DVM | Technical Information, Application | publications | technical-information application | |

| Article – Laboratory for Mechanics and Experimental Dynamics, ETH Zurich | ETH Zurich, Laboratory for Mechanics and Experimental Dynamics – Article on Dynamic viscosity and density sensing featuring Rheonics (previously Viscoteers) | Publications | DVM, DVP, SRV, SRD | Technical Information | publications | technical-information | |

| Manual – DVM | DVM-HPHT Installation and Operating Instructions | Manuals | DVM | Training | manuals | training | |

| Product Portfolio – SRV, SRD, DVM, DVP | Overview of the Standard Products – Information on Specifications, Electronics, Communication, Mechanical, Dimensions, Software and installation. | Datasheets & Brochures | SRD, DVM, DVP, SRV | Marketing, Technical Information | datasheets | marketing technical-information | |

| Datasheet – DVM | Information on Specifications, Electronics, Communication, Mechanical, Dimensions, Software and installation. | Datasheets & Brochures | DVM | Technical Information | datasheets | technical-information |

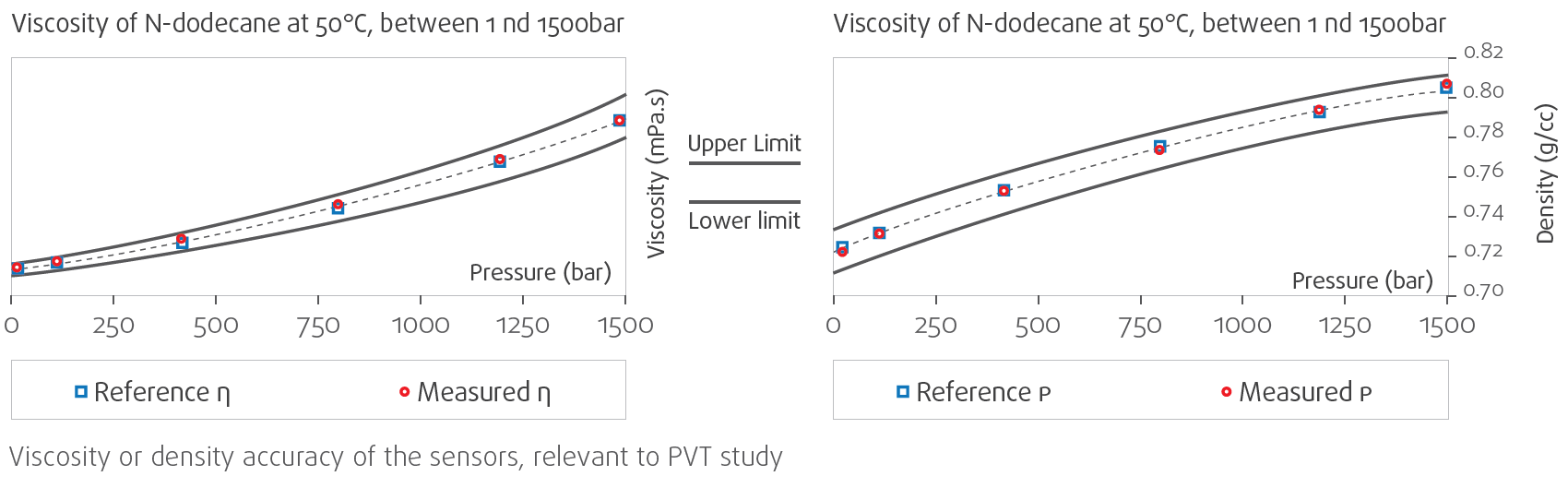

Density Viscosity for PVT studies

PVT analysis is performed to relate surface production to underground withdrawal for an oil reservoir and to simulate what takes…