Rheonics EHEDG certified inline viscosity and density sensors for food and pharmaceutical applications

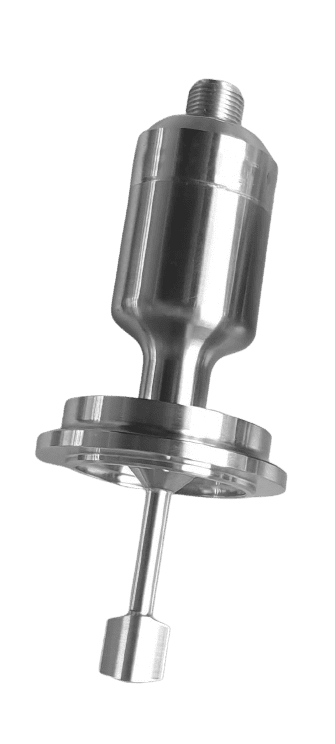

EHEDG certified inline viscosity and density sensors: SRV & SRD

The sensors available from Rheonics continuously offer real viscosity values for any beverage and ensure an excellent total cost of ownership. The SRV and SRD models are EHEDG-certified (EL Class I) and maintenance-free.

EHEDG certified (a) inline viscometer, (b) inline density meter and, (c) long insertion viscosity probes

Apart from process monitoring, the 3-seconds measuring interval allows a stable and reliable closed-loop control of carbonators. The SRV and SRD models employ a well-established and proven measurement technology with highest reliability and accuracy, while requiring minimum maintenance about once a year.

- Ideal for beverages that contain fruit pulp or fibers

- Accurate and reliable measurement technology

- The simple maintenance and long service intervals ensure very low downtime

- Developed in accordance with EHEDG guidelines

- A patented technology eliminates the possibility of inaccurate measurements, for example after hot cleaning (CIP).

- Any beverage can be measured independently of the product

Experts estimate the time spent cleaning in the food and beverage industry to be as much as 30 percent. Thus, it is also understandable why the manufacturers attach great importance to a cleaning-friendly design (hygienic design).

The SR sensors have been designed in compliance with EHEDG guidelines and its established measurement principle offers accurate results at any time. These sensors employ a patented technology that avoids the risks of inaccurate measurements, for example, after hot cleaning (CIP). The SR sensors are EHEDG-certified, thus reducing the time and effort needed for cleaning processes.

Key features

Zero Maintenance: Save Time and Money

The SRV & SRD sensors do not require any maintenance. They can be removed from the product line without cost-intensive and time-consuming production downtimes.

Product-Independent Measurement: Users can be Flexible with the Beverage Types

These sensors have the ability to handle any product type, even those that contain fruit pulp or fibers. The SRV & SRD’s EHEDG model avoids the need for time-consuming product-specific adjustments. The sensor makes product changes easier for users irrespective of whether it handles sparkling water, beer, carbonated soft drinks, or wine.

Easy Integration and Automation in the process

The sensors can be installed inline or in a bypass or tank, based on the needs of users. They can be combined easily into the workflow with the help of Rheonics Control Panel Software.

It is possible to adapt the sensors to support various communication options like EtherNet/IP, Analog, Modbus TCP, Modbus RTU, PROFIBUS, HART and PROFINET IO.

Applications of EHEDG Sensors

Wherever food, beverages, pharmaceutical products or even cosmetics are manufactured, processed or packaged, ‘hygiene’ or ‘wash-down’ sensors help machine builders to ensure equipment complies with strict plant hygiene standards.

Essentially, the food sector focuses on cleaning, whereas the pharmaceutical industry focuses on sterility. Although product contamination must be avoided in both cases, pharmaceutical products are subject to stricter regulations. Other industries, like cosmetics and biotechnology, place an extreme emphasis on consumer safety and protection. The goal of engineers is to reduce the risk of biological, physical and chemical contamination by improving cleaning ability.

Few examples of industrial manufacturing applications where EHEDG sensors are used are:

Amino Acids

Cheeses

Concentrated Milk

Enzymes

Fish extract

Flavors

Gelatins

Gels

Ice creams

Lotions

Meat extract

Oils

Pastes

Powder Milk

Sauces

Skincares

Starches

Yeasts

Flavors

Toothpastes

Hygienic design and construction for inline, probe-based viscometers and density meters

Even though each sensor variant must qualify for certification individually, the guiding principles for design remain the same. The following are the primary design and manufacturing criteria.

Choosing the Material of Construction

In hygienic applications, stainless steel SS316 grade is used primarily as the material of choice for probe-based sensors. The EHEDG specifies the following criteria for selecting materials:

- Chemically inert to application media, cleaning detergents, and disinfectants

- Corrosion-proof

- Toxic-free

- Non-tainting

- Mechanically stable

Process standardization in manufacturing

Though EHEDG does not require manufacturing processes to be qualified, standardization and qualification can help ensure sustainability.

Geometry Considerations

There may be curves, acute angles, and crevices in the surface geometry of inline sensors, which could result in the deposit of food particles. In the case of sensors with such surfaces, the product is evaluated from a hygienic perspective.

Importance of Surface finish

For the inline sensor surface in contact with the application media, EHEDG recommends a Surface Roughness Average of 0.8 micrometres.

Hygienic Pipe Fittings for inline sensors

Periodically, EHEDG releases its approved set of pipe fittings. It is beneficial to use standard pipe fittings since they are compatible with many types of inline sensors. Manufacturers of inline sensors sometimes provide EHEDG-approved pipe fittings specially designed for their product. Aside from the certified sensor itself, it is just as important to ensure hygienic integration into the process.

Industry requirement for hygienic design

The food and drug industries require high levels of hygiene. Using non-compliant equipment or a non-compliant cleaning process can put consumers’ health at risk. It is the primary goal of hygienic design to ensure sanitation processes are valid.

The European Hygienic Engineering and Design Group (EHEDG) is an association of equipment suppliers for food production, food processing companies, research institutes and public health facilities. EHEDG (European Hygienic Equipment Design Group) supports hygiene measures in food production and packaging since 1989 and is a foundation of food-related organizations. In all areas of food production, EHEDG contributes to hygienic engineering and design to ensure safe food production. The EHEDG certifies hygienic components that meet both theoretical and practical requirements. Europe is the main region with an EHEDG certificate.

Source: EHEDG

In 2000, the guidelines were supplemented by a certification scheme for closed-process components. As the scheme has evolved, the focus of the guidelines has shifted from a component perspective to being holistic, focusing on production plants, process lines, cleaning procedures, and sound process execution.

The new guidelines focus on the holistic approach in processes, including factory design, process line design, utility systems, process management, and validation of the hygienic status of final installations.

EHEDG was initially developed for food processing, but many of its principles are applicable to a broader audience, like when sterile production is the focus, like in the pharmaceutical industry. A hygienic design is intended to make production equipment easier to clean, but also limit the risk of biofilm build-up, which is equivalent to allergen retention. Physical and biological/chemical processes of retaining biological and organic materials may differ, but the process design requirements are very similar.

What is hygienic design for food processing equipment?

In hygienic design, all components of food processing machinery are built to facilitate cleaning and to reduce contamination risks with biological, chemical or physical agents.

A few examples of hygienic design for food processing machinery include:

- Sealing off dead spaces, such as crevices and gaps

- Ensuring all areas in contact with food can be cleaned

- Eliminating the accumulation of condensation

- Using materials that are easily cleaned without abrasion

- By removing components that could loosen, break off, and fall into food

- The installation of a drying or draining mechanism for equipment sanitized with wet cleaning

Benefits of hygienic design in production processes

Safety, Quality, Compliance

When producing products for human consumption, product safety is non-negotiable. However, the benefits of hygienic design extend beyond ensuring end-user safety. A hygienic design process improves product quality, reduces environmental impact, and improves productivity by reducing maintenance costs. Hygienic design specifications encompass an important aspect of product safety that, when not handled properly during planning, design, installation, and commissioning, may hamper the ability of the process plant to provide high-quality products.

Optimizing cleaning costs

A hygienic design approach improves productivity, as well as reducing contamination risks and helping food processors and manufacturers meet food safety standards.

Cleaning a food processing or manufacturing facility is one of the most time- and resource-consuming aspects of the process. It is reported that half of food industry businesses spend at least 10% of their annual turnover on cleaning.

Hygienic design of food processing equipment makes cleaning processes faster and reduces the amount of time and money businesses spend sanitizing machinery.

Why hygienic design matters for an inline sensor?

Prevention of ingress, build-up of application media and bacterial growth

Probe-based sensors are directly in contact with application media. There will always be some build-up, even with free-flowing liquids. If the viscosity sensor is not specifically designed, application media particles can accumulate on its surface and crevices.

If left unclean, these pockets of particles can serve as breeding grounds for bacteria. For example, in a dairy plant, this could cause the entire batch of raw milk to curdle. This is particularly important in pharmaceutical plants.

Independent of the principle of measurement, mounting arrangements may come into contact with the measurement media. Between threads or joints, crevices create an ideal environment for bacteria to grow.

Prevention of foreign particulate contamination

Hygienic equipment and factories shall be designed to prevent wear and breakage of parts to avoid foreign particulates entering food. It includes provisions to prevent ingress of foreign particulates, and the ability to detect and remove them.

Prevention of chemical contamination

Sensors should be designed to prevent any contamination from cleaning chemicals, lubricants, signal transfer liquids, thermal heating and cooling fluids.

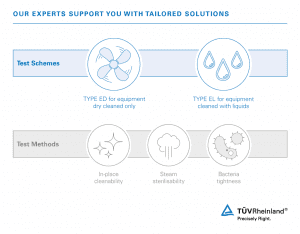

EHEDG Certification Types and Classes

There are two main EHEDG certifications: Wet processing (EL) and dry processing (ED). Sub-notation is used in both classes for labelling equipment, which can be cleaned in-place Class I, and equipment that needs to be dismantled for cleaning Class II.

ED (dry processing) has only two options, whereas EL (wet processing) includes both Aseptic and AUX certifications. There are four main categories of certification:

- EL Class I and II

- EL Class I and II Aseptic

- EL Class I AUX

- ED Class I and II

Experts estimate the time spent cleaning in the food and beverage industry to be as much as 30 percent. Thus, it is also understandable why the manufacturers attach great importance to a cleaning-friendly design (hygienic design).

EHEDG Test Schemes and Methods | Source: TUV Rheinland

Fusion of speed and excellence: Repeatable and reliable data and ideal for closed-loop control

The sensors feature a measuring interval of only a few seconds, thus known to be the fastest commercially available viscosity/density sensors, which are also ideal for closed-loop control.

These sensors enable users to always find the actual viscosity, density and concentration of all beverages in their process, ensuring the highest repeatability and accuracy even under start/stop conditions. They offer accurate measurements even during long flow stops, directly in the production line.

Food and Pharma Industries benefit from hygienic design

The levels of cleanliness vary, and in the food industry, equipment must be cleanable and chemical disinfection must be effective. In contrast, in pharmaceutical production steam sterilization follows cleaning. Steam sterilization has traditionally led to less focus on equipment design, and hygienic design has become more sophisticated and applied in the food processes, where improving the quality of the cleaning step is critical to product safety.

By reducing the time and resources spent cleaning, hygienic design boosts businesses’ profitability in addition to improving the quality and safety of their products. Additionally, since both legal regulations and third-party certification programmes evaluate hygienic design, businesses in the food industry can facilitate their approvals and certifications by ensuring compliance with hygienic design guidelines throughout all their processes.

Batter mixing and coating: Using lab rotational viscosity measurement for real-time process control with an inline viscometer

Customer application of the Rheonics SRV sensor to measure batter viscosity in a batter mixing…

Mayonnaise Production and Rheonics Inline Viscosity Monitoring

Mayonnaise, a globally enjoyed condiment, is a classic oil-in-water emulsion, distinct from water-in-oil emulsions like…

Milk of Lime (MOL Slurry) – Real-time monitoring and controlling optimum concentration

For process engineers, it's essential to develop an efficient and reliable method to monitor and…

Mixing Process Management

Mixing is the fundamental step in the manufacture of many products. Even though it may…

Online viscosity monitoring for quality control in emulsions formulation, testing and processing

Emulsions are used in almost every aspect of daily lives. Their processing and development expands…

Vaccine production quality control with inline viscosity monitoring

Innovate vaccine production and release, to address the global shortage of almost all vaccines Increase…

Optimizing liquid packaging, filling operations with inline viscosity management

Challenge Fluctuations in liquid products consistency in packaging, filling, dispensing operations means companies run risk…

Viscosity Management in Medical Device Coatings: Enhancing Performance and Compliance

Viscosity and density play a crucial role in medical device coatings, directly impacting product cohesion,…

Rheonics viscosity and density sensors are CIP compatible and adds advanced ‘intelligence’ to CIP systems

Viscosity is a property that is affected at the molecular level and has tremendous amount of information about the process fluid but has been hard to quantify reliably with existing instruments.

Primary benefits with Rheonics Viscosity and Density Sensors with respect to the Clean In Place System requirements:

- Rheonics sensors are CIP ready and comply with hygienic design requirements of processing equipment

- Monitor, optimize the CIP process and detect cleaning end points

- Easy installation and no reconfigurations/recalibrations needed – zero maintenance/down-times

Why is it important to optimize the CIP Processes in Food and Beverage Operations and detect the cleaning end point?

- To reduce cleaning time

- To reduce job changeover time

- To better manage materials and chemicals that must be then recycled/disposed/recovered with reduced wastage

- To reduce energy and water usage

Modern CIP systems, equipped with Rheonics sensors and automation software enable a simple drill down into all aspect of the process. This traceability of the system offers a number of benefits:

- Operators can check each CIP operation to verify whether it has worked correctly – real-time monitoring of the initial, intermediate and final state of the line

- Diagnostics are simple to perform and deliver detailed information on each element of the cleaning cycle

- Faults and issues can quickly be highlighted and rectified

- Plant managers can generate detailed operational reports

- Food security reporting to regulators is easy to assemble and more comprehensive

Continuous research and close cooperation with customers give us both deeper and broader knowledge about food safety issues, ranging all the way from food processing, through filling and packaging. We enable our customers to benefit from this knowledge and experience through validated production solutions.

What is CIP? Optimizing CIP (Clean In Place) Systems with inline viscosity & density measurements

What is CIP? In CIP systems, cleaning takes place without dismantling the system. CIP refers to all those mechanical and chemical systems that are necessary to prepare equipment for food processing, either after a processing run that has produced normal…

| Title | Description | Link | File Category | Products | document_categories_hfilter |

|---|---|---|---|---|---|

| Drawings – SRD – EHEDG | SRD – EHEDG (European Hygienic Engineering and Design Group) certified variants | Drawings | SRD | drawings | |

| Drawings – SRV – EHEDG | SRV – EHEDG (European Hygienic Engineering and Design Group) certified variants | Drawings | SRV | drawings |

Rheonics density meters and viscosity meters are available as probes and flow-through systems for installation in tanks, process lines and reactors. All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.