Inline process density and viscosity monitoring and control

Rheonics density meters and viscometers bring fluid intelligence and process control to broad range of customer applications.

SOLUTIONS

Precision built in Switzerland, each Rheonics online fluid density meter and viscometer is designed to match your application needs. Whether you need to measure density and viscosity downhole at 30,000 psi and 200 °C or to control the ink color density in your printing press, we have a solution for you.

Turnkey integrated solutions for your applications.

Lithium batteries keep both essentials and comfort of modern life running with safety and reliability. They have a long list…

Batters mixes are widely used as a coating for deep-fried foods and in many other products including cakes, waffles, doughnuts,…

Processes in refineries where viscosity & density measurements and management play central role in refinery operations are the following: Accurate…

Key advantages of viscosity management in mixing applications: Accurate and efficient mixing operations – significant savings in material costs and…

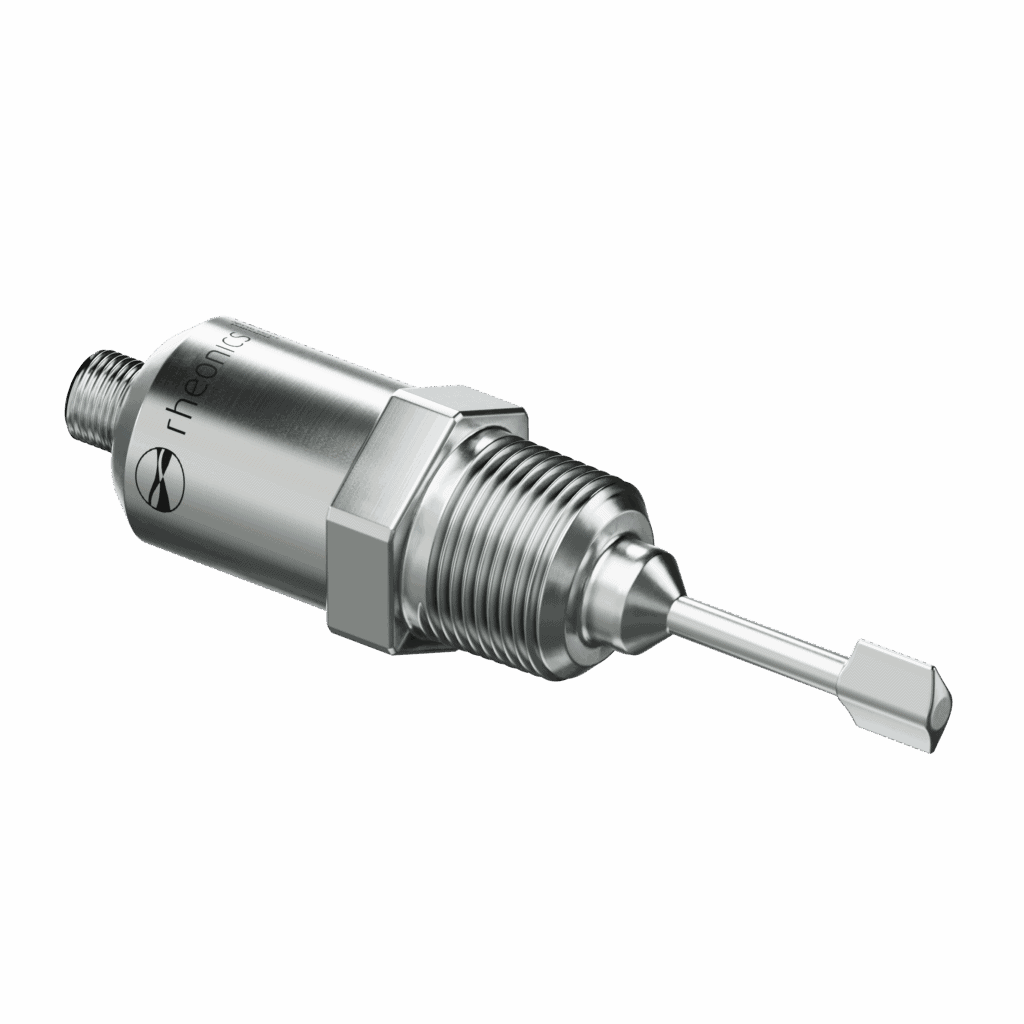

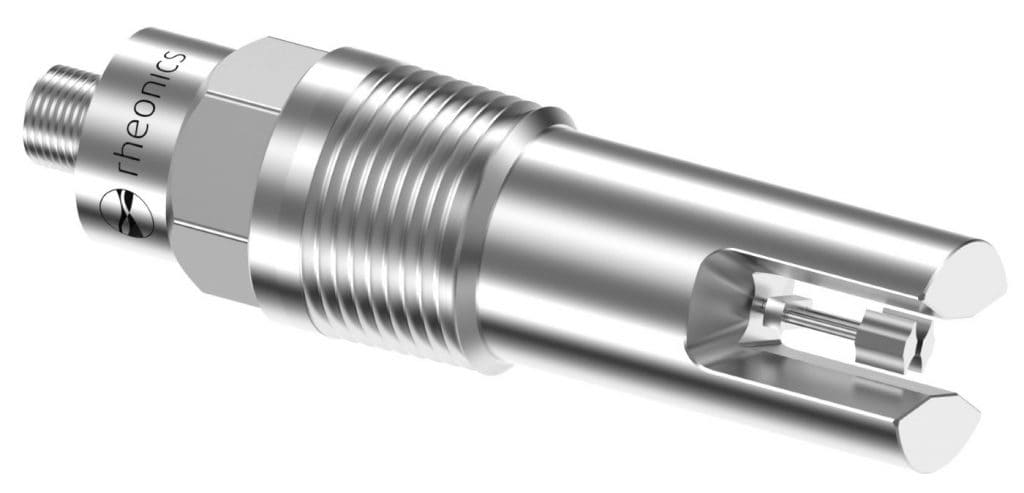

PRODUCT PORTFOLIO

Rheonics density meters and viscometers are available as probes and flow-through systems for installation in tanks, process lines and reactors.

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

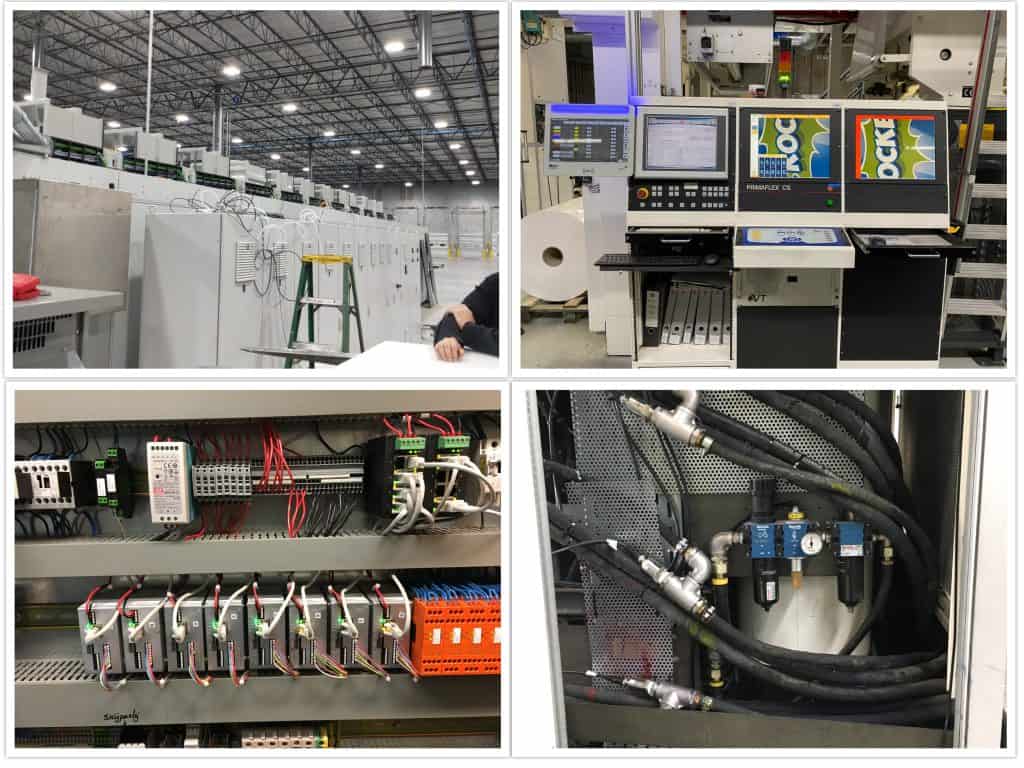

RPS InkSight - Multi-station ink viscosity control system

Winners of the 2021 FTA Technical Innovation Awards

RPS InkSight is a highly accurate Multi station ink viscosity control system. It delivers color excellence through tight viscosity control. For over 20 years, the FTA Technical Innovation Award has recognized the most innovative and impactful technologies for the ever-evolving package printing and converting industry. The recipients of the Technical Innovation Award are deemed by a panel of industry experts to have the potential to change flexography’s future for the better.

InkSight fundamentally changes the nature of the flexo printing process, from initial job setup all the way to jobs that, once delivered, secure a clear path to repeat business… It can produce a change in the very culture of the flexo industry by adding job-length consistency, accuracy and efficiency.

SEAMLESS INTEGRATION

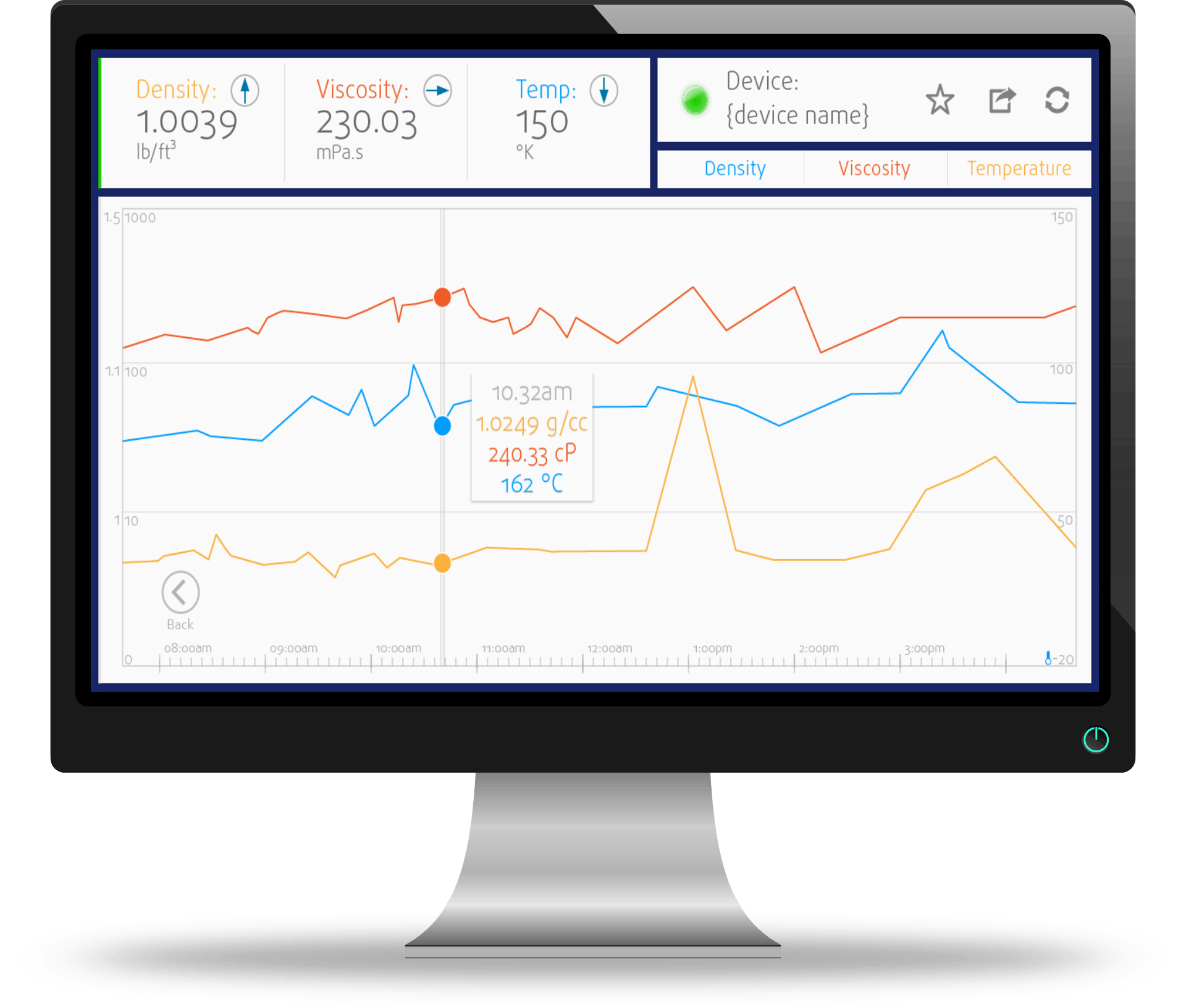

Measure, Monitor, Control, Optimize - Density, Viscosity & Temperature

Configure to your application

Each Rheonics online fluid densitometer and viscometer is designed to match your application needs. Whether you need to control the ink color density in your printing press or need to monitor slurry mixing for battery manufacturing we have a customized solution for your application.

ACQUIRE → ANALYSE → OPTIMIZE → MONETIZE

Data-driven process optimization

Process optimization begins with smart analysis of high-quality data. Our sensors supply the data. But that’s just the beginning. We’ll work with you to collect, analyze, process and even store the data you need to put you in control of your process.

In addition, use Rheonics designed solutions to automate process control with built in AI level 5 autonomous control and decision making.

Multi-platform data acquisition and analysis

- Tried & tested integration with PLC and IPC from all vendors: Siemens, B&R, ABB, Rockwell, Delta V, Beckhoff, Schneider, Emerson

- Measurement data acquisition on mobile devices, PC and through Cloud

- Access data and configure device through handheld mobile devices

- Bluetooth LTE4.0, Wireless Wi-fi and Ethernet LAN connectivity

- Cloud connectivity API for Amazon AWS, Microsoft Azure, Google Cloud

- Application for Windows 10, Linux, Android, iOS

DIVERSIFIED MARKETS :: CORE BRAND CUSTOMERS

Enabling process intelligence for your applications

Our sensors enable process monitoring & optimization across multiple industries – whether your application needs downhole, harsh environment density & viscosity monitoring or robust control of non-Newtonian fluids in your manufacturing processes – we have a product that fits your needs.

Transforming industries sustainably with fluid-sensing technology

Our purpose-driven approach helps us advance environmental and social priorities across the world’s most essential industries.