- All

- Adhesive

- Printing and Coating

- Industrial Mixing and Grinding

- Food and Beverages

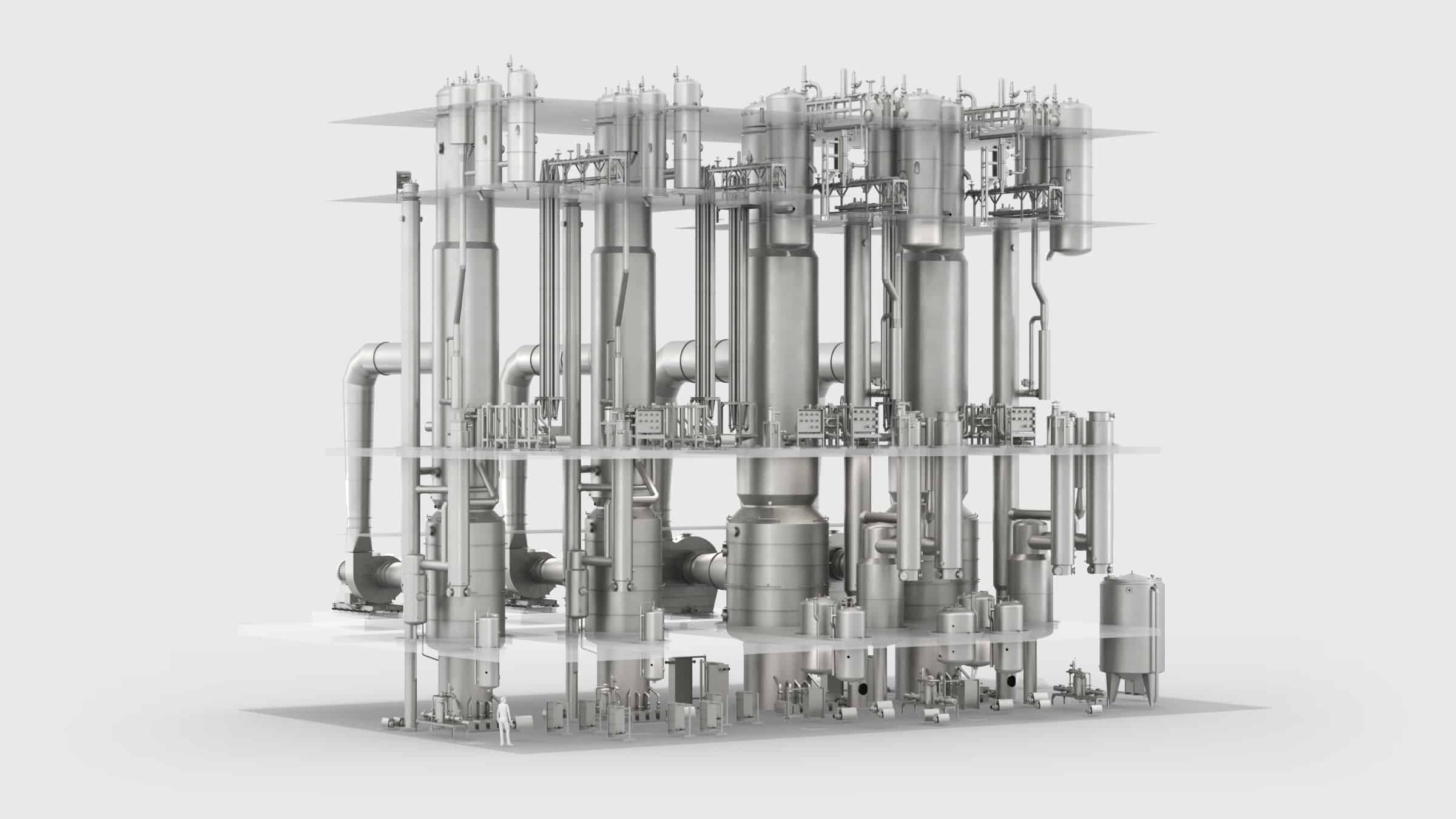

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Automating and optimizing mining operations with Rheonics Sensors and Solutions

The mining industry has always been known for its complexity and hard environments. From ore extraction to final product recovery,…

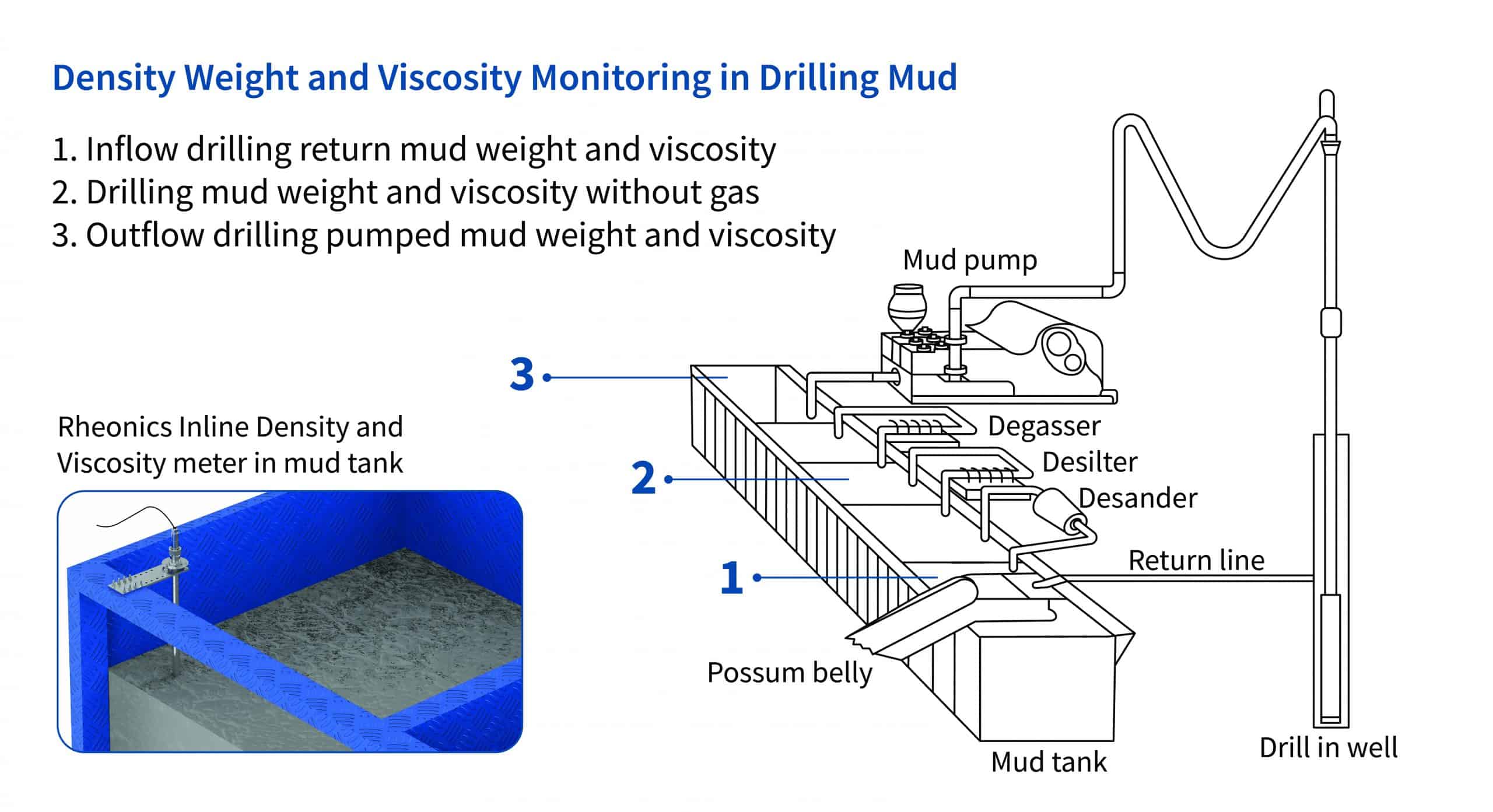

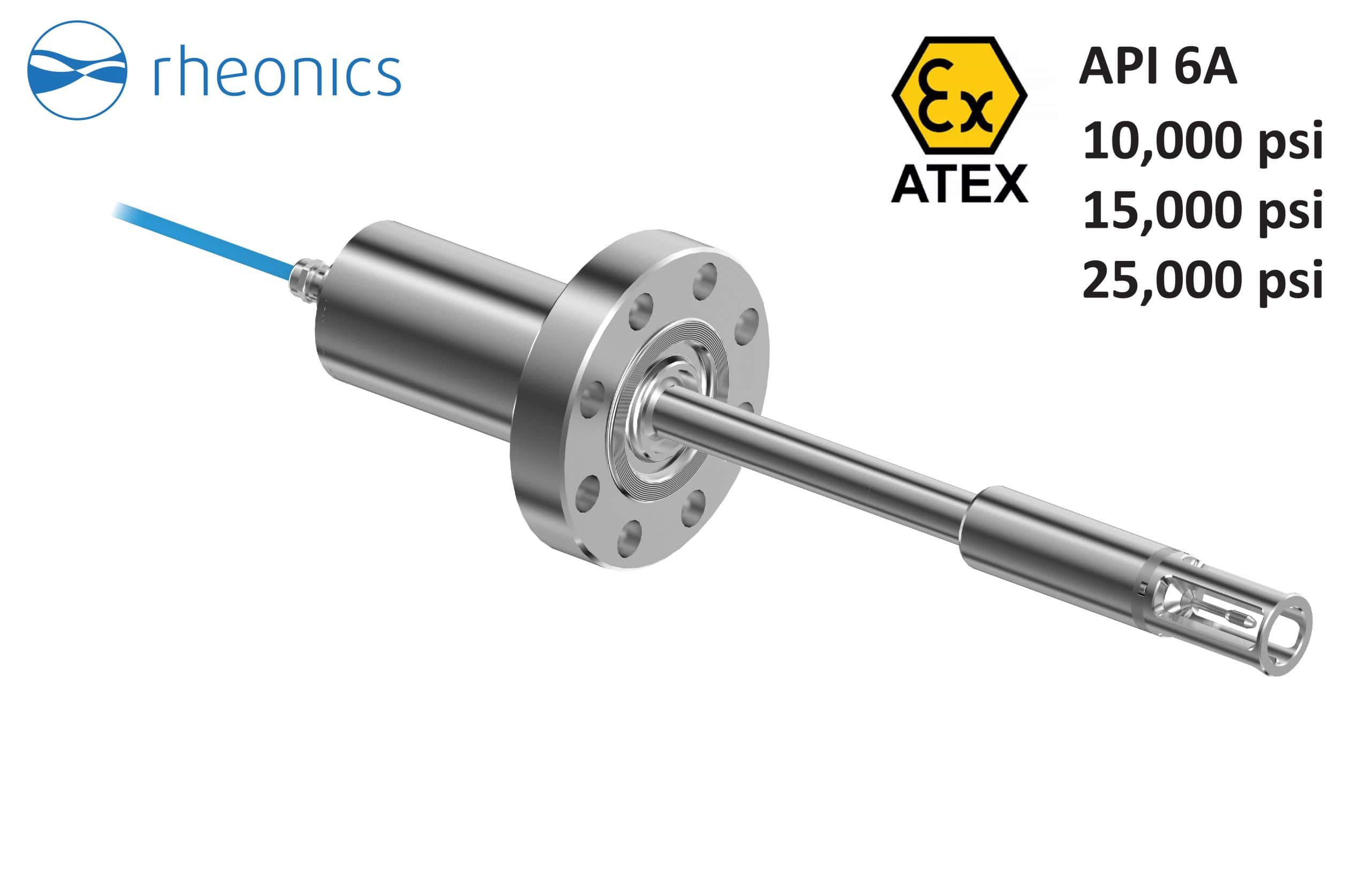

Drilling Mud Weight and Viscosity Monitoring to Optimize Well Performance

Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or…

Adhesives and Sealants Industry Overview and Rheonics Sensors Use

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Density and Concentration Brine pond monitoring in lithium extraction process

Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process…

Monitoring Density and Viscosity in 3D Cement Printing

Density and viscosity are critical parameters in 3D cement printing as they directly affect the printability, structural integrity, and layer…

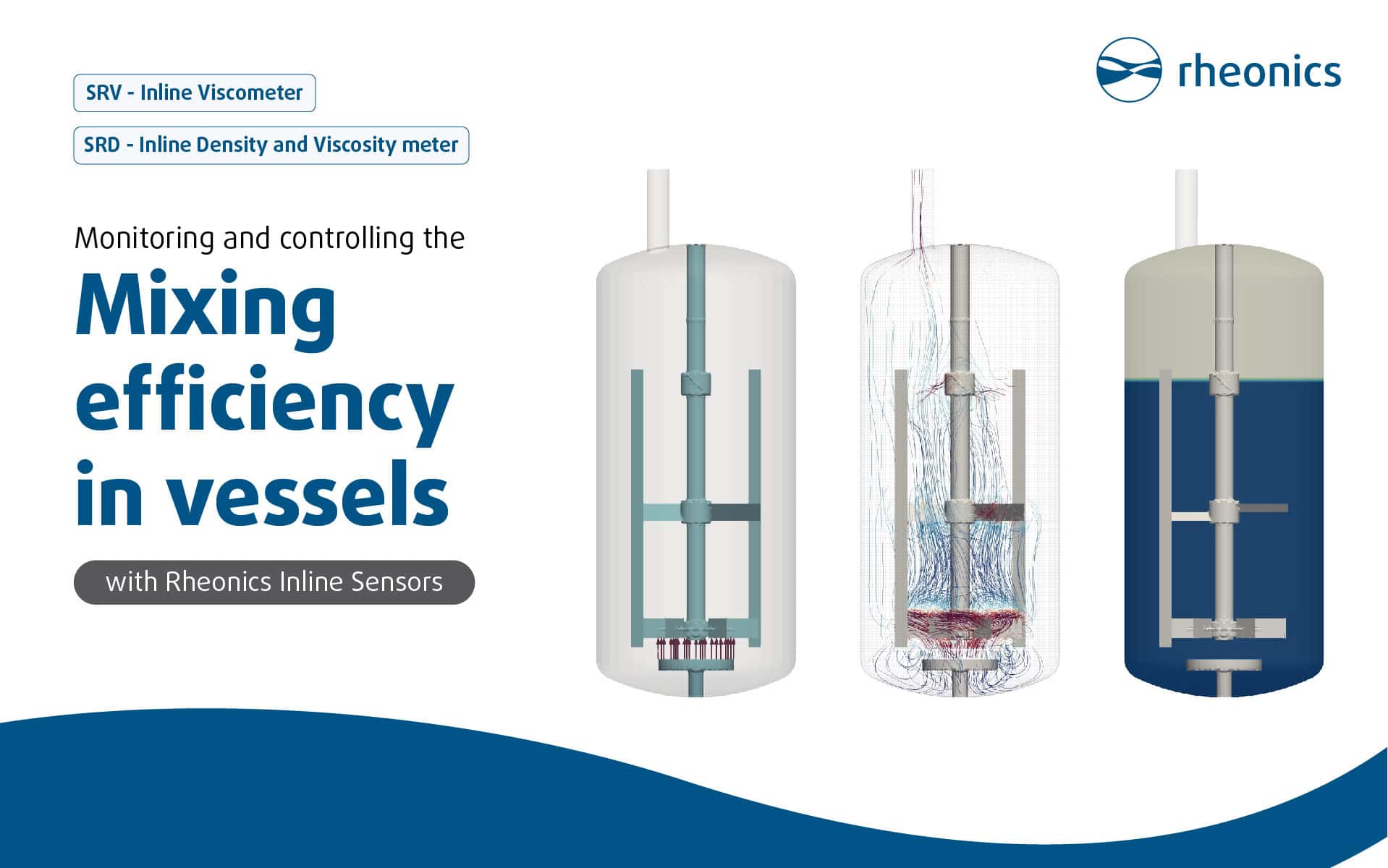

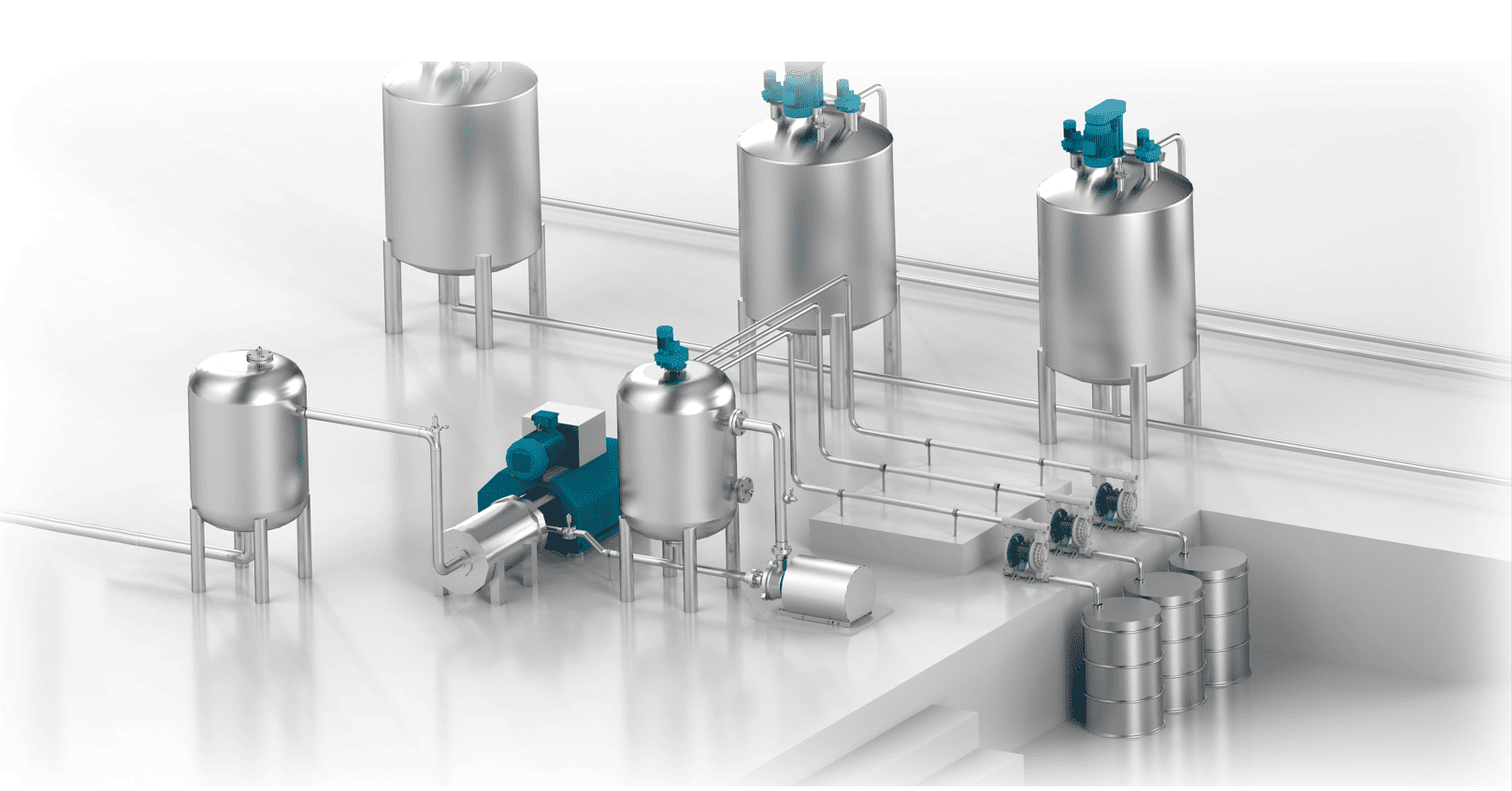

Mixing vessels – monitoring and controlling the mixing efficiency

Rheonics process viscometer SRV or Rheonics process density and viscometer SRD can be installed in a variety of locations in…

DeSander and Separator sand level realtime monitoring for automatic removal

The ability to monitor the level of sand in desanders, separators, and flowback systems allows for automation and higher efficiency…

Real-time quality control of paint, ink, coating manufacturing using process viscometer and density meter

Paint, ink and coating manufacturing processes follow similar steps, from initial mixing, until final packaging or storage, requiring a grinding…

Inline viscometers boost efficiencies of spray drying processes in milk powder manufacturing

The process of converting liquid milk into dry powder involves removing most of the water. The amount of water removed…

Glaze slurry viscosity monitoring and control for preventing defects in coating

Defects in glaze coating are driven by variation in glazing causing color differences, coating thickness variation, cracks. Monitoring and controlling…

Polyelectrolyte preparation and dosing equipment deploy inline viscosity automation systems

Treatment plants are faced with the challenge of stricter regulations and higher standards for finished water quality. New developments in…

Meeting rigorous quality control of asphalt for every load at the terminal with real-time viscosity measurements

Asphalt has proven itself to be one of the most versatile and effective materials for paving – be it road…

Monitor non-newtonian fluids through the complete process cycle

Finally! Slurry monitoring using large range sensor with repeatable measurements in non-newtonian fluids.