- Texture and product consistency are of utmost importance to customer – in manufacturing, viscosity is the correlated parameter to ensure consistency of texture and product-feel

- Data captured and processed by Rheonics viscometers helps you reduce variation significantly leading to a higher retention of solids and hence higher yields.

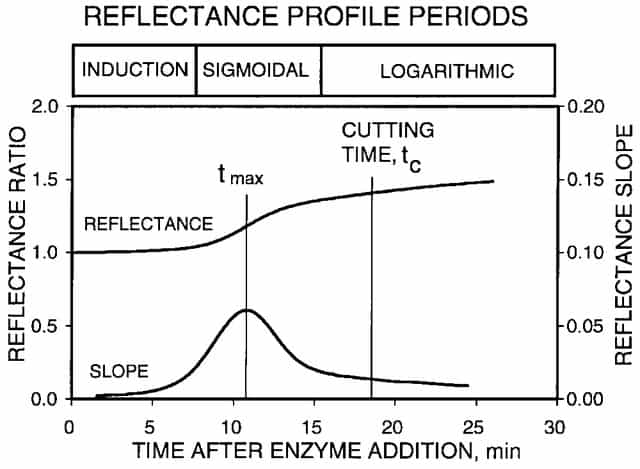

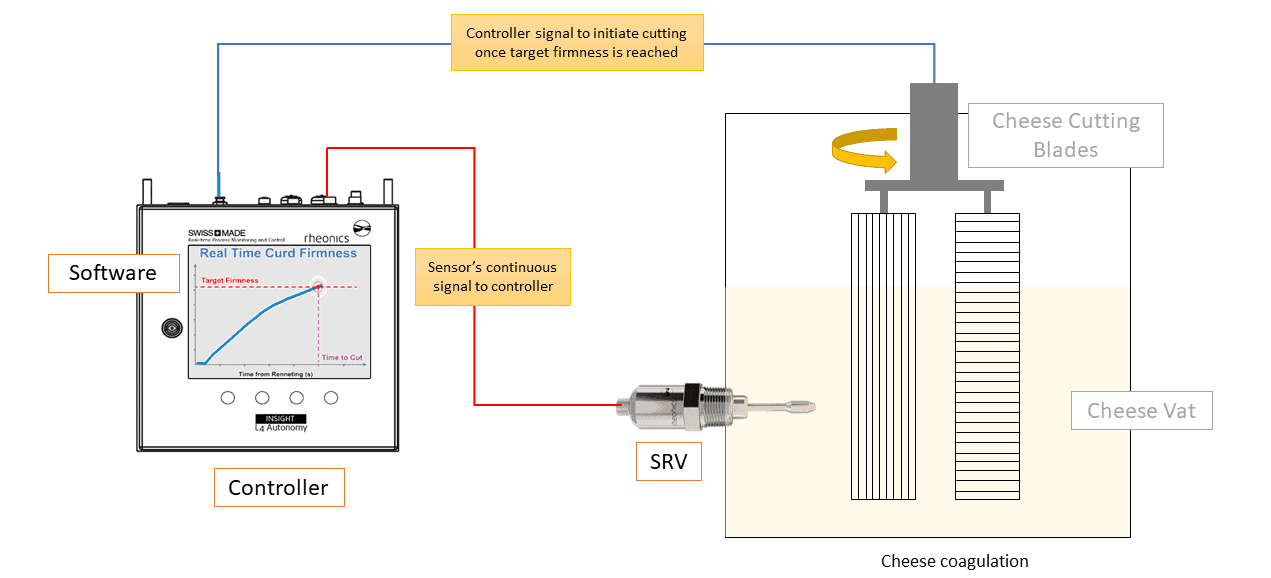

- Firmness kinetics and milk gel firmness are plotted live before the cheesemakers’ eyes for quick analysis, quick reaction and eventually automated gel cutting.

Introduction

Cheese is a staple diet in many parts of the world. Consumers value taste and texture highly. Adding to texture’s importance is the intricate manner in which it interacts with its higher profile teammates: taste, aroma and flavor. With increased competition, there is a growing emphasis on production efficiency and product quality, the use of process control to achieve these aims is becoming universal, resulting in benefits such as improved product quality, reduced waste, reduced material and energy costs, optimization of processing time and greater process flexibility.

Cheese making is a highly standardized procedure during which milk is converted into various types of cheese through enzymatic destabilization of casein proteins to form curd. However, the scale of this process varies widely from producer to producer. Cheese can be manufactured in large commercial dairy plants in tanks that fill an entire room, artfully crafted in small artisan vats, or made in a large pot in a residential garage. Regardless of the scale, accurate cutting time determination is extremely important to both the quality and the quantity of cheese being produced.

In diary food processing, the quality of the end product is highly dependent on that of the raw material(s) used, type and characteristics of ingredients used and the processing methodology and technology used. Raw materials can vary due to seasonal fluctuations (as with milk), there are particular advantages in using sensors which determine the dynamic state of a process on-line and in real time.

Application

Cheese is defined as the fresh or ripened product obtained by coagulation of milk and subsequent separation of the liquid and solid phases constituting the milk coagulum called whey and curd, respectively. The curd is further processed into cheese. Formation of a milk gel and cutting the gel into curd grains to allow whey separation are two major unit operations in cheese making. The first step of gel formation consists of casein micelle colloidal destabilization owing to chemical modification of the protective k-casein hairy coat by the coagulating agents. The second step consists of aggregation of the destabilized casein micelles to form the gel network. Further cross-linking of casein micelles results in the development of a firm gel.

For most cheese types, whey and curd separation does not take place spontaneously and requires cutting the gel into small cubes (curd grains). This operation increases the gel surface/volume ratio, allowing the whey to escape while curd grains contract.

The retention rate of milk solids in curd highly depends on the cutting firmness of the gel. The solids retention rate or “vat yield’’, contrary to the overall cheese yield, specifically measures the performance of the coagulation step and represents the efficiency of coagulation and gel cutting steps to convert milk into cheese curds.

Coagulation monitoring

The milk coagulation process, in particular, during cheese production has received a great deal of attention. Real-time estimation of curd firming and prediction of cutting time are essential for milk coagulation control during cheese making. Changes in the composition of milk and coagulation conditions exert a significant impact on the hardness of the curd and therefore cutting time.

Smaller scale factories tend to have more flexible production schedules which help increase the variability of the duration of coagulation processes. Conversely, the large factories are strongly automated and production scheme are perfectly programmed which often prevents for cutting time modification. They resort to milk standardization for control. But unfortunately, there is always some risk of changes in processing conditions and human errors, which could result in significant economic losses as a result of large-scale production sequence.

An inline sensor monitoring the evolution of coagulation and hardness of the curd could provide real-time information that would allow operators to take appropriate measures to minimize the loss of fat and fines.

What is ‘cut time’ and why is cutting time so important?

In cheese-making, the coagulum needs to be cut when it has become sufficiently firm to form discrete particles, which expel whey without fragmenting. For this reason, the moment of curd cutting occurs some time later than the point of gelation. This implies a need to measure the firmness of a gel as it forms and up to the point where it is ready to synerese.

Coagulation is complete when a firm gel has been formed from the aggregated proteins. This point is known as the “cut time”, or the stage at which the gel must be cut in order to separate the curd from the liquid whey. When the gel is cut, it then undergoes syneresis, a process by which it expels the liquid whey proteins. When syneresis is completed, the final product is curd particles suspended in liquid whey.

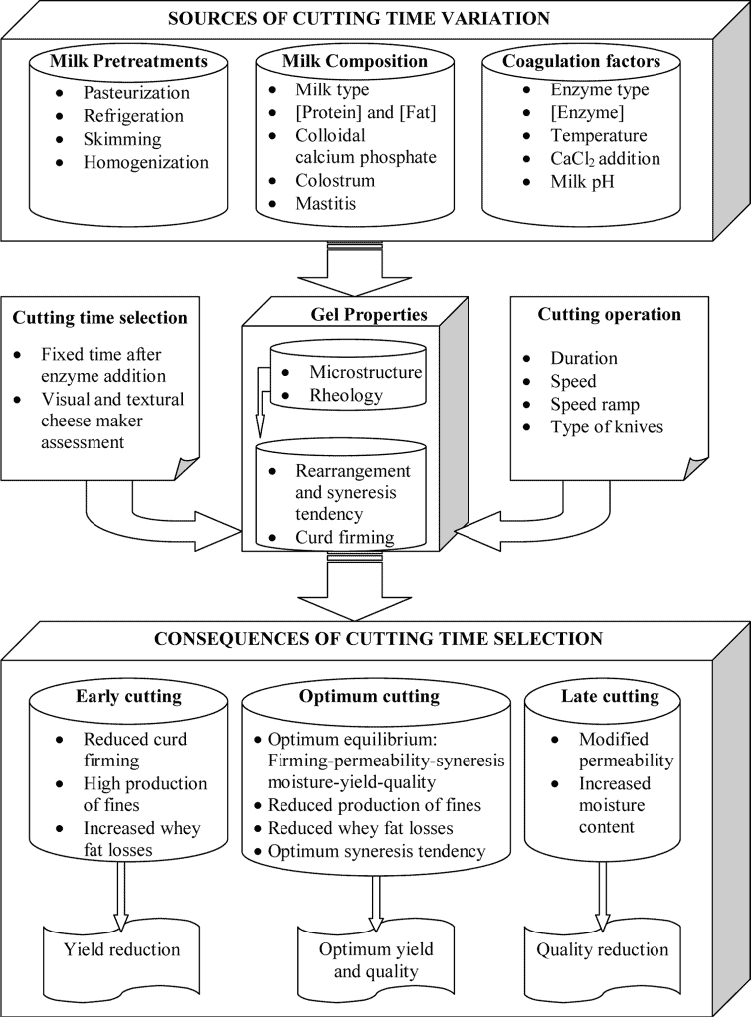

Cutting time (CT) selection depends on rheological and microstructural properties of gels, such as coagulum firmness and rearrangement capability that, in turn, depend on coagulation factors, milk composition, and milk pre-treatment.

For this reason, CT selection greatly affects moisture, yield, and quality of cheese and whey fat losses. Cutting and stirring speeds can also exert a marked impact on curd particle size and/or fat losses to the whey at draining. At constant cutting and stirring speeds, cutting the gel too soon enhances the mechanical impact of cutting and stirring operations on curd grains, which increases curd fines and whey fat losses, decreasing cheese yield.

By contrast, delaying CT tends to produce the opposite effect on cheese yield. But, excessive delay in cutting also produces an overly firm gel, unable to collapse, which increases curd moisture content. Excessive moisture content causes a ‘‘fake’’ increase in yield and could alter the ripening process, compromising cheese quality. The economical impact in terms of yield and quality of a defective CT selection has not been rigorously reported.

Reference: Cutting Time Prediction Methods in Cheese Making, M Castillo (2006)

Overview of the ‘conventional’ Cutting time selection procedures

Regardless of producer size and type of cheese, the milk gel-cutting step is probably the least controlled step in the cheese making process and a large part of the overall cheese yield depends on this critical step. Cheesemakers need an instrument to make accurate and real time measurements of coagulating milk firmness in order to make the right decision at the right moment. Early techniques involved moving plungers or diaphragms which sensed resistance of coagulum to movement. However, these suffered from the disadvantage that the movement tended to disrupt the gel as it formed and thus interfered with the measurement of gel elasticity. While such devices proved highly useful for research on cheese-making, their use was confined to laboratory work because of their size, integration difficulties and intrusiveness in a cheese vat.

In practice, the gel is usually cut after a predetermined reaction time has elapsed or upon the operator’s judgement based on subjective evaluation of textural and visual gel properties. It is a very common practice, but its reliability is questionable since there are many factors which could alter the curd firmness and gel microstructure to vary the optimum cutting time.

Many cheese manufacturers resort to finger palpation, a technique with known disadvantages such as the inability to perform the test in real time and scarcity of experienced cheesemakers. A method that is also subjective and not quantitative. The above method, however, leaves a wide margin for variability based on the judgment of the tester. As the dairy industry began to grow and cheese manufacturing began to be done in larger production facilities, it became apparent that a more scientific and standardized method for determining cutting time should be developed.

Another possibility is cutting the curd by relying on empirical inspection. Cheesemakers can select the cutting time with amazing consistency based on experience, but it certainly cannot be optimised by the empirical inspection method.

Most of the non-destructive systems measure changes in conductivity of certain physical properties such as electric current, heat, ultrasound, or electromagnetic radiation. Electrical conductivity increases 0.5–1% during milk coagulation, but this monitoring technique has some significant limitations such as large temperature coefficient of conductivity and possibilities of interference between the original milk electrolytes and the measurement. A thermal conductivity sensor detects changes in convective heat transfer from a ‘‘hot wire’’ to the surrounding milk that are caused by the variation in viscosity during coagulation.

Hot wire sensor has been demonstrated to measure very accurately the gelation point, but was not so accurate in predicting curd cutting point. The viscosity increases exponentially between the beginning of aggregation and the onset of visual coagulation, which makes the hot wire not so well suited for measuring gel stiffness. The hot wire is not suited to a variable protein environment, as protein has a large effect on curd firming rate but only a minor effect on the time at which a gel begins to form, which is what the hot wire measures.

The lack of a rigorous CT characterization and the usual changes in milk protein content are forcing modern cheese plants to standardize the protein content of milk in an attempt to control coagulation, gel firming, curd syneresis, cheese yield, and product quality. A plethora of different techniques have been proposed in the period of more than seven decades for monitoring milk coagulation and curd firming, which clearly shows that industrial requirements for CT selection have not been fully satisfied by the traditional methods.

Optical methods: Diffuse reflectance changes during the culture of cottage cheese

The interaction of light particles with particles of matter, after which the light particles may change direction or experience a partial loss or gain of energy is known as “light scattering”. This intensity can vary based on the materials with which the light is interacting, thus the interpretation of light scatter has many applications. One such application is in the cheese-making process, as several optical methods have been successfully developed to monitor the coagulation and predict the cut time of certain cheeses. The light scatters in all directions off of the micelle, therefore there is little absorption by the protein.

In the case of monitoring coagulation or predicting cut time using light scatter, several different factors come into play. First, as stated above, light scatters off of micelles in milk in all directions. However, in the cheese-making process, after addition of an enzyme the micelles begin to denature and aggregate. Light scatter off of denatured micelles is much more intense. Therefore, this property of light interactions can be used to quantify the firmness of the coagulum.

Since the cutting time is selected based on a model, there is always some mismatch between the actual and the predicted cutting time. While handling changes to composition and ingredients, it may always be associated with a need to come up with a new, better suited model to make reliable predictions, since this method is not direct. The correlation between parameters need to be generated from the diffuse reflectance profile and cutting time to develop an algorithm for cutting time prediction. There will always be an associated measurement error with indirect methods.

Viscosity for QC and in-line process measurements in dairy processing industry

The largest influences on the cheese-making process are the characteristics of the milk that is used in the process. The milk proteins, in particular, are very important to the quality of the cheese, the outcome of which is highly dependent on the structure and interactions of these proteins. Changes in milk composition can influence the taste and texture of cheese in a variety of ways. To that end, milk composition in the cheese-making process is highly standardized to achieve uniform fat-to-protein ratios depending on the specific type of milk desired.

The effect of milk seasonality was confounded by other uncontrolled variables (heat treatment, temperature, pH and rennet type). This shows the value of on-line measurement, since it has not been possible to predict curd firmness in a commercial cheese-making situation from offline measurements due to the interactive effects of so many variables.

Inline process measurements for continuous manufacturing to enhance yields, safety and productivity

As cheese manufacture became increasingly mechanized and food safety issues became more critical, the commercial cheese factory began to operate around a series of enclosed vats with less opportunity for the cheesemaker to manually assess the gel strength. The scale of operation of modern plants, coupled with ever-increasing demands on quality control, have led to an interest in systems which monitor curd formation on-line. In addition, simultaneous operation of a suite of cheese vats requires a time-based cycle with all vats filling and emptying in sequence to assist a fairly continuous flow of milk from the intake/pasteurising plant. Hence, an online device for measuring curd formation is highly desirable but it would need to be non-intrusive and cleanable-in-place. Two key reasons which can make an inline process measurement extremely valuable:

- Continuous production: To support mechanized processes in industries and be able to scale the production processes at ease, the cheese manufacturers need reliable process instrumentation providing them with real time insights in order to be able to adapt quickly. Automation of corrective actions and reducing need for manual interventions elevates the safety standards and increases the reliability of the operations.

- Safety & Hygienic standards of food processing: There is a serious need to move away from manual measurements which can compromise with regulatory norms and customers’ expectations of hygiene. The inline measuring devices need to be equipped with sanitary process connections, must be easy to clean and be CIP/SIP compatible.

Industrial cheese vats (Source – TetraPak)

Inline viscometer for cutting time

Typical manufacturing processes involved in dairy processing like thermal cycles and mechanical operations (stirring, filtration, kneading, compression, etc) can significantly change the rheological property, and in turn the final product characteristics. To control a manufacturing process, a quality or parameter which characterizes the current state of the process must first be identified and then measured. Viscosity is a key physical property of the coagulating milk, which gives deeper insights to what is exactly happening at the molecular level that often characterizes the state of a process quite well, whether alone or in combination with other physical and chemical properties.

Compared with other online measurements such as hot wire and optical methods, viscosity characterization is a direct method – there is no need to rely on prediction models or estimations. An inline viscometer which has a small form factor, is installed with ease, is compatible with the hygienic standards and integrates easily with the industrial PLC system provides significant value to dairy manufacturers to accurately time the cheese cutting.

Much more than just cutting time determination for the cheese makers

Cheese produced needs to be of consistently high quality to stringent specifications from raw materials which may vary in their composition or physical properties. The consumer expects a product to have an appropriate and consistent texture – a property affected by the viscosity.

In summary, in-line viscosity measurement and control can provide an effective and beneficial means of process control in the cheese manufacture through the following main ways:

- Detecting end-point of the mixing, homogenization and coagulation process: During the coagulation process, characterizing the viscosity is useful in determining the stability, and end-point. During homogenization, the formulation will undergo a substantial viscosity increase as the droplet size is reduced. The amount of this increase will, therefore, be a good indicator of emulsion quality. Monitoring viscosity online enables manual or automatic adjustments to stirring intensity, rotational speed, and other processing variable depending.

- Better ingredients management and handling: Concentration has a strong correlation with viscosity; hence the viscosity information can be effectively used to predict or cross-check

For these reasons, viscosity measurement obtained with an inline viscometer can provide an excellent QC benchmark and ensure QA/QC of the process and end-product.

Dairy plant viscosity measurement and process challenges

Engineers and plant operators in dairy products processing realize the need to make viscosity measurements and intervene through appropriate corrective actions to drive high-quality and consistent product rheology. However, making these measurements have challenged them over the years.

Offline grab-samples are simply unreliable and not suited for dairy industry

Monitoring the viscosity of a fluid in a process often means taking a sample of the fluid from a tank or pipeline, and bringing the sample to a laboratory where its rheological properties are measured on a laboratory viscometer or rheometer. Based on the findings, the process operator must be informed whether the fluid is at the desired viscosity, or if further action is required then new measurements must be made after intervention. This system is called off-line or manual control, with several obvious disadvantages – it is time-consuming and often inaccurate even with experienced operators. Most often the results are too late to save a batch.

The alternative is to use an in-line viscometer that will continuously monitor the viscosity of the process fluid throughout the process. This instrument gives an output signal which, if displayed, provides the operator with the necessary information to control the process. Alternatively, viscometer outputs are connected to a PLC (Programmable Logic controller) / DCS (Digital Control System) for automatic process control.

Issues with conventional viscometers for inline installation

Traditional viscometers encounter problems related to the fluid flow in pipeline and tank-mixing installations. In general, viscometers do not function properly in turbulent flow. Rotational instruments will only operate up to a certain maximum flow rate. The flow has to be controlled for pressure drop viscometers. Flow related problems can be avoided by installing the viscometer on-line and conditioning the sample flow to suit the instrument. Instrument response time can be related to the flow conditions, as an adequate sample renewal rate is required for effective control. In the case of tank installation, it is desirable to place the instrument in a position where the adjacent fluid represents the overall state of the process fluid, and to avoid ‘dead areas’. Instruments used in a process environment have to be robust and able to resist any corrosive materials that they may encounter, especially during cleaning.

Rheonics’ Solutions for coagulation monitoring in cheese production

Where a food process is continuous, on-line sensing (which determines the state of a process in real time) is an ideal method to address the problem. For useful applications, sensors must fulfil several requirements, e.g. ability to interface with plant monitoring/control systems, robust measurements regardless of flow or ambient conditions, cleanability and stability with time and temperature.

Rheonics process control sensors for the food industry, in parallel with developments in process control technology, has the potential to increase the levels of process automation and equip the factory engineers achieve maximum benefits of digitalization, process data realization and long-term action plans, data-based maintenance and reliability planning and high repeatability in terms of the cheese products quality, yield and consistency.

Viscosity & Density Meters

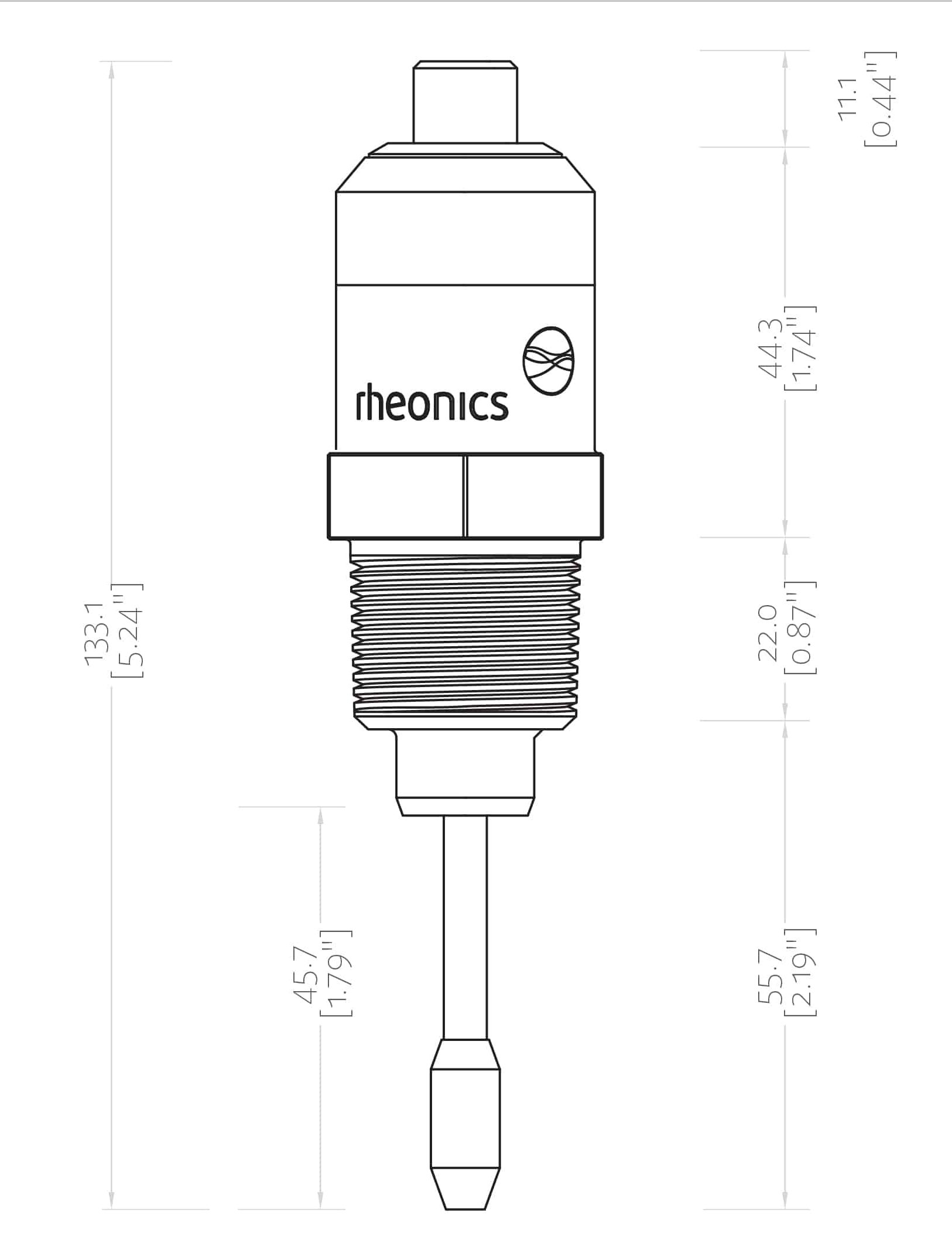

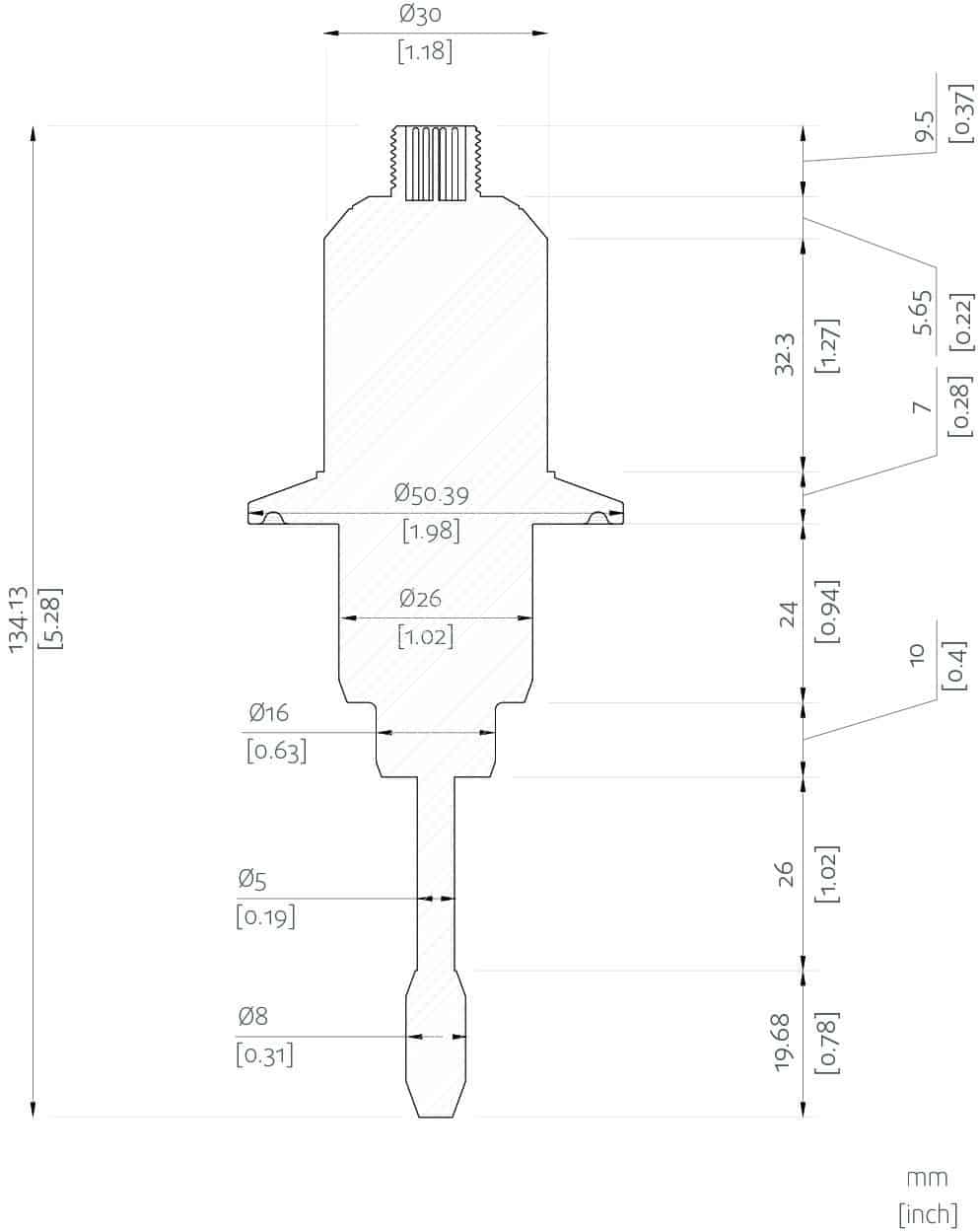

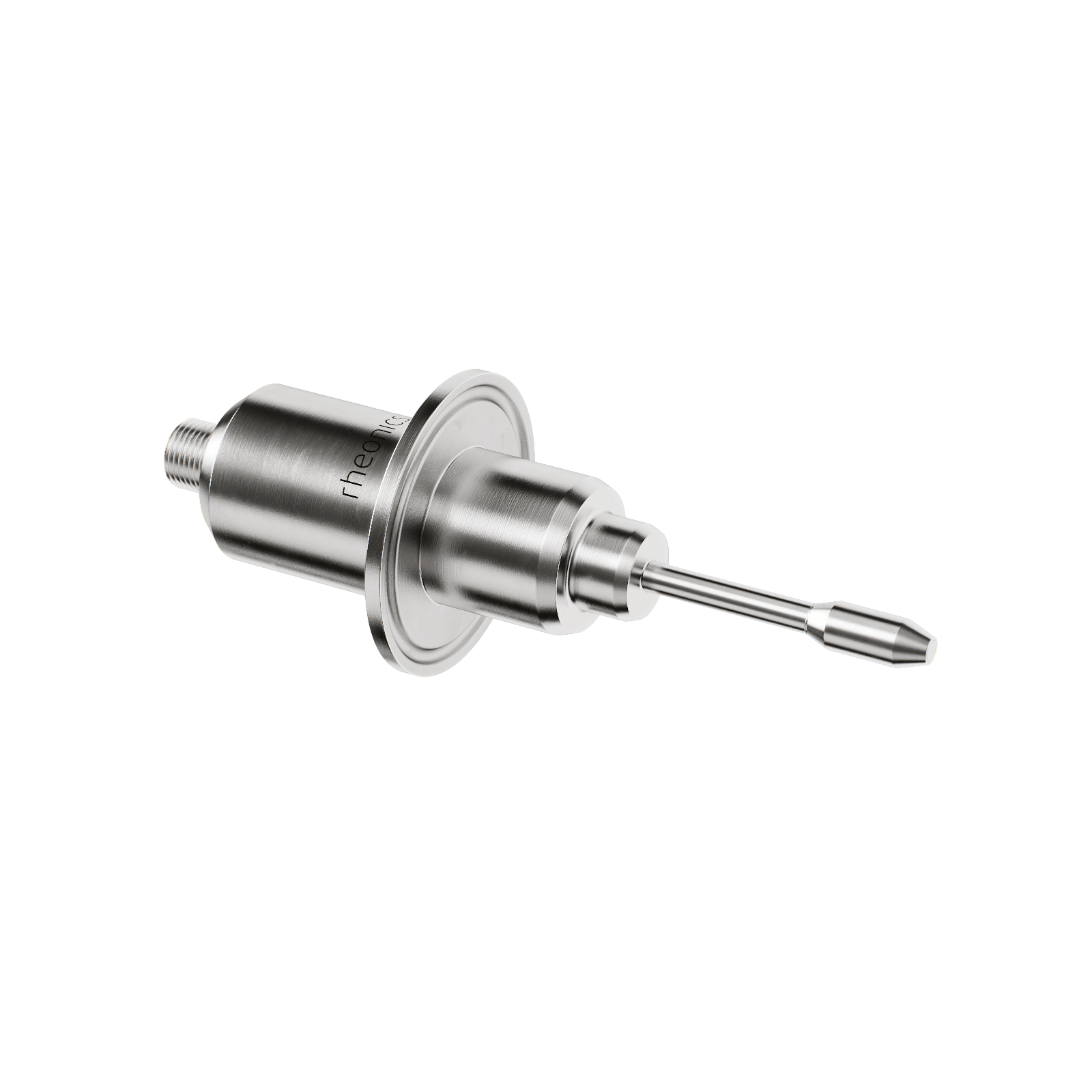

- In-line Viscosity measurements: Rheonics’ SRV is a is a wide range, in-line viscosity measurement device capable of detecting viscosity changes within any process stream in real time.

- In-line Viscosity and Density measurements: Rheonics’ SRD is an in-line simultaneous density and viscosity measurement instrument. If density measurement is important for your operations, SRD is the best sensor to cater to your needs, with operational capabilities similar to the SRV along with accurate density measurements.

These instruments give an output signal and reading on a software panel which, if displayed, provides the operator with the necessary information to control the process. Alternatively, it may be possible to send the output to an automatic process controller. Integrated control systems enable the viscosity/density information in the process line to be used effectively.

Using an SRV in a dairy product preparation process line, results in improved productivity, profit margins and achieves regulatory conformance. Rheonics sensors have a compact form factor for simple OEM and retrofit installation. They require zero maintenance or re-configurations. The sensors offer accurate, repeatable results no matter how or where they are mounted, without any need for special chambers, rubber seals or mechanical protection. Using no consumables and not requiring re-calibration, SRV and SRD are extremely easy to operate resulting in extremely low lifetime running costs.

During the coagulation of milk, once the curd reaches the optimal elasticity that ensure a high retention rate of solids, a signal is sent to the automation system to start the cutting step.

Rheonics solutions are advantageous over a hotwire or light scattering based technology that both deliver a prediction of cutting time without measuring actual firmness. With Rheonics, perform your gel cutting exactly at the right firmness and you’ll get the highest retention of milk solids. In other words, you’ll get the highest production of cheese.

- The process control instrument located near (but outside) the vats that delivers accurate and real time measurement of milk coagulum firmness.

- Firmness kinetics are plotted live before the cheesemakers’ eyes for quick analysis, quick reaction and eventually automated gel cutting.

- Measures directly milk gel firmness and automatically triggers the gel cutting when optimal firmness is reached.

- High immunity to plant vibrations, ease of cleaning (optimizes CIP/SIP systems) and low maintenance requirements and has no moving parts

Once the process environment is established, there is usually little effort required to maintain the integrity consistency of the systems – operators can rely on the tight control with Rheonics dairy products production quality management solution. Achieving higher quality, increased yields, reduced losses and less downgrading of product.

Rheonics' Advantage

Compact form factor, no moving parts and require no maintenance

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations. They have a small footprint enabling Inline installation in any process line, avoiding any additional space or adapter requirement.

Hygienic, sanitary design

Rheonics SRV and SRD are available in tri-clamp and DIN 11851 connections besides custom process connections.

Both SRV & SRD conform to Food Contact Compliance requirements according to US FDA and EU regulations.

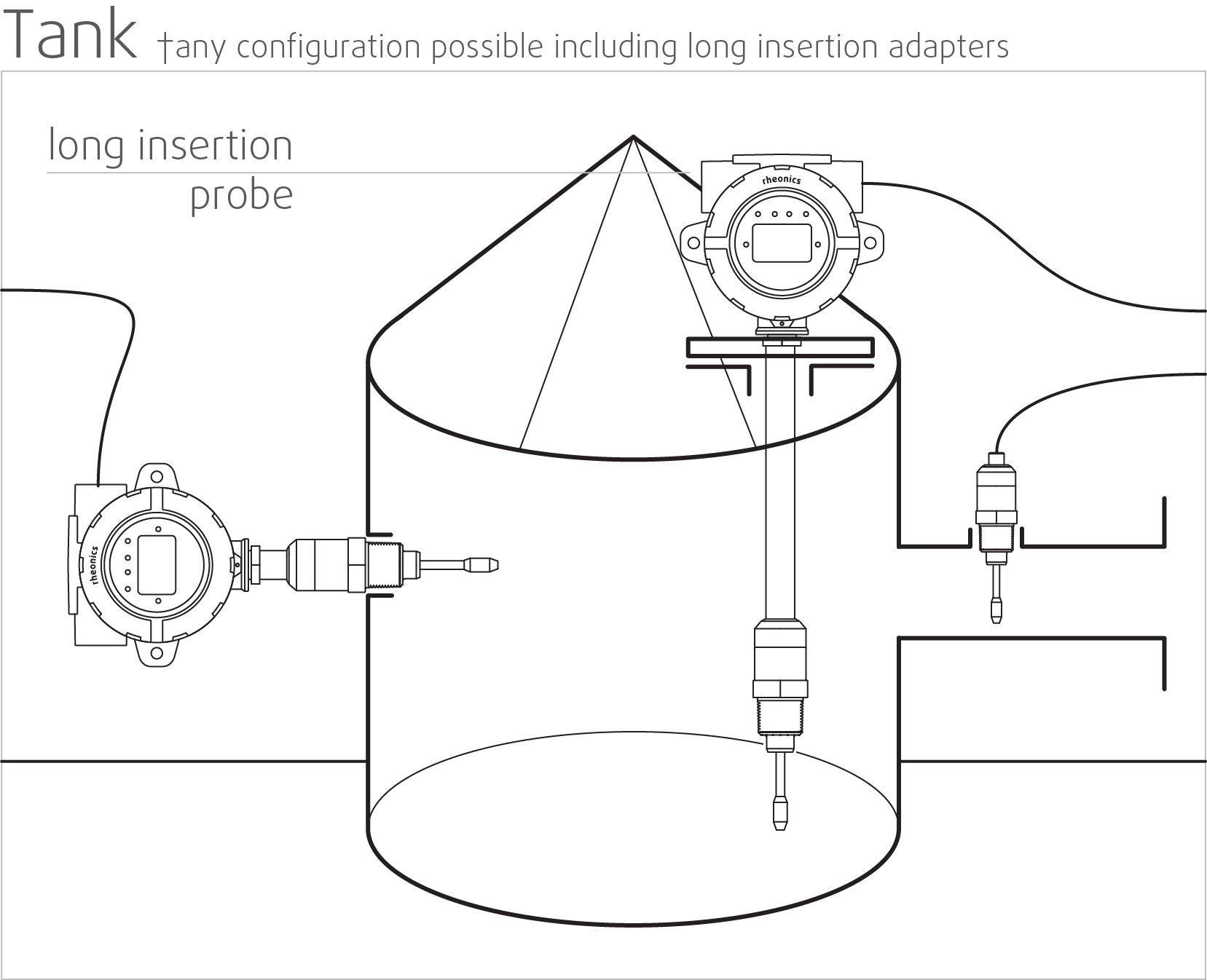

High stability and insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions and flow rates. Sensor element sits directly in the fluid, with no special housing or protective cage requirements.

Instant accurate readouts on quality – Complete system overview and predictive control

Rheonics’ software is powerful, intuitive and convenient to use. Real-time process fluid can be monitored on the integrated IPC or an external computer. Multiple sensors spread across the plant are managed from a single dashboard. No effect of pressure pulsation from pumping on sensor operation or measurement accuracy. No effect of vibration.

Easy installation and no reconfigurations/recalibrations needed – zero maintenance/down-times

In the unlikely event of a damaged sensor, replace sensors without replacing or re-programming electronics. Drop-in replacements for both sensor and electronics without any firmware updates or calibration changes. Easy mounting. Available with standard and custom process connections like NPT, Tri-Clamp, DIN 11851, Flange, Varinline and other sanitary and hygienic connections. No special chambers. Easily removed for cleaning or inspection. SRV is also available with DIN11851 and tri-clamp connection for easy mounting and dis-mounting. SRV probes are hermetically sealed for Clean-in-place (CIP) and supports high pressure wash with IP69K M12 connectors.

Rheonics instruments have stainless steel probes, and optionally provide protective coatings for special situations.

Low power consumption

24V DC power supply with less than 0.1 A current draw during normal operation.

Fast response time and temperature compensated viscosity

Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest, versatile and most accurate in the industry. SRV and SRD give real-time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions.

SRV is available with the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi

- Temperature range from -40 up to 200°C

- Viscosity range: 0.5 cP up to 50,000 cP (and higher)

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Clean in place (CIP) and Sterilization in place (SIP)

SRV (and SRD) monitors the cleanup of the fluid lines by monitoring the viscosity (and density) of the cleaner/solvent during the cleaning phase. Any small residue is detected by the sensor, enabling the operator to decide when the line is clean/fit for purpose. Alternatively, SRV (and SRD) provides information to the automated cleaning system to ensure full and repeatable cleaning between runs, thus ensuring full compliance to sanitary standards of food manufacturing facilities.

Superior sensor design and technology

Sophisticated, patented electronics is the brain of these sensors. SRV and SRD are available with industry standard process connections like ¾” NPT, DIN 11851, Flange and Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV/SRD giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Electronics built to fit your needs

Available in both a transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process lines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

Analog and Digital Communication Options

Optional Digital Communication Options

ATEX & IECEx Compliance

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Implementation

Directly install the sensor in your vat to do real-time viscosity and density measurements. No bypass line is required: the sensor can be immersed in-line; flow rate and vibrations do not affect the measurement stability and accuracy. Optimize mixing performance by providing repeated, consecutive, and consistent tests on the fluid.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers and density meters have the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed