Coil coating is a high-speed, precision process where fluid properties directly affect coating uniformity and adhesion. Inline viscosity and density monitoring allows operators to detect deviations instantly, ensuring consistent quality, reducing scrap, and optimizing throughput.

Table of Content

- Introduction

- Coil Coating Lines

- Key applications

- The importance of viscosity/density in Coil Coatings processes

- Production/Application process

- Rheonics Type-SR Inline Sensors Overview

- Recommended installation

- Mechanical Installation Considerations

- SRV and SRD Installation Requirements

- SRD Additional Installation Requirements

- Recommended solutions by Rheonics

- Process Conditions and Best Practices

- References

Introduction

![Figure 1 - Color-Coated coils [1]](https://rheonics.com/wp-content/uploads/2026/01/color-coated-coils.jpg)

Figure 1 – Color-Coated coils [1]

Coil coating is a continuous process where metal strips are coated with primers, paints, or protective layers for construction, appliance, and automotive applications. The process requires precise control of coating fluid properties to achieve uniform thickness, proper adhesion, and surface finish. Viscosity and density are critical parameters, as they influence coating flow, leveling, wetting, and curing.

Traditional lab-based sampling measurement methods, such as Zahn cups or rotational viscometers, can be slow and may not represent process conditions accurately. Inline measurements provide real-time data, enabling immediate adjustments to maintain consistent quality and reduce scrap.

Rheonics sensors provide operational advantages:

- Continuous, accurate, real-time inline measurement of viscosity, density, and temperature.

- Reliable performance at high line speeds and variable temperatures.

- Compact design unaffected by vibrations, ideal for high-speed coating lines.

- Integration with PLC/DCS systems via Modbus, Ethernet/IP, 4–20 mA outputs, and more.

- Factory-calibrated, with optional verification for QC standards.

- Reduced waste, improved line efficiency, and ROI possibility within the first year.

Coil Coating Lines

Coil coating processes require precise control of coating formulation properties to ensure uniform film thickness, surface finish, and curing performance. Inline monitoring of rheological properties such as viscosity and density is critical for maintaining coating stability during application, circulation, and recirculation.

![Figure 2 - Coating stage with liquid paints [2]](https://rheonics.com/wp-content/uploads/2026/01/coating-stage-liquid-paints.jpg)

Figure 2 – Coating stage with liquid paints [2]

Key applications

Coil coating materials typically include primers, basecoats, and topcoats, which can range from low- to high-viscosity formulations:

- Primers: Ensure adhesion and corrosion protection.

- Topcoats: Provide color, gloss, and decorative properties.

- Protectives coatings: Add durability and chemical resistance.

Continuous inline measurement supports consistent coating quality across different colors, materials, formulations, and production speeds. Coatings are applied using a roller. Lines operate at high speeds (up to 1000 m/min), making real-time control of coating fluids critical.

Figure 3 – SR-Type probes installed in the coating stage

The importance of viscosity/density in Coil Coatings processes

Inline viscosity and density monitoring help operators prevent defects, maintain proper coating weight, and ensure consistent pigment distribution.

Viscosity measures a fluid’s resistance to flow. In coating processes, viscosity affects:

- Coating thickness uniformity and leveling.

- Adhesion to the metal substrate.

- Smooth application through roller systems.

Density measures the mass per unit volume. In coating lines, density affects:

- Pigment concentration and color consistency.

- Coating weight per unit area, crucial for quality control.

- Detection of batch inconsistencies in raw materials or formulations.

Inline real-time monitoring solves challenges associated with lab-based measurements, such as non-representative sampling, time delays, and difficulty replicating process conditions.

Production/Application process

Figure 4 – Coil Coating process diagram

A coil coating line is designed to run at a constant speed throughout all its stages. This is achieved by using accumulators at the beginning and at the end of the line.

The process begins with an uncoiler and a welding section to join new material. It then moves through an entry accumulator, which ensures continuous production during coil changes. Next, the uncoiled strip passes through a cleaning section to remove any contamination from the metal surface.

At this point, the sheet enters the coating stage, where it first passes through the first roller coater to apply a primer coating. The applied coating is then cured and dried. Afterwards, the sheet receives a topcoat material in the second roller coater, followed by another curing and drying step before the next stages.

At this stage of the process, viscosity and density sensors can be installed to monitor the coating fluids at different locations, like supply tanks, recirculation lines, hoses with inline flow cells, or coating trays, as shown in Figure 4.

Finally, the coated strip passes through the exit accumulator and recoiler, where it is cut at the coil’s end and prepared for the next batch.

Rheonics Type-SR Inline Sensors Overview

Rheonics Type-SR sensors (SRV and SRD) measure viscosity, density, and temperature inline for process monitoring and control. The SRV measures viscosity and temperature, while the SRD also provides density.

These sensors are factory-calibrated and require no recalibration during their lifetime. However, clients may need calibration or verification for quality control. Optional adjustments or offset corrections can match specific references. For details, see Calibration of inline process viscometer SRV in field and factory.

Rheonics sensors use balanced torsional resonator (BTR) technology. This patented design makes the sensors compact, lightweight, and resistant to external vibrations.

Rheonics SRV and SRD sensors are well-suited for coil coating lines. Installed directly in the coating circulation or supply lines, they provide continuous real-time measurements of coating properties during production. Inline readings enable consistent coating quality, reduced solvent and material waste, and improved line stability across color and formulation changes.

Figure 5 – Rheonics SRV/SRD sensor: Versatility in installation options

Recommended installation

Mechanical Installation Considerations

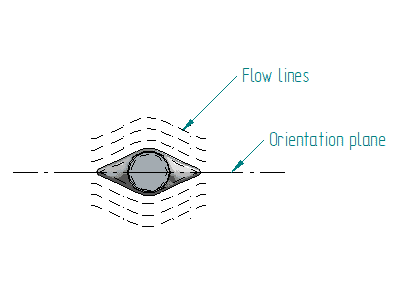

Certain installation aspects apply to both Rheonics sensors, SRV and SRD. Each variant shares the same resonator design, and proper installation depends on correctly positioning the probes’ sensing area (red-shadowed areas in Figure 6). The main points are:

SRV and SRD Installation Requirements

- The area should be free of deposits or obstructions

- The area should be completely immersed in the fluid of interest.

SRD Additional Installation Requirements

In addition to the two main requirements above, the SRD sensor has two additional considerations:

- Maintain thermal stability when the fluid and the external environment have a temperature gradient greater than 15°C. (Only for SRD, more information here: Maintaining the SRD’s temperature balance for high-density accuracy)

- Align the sensing tip with the fluid flow direction as shown in Figure 7. (Only for SRD, more information here: SRD fluid end orientation)

These conditions can be reviewed in more detail in the next article, SRV and SRD Suitable Installations.

Figure 6 – Type-SR sensors: Installation considerations

Figure 7 – SRD recommended tip orientation

Recommended solutions by Rheonics

The Rheonics Type-SR sensors feature a modular, compact design that supports various configurations depending on application conditions. For example:

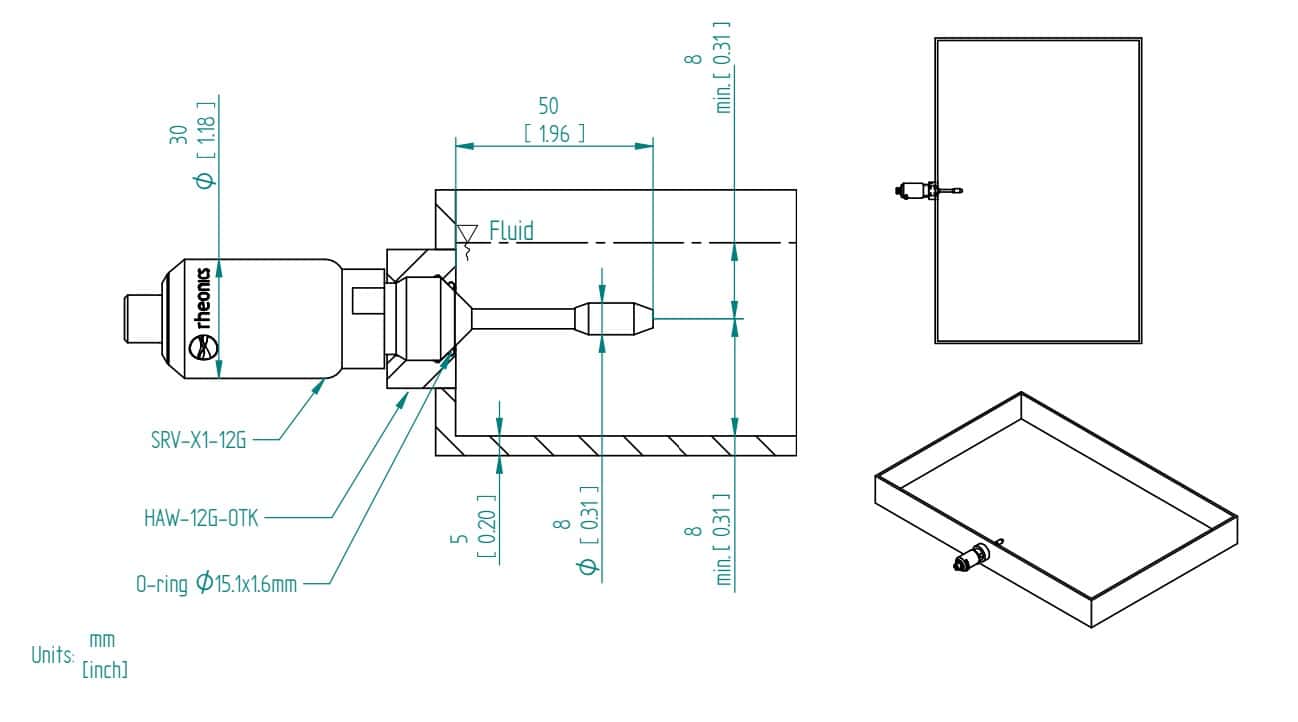

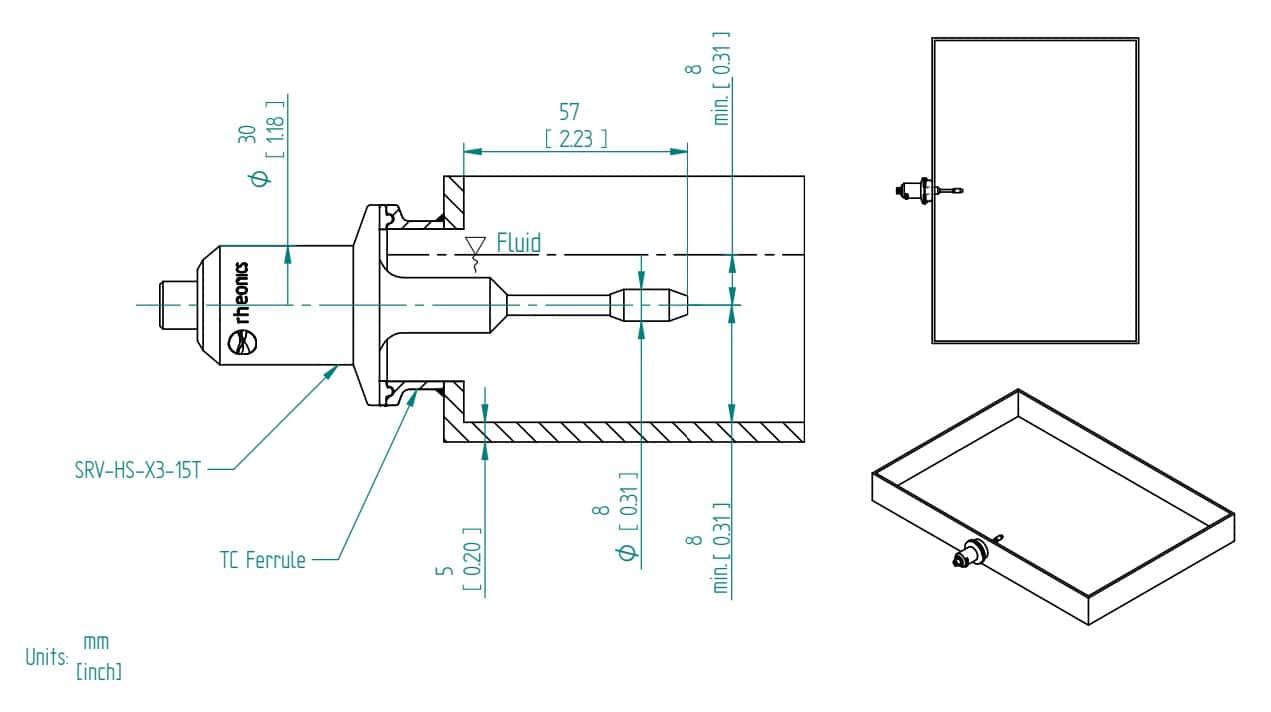

Installation in trays or dishes

Coil coating applications usually use trays to hold fluid during the coating process. Rheonics’ Type-SR sensors can be installed directly in the tray using our HAW (MTK or OTK) and WFT weldolets. Below are example drawings of these accessories installed in fluid trays.

Figure 8 – SRV-X1-12G installed in a dip coating tray using an HAW-12G-OTK

Figure 9 – SRV-X3-15T installed in a dip coating tray using a WFT-15T

HPT-12G: HPHT flow cell

For small pipelines or hose installations, Rheonics offers the HPT-12G (see Figure 10). This flow cell suits high-pressure, high-temperature processes and positions the sensor parallel using a threaded process connection.

The HPT-12G works only with the SRV-X1-12G, which has a G 1/2” threaded connection. This ensures a flushable seal compatible with CIP, ideal for coating and paint lines. See HPT-12G for details.

Figure 10 – HPT-12G, flow cell for SRV-X1-12G sensor

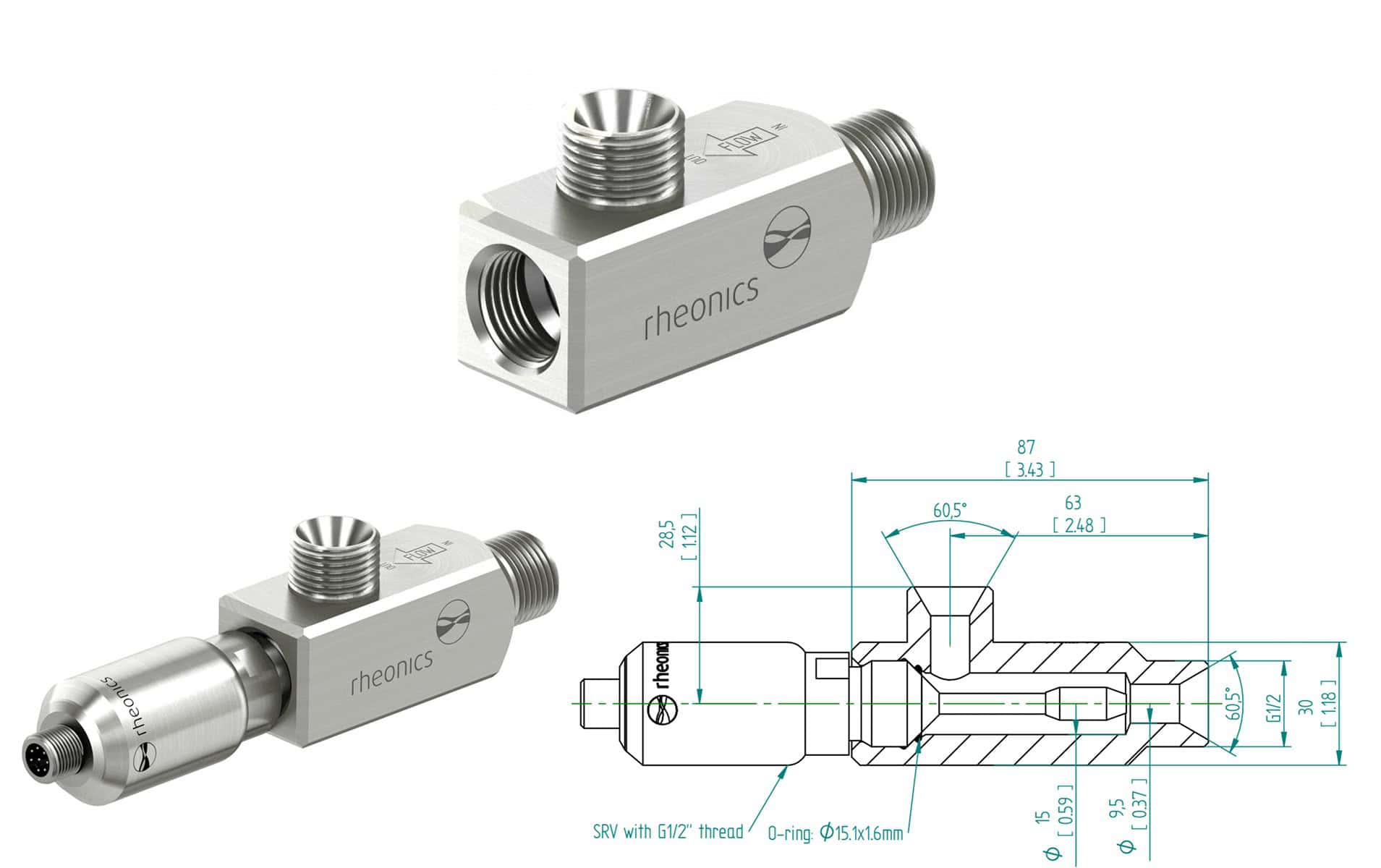

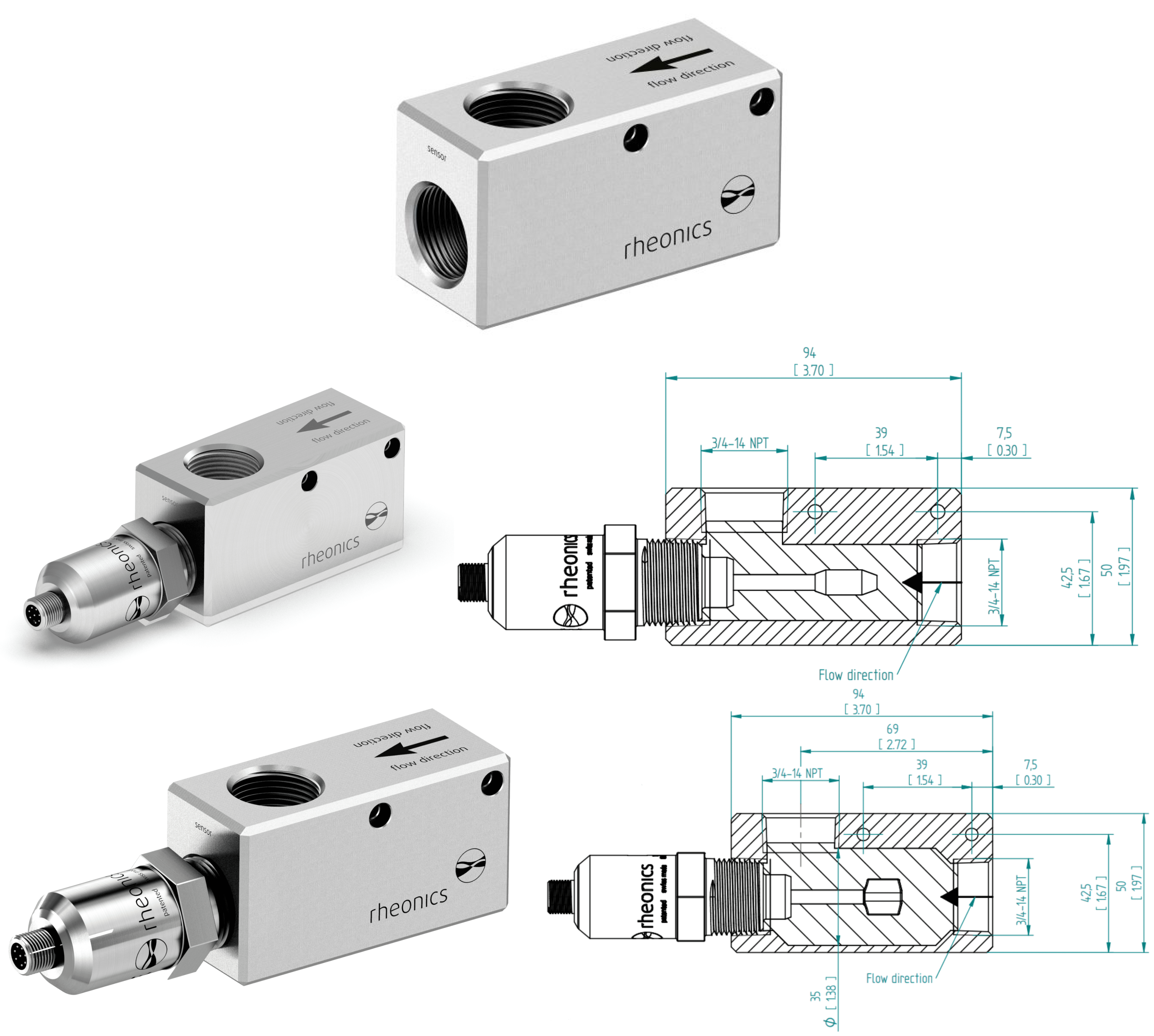

IFC-34N-SRX: Pipe installation flow cell

For DN5 to DN25 (1”) pipes inline installation, the IFC-34N-SRD flowcell fits well, positioning the probe paralell with a threaded NPT process connection, as shown in Figure 11.

The accessory works only with the SRV-X1-34N and SRD-X1-34N, both with 3/4” NPT threaded connections. It has inlet and outlet ports of the same size to connect tube adapters or tubes for recirculation or bypass lines. For details, see IFC-34N-SRV and IFC-34N-SRD.

Figure 11 – IFC-34N-SRX: Installation and dimensions

Process Conditions and Best Practices

Flow speed limit

Rheonics sensors are generally compatible with flow speeds up to 10 m/s, since atomizer supply lines, flow speeds can reach such high velocities to prevent settling, it is recommended to install the probe parallel to flow direction in elbows, as this can reduce mechanical impact, however, speeds in this range can still add too much noise to readings. For more details, see Rheonics Type-SR sensors for high flow rate and high viscous applications

Cleaning Process and CIP/SIP Procedures

Periodic cleaning of the SRV or SRD sensor might be necessary to ensure long-term accuracy. Coating fluids tend to form sediment or solid deposits that can adhere to the sensor tip and distort readings, especially in high-viscosity conditions. For more information on cleaning procedures, seeHow to clean your Rheonics probe?.

Additionally, the mechanical design of the sensors is hygienic by default, making the sensors suitable for Clean-in-Place (CIP) procedures.

Moving Parts and Obstructions

Coating solutions and materials are often prepared in mixing tanks with mechanical components such as stirring arms or paddles. It is essential to ensure sufficient clearance between the sensor and any moving parts to avoid interference or damage.

Bubbles

Regarding bubbles, the SRV sensor is not affected by the presence of bubbles in the fluid. In contrast, the SRD sensor, which measures both viscosity and density, is not recommended to be used with high concentrations of bubbles since this may lead to measurement inaccuracies, as the density measurement is more sensitive to these.

References

- [1] Metaltrade Comax. “Coil Coating line products”.

- [2] BDM Coil Coaters. “Premier Steel Coil Coating Solutions”.

- [3] ECCA. “Coil coating line animation”.

- [4] Rheonics SRV » inline online Viscometer for fluid viscosity monitoring

- [5] Rheonics SRD » Density Meter inline online specific gravity concentration