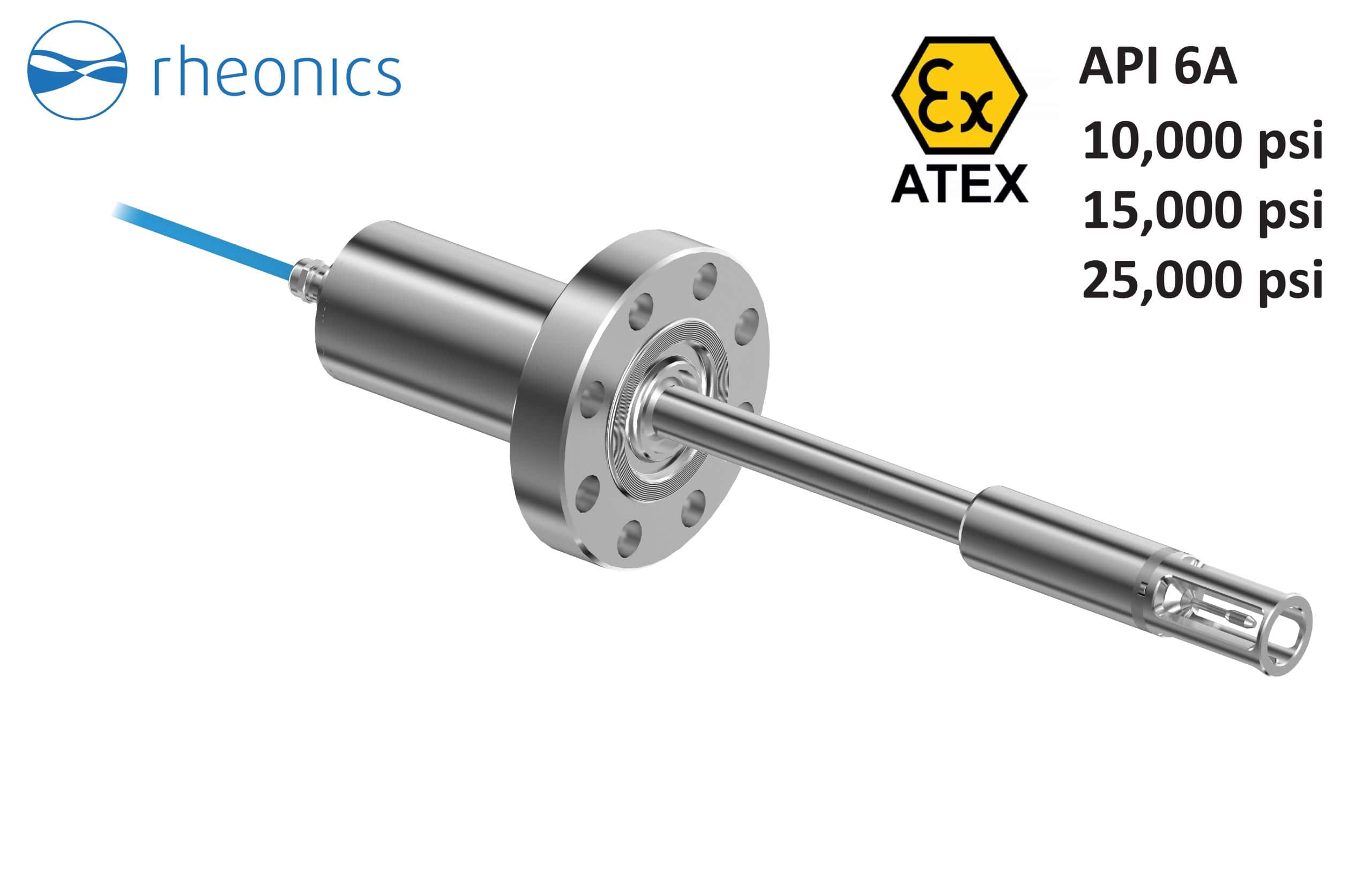

in-line, online, real-time viscosity & density meter for viscous, abrasive, sticky slurry

- Sensor probe with self-cleaning harmonics

- Eliminates need for removal and cleaning

- Continuous monitoring without concern for deposits

- Measures reliably in the most deposition prone slurries

- Major step towards Industry 4.0 compliance

- Eliminates manual plate-weight or efflux cup measurements

| Density Range (SRD only) | 0.0 - 4.0 g/cc 0.0 - 4000 kg/m3 0.0 - 33.38 lb/gal |

| Density Accuracy (SRD only) | 0.01 g/cc (0.001 g/cc & higher accuracy available) |

| Viscosity Range | 1 to 3,000 cP (SRD) 1 to 200,000cP (SRV) Wider range available |

| Viscosity Accuracy | 5% of reading (standard) 1% & higher accuracy available |

| Reproducibility | Better than 1% of reading |

| Temperature | -20 to 65 °C (-5 to 150 °F) |

| Material | Stainless Steel 316L |

| Sealing Material | Cleanwave - Sensor FKM (Fluoroelastomer, FPM, and Viton) |

| Total Length | Customizable |

| Installation Accessories | Mounting Base Installation Connection Adapters |

| Air Line Size | 6 mm |

| Air Line Pressure | 2-6 bar (30-90 psi) |

CleanWaveTM technology is integrated with Rheonics inline viscometer or Rheonics inline density meter and viscometer to create SlurrySense, a measurement probe that prevents deposits from forming using an inbuilt vibrator. The CleanWaveTM vibrations can be used continuously or intermittently to, respectively, prevent or slough off deposits. With the sensor probe cleanness maintained, the Rheonics inline viscometer or Rheonics inline density meter and viscometer can continuously provide reliable consistency readings without the need for operator cleaning interventions.

English Video Explanation:

Japanese Video Explanation:

Chinese Video Explanation:

| Title | Summary | Link | File Category | Products | Tags | Type | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|---|

| Article – Rheonics SlurrySense – INCAST 2025 | SlurrySense product article, presented in INCAST 2025 | Publications | SlurrySense | publications | ||||

| Presentation Deck – Rheonics SlurrySense – EICF 2025 | SlurrySense product deck describing operation and data examples, presented in EICF 2025 | Information and Training Decks | SlurrySense | training-deck | ||||

| Flyer – Rheonics SlurrySense Product Launch | Rheonics SlurrySense Product Launch Flyer | Datasheets & Brochures | SlurrySense | datasheets | ||||

| Flyer – Rheonics SlurrySense Technical Information | Rheonics SlurrySense Product Technical Flyer |

| Datasheets & Brochures | SlurrySense | datasheets | |||

| Drawing – Rheonics SlurrySense SRD | 2D drawing of Rheonics SlurrySense SRD and mounting adapter | Drawings | SlurrySense | drawings |

- All

- Adhesive

- Printing and Coating

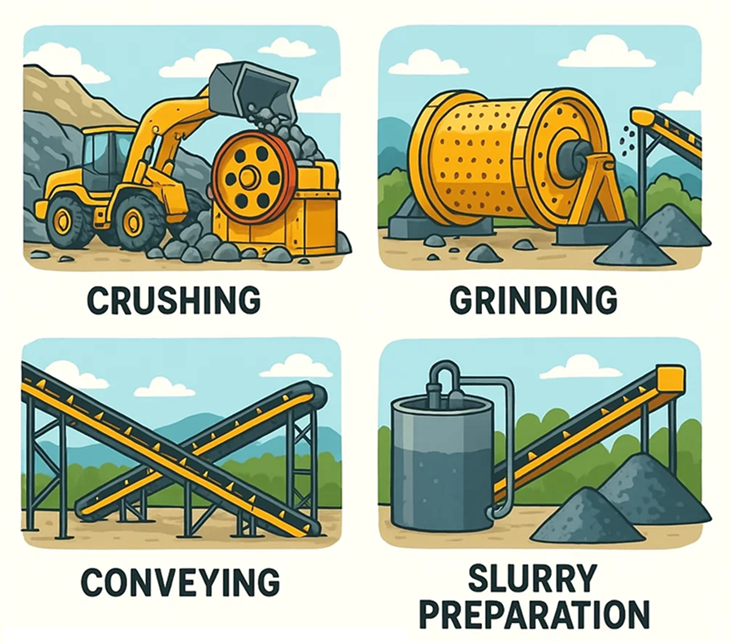

- Industrial Mixing and Grinding

- Food and Beverages

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Enhancing Safety and Process Control in Combustible Dust Environments with EX Certified Rheonics Density Meters and Viscometers

Combustible dust poses a significant explosion risk across industries such as food processing, chemicals, mining, and metal powders. This application…

Viscosity Management in Medical Device Coatings: Enhancing Performance and Compliance

Viscosity and density play a crucial role in medical device coatings, directly impacting product cohesion, surface quality, and therapeutic effectiveness…

Optimizing Hotmelt Adhesive (HMA) Processes with Advanced Viscosity Control

Adhesive hotmelt’s viscosity is a critical property, as it directly impacts its ability to be applied and form a strong…

Monitoring Battery Slurry Production with Inline Viscometers and Density Meters

In battery manufacturing, viscosity and density play a critical role in achieving consistent slurry quality, optimizing performance, and improving the…

Inline Viscosity and Density Monitoring for Gelatin Capsule Production

Capsules are a solid oral dosage form used for the delivery of medical drugs, vitamins, minerals, and other health-related ingredients…

Automating and optimizing mining operations with Rheonics Sensors and Solutions

The mining industry has always been known for its complexity and hard environments. From ore extraction to final product recovery,…

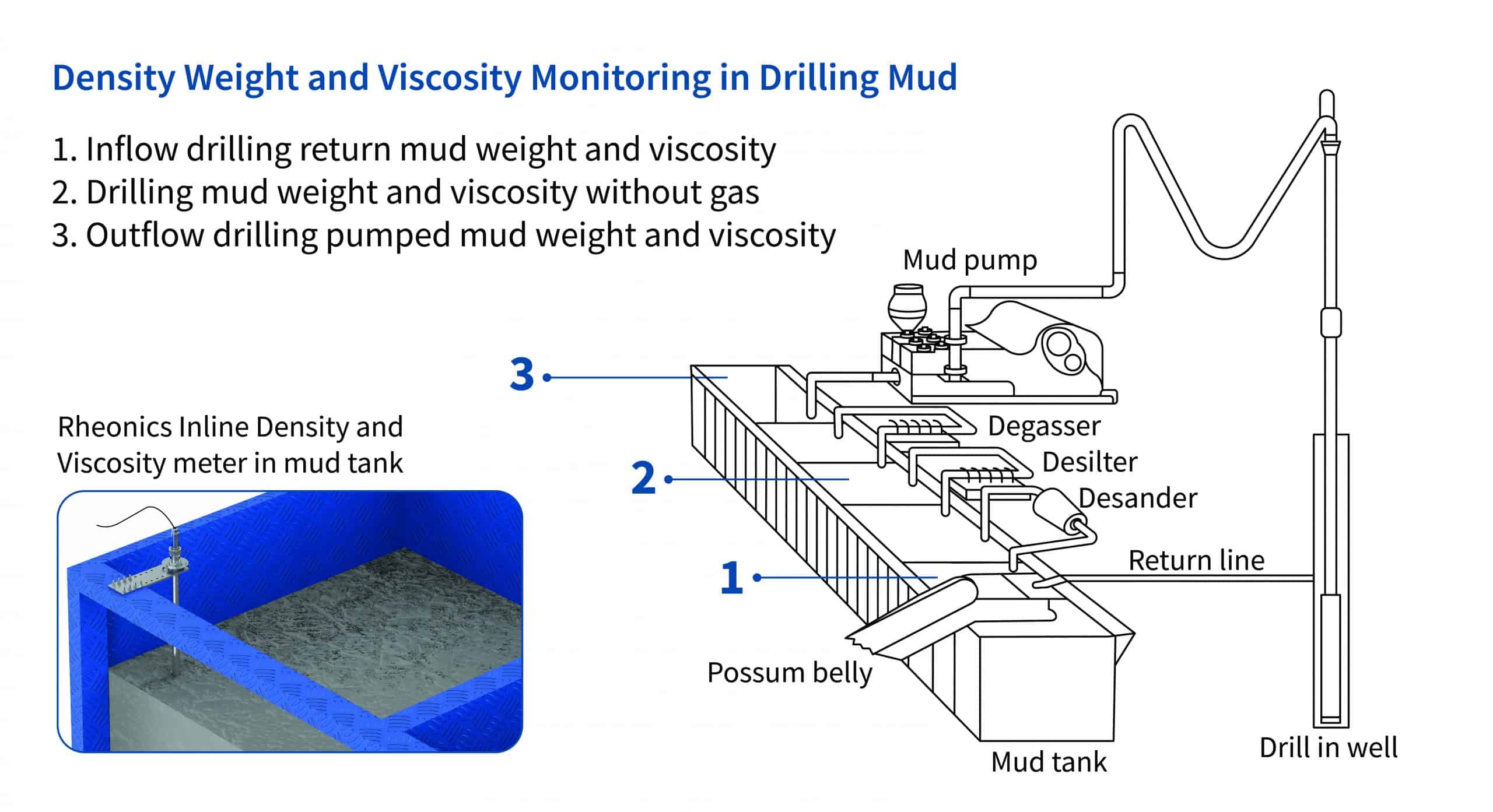

Drilling Mud Weight and Viscosity Monitoring to Optimize Well Performance

Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or…

Adhesives and Sealants Industry Overview and Rheonics Sensors Use

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Density and Concentration Brine pond monitoring in lithium extraction process

Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process…

Monitoring Density and Viscosity in 3D Cement Printing

Density and viscosity are critical parameters in 3D cement printing as they directly affect the printability, structural integrity, and layer…

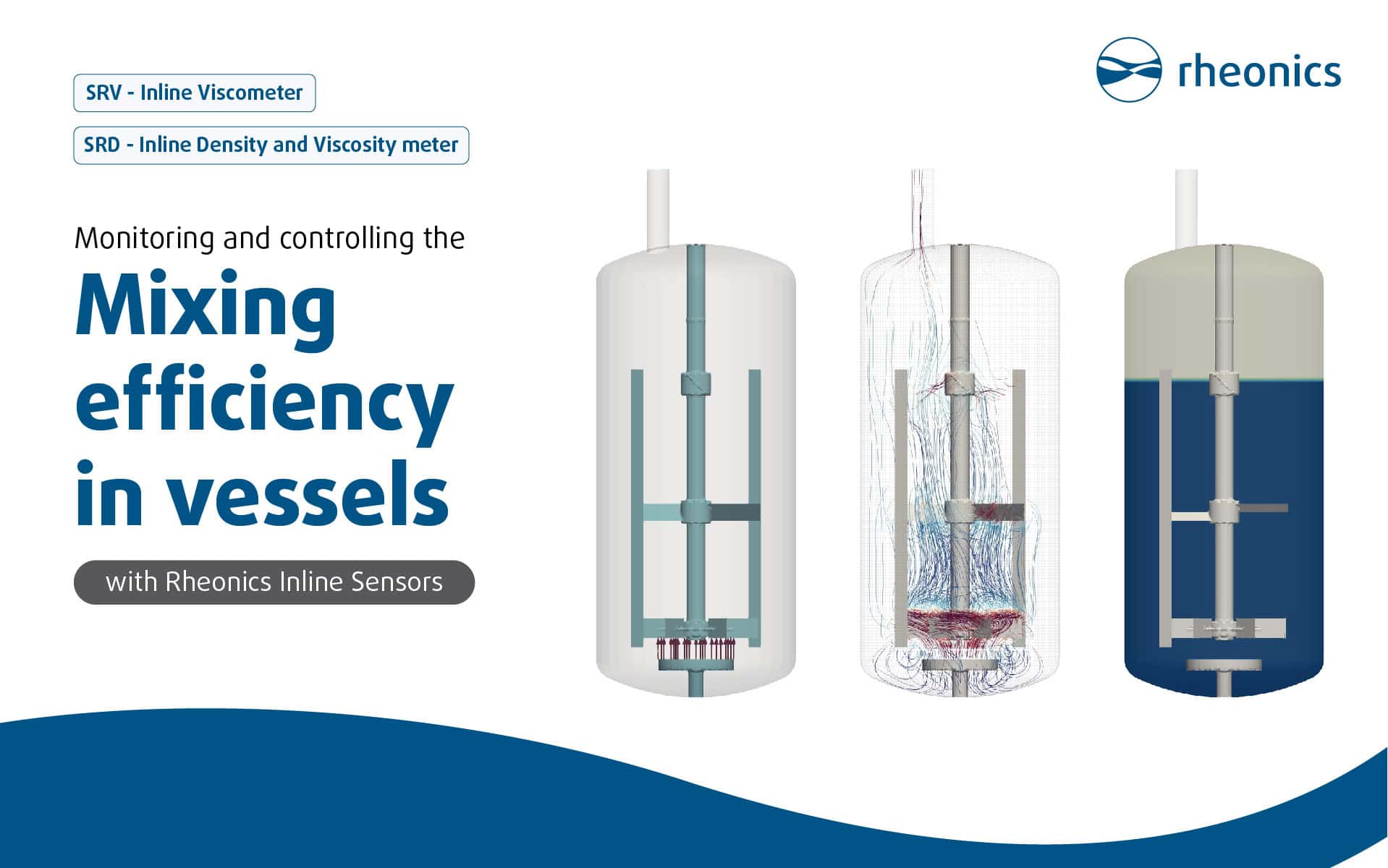

Mixing vessels – monitoring and controlling the mixing efficiency

Rheonics process viscometer SRV or Rheonics process density and viscometer SRD can be installed in a variety of locations in…

DeSander and Separator sand level realtime monitoring for automatic removal

The ability to monitor the level of sand in desanders, separators, and flowback systems allows for automation and higher efficiency…