Adhesive hotmelt’s viscosity is a critical property, as it directly impacts its ability to be applied and form a strong bond. In modern production, inline viscosity monitoring has become an essential tool for real-time quality control, ensuring batch-to-batch consistency and preventing defects that could arise from incorrect viscosity levels.

- 1. Introduction

- 2. Industry Overview

- 2.1 Hotmelt Adhesives HMA

- 2.2 Types of HMA

- 2.3 Hotmelt adhesive production process

- 2.4 Key monitoring parameters

- 3. Rheonics Inline Viscometer

- 3.1 SRV viscometer installation for HMAs production process

- 3.2 Benefits of inline viscosity monitoring

- 4. References

Introduction

Hotmelt adhesives (HMA) are complex formulations of polymers, resins, waxes, and additives that give them their unique properties. Customers rely on the adhesive to perform consistently in their application, like packaging, bookbinding, product assembly, etc. Thus, a way to monitor its composition inline is fundamental for quality assurance. Viscosity is a key parameter to monitor the HMA production for a multitude of reasons, impacting everything from raw material quality to final product performance and production efficiency.

Industry Overview

Hotmelt Adhesives HMA

A hotmelt adhesive (HMA) or “hot glue” is a type of thermoplastic polymer adhesive that has a solid state at room temperature and is applied as a molten liquid due to heating. Heating is normally done with heat guns or similar devices, these transform the glue solid state to a molten or liquid state that creates a bond by cooling and solidifying. This mechanism of setting purely by the loss of heat is a fundamental characteristic and a primary advantage of HMAs, as it eliminates the drying or curing steps often required by solvent-based or water-based adhesive systems [1].

HMA has key characteristics that make them a widely used adhesive:

- Fast setting speed: Creates a bond within seconds after application.

- Solvent free composition: Reduces or eliminates Volatile Organic Compound (VOC) emissions.

- Versatility in Substrate Bonding: porous (e.g., paper, wood) and non-porous substrates (e.g., plastics, metals).

- Good for gap filling use: Minimum or no shrinking after cooling

- Long Shelf Life: In their solid state, HMAs are easy to store and transport with minimum requirements to maintain their characteristics

- Different presentations: Commonly used as glue sticks, but also available as Pellets, Chips, Pillows, Blocks and Slats.

![Figure 2: HMA’s application using hot guns [2]](https://rheonics.com/wp-content/uploads/2025/08/image-20250721-190417.jpg)

Types of HMA

The types of Hot Melt Adhesives (HMAs) are predominantly classified and understood based on their primary base polymer. This is because the base polymer forms the “backbone” of the adhesive and largely dictates its fundamental properties, such as strength, flexibility, adhesion to different substrates, thermal stability (how well it performs at high or low temperatures), chemical resistance, melt viscosity, cost, and open time. While tackifiers, waxes, plasticizers, and other additives are crucial for fine-tuning specific performance characteristics, the base polymer provides the inherent capabilities of the HMA.

| HMA Polymer Base | Key Characteristics | Typical Melt Viscosity Range (cP at specified temp) | Typical Application Temp. Range (°C/°F) | Common Applications |

|---|---|---|---|---|

| EVA (Ethylene-Vinyl Acetate) | Low cost, versatile, good adhesion to cellulosic materials, fast setting, generally easy to process | 500 - 5,000 cP (typical, varies widely) | 150-180°C / 302-356°F | Packaging, woodworking, bookbinding, assembly |

| PE (Polyethylene) | Good for porous substrates (cartons), good thermal stability, low odor, moisture barrier | 1,000 - 3,000 cP | 160-190°C / 320-374°F | Packaging (carton sealing) |

| APAO (Amorphous Polyalphaolefin) | High heat resistance, tacky, soft, flexible, good thermal stability, bonds to difficult substrates | 500 - 15,000+ cP | 160-190°C / 320-374°F | Hygiene products, automotive, textiles, product assembly (plastics, foam) |

| mPO (Metallocene Polyolefin) | Precise properties, reduced material use, good thermal stability, low odor, minimal stringing, extreme temp capable, some grades offer renewable content. | 500 - 5,000 cP | 150-180°C / 302-356°F | Packaging (food, freezer-to-microwave), assembly, nonwovens |

| PA (Polyamide) | High temp resistance, high temperature application, oil/chemical resistance, good adhesion to metals & some plastics, can be expensive | 2,000 - 10,000+ cP (often higher) | 185-215°C+ / 365-419°F+ | Automotive, electronics, demanding woodworking, filters |

| PUR (Polyurethane Reactive) | Very strong bonds, moisture-curing (crosslinks), excellent thermal/chemical resistance, flexible, more expensive | 2,000 - 60,000+ cP | 100-140°C / 212-284°F | Woodworking, construction, automotive, electronics, bookbinding, product assembly |

| SBC (Styrenic Block Copolymer) | Rubber-based, good low-temp flexibility, high elongation, often used for Pressure Sensitive Adhesives (PSAs) | 500 - 50,000+ cP (for PSAs) | 150-180°C / 302-356°F | Tapes, labels, hygiene products, elastic attachment |

Hotmelt adhesive production process

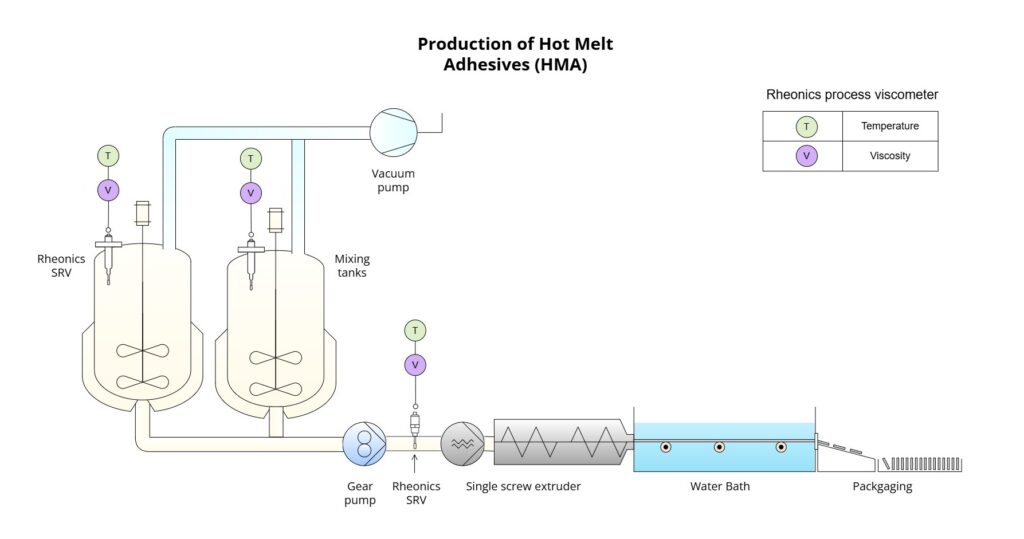

HMA’s production can vary depending on the type of adhesive desired. Figure 3 shows a production process example where adhesive mixing is done in tanks, then the melted material is pumped through a single screw extruder and a die that gives the adhesive its final shape. The HMA is finally cooled down using a water bath and finally cut in the required length. Next, the main steps are described.

Raw Material Preparation

The specific raw materials are carefully selected and precisely measured according to the desired formulation for the hot melt adhesive. Different polymers, tackifiers, waxes, and additives, all in solid state, are chosen based on the intended application and required performance characteristics.

Melting and Mixing

The solid raw materials are then transferred to a mixing vessel or reactor with jacketed vessel to achieve the required melting temperature. Alternatevily, mixing can be done in twin-screw extruders that will also do the final extrusion later.

During the mixing process, materials are heated to a specific temperature (typically between 100°C to 235°C, depending on the formulation). When heated, the intermolecular forces holding the polymer chains together weaken, allowing the material to flow, resulting in a molten flowable state, the so-called liquefied material. [3] It is from this material state that key process parameters are taken, evaluated and characterized for production quality ensurance.

Agitators or the screws in an extruder ensure thorough and homogeneous blending of all components. This melting and mixing step is critical for achieving consistent quality, viscosity, and functionality of the final product.

Important: Hot melt adhesives (HMAs) are unique in that they are 100% solid and do not use water or solvent as a carrier. This is a major advantage, as it eliminates drying or curing steps and reduces environmental concerns associated with volatile organic compounds (VOCs). This is a thermoplastic polymer, meaning they become plastic or malleable upon heating and solidify upon cooling.

Note: Most hot melt adhesives are thermoplastic, which means they become liquid when hot and solidify when cool. They are also reversible; meaning that if reheated enough, they’ll melt again and lose their internal strength.

To avoid losing bond strength at high temperatures (unless reversibility is intended), the adhesive’s polymer molecules need to be chemically crosslinked after they’ve set. This crosslinking makes the bond more permanent and resistant to heat. It is achieved by adding specific reactive components into the adhesive formulation during its mixing. Hot melts that undergo this chemical reaction after cooling are called reactive hot melt adhesives. Polyurethane Reactive (PUR) hot melts are an example of reactive HMAs.

Degassing

In some cases, especially for applications where air bubbles could negatively affect performance, a degassing step is included. This involves applying a vacuum to the molten adhesive mixture in the vessels to remove any trapped air or volatile components.

Filtration

The molten adhesive can be passed through a filtration system. This removes any impurities, undissolved particles, or foreign matter, ensuring the purity and quality of the final product.

Extrusion and Cooling

The molten adhesive is then extruded through a die into the desired form, such as pellets, chips, blocks, sticks, or sheets. Immediately after shaping, the hot melt adhesive is cooled rapidly, often using cooling belts or water baths. This rapid cooling causes the adhesive to solidify into its solid form.

Packaging

Once the hot melt adhesive passes all quality control checks, it is packaged into various containers suitable for distribution and application, such as bags, drums, cartridges, or other specialized forms, depending on the end-user’s needs.

Key monitoring parameters

Several performance properties of hotmelt adhesives are critical for ensuring smooth and efficient production processes and achieving desired bond quality. Key parameteres in production are measured in the liquefied material state, while other tests are done with the solids raw materials and final adhesive, these are called selection criteria parameters [3].

Temperature:

Mixing temperature is crucial for ensuring all components melt and blend homogenously. Melt Temperature is the temperature of the molten adhesive just before extrusion or packaging, this impacts final viscosity and workability.

Viscosity: Defined as the molten adhesive’s resistance to flow, viscosity has a paramount importance. It dictates how easily the adhesive can be pumped and applied, its ability to wet the substrate surface for good adhesion, and the control over bead size or spray pattern. Viscosity is highly dependent on temperature; an increase in temperature typically leads to a decrease in viscosity. Uncontrolled or out-of-specification viscosity during mixing and right before extrusion is a primary source of many production line problems, from inconsistent application to bond failure.

Mixing Speed/Shear: The intensity of mixing is critical for homogeneity, so it must be controlled to ensure uniform dispersion of components without degrading shear-sensitive polymers.

Pressure: Monitored within extruders or mixing vessels to ensure smooth flow and prevent blockages. Vacuum pressure is relevant when vacuum is required.

With the final product, after extrusion, additional parameters are evaluated, such as:

Softening Point: This is the temperature at which the solid HMA begins to soften and flow, or become plastic. It is largely determined by the type of base polymer and the amount and type of wax in the formulation. The softening point guides the minimum application temperature and influences the heat resistance of the final bonded assembly.

Open Time: This refers to the maximum period allowable after the molten adhesive has been applied to the first substrate, within which the second substrate must be brought into contact to form a satisfactory bond [4]. The open time must be carefully matched to the speed and mechanics of the assembly process. If it’s too short, poor wetting and a weak bond will result. If it’s too long, production speed may be compromised, or parts may shift before the bond sets.

Set Time (Setting Speed): This is the time required for the HMA to cool and solidify sufficiently to form a bond of acceptable strength, allowing the assembled parts to be handled or moved to the next stage of production. Fast set times are one of the principal advantages of HMAs, contributing to high production speeds.

Pot Life Stability: This property describes the ability of the HMA to maintain its specified characteristics (e.g., viscosity, color, absence of charring or gelling) when held in a molten state within the application equipment’s tank or reservoir for extended durations. Poor pot life leads to adhesive degradation, which can cause nozzle clogging, inconsistent application quality, and increased equipment maintenance. Antioxidants are typically included in HMA formulations to improve pot life stability.

Rheonics Inline Viscometer

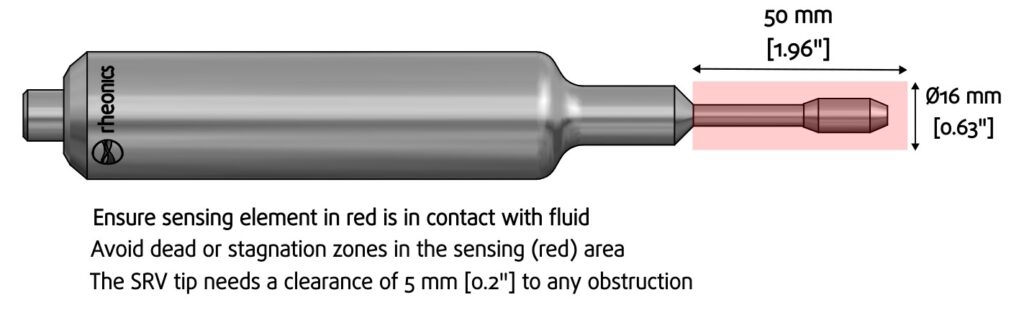

Rheonics SRV is an inline process viscometer that measures a wide range of viscosity and temperature in real-time. It is suitable for installation in mixing and storage tanks, and in pipelines for continuous measurement of process fluid. Rheonics SRV is compatible with high-speed mixing processes and is unaffected by the presence of bubbles in the fluid or external vibrations.

Rheonics sensors are based in the patented Balanced Torsional Resonator (BTR) technology, which enables the probe to be compact and light, yet robust for the industrial environment and compatible with high temperature applications (up to 285°C), vacuum and high pressure applications. Rheonics SRV has no moving parts, it is a hermetically sealed probe offered in Stainless Steel 316L wetted material.

The SRV sensor is offered in different probe variants, varying in length and process connection, which ensures easy installation for each application. All SRV probes use the same sensing element, which enables easy scalability in production processes.

SRV viscometer installation for HMAs production process

As previously explained, viscosity is a critical parameter for HMAs as it directly impacts their processability, application performance, and ultimately, the final bond strength. By using Rheonics SRV inline viscometer, both viscosity and temperature can be monitored inline, especially recommended during mixing and extrusion processes, as shown in Figure 3.t.

Installation in Tank

Rheonics SRV can be installed in tanks from the bottom, wall or top sections. This depends on the tank’s design, i.e. size, jacketed walls and mixing shafts interferences, etc. and user’s preferences like accesibility, ease for installation etc.

For a correct SRV sensor installation in tank for HMAs production monitoring, next recommendation should be followed:

- Ensure sensing element is in contact with the molten material. For installations from the tank’s top this may require using a long insertion SRV. In wall and bottom installations, avoid dead zones that can lead to stagnation zones affecting the sensing area – see Figure 5.

- Make sure the SRV probe won’t be damaged by the mixing shafts inside the tank.

Figure 6: SRV installation options in tank and recirculation lines – Rheonics inline viscometer and density meter in tank and recirculation line for mixing processes

Installation in Line

Lines used to transport the hotmelt adhesive from the mixing tank to the extruders need to maintain a high temperature and pressure to ensure constant fluid properties. To achieve this, pipes are jacketed and positive displacement pumps are used such as gear or piston pumps. Gear pumps are prefered to ensure smooth, continous flow, while piston pumps enable high pressure in lines but produce a slightly pulsating flow.

Rheonics SRV is suitable for installations inline even at high temperatures and pressures. SRV operates with static and flowing fluids, and have no operation issues with pulsating flow. The recommended SRV installation in pipelines for HMAs is in an elbow, with the probe against the fluid flow direction.

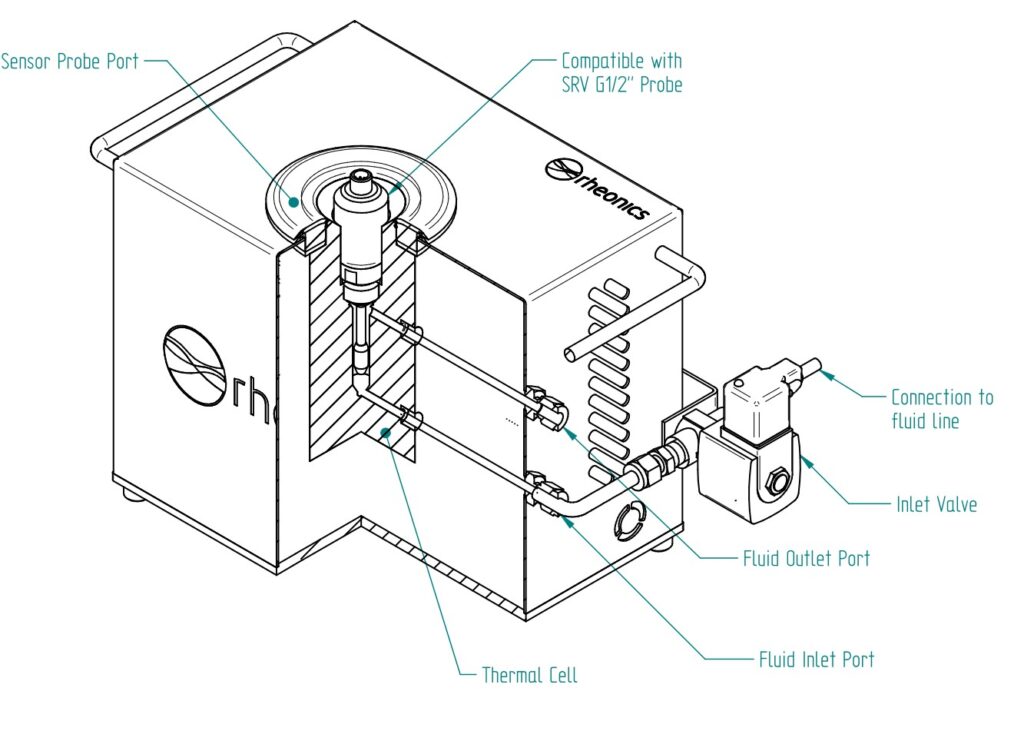

Installation in small or by-pass line

It is common to use small or by-pass lines connected to main lines in hotmelt adhevise production to take samples and study the rheological properties of the fluid. In these lines, it is key to maintain certain pressure and temperature for the fluid.

In this scenario, Rheonics offers accessories such as:

- Flow cells: See all SRV inline flow cells.

- Heating chamber: Rheonics STCM-IFP is an inline chamber that allows temperature control and good temperature isolation, maintaining the temperature of the fluid as it comes.

Figure 7: Inline Thermal Chamber for SRV Viscometer Rheonics STCM Line for Type-SR » rheonics :: viscometer and density meter

Benefits of inline viscosity monitoring

- Real-time Feedback and Control:

Unlike offline lab tests which provide delayed results, Rheonics inline SRV viscometer gives instantaneous, continuous data. This allows operators to see precisely how the viscosity is developing as raw materials are added and mixed. This enables immediate adjustments to process parameters like temperature, mixing speed, or even raw material feed rates.

- Easy Data Integration:

Rheonics SRV uses a powerful electronics, called SME. This device takes readings from the sensor probe and outputs the measured viscosity and temperature. It also runs multiple industrial communication protocols natively, such as Modbus, Profinet, Ethernet/IP, HART, etc. for integration with local monitoring and control systems.

- Improved Product Consistency and Quality:

By maintaining tighter control over viscosity during production, manufacturers can significantly reduce batch-to-batch variations. This leads to more consistent product quality, fewer off-spec batches, and ultimately, happier customers.

- Optimized Production Efficiency:

Detecting deviations early means problems can be corrected before an entire batch is ruined, reducing waste of expensive raw materials and energy.

Energy Optimization: Knowing the exact viscosity allows for optimizing mixing energy input and heating, potentially leading to energy savings.

- Process Understanding and Troubleshooting:

Rheonics SRV provides a comprehensive historical record of HMAs viscosity and temperature. This data is invaluable for process optimization, identifying trends, and quickly diagnosing the root cause of any production issues that may arise.

- Reduced Manual Intervention and Safety:

Automated inline measurement reduces the need for manual sampling, which can be hazardous given the high temperatures of molten HMAs. It also frees up labor for other tasks.

References

[1]:Properties, Types & Applications of Hot Melt Adhesives

[3]: https://www.klebstoffe.com/wp-content/uploads/2020/04/TKH_4_englisch.pdf