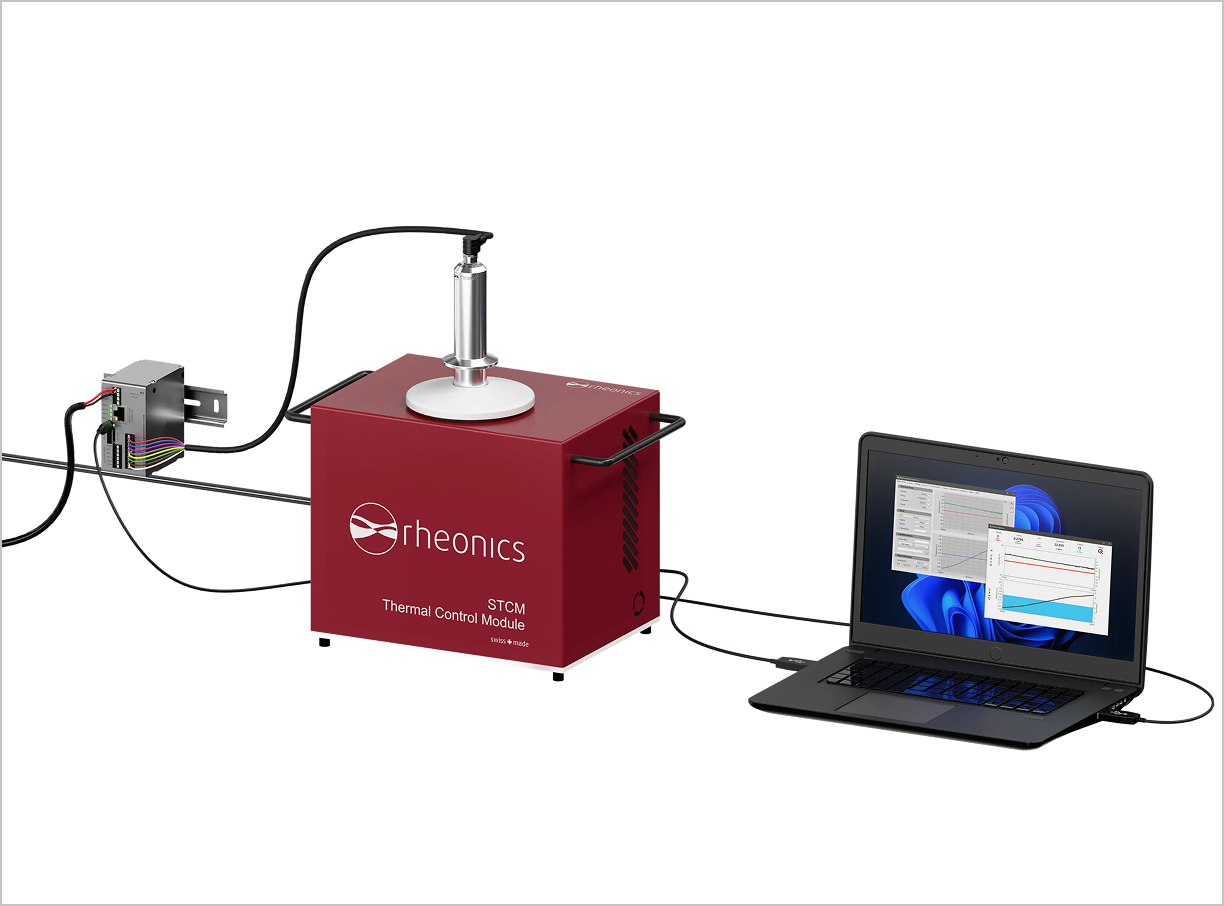

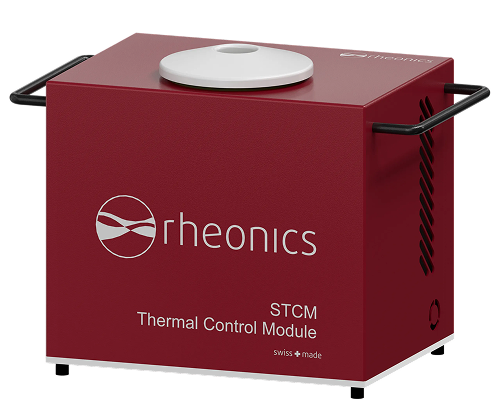

Rheonics STCM-PL

Type-SR Temperature Control Module – Solid State TCM Version

- Static fluid measurement setup for Type-SR Sensor probes (SRV ans SRD)

- Integrated solid-state heating and cooling module

- Fluid temperature range: 10 °C (or 15 °C below room temperature) up to 150°C

Specification

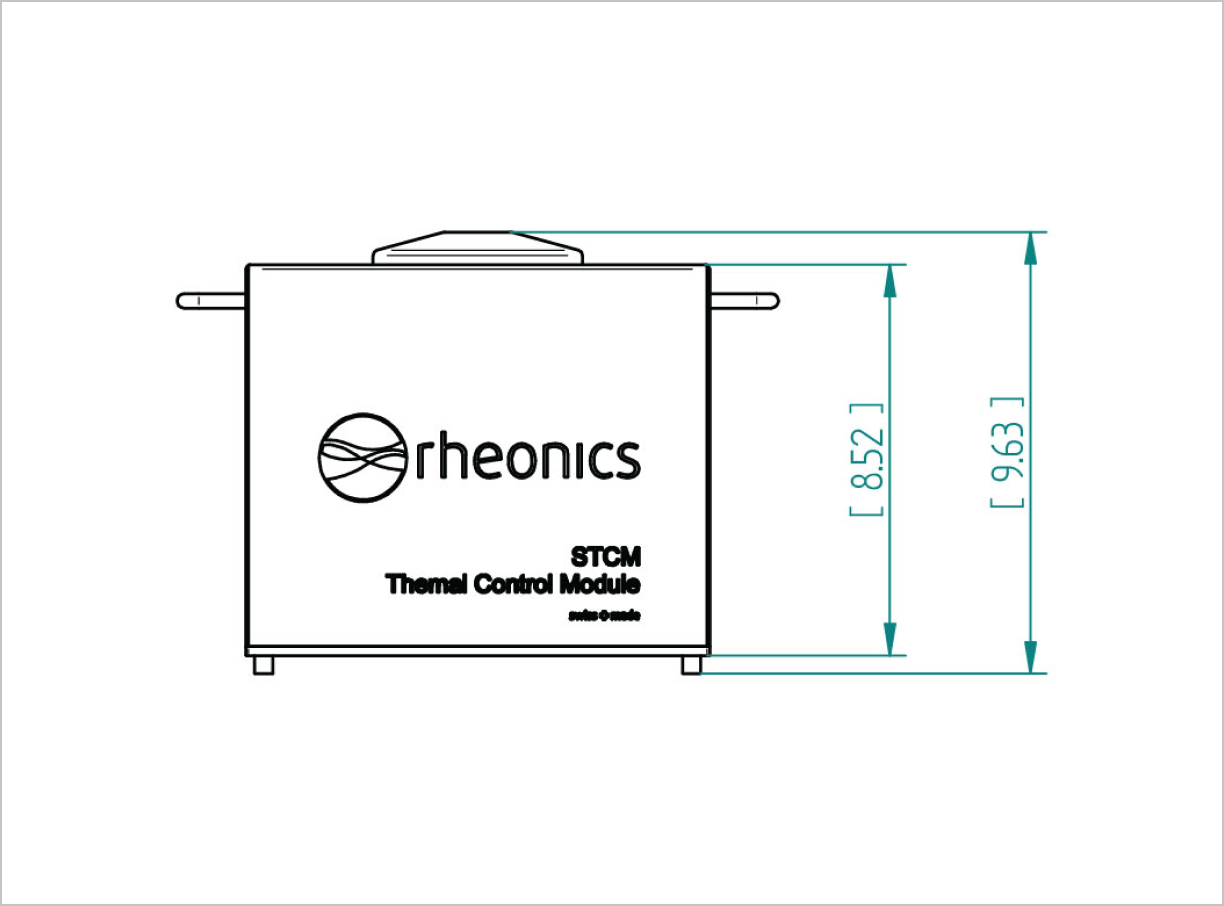

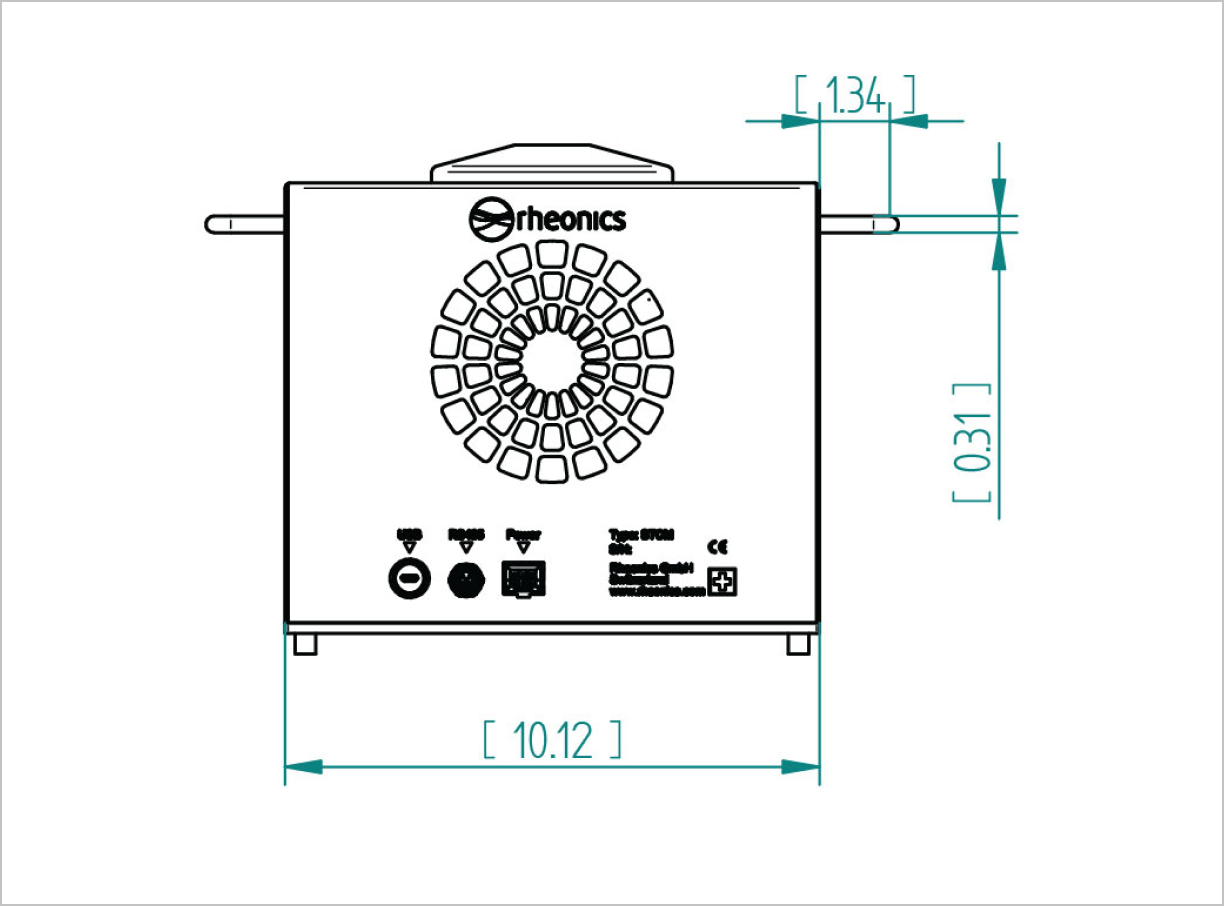

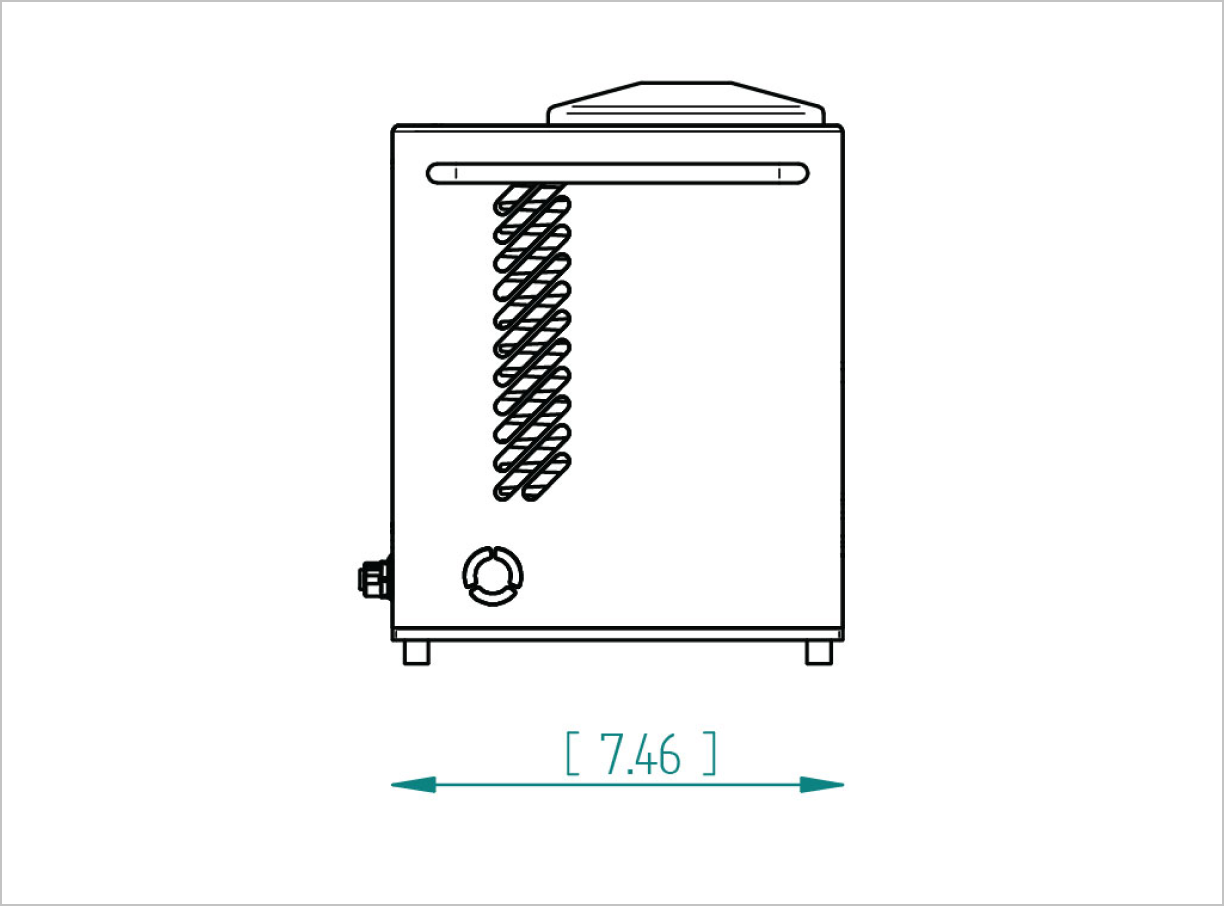

380 × 235 × 220 (mm)

15 × 9.5 × 8.5 (inch)

110/220 V AC

max. 360W

11 Kg (24 lb)

10 °C (or 15 °C below room temperature) up to 150°C

max. 65 °C ambient

max. 150 °F ambient

0.005 °C

- SME-BOX (E4)

- Laptop or PC

- RPS

USB-C and RS-485

How does it work?

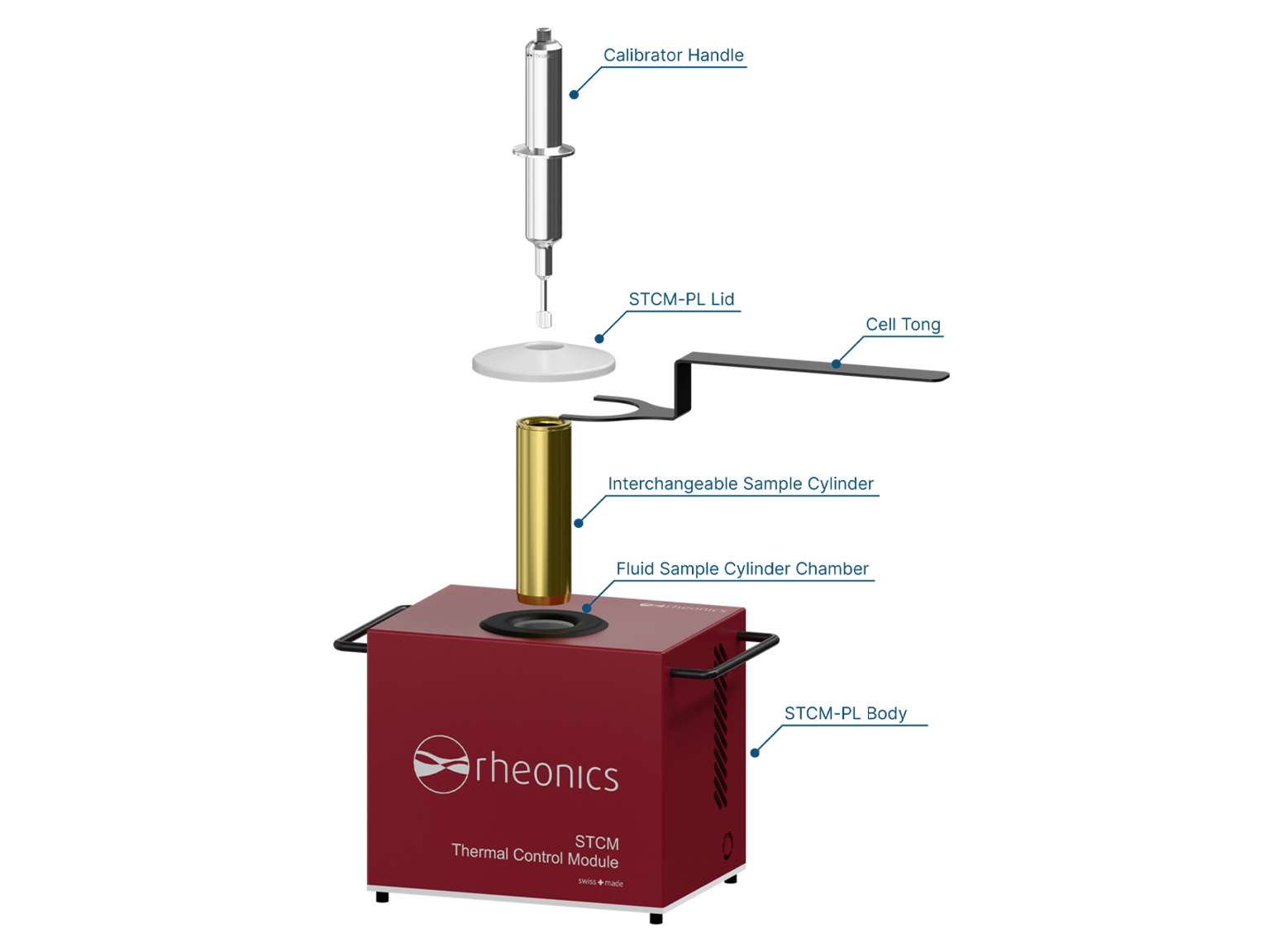

Prepare it

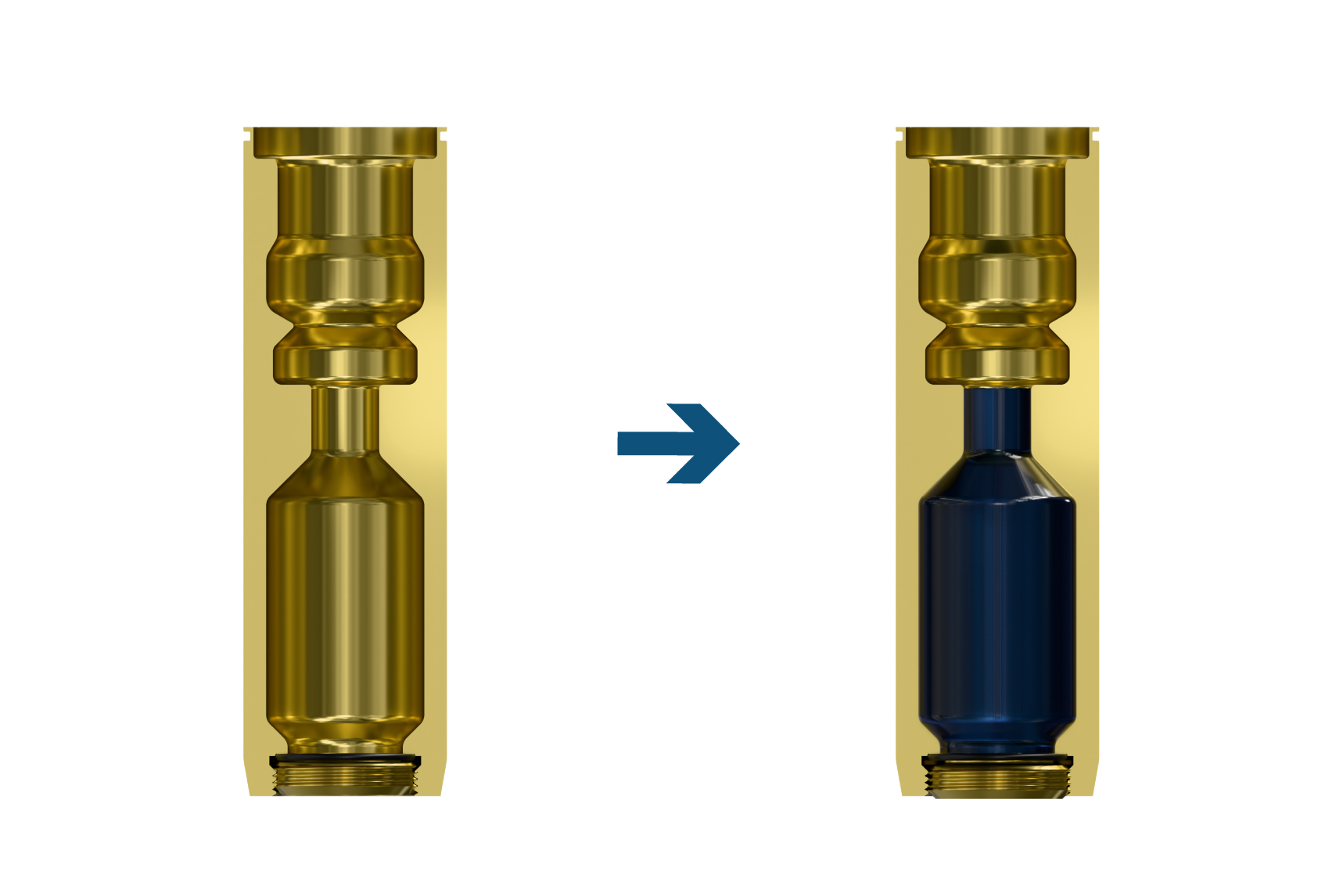

The STCM-PL uses a Thermal Cell that should be filled with the desired fluid and then place the sensor probe within it.

Assemble it

The Type-SR sensor probe and fluid sample cylinder are placed in the

STCM-PL.

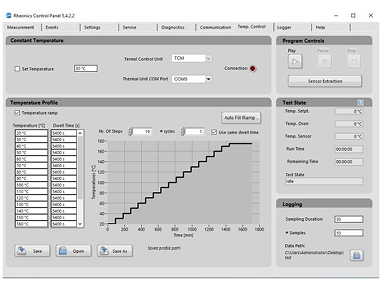

Start Measuring

The Temperature Control Interface on the RCP-TCM software is then used to control the temperature of the fluid, record, and save the data measured.

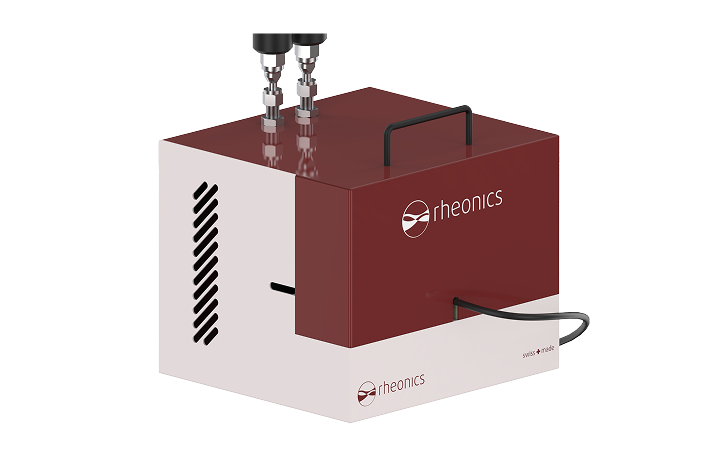

STCM-PL Overview

The STCM-PL is a Rheonics Thermal Control Module for measuring fluid properties at different temperature setpoints using Rheonics SRV inline process Viscometer or SRD Inline process density meter and viscometer. The STCM-PL is designed for laboratory and in-field mobile setups where accurate readings of viscosity and density are needed while maintaining a tight control of temperature.

Heating and cooling are achieved through a solid-state heating and cooling module with an advanced model-based controller. The STCM-PL was designed after extensive simulation and testing to ensure a high level of thermal stability, accuracy, and repeatability.

Rheonics STCM-PL eliminates the need for bulky and expensive thermal test chambers (climate chambers) for temperature control. It reduces the footprint of the thermal module to the same size as a Nespresso coffee machine while achieving 10x better stability and uniformity compared to a 100L commercial thermal chamber.

STCM-PL Comparison

When temperature control is required for the Type-SR sensors’ operation, some alternatives to the STCM-PL are baths and thermal ovens. These are commonly used but have disadvantages, predominantly in the form factor and temperature accuracy.

The main difference between the use of the STCM-PL and other laboratory standard setups for static fluids in controlled temperatures (e.g., beaker in laboratory ovens) is the accurate and stable temperature control of the fluid that the STCM-PL achieves. Temperature is a key parameter of a fluid; it affects the way particles interact within the fluid, hence it has a significant impact on the viscosity. Temperature should be controlled and maintained constant to achieve accurate and reliable viscosity and density readings.

| Rheonics STCM-PL vs. Alternative Temperature Control Systems | |||||

|---|---|---|---|---|---|

| Product Characteristics |  |  |  |  |  |

| Name | Rheonics STCM-PL | Heat Trace | Viscosity and Density Bath | Laboratory Oven | Climate Chamber |

| Size | 380 x 235 x 220 (mm) | 380 x 235 x 220 (mm) | 380 x 235 x 220 (mm) | 380 x 235 x 220 (mm) | 380 x 235 x 220 (mm) |

| Temperature Range | 10 °C to 150 °C | 10 °C to 150 °C | 10 °C to 150 °C | 10 °C to 150 °C | 10 °C to 150 °C |

| Temperature Accuracy | 0.05 °C | 0.05 °C | 0.05 °C | 0.05 °C | 0.05 °C |

TCM Product line

STCM-IFP

Integrate the device directly in a bypass line for static viscosity analysis. A dedicated valve controls the intake of new fluid samples, while an integrated solid-state module provides active heating and cooling for precise fluid temperature control.

See More

STCM-BB

Take a sample from the process and measure the viscosity and/or density of the fluid. Uses an External bath for temperature control.

Calibrator

Use the Rheonics Calibrator along with the Rheonics Calibrator Software to certify your SRV and SRD sensor calibration.

DTCM-PL

Ensure uniform temperature distribution across the DVM sensor to enable High-Pressure High-Temperature measurements. Uses a Solid-State Heating and cooling module for temperature control.

DTCM-BB

Ensure uniform temperature distribution across the DVM sensor to enable High-Pressure High-Temperature measurements. Uses an External Bath for temperature control.