System Integrators

Ensure integration success for reliable factory operations. A structured approach yields maximum value when engaging an integration partner.

Employing a system integrator can help manufacturers improve their operational structure. To minimize expenditures and risk, and to speed implementation for integration success, system integrators need to adopt a structural approach.

Steps to system integration success

Rheonics works with System Integrators and Machine Builders to equip them deliver density and viscosity management solutions along with their machines to their end-users. End-users are constantly looking to reap full benefits of Industry 4.0, digitalization and factory automation, and we look forward to empowering machine builders achieve exactly what the factory users need for their processes.

Industry Focus and Expertise

Food and Beverages

Rheonics sensors come with special process connections to maintain the hygienic standards for food applications.

- Batter mixing

- Chocolate

- Dairy products

- Food emulsions

Pharmaceuticals

Broad portfolio of companies in pharmaceutical industry who have deployed Rheonics sensors for their process precision needs and compliance requirements.

- Pharmaceutical printing

- Tablet coating

- API manufacturing

- Medicines and drugs – eye drops, cough, nourishments

Coating

Custom-built solutions from Rheonics help coating machine builders enable the coating consistency for their application and helps their end-users move towards zero-defects.

- Automotive painting and coating

- Anti-corrosion coating

- Battery electrode coating

- Coils, sheet metal and wire enamel coating

- Sealants and adhesives coating

Printing

Turnkey integrated automation solution for full control over your printing and coating process. InkSight measures and controls viscosity within 0.5 cps : 100 times greater resolution than average efflux cups. Rheonics has deep expertise working with printing equipment builders and empowering them with the much needed ink viscosity management solutions.

- Printing presses – Flexographic, gravure, corrugated, rotogravure

- Contact lens printing

- Pad printing

- Water-based and solvent-based inks

Investment Casting

Inline viscosity monitoring solutions help investment casters achieve advanced process control over the slurry preparation (mixing) and coating process to build top-quality and defect-free shells with more real-time insights into their processes.

- Shell-building for investment casting for use in aerospace, automotive, gas turbines

- Maintains the set slurry viscosity in mixing tanks regardless of temperature and humidity fluctuations, mixing equipment condition – no need of efflux cups and hydrometers

- Reduction in lead times, enhance capacity utilization, reduce scraps and wastes and optimize efficiency

Solutions Portfolio - density and viscosity management

SENSORS

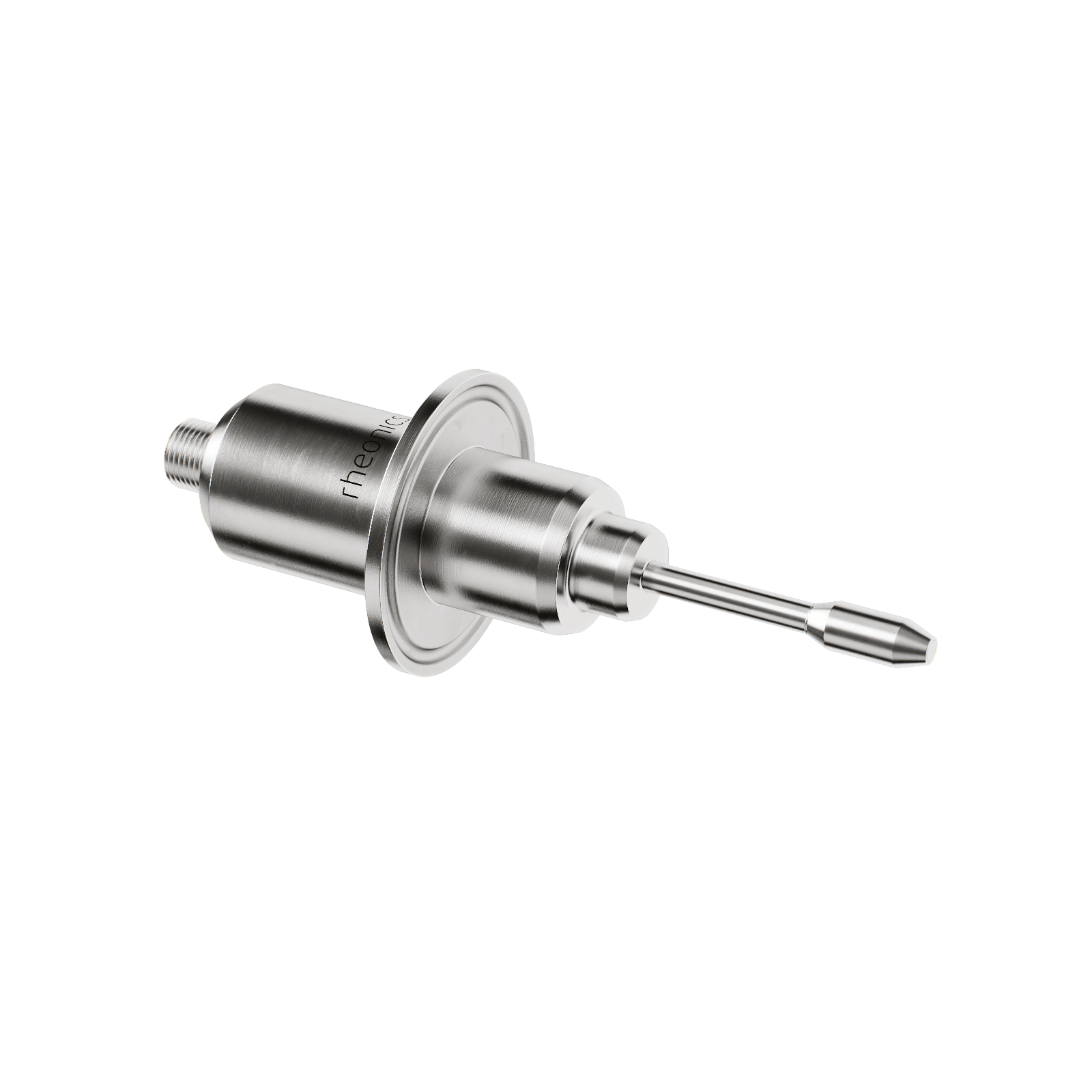

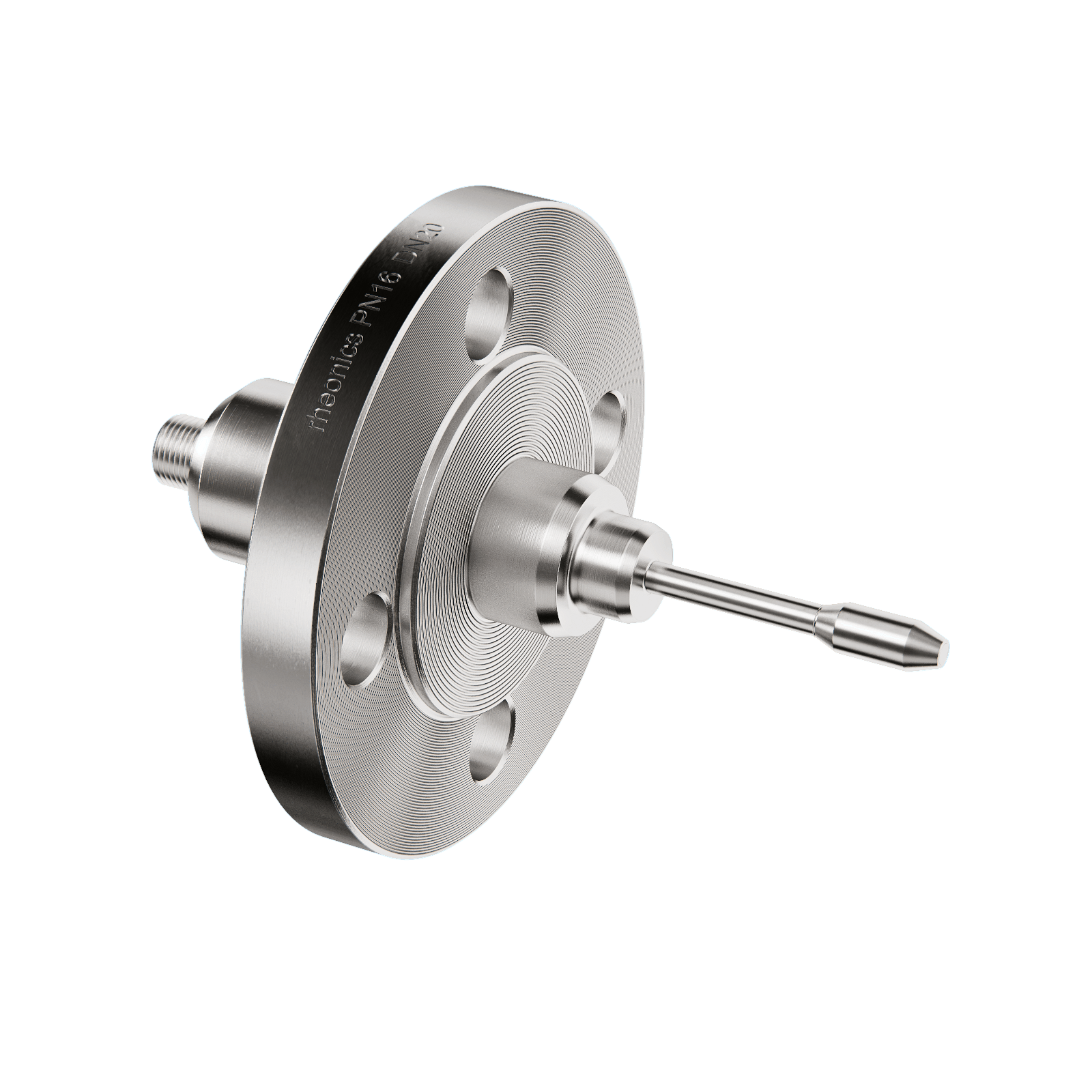

You can expect the sensor on every station to measure and perform equally on any other station. The Rheonics SRV sensor is factory calibrated and traceable to NIST standards.

- Small Form Factor – Fits in your palm while more robust than any other inline viscometers!

- All 316L stainless steel wetted parts – Hermetically sealed, metal-metal process sealing – no elastomer

- Repeatable, Reproducible – Newtonian, non-Newtonian, Single and Multi-phase fluids

- Wide viscosity range – Air to 50,000+ cP

- Built-in fluid temperature measurement – Excellent thermal compensation to achieve consistency over the years

- No re-calibration needed – ever!

- Single instrument for simultaneous process density (specific gravity), viscosity and temperature measurement

- Compact form-factor for simple installation

- Real-time, stable, repeatable and reproducible measurements in Newtonian & non-Newtonian fluids

- Measures kinematic and dynamic viscosity

- Easy to clean, no maintenance or re-configurations needed

- Scale across multiple locations/installs without application re-engineering

CONTROLLERS

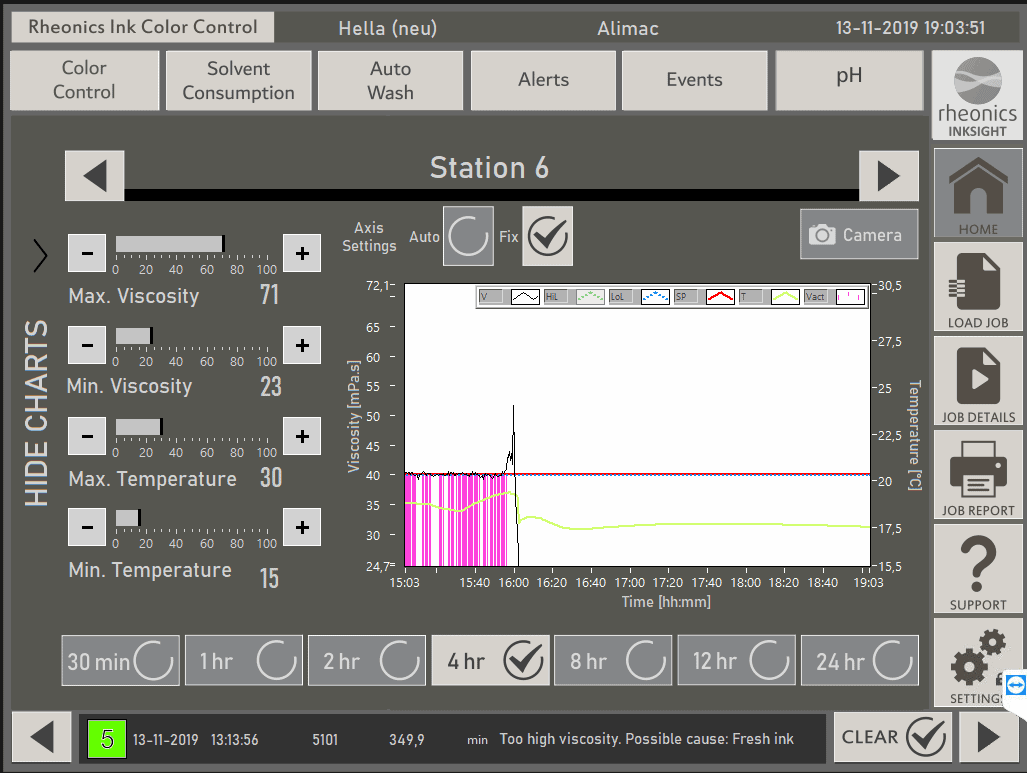

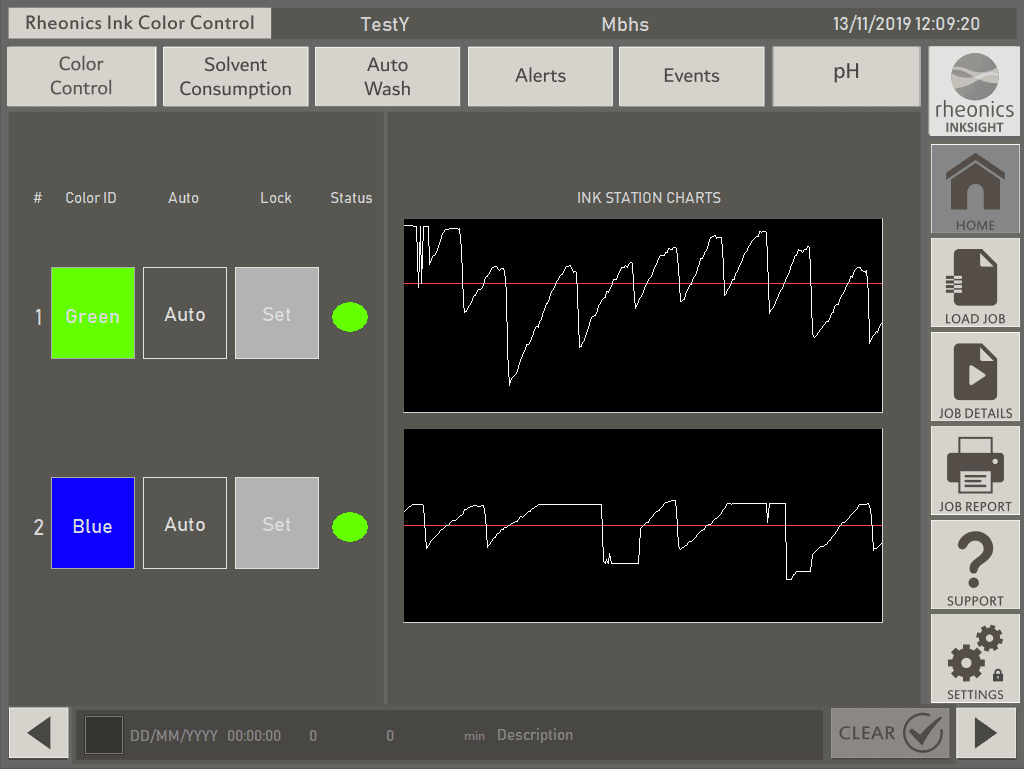

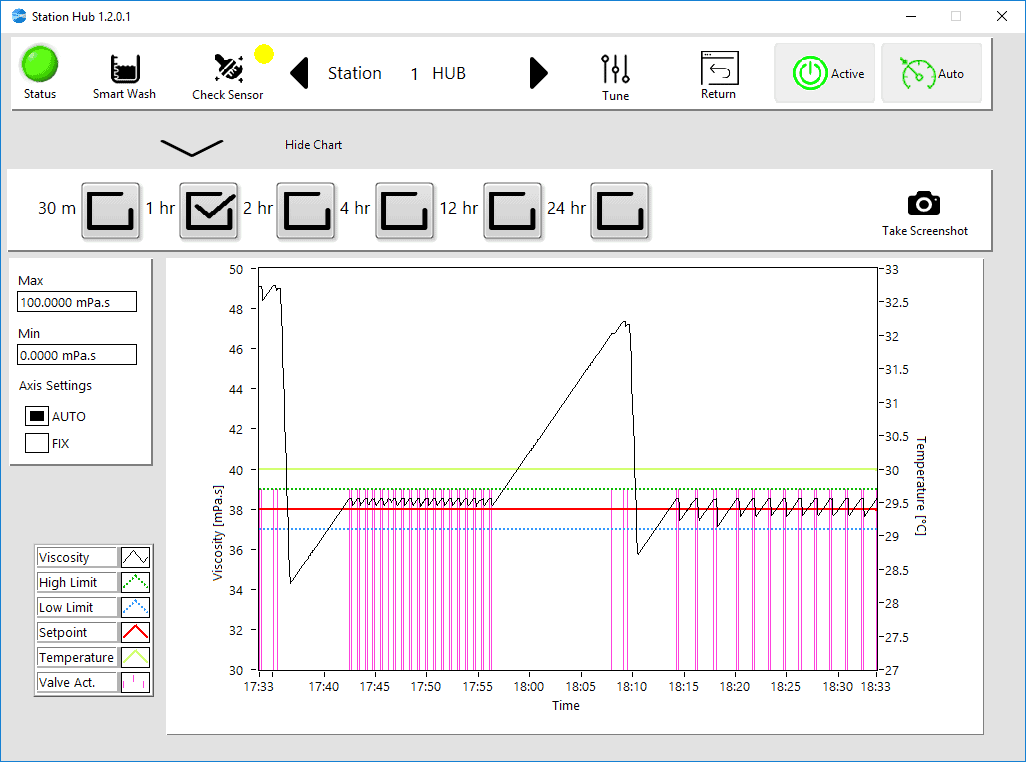

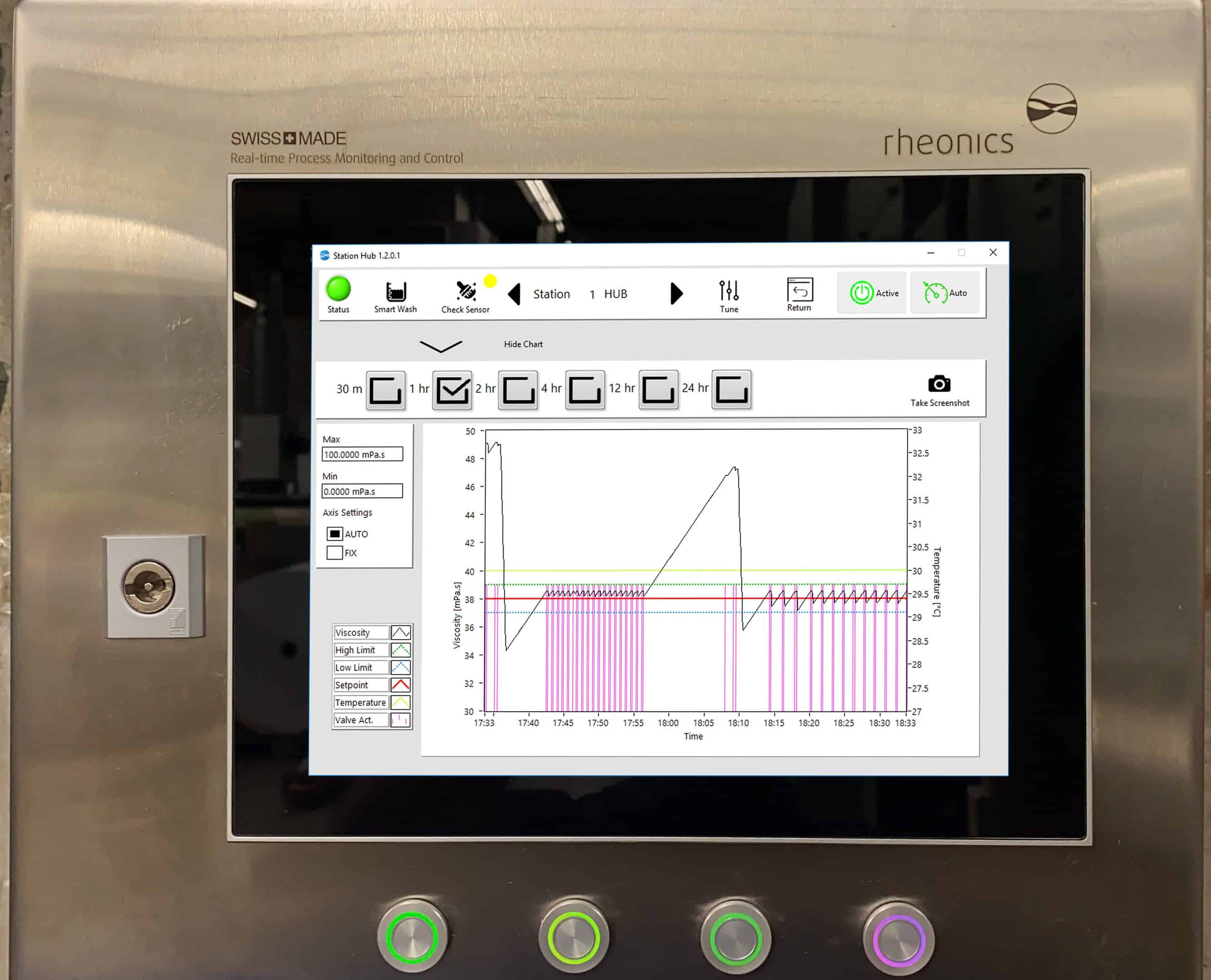

Level 5: Predictive Tracking Controller ensures precise control of viscosity.

Intuitive HMI gives one touch ViscosityLock functionality. Stay on top of your processes with complete control of process variables and to ensure you meet all your Quality Control requirements.

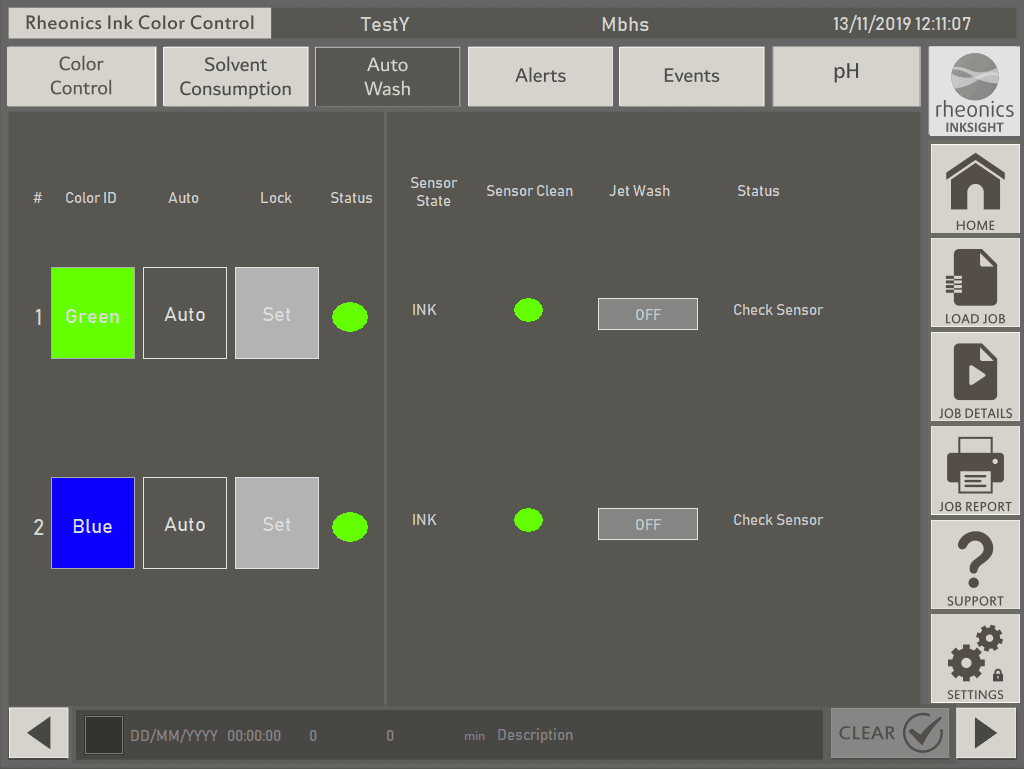

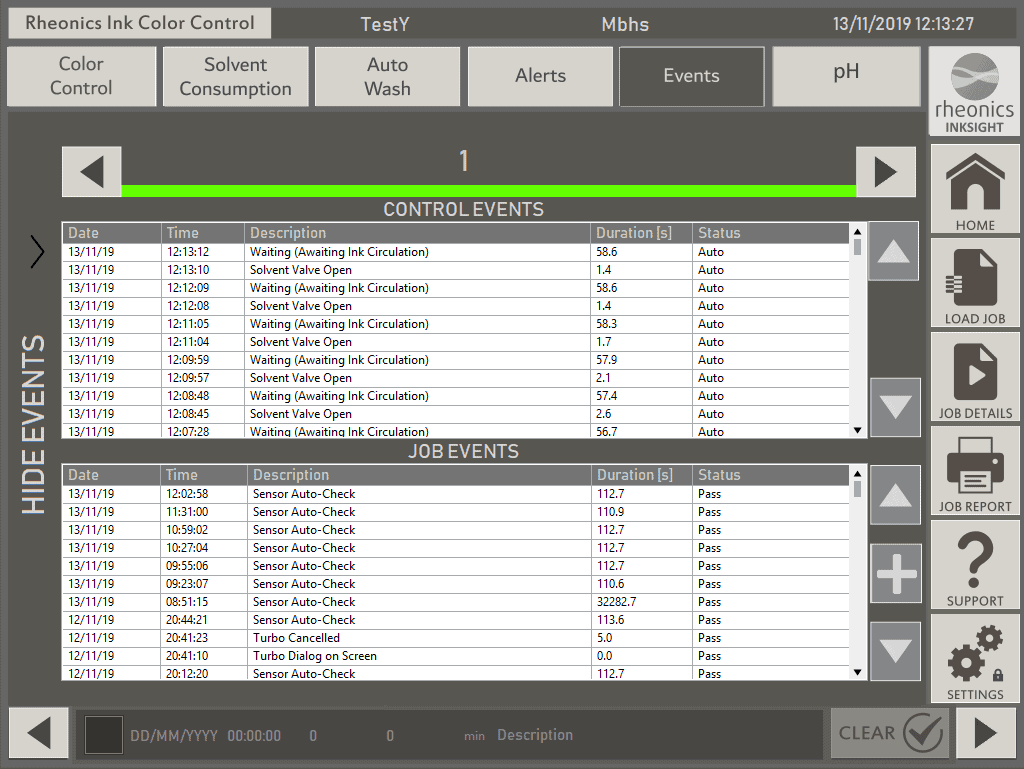

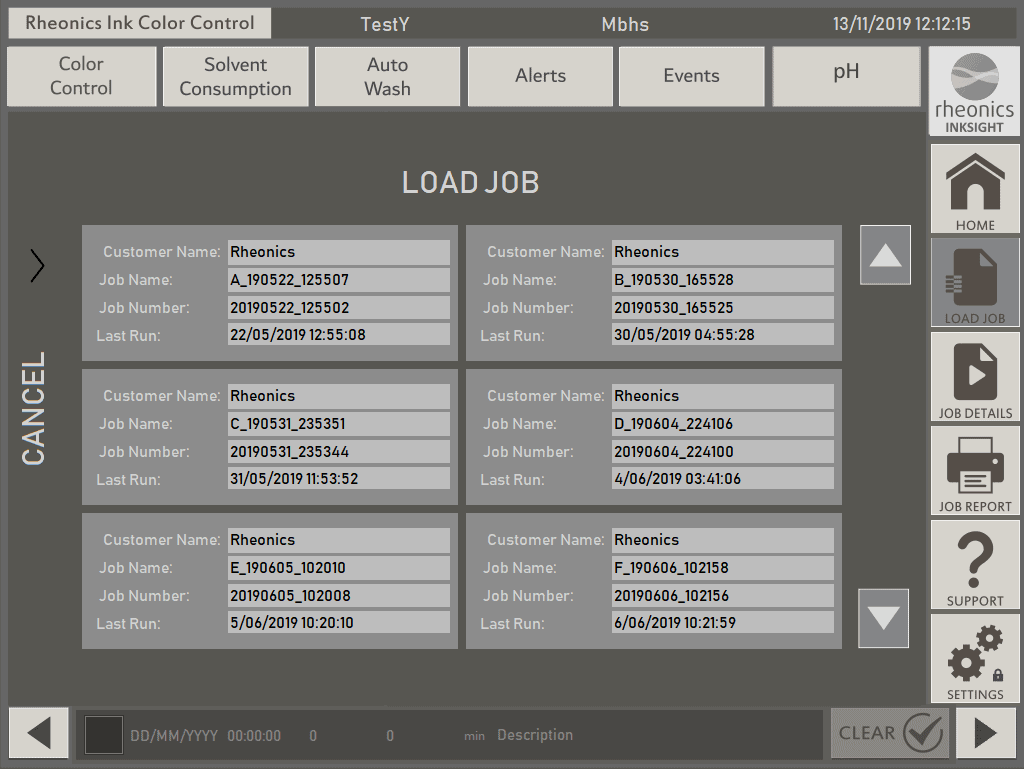

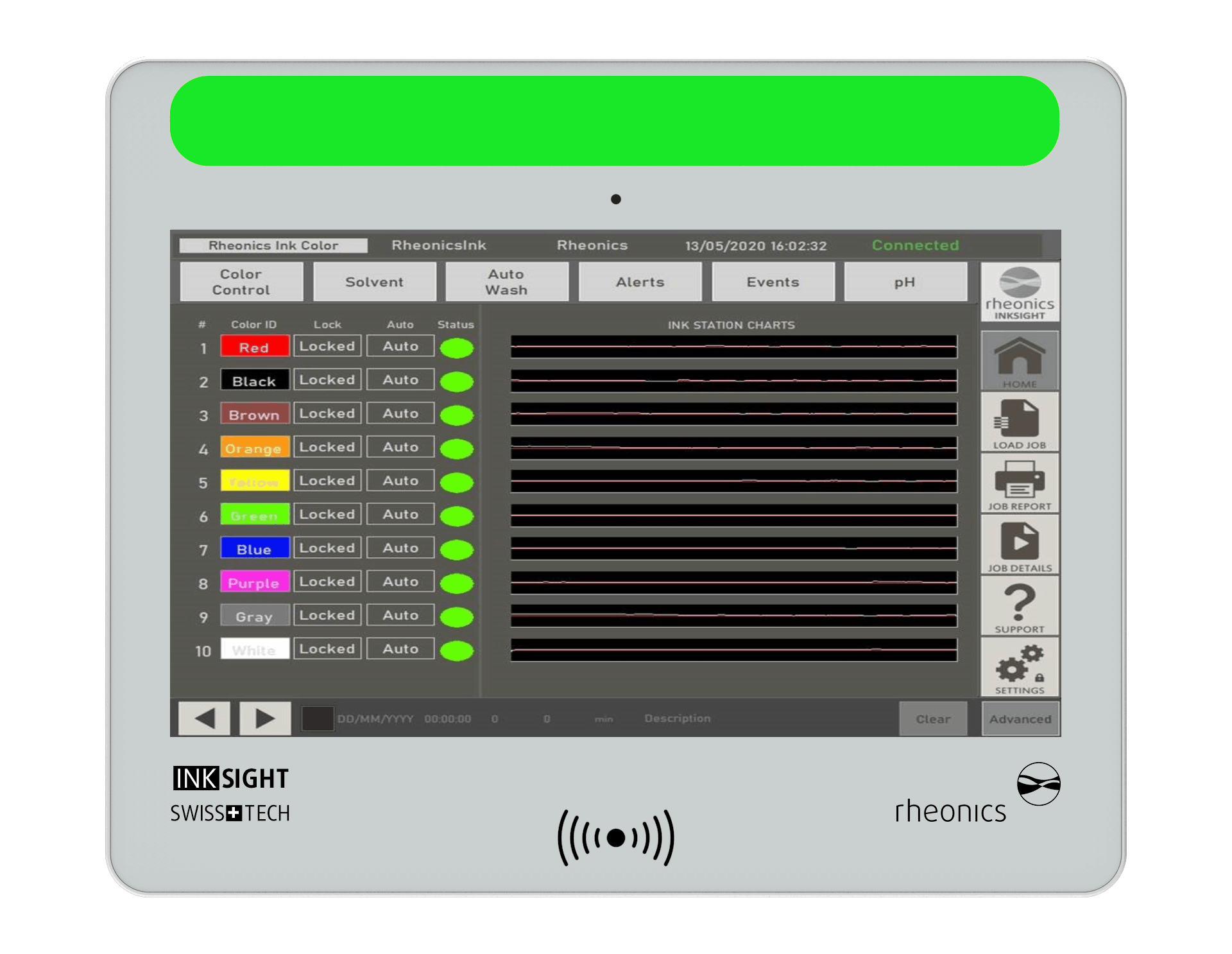

Rheonics’ InkSight ColorLock software is powerful, intuitive and convenient to use. Multiple stations are managed from a single dashboard. It supports multiple HMIs for operator, production supervisor, quality manager and management view.

STANDALONE SYSTEMS

Achieve best in class quality, dramatically reduce setup time and optimise use of pigments and solvents. Improve productivity and efficiency through complete automation of factory processes.

• Robust, maintenance free viscosity sensor eliminates need for re-calibration

• Agile viscosity controller reduces viscosity variation to less than 1% over entire run

• One-click, intuitive graphical interface touch-screen

• Tighter, more accurate density/viscosity control

SOFTWARE - MONITORING & CONTROL

Rheonics’ software is powerful, intuitive and convenient to use. Multiple stations are managed from a single dashboard. It supports multiple HMIs for operator, production supervisor, quality manager and management view. Each application requirement is different and we understand that to build and support custom-built softwares for your applications.

• Proprietary advanced 5th generation AI system for simple click monitoring and control

• API for data acquisition and integration into press manufacturer’s HMI

• On-demand in-built remote support management of job run

Add-on functionalities with Rheonics Systems

We enable you to focus on the quality of your products and processes instead of measurement skills!

Global Support

Process experts help when you need it the most.

Rheonics provides a worldwide network of engineers, application experts and technical sales professionals to help you size, select and troubleshoot printing and coating automations for your applications. Please visit our support portal to access our knowledge base articles and to submit a support ticket with us.