- All

- Adhesive

- Printing and Coating

- Industrial Mixing and Grinding

- Energy and Hydrocarbons

- Petrochemicals

- Chemical

- Automotive

- Paper and Packaging

- Life Sciences and Medical

- Pumping and Pipeline

- Marine

- Mining, minerals and metals

Viscosity Management in Medical Device Coatings: Enhancing Performance and Compliance

Viscosity and density play a crucial role in medical device coatings, directly impacting product cohesion, surface quality, and therapeutic effectiveness…

Optimizing Hotmelt Adhesive (HMA) Processes with Advanced Viscosity Control

Adhesive hotmelt’s viscosity is a critical property, as it directly impacts its ability to be applied and form a strong…

Monitoring Battery Slurry Production with Inline Viscometers and Density Meters

In battery manufacturing, viscosity and density play a critical role in achieving consistent slurry quality, optimizing performance, and improving the…

Inline Viscosity and Density Monitoring for Gelatin Capsule Production

Capsules are a solid oral dosage form used for the delivery of medical drugs, vitamins, minerals, and other health-related ingredients…

Automating and optimizing mining operations with Rheonics Sensors and Solutions

The mining industry has always been known for its complexity and hard environments. From ore extraction to final product recovery,…

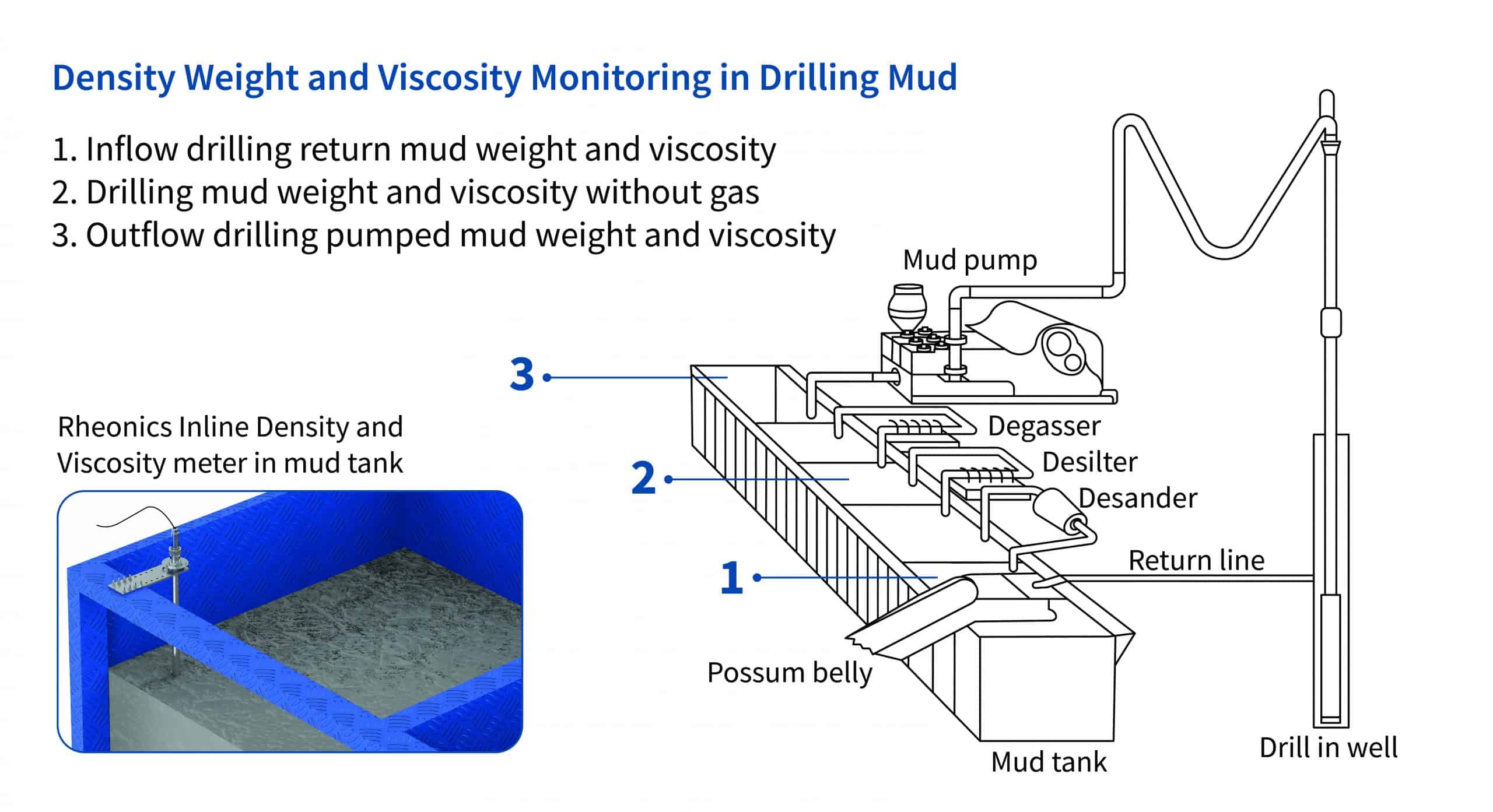

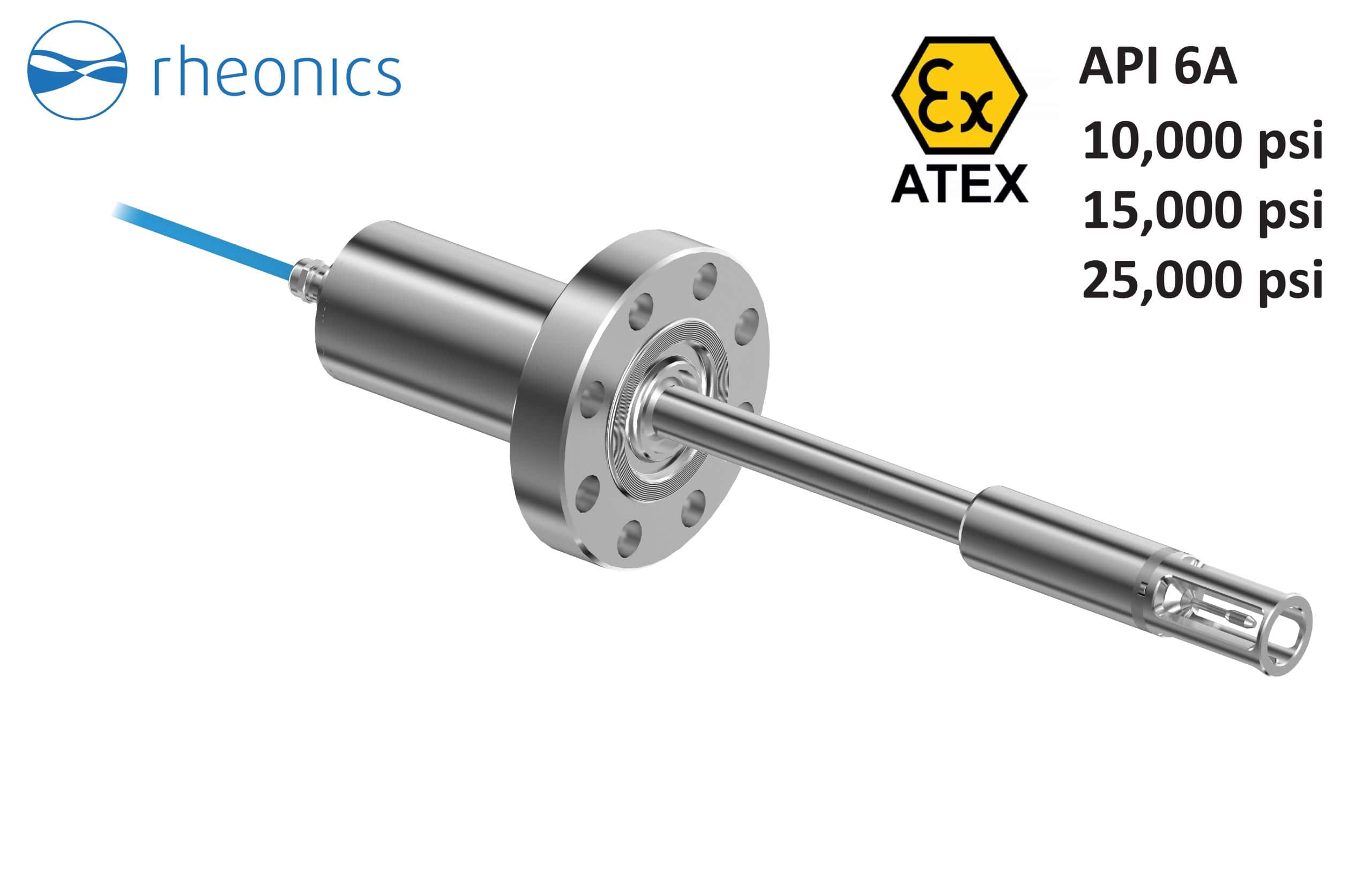

Drilling Mud Weight and Viscosity Monitoring to Optimize Well Performance

Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or…

Adhesives and Sealants Industry Overview and Rheonics Sensors Use

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Density and Concentration Brine pond monitoring in lithium extraction process

Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process…

Monitoring Density and Viscosity in 3D Cement Printing

Density and viscosity are critical parameters in 3D cement printing as they directly affect the printability, structural integrity, and layer…

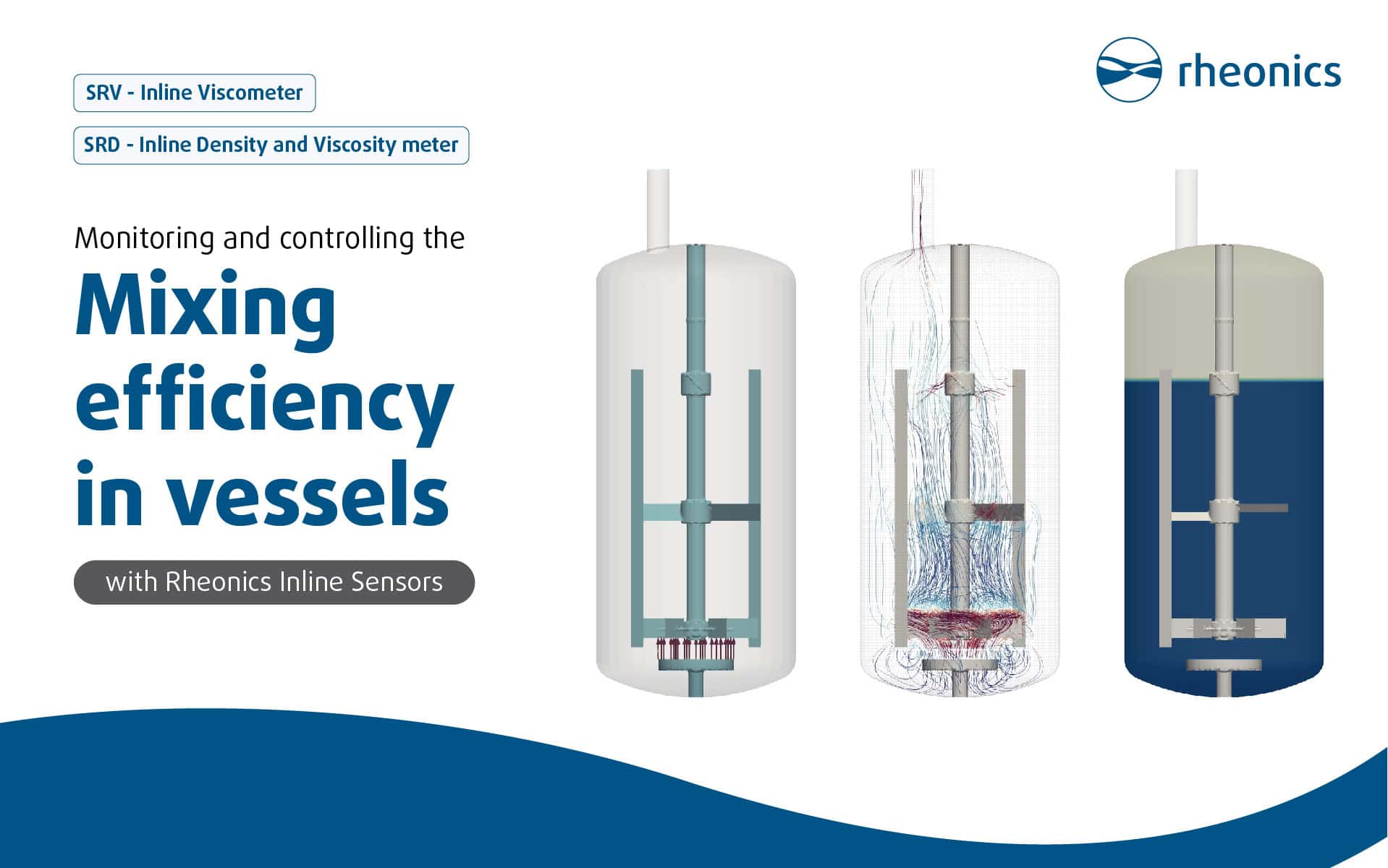

Mixing vessels – monitoring and controlling the mixing efficiency

Rheonics process viscometer SRV or Rheonics process density and viscometer SRD can be installed in a variety of locations in…

DeSander and Separator sand level realtime monitoring for automatic removal

The ability to monitor the level of sand in desanders, separators, and flowback systems allows for automation and higher efficiency…

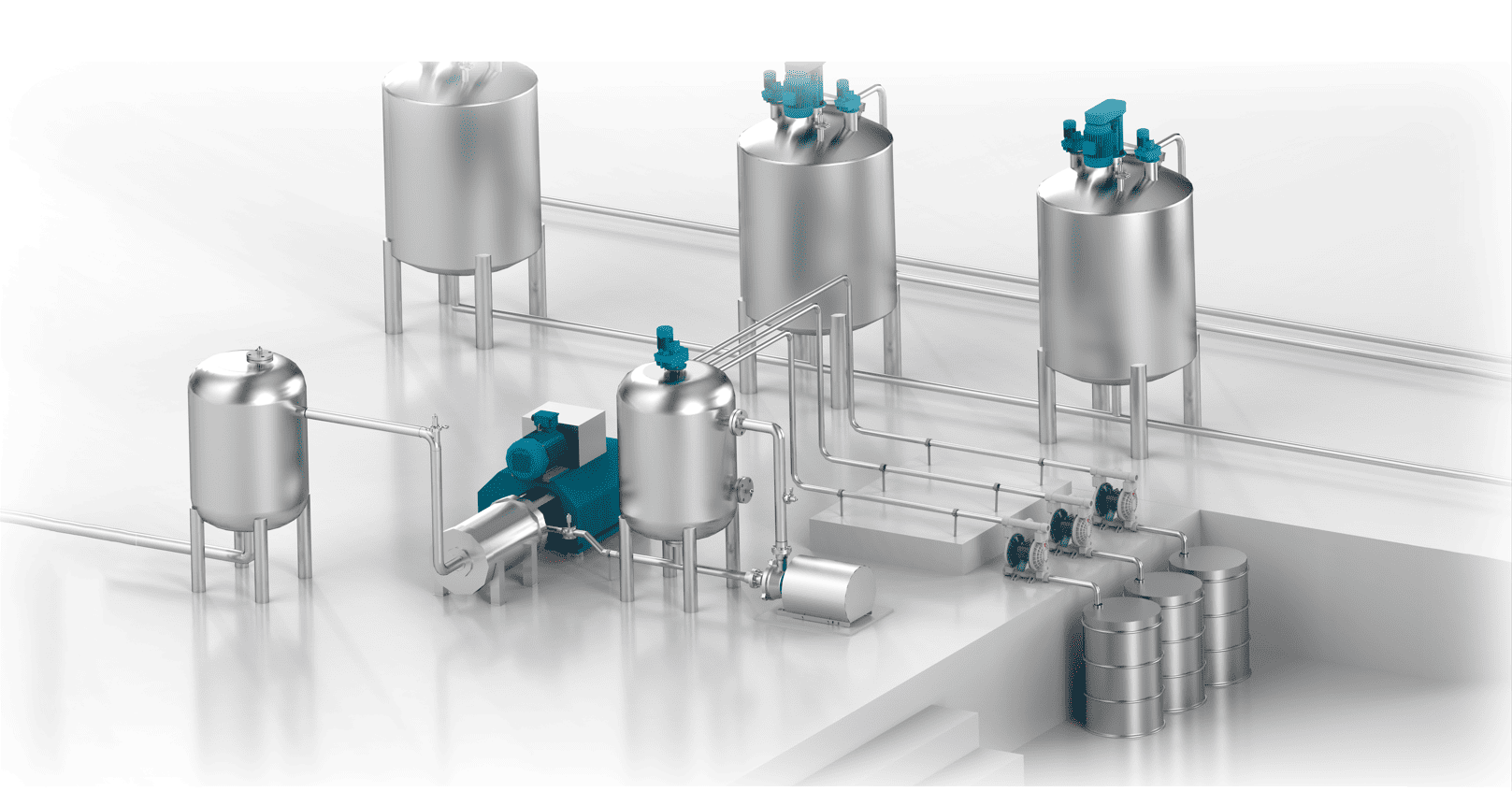

Real-time quality control of paint, ink, coating manufacturing using process viscometer and density meter

Paint, ink and coating manufacturing processes follow similar steps, from initial mixing, until final packaging or storage, requiring a grinding…

Monitor non-newtonian fluids through the complete process cycle

Finally! Slurry monitoring using large range sensor with repeatable measurements in non-newtonian fluids.