Asphalt has proven itself to be one of the most versatile and effective materials for paving – be it road or roof. Ensuring that asphalt meets regulatory norms like ASTM, AASHTO, DIN, EN while reducing emissions related to its production and use is a win-win. Real-time inline viscosity monitoring and control of asphalt from production in refineries to final loading at terminal for transport to paving site improves bottom-line and protects personnel. Cost reduction and safety improvements are achieved through optimizing the use of solvents & modifiers to achieve fit-for-purpose asphalt mixture. The measuring process creates zero emissions and can be done completely inline without need for offline grab samples. A resonant sensor based inline viscometer takes viscosity measurements into the digital world in tune with modern road design and enables real-time management of bitumen properties across the complete asphalt life cycle.

Application

The two main parameters of polymer blended bitumen for the production of Hot Mix Asphalt (HMA) are viscosity and temperature. Asphalt-cement viscosity describes resistance to compaction of paving mixture. Using viscosity measurements in pipes and tanks, engineers can ensure that the quality control parameters are adhered to and the product is within specifications. An inline viscosity measurement could be used as a process feedback variable in an automatic blending control system to regulate the temperature, mixing time, and addition of performance enhancing additives.

For asphalt mixing and transportation operations, viscosity data provides more meaningful insights when collected and analysed over time. Data analysis helps process engineers diagnose quality issues. Operators can schedule maintenance and make necessary upgrades to their equipment to improve reliability and efficiency.

Stages in the asphalt ecosystem where viscosity measurements bring value

There are two separate stages in the life of every hot-mix asphalt pavement. The construction stage from cold aggregate feed and asphalt storage to finished pavement. The properties of bitumen change as it ages in bulk storage, transport, and storage on-site. The change in bitumen properties needs to be monitored and suitable corrective actions undertaken across the value chain to ensure correct properties prior to application.

Stages of bitumen application where real-time viscosity measurements can improve operations

| Segments | Challenges | Value of viscosity management |

|---|---|---|

| Asphalt Production (Refineries) | • Meeting target properties accurately in harsh conditions with temperature and environment fluctuations • Raw material and process manufacturing fluctuations mean periodic laboratory testing does not represent the asphalt being produced. • Inconsistency leads to considerable amount of money and time spent on post-process blending to meet the minimum target specifications | • R&D and testing of formulations • With real-time viscosity monitoring, adjustments can be made in the production processes and corrective actions can be automated. • Helps in achieving sustainable production goals – minimise material & energy costs with optimisation in mixing process. |

| Transportation from asphalt mixing plant to point of application with Material Transfer Vehicles | • Change of asphalt properties during transport from refinery to the pavement (application sites) due to ageing and micro-contamination | • Prevention of change in properties during bulk storage and transportation due to ageing and contamination. • To ensure QC before transfer from mix plants to the trucks – loading, unloading. |

| Application Point (Paving) | • Material Transfer Vehicle to re-blend material prior to application throughout – adjusting for temperature & environment factors. • Viscosity of asphalt-cement in a paving mixture influences its compaction by rolling during construction and by traffic during pavement’s early service life. | • Ensuring homogeneity in the mixture and ensuring correct properties just before application. • Compaction of paving mixture to specified density is achieved reliably by rolling equipment, with adequate compaction effort. |

Viscosity as a tool for R&D – New asphalt-mix development and improvement studies

Viscosity is a property that is affected at the molecular level and has tremendous amount of information about the process and the fluid behaviour. Addition of viscosity modifiers to create high-viscosity modified asphalt pavement has proved to have a strong ability to resist shear flow and deformation, strong bonding strength and increased low-temperature performance of the material. The quantity and types of addition need to be fine-tuned and viscosity measurements are key elements of conducting R&D, experimentation, and asphalt characterization studies. Temperature / viscosity relationship is important when determining the performance parameters such as adhesion, rheology, durability, and application temperature of bitumen. Therefore, accurate viscosity analysis of bitumen at different temperatures has become an important test.

Viscosity of asphalt binder at high temperatures is important because it affects the following:

- The ability of the asphalt binder to be pumped between storage facilities and into the HMA manufacturing plant.

- The ability of the asphalt binder to be properly mixed with and to coat aggregate and other HMA constituents in the HMA manufacturing plant.

- The ability of the resultant HMA to be placed and compacted with reasonable effort.

Density information critical to paving troubleshooting and to avoid paving problems

Long-term pavement performance is the result of the smoothness and mat quality of the HMA mixture. Smoothness affects the transportation costs of the road user and directly influences vehicle maintenance costs, fuel consumption, speed, passenger comfort, safety, and vehicle noise. Poor mat quality also affects the pavement performance and may be caused by cracks, segregation, poor joints, and other defects. Furthermore, low density may cause the mix to deform, make the mix more susceptible to moisture, prematurely harden the asphalt, decrease the fatigue resistance, or reduce the structural strength of the pavement. Possible problems with inadequate density management in paving operations are:

- Non-uniformity in the HMA mix

- Thickness and mat quality variations

- Mat shoving ahead of roller

- Unsatisfactory compaction

Typical test methods for characterizing bitumen relevant properties and impact on resistance to rutting

Usage of modified asphalt binders has been on the rise. As a result, additives such as polymers, rubbers, acids, and oils have been used for asphalt modification. Performance properties of asphalt binders such as resistance against high-temperature rutting have been significantly increased due to modification of the asphalt binder.

There are many different components of asphalt that help define its behavior and functions. Viscosity, complex shear modulus, and stiffness are among those components that are especially important when trying to understand the behavior of asphalt. There are many identified correlations between bitumen relevant properties and the resistance to permanent deformation of bituminous mixtures. The bitumen properties and the associated tests are presented in the table below.

Bitumen properties and test types to study impacts on rutting

| Properties | Tests |

|---|---|

| Viscosity | Capillary Viscometer Test Coaxial Cylinder Viscosity Test Cone and Plate Viscosity Test Creep Zero/Low Shear Viscosity Oscillation Zero/Low Shear Viscosity |

| Softening point | Ring and Ball (R&B) Test |

| Elastic and recovery properties | Multiple Stress Creep and Recovery (MSCR) Test Elastic Recovery Test |

| Complex modulus and phase angle | Dynamic Shear Rheometer (DSR) Test |

| Performance Grading | Performance Grade (PG) classification |

Measurements for rheological asphalt binder specifications correspond to international standards such as ASTM, AASHTO, DIN EN, CEN/TS, IS, GOST and SATS. For characterizing the high-temperature performance of modified asphalt binders, many transportation agencies use AASHTO (American Association of Highway and Transportation Officials) standards and grading systems for conducting the tests.

How viscosity measurements can be made and reliably put to use?

Inline/online viscometers measure directly the viscosity of material in a tank or pipe while it’s in use, providing real-time data. They are a suitable alternative to time-consuming lab procedures and tedious measurements management, even with experienced operators. The actual cost-of-operation may be significantly less than with benchtop viscometers.

The vibrational viscometer is a popular inline viscosity measurement instrument that does not involve moving parts. The principal advantage of these instruments is the measurement of continuous viscosity at operating temperatures. Although sensitive to changes in viscosity, this type of instrument is insensitive to changes in binder flow rate and vibration. It is designed to operate in harsh environments of an asphalt plant. It can effectively monitor and control the modified asphalt binders process to ensure that the asphalt output is always consistent even with raw material variability.

The real opportunity is to look beyond the basic requirements and use viscosity data in a timely manner to ensure consistent asphalt quality throughout the lifecycle. Using such binder will ensure reliable performance when placing asphalt on the ground. Inline viscosity measurement allows for conformance with required standards like AASHTO M332 MSCR grading system, AASHTO T-350 MSCR test procedure which are widely adopted by transportation agencies.

Asphalt 4.0 – Staying ahead of problems by using data and digitalization

Customer specifications vary with region, since roads are subject to radically different environments. The raw material for making asphalt is basically the leftover items in the crude oil barrel after high value products have been extracted or refined. That material can be very non-homogenous, and can vary radically in make-up from barrel to barrel depending on the source of the crude.

Temperature and humidity variations, mixing equipment condition, formulations, line-integration, machine interactions and time of mixing are some of the many parameters which can alter the produced asphalt-mix quality across batches. Technologies required to assist repeatable operations despite so many influencing factors now exist. Once the manufacturer invests in process monitoring equipment, the current industrial control systems are well developed to be able to use the viscosity data from the processes to standardize operations and quality.

The key value drivers of embracing real-time inline viscosity monitoring equipment by asphalt industry are the following:

Real-time monitoring to achieve consistent quality of delivery. Any deviation can be quickly caught and corrected without wasting a full load or worse creating future issues with road or roof. Traceable quality assurance gives higher producer confidence and reduces liability arising from quality complaints.

Automated corrective actions for ensuring production efficiency and consistency. Closed control loops through sensor-based, in-line quality inspection reduce waste and increase yield through early process deviation detection, root cause analysis, and automatic correction for asphalt producers.

Circular innovation: More agility in dealing with new asphalt-mix variants in production, compliance and provenance. Fine unique asphalt grades are produced by refineries, each with a different viscosity that must meet a target specification. With inline viscosity measurements, these producers get insights about of how the new formulations/compositions will behave and how they might need to adjust current blending systems and control parameters.

Big data provides robust evidence to base decisions for greater efficiency. The data provided by the process monitoring equipment enables them to tweak various process parameters and optimise the production process. Interconnection and information transparency enables decentralization of decisions within and outside the production facilities.

Higher quality standards and adapting to customer requests. The technology, data, and information that can help transform manufacturing operations can also make processes and systems more responsive to the end-user needs.

Complete track and trace of production process. Real-time monitoring of asphalt production data enables track and trace of every step in the process chain ensuring full compliance with both regulatory and agency requirements.

Accurate and responsive in-line viscosity measurement and control

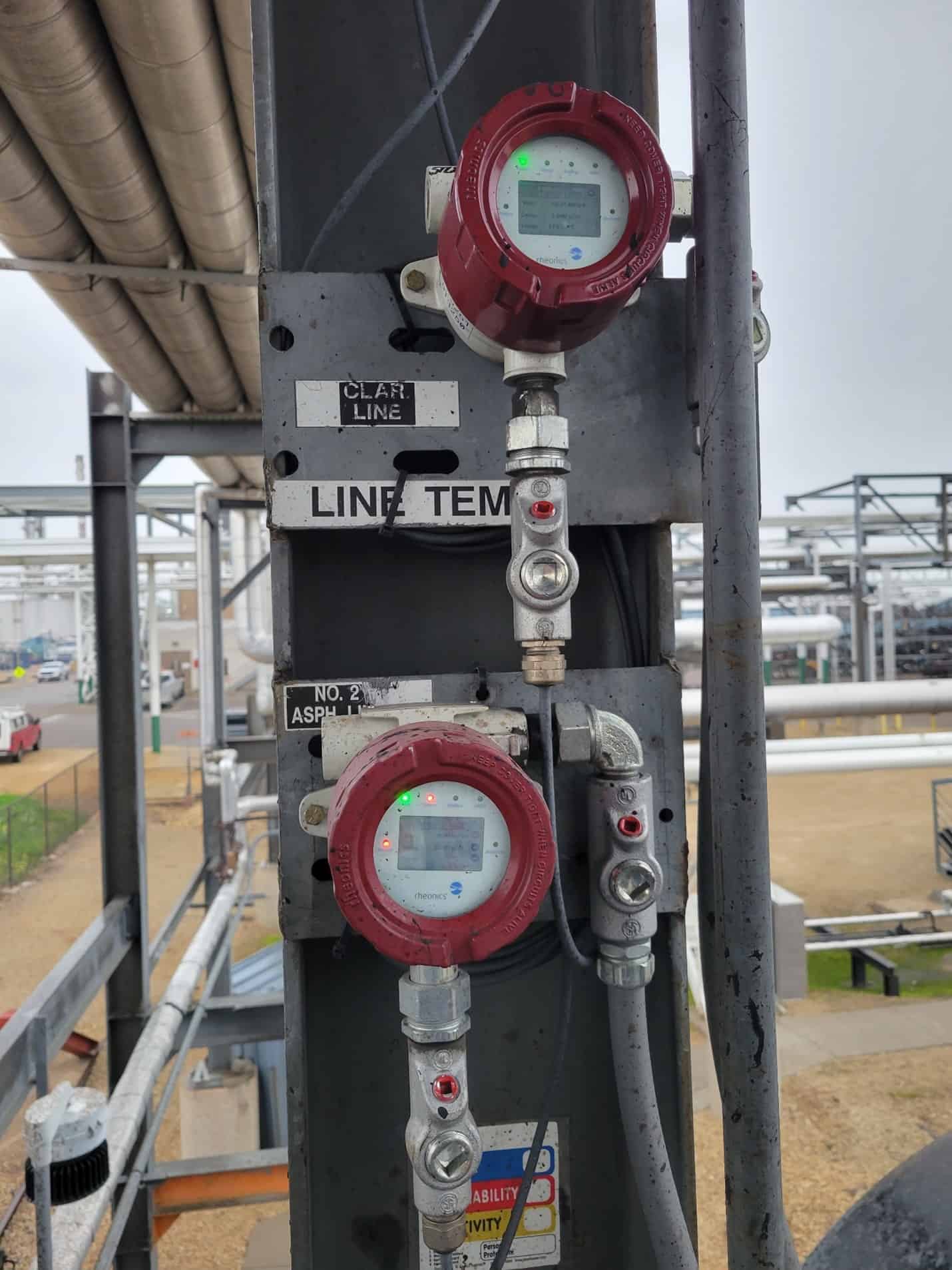

Automated in-line viscosity measurement enables continuous monitoring of bitumen in production, transit and at the point of application. It enables control of the viscosity to assure uniform quality across all stages. Inline viscosity management with the Rheonics SRV can help alleviate some of the most common paving issues due to inconsistent asphalt supply – cracks (longitudinal, transverse, alligator, slippage, edge), bleeding, tearing, waviness, potholes, depressions, rutting, upheaval, raveling and shoving. Effective control of the viscosity of the asphalt leads to a significant improvement of the paving process by improving quality and reducing reworks.

Consistent product quality and control of blending can be accomplished by using the data from the sensor and integrating it in the production/blending control system. Data exported to the production control can be utilized to maintain the product within the defined specifications.

Rheonics’ solutions for improving operations in asphalt production, transportation and application

Automated in-line viscosity measurement and control is crucial to control the viscosity during manufacturing process and ensure critical characteristics are in full compliance with requirements across multiple batches, without having to rely on offline measurement methods and sample taking techniques. Rheonics offers the following solutions for process control and optimisation,

Viscosity & Density Meters

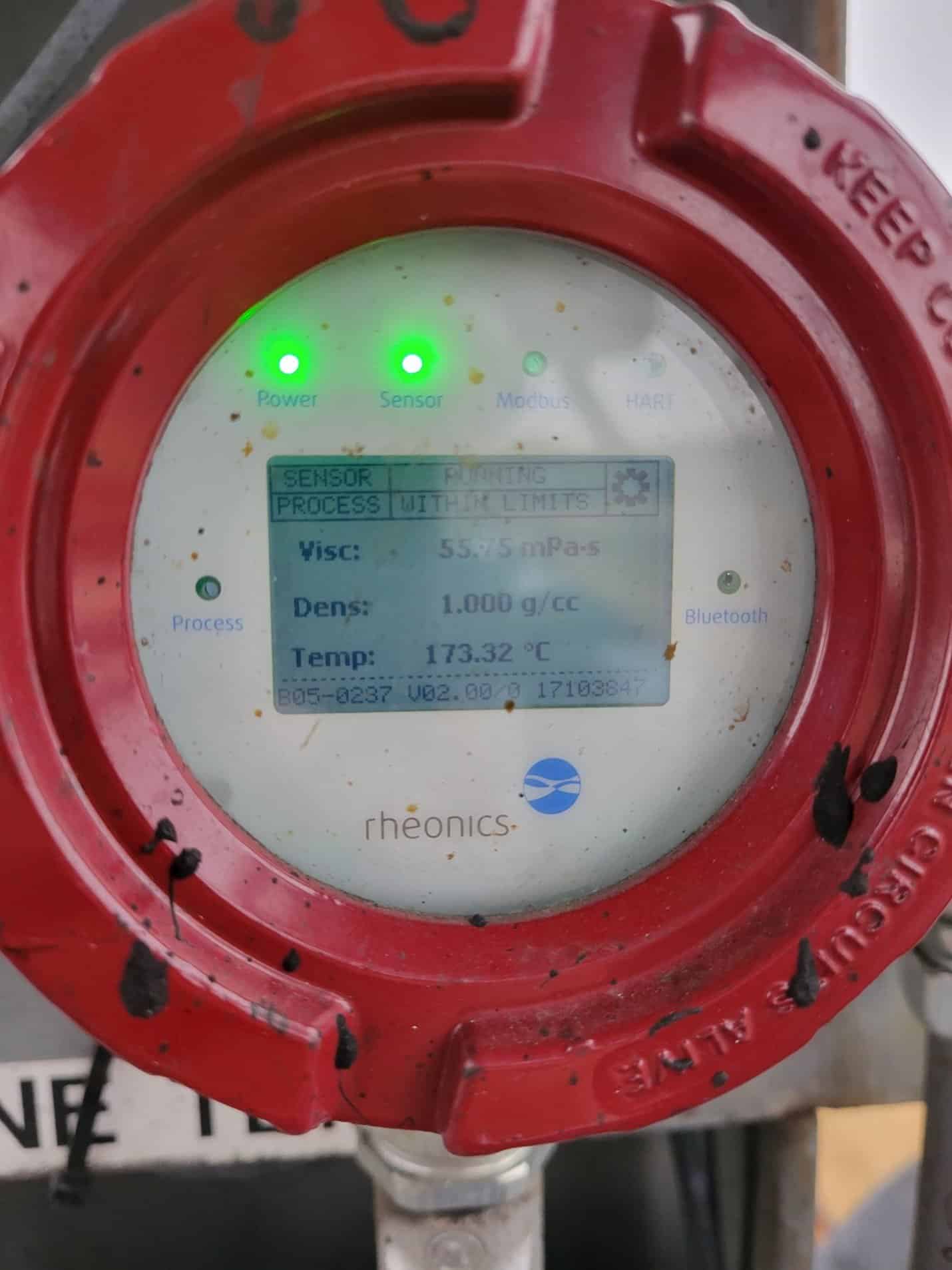

- In-line Viscosity measurements: Rheonics’ SRV is a is a wide range, in-line viscosity measurement device capable of detecting viscosity changes within any process stream in real time.

- In-line Viscosity and Density measurements: Rheonics’ SRD is an in-line simultaneous density and viscosity measurement instrument. If density measurement is important for your operations, SRD is the best sensor to cater to your needs, with operational capabilities similar to the SRV along with accurate density measurements.

Integrated, turnkey quality management

Rheonics offers an integrated turn-key solution for quality management made of:

- In-line Viscosity measurements: Rheonics’ SRV – a wide range, in-line viscosity measurement device with in-built fluid temperature measurement

- Rheonics Process Monitor: an advanced predictive tracking controller to monitor and control in real-time variations of process conditions

- Rheonics RheoPulse with automatic dosing: A Level 4 autonomous system that ensures no compromise with set limits of viscosity and automatically activates by-pass valves or pumps to adaptively dose mixture components

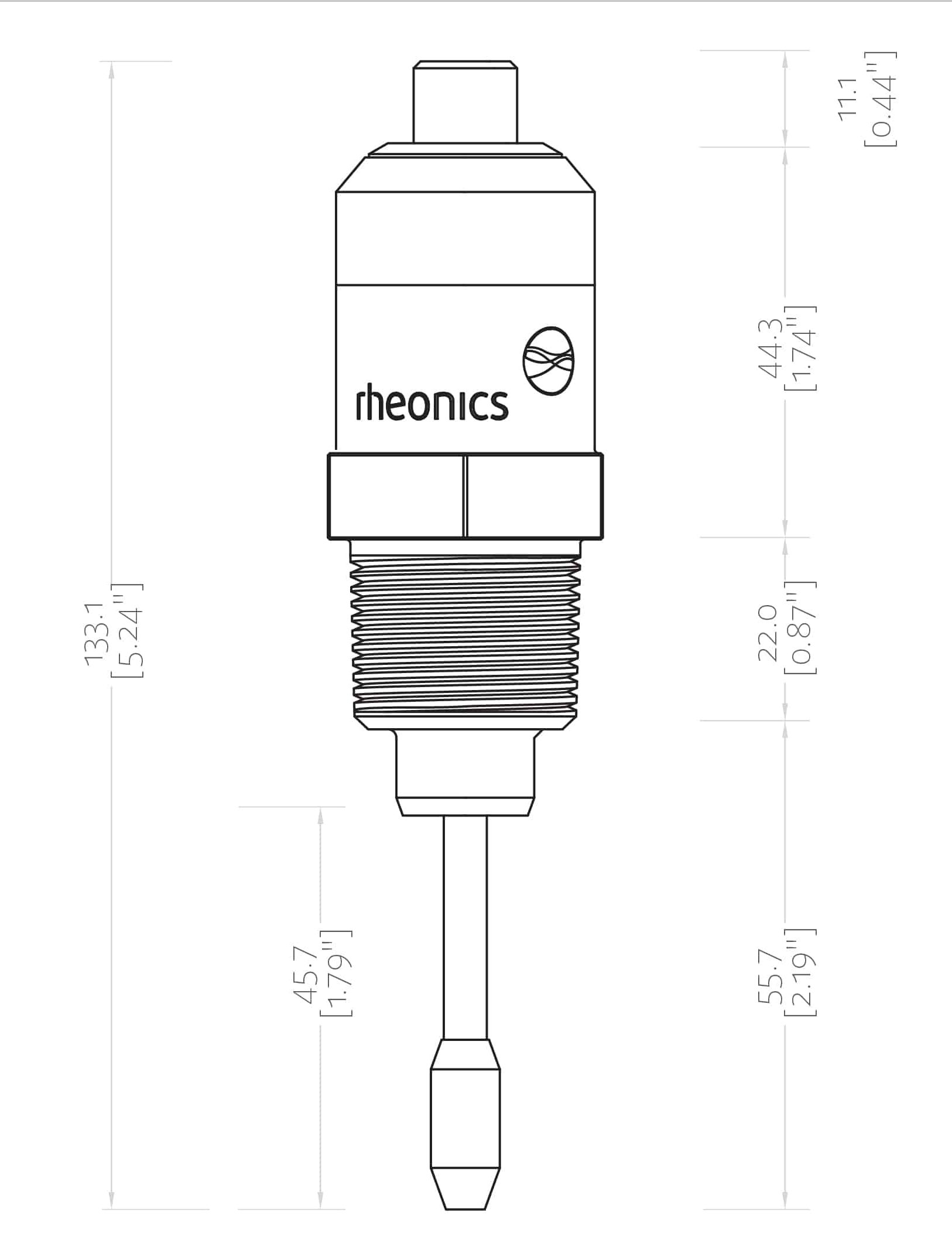

The SRV sensor is located in-line so it continuously measures the viscosity (and density in case of SRD). Alerts can be configured to notify operator of necessary action or the entire management process can be fully automated with RPTC (Rheonics Predictive Tracking Controller). Using an SRV in an manufacturing process line, results in improved productivity, profit margins and achieves regulatory conformance. Rheonics sensors have a compact form factor for simple OEM and retrofit installation. They require zero maintenance or re-configurations. The sensors offer accurate, repeatable results no matter how or where they are mounted, without any need for special chambers, rubber seals or mechanical protection. Using no consumables and not requiring re-calibration, SRV and SRD are extremely easy to operate resulting in extremely low lifetime running costs.

Once the process environment is established, there is usually little effort required to maintain the integrity consistency of the systems – operators can rely on the tight control with Rheonics production quality management solution.

Rheonics' Advantage

Compact form factor, no moving parts and require no maintenance

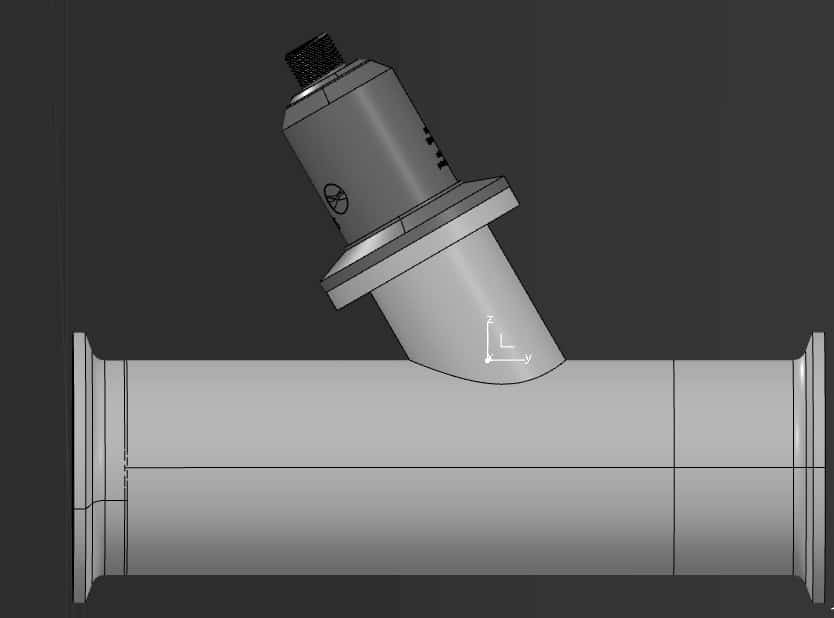

Rheonics’ SRV and SRD have a very small form factor for simple OEM and retrofit installation. They enable easy integration in any process stream. They are easy to clean and require no maintenance or re-configurations. They have a small footprint enabling Inline installation in any process line, avoiding any additional space or adapter requirement.

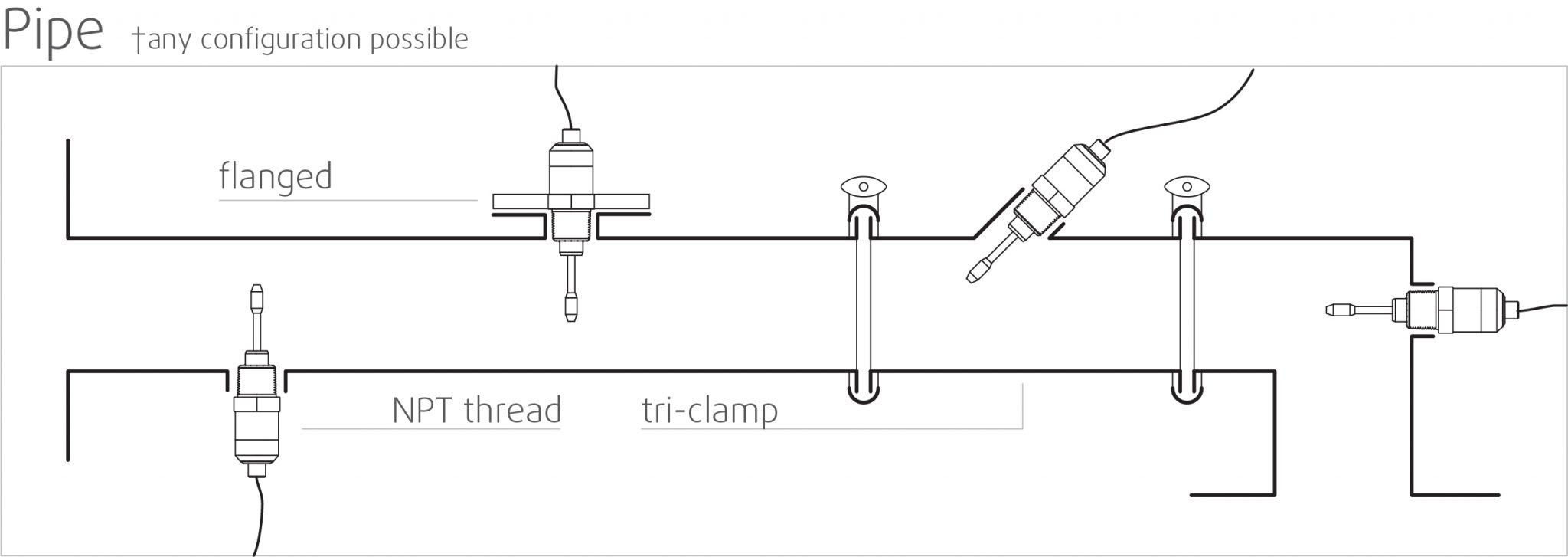

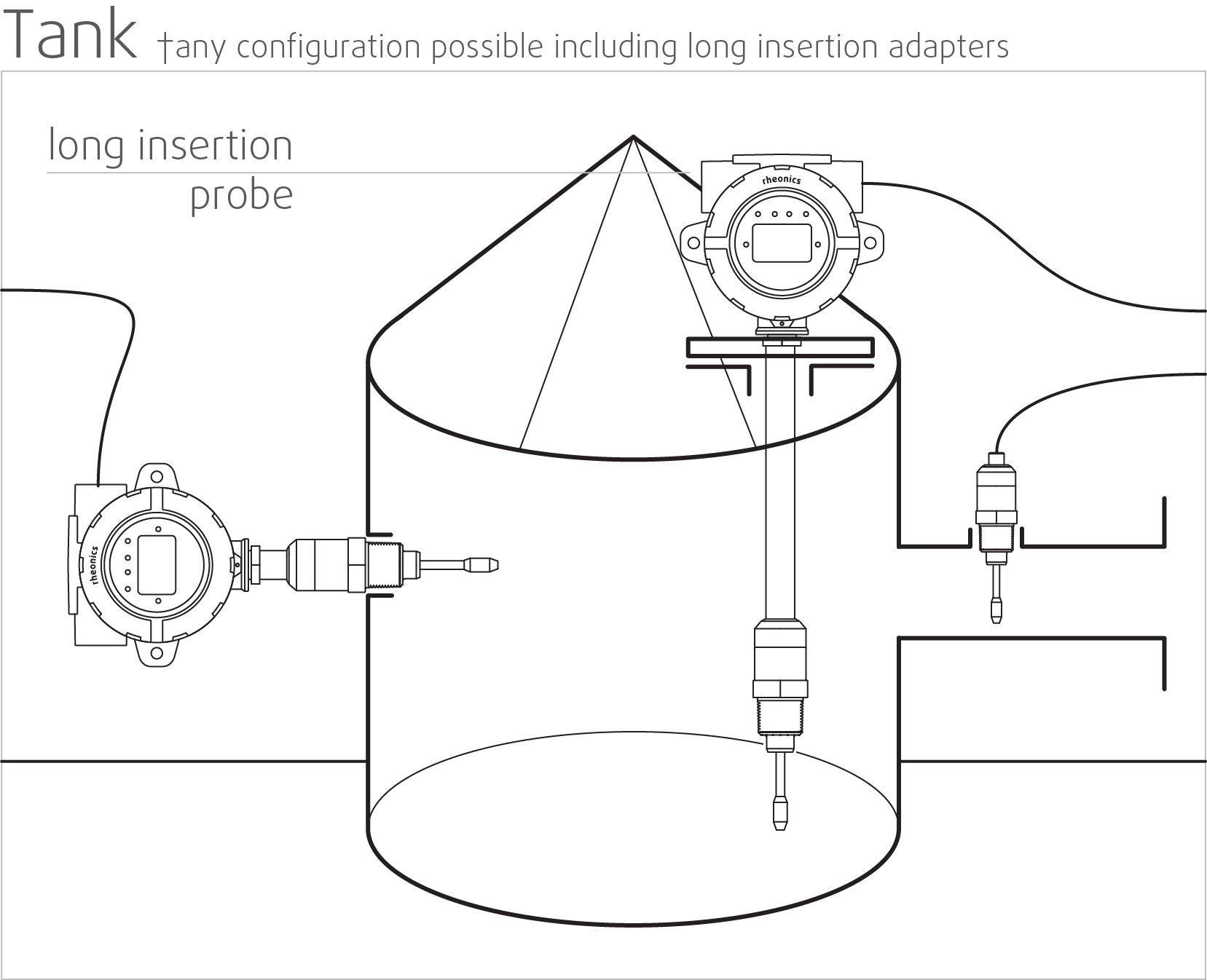

High stability and insensitive to mounting conditions: Any configuration possible

Rheonics SRV and SRD use unique patented co-axial resonator, in which two ends of the sensors twist in opposite directions, cancelling out reaction torques on their mounting and hence making them completely insensitive to mounting conditions and flow rates. Sensor element sits directly in the fluid, with no special housing or protective cage requirements.

Instant accurate readouts on production quality – Complete system overview and predictive control

Rheonics’ software is powerful, intuitive and convenient to use. Real-time process fluid can be monitored on the integrated IPC or an external computer. Multiple sensors spread across the plant are managed from a single dashboard. No effect of pressure pulsation from pumping on sensor operation or measurement accuracy. No effect of vibration.

Inline measurements, no bypass line is needed

Directly install the sensor in your process stream to do real time viscosity (and density) measurements. No bypass line is required: the sensor can be immersed in-line; flow rate and vibrations do not affect the measurement stability and accuracy.

Easy installation and no reconfigurations/recalibrations needed – zero maintenance/down-times

In the unlikely event of a damaged sensor, replace sensors without replacing or re-programming electronics. Drop-in replacements for both sensor and electronics without any firmware updates or calibration changes. Easy mounting. Available with standard and custom process connections like NPT, Tri-Clamp, DIN 11851, Flange, Varinline and other sanitary and hygienic connections. No special chambers. Easily removed for cleaning or inspection. SRV is also available with DIN11851 and tri-clamp connection for easy mounting and dis-mounting. SRV probes are hermetically sealed for Clean-in-place (CIP) and supports high pressure wash with IP69K M12 connectors.

Low power consumption

24V DC power supply with less than 0.1 A current draw during normal operation.

Fast response time and temperature compensated viscosity

Ultra-fast and robust electronics, combined with comprehensive computational models, make Rheonics devices one of the fastest, versatile and most accurate in the industry. SRV and SRD give real-time, accurate viscosity (and density for SRD) measurements every second and are not affected by flow rate variations!

Wide operational capabilities

Rheonics’ instruments are built to make measurements in the most challenging conditions.

SRV is available with the widest operational range in the market for inline process viscometer:

- Pressure range up to 5000 psi

- Temperature range from -40 up to 200°C

- Viscosity range: 0.5 cP up to 50,000 cP (and higher)

SRD: Single instrument, triple function – Viscosity, Temperature and Density

Rheonics’ SRD is a unique product that replaces three different instruments for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating three different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Superior sensor design and technology

Sophisticated, patented electronics is the brain of these sensors. SRV and SRD are available with industry standard process connections like ¾” NPT, DIN 11851, Flange and Tri-clamp allowing operators to replace an existing temperature sensor in their process line with SRV/SRD giving highly valuable and actionable process fluid information like viscosity besides an accurate measurement of temperature using an in-build Pt1000 (DIN EN 60751 Class AA, A, B available).

Electronics built to fit your needs

Available in both a transmitter housing and a small-form factor DIN rail mount, the sensor electronics enables easy integration into process lines and inside equipment cabinets of machines.

Easy to integrate

Multiple Analog and digital communication methods implemented in the sensor electronics makes connecting to industrial PLC and control systems straightforward and simple.

Analog and Digital Communication Options

Optional Digital Communication Options

ATEX & IECEx Compliance

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Rheonics Instrument Selection

Rheonics designs, manufactures and markets innovative fluid sensing and monitoring systems. Precision built in Switzerland, Rheonics’ in-line viscometers and density meters have the sensitivity demanded by the application and the reliability needed to survive in a harsh operating environment. Stable results – even under adverse flow conditions. No effect of pressure drop or flow rate. It is equally well suited to quality control measurements in the laboratory. No need to change any component or parameter to measure across full range.

Suggested product(s) for the Application

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed