Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or mud weight, is the primary variable for controlling hydrostatic pressure to prevent fluid influx and formation fracture. Viscosity is essential for hole cleaning, ensuring cuttings are transported to the surface efficiently.

Table of Content

- Introduction

- Common challenges

- Rheonics Inline Viscosity and Density Sensors

- Sensor Data Integration

- Recommended installation for drilling mud monitoring

- Order Rheonics sensors

Introduction

Drilling fluids or muds properties monitoring is key to a successful well drilling process in the oil and gas industry. During drilling, the fluid or mud reduces working stresses, working as a lubricant and cooling the drill. When the drilling stops, the mud prevents the well’s cuttings from refilling the well hole by applying the required pressure on the well’s walls.

A drilling process can last months, and the drilling mud required needs to be closely monitored to ensure that a consistent fluid is fed to the well hole and recirculated. Monitoring parameters like density and viscosity of drilling fluid offers effective means to control mud and drilling process safety and efficiency. Drilling performance is optimized by the ability to recognize changes in the drilling fluid, analyze data trends and act upon what is causing changes in real time.

Rheonics inline viscosity and density sensors excel in the oil and gas industry due to their simplicity of installation, robustness, and repeatability of readings that enable online monitoring and control of fluids.

Learn more on mud weight relevance.

Common challenges

Properties such as the density and viscosity of the drilling fluid or mud must be within the designed specifications.

Density is key to determine the mud weight, related to the pressure applied on the walls of the well.

Viscosity varies during the process, when drilling you want a fluid-behavior mud to favor the movement, whereas when drilling stops, you require a more solid behavior to avoid cuttings from refilling the hole.

Measuring viscosity and density with traditional instrumentation is slow, labor-intensive, time-consuming and prone to inaccuracies.

Rheonics Inline Viscosity and Density Sensors

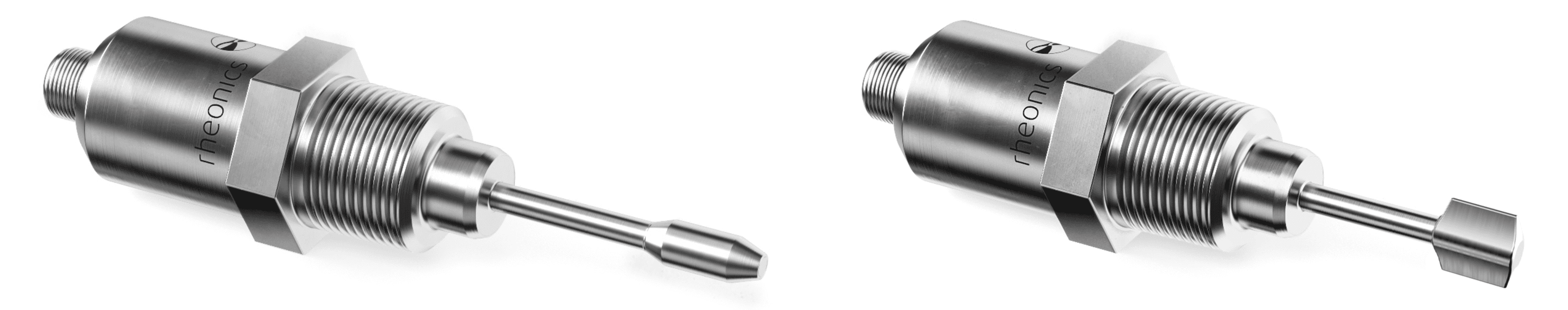

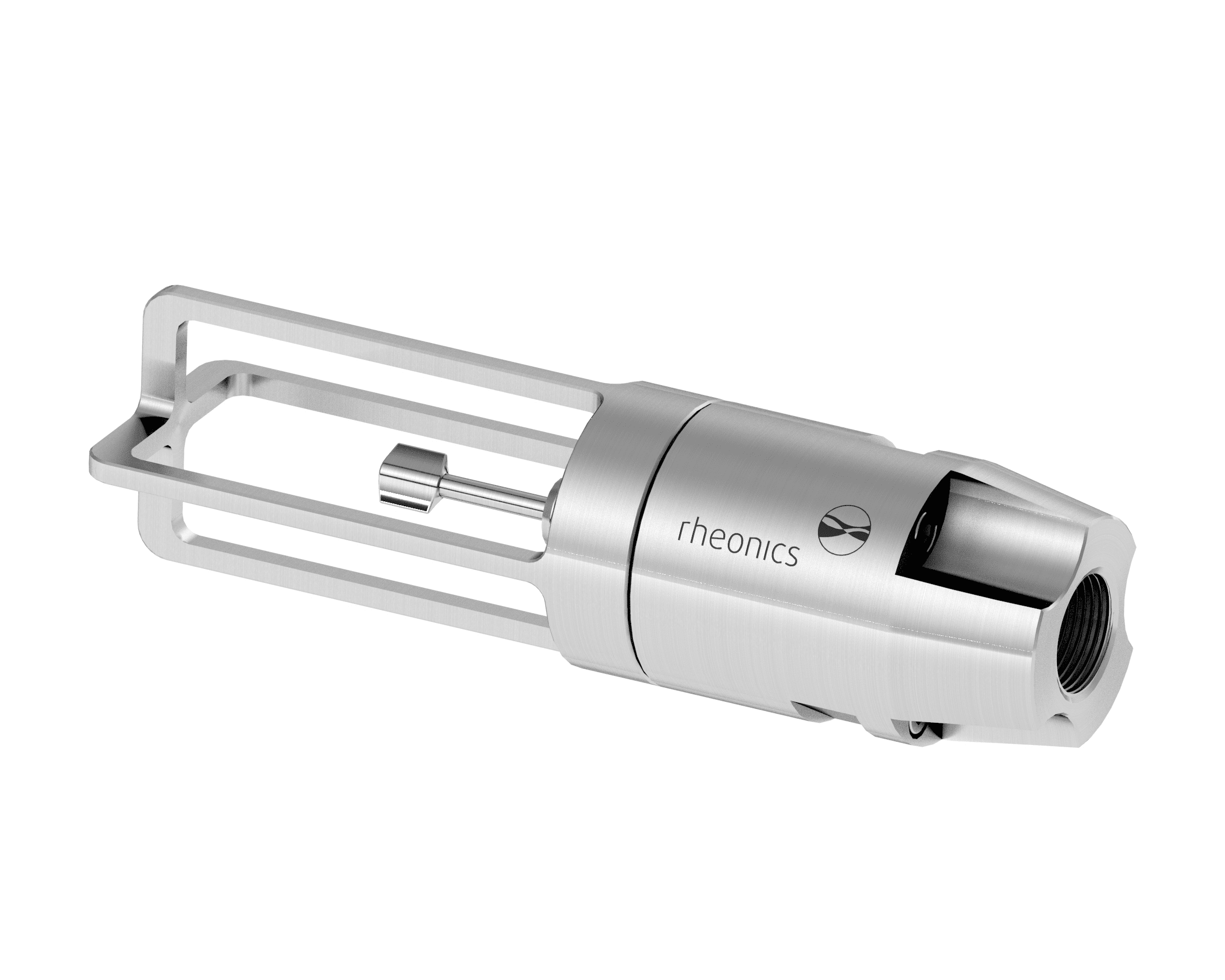

Rheonics enables continuous, accurate, real-time mud density, viscosity and temperature data measured by the single inline Rheonics SRD sensor. Alternatively, the Rheonics SRV sensor is able to measure viscosity and temperature.

Rheonics Type-SR sensors (SRV and SRD) are compatible with the harsh conditions of drilling fluids. Our sensor probes use a Stainless Steel 316L material which is generally compatible with the application. However, Hastelloy C22 is also available for specific requirements of fluid compatibility.

What is required for repeatable and accurate readings?

- Immerse the sensor probe’s sensing element completely in the fluid

- Avoid deposits on the sensing element that block the sensing element – Keep the probe clean

- Ensure the probe is ordered with the right temperature and pressure rating required on the application. Standard ratings are 125°C (250°F) and 15 bar (200 psi) which generally covers the limits in drilling mud.

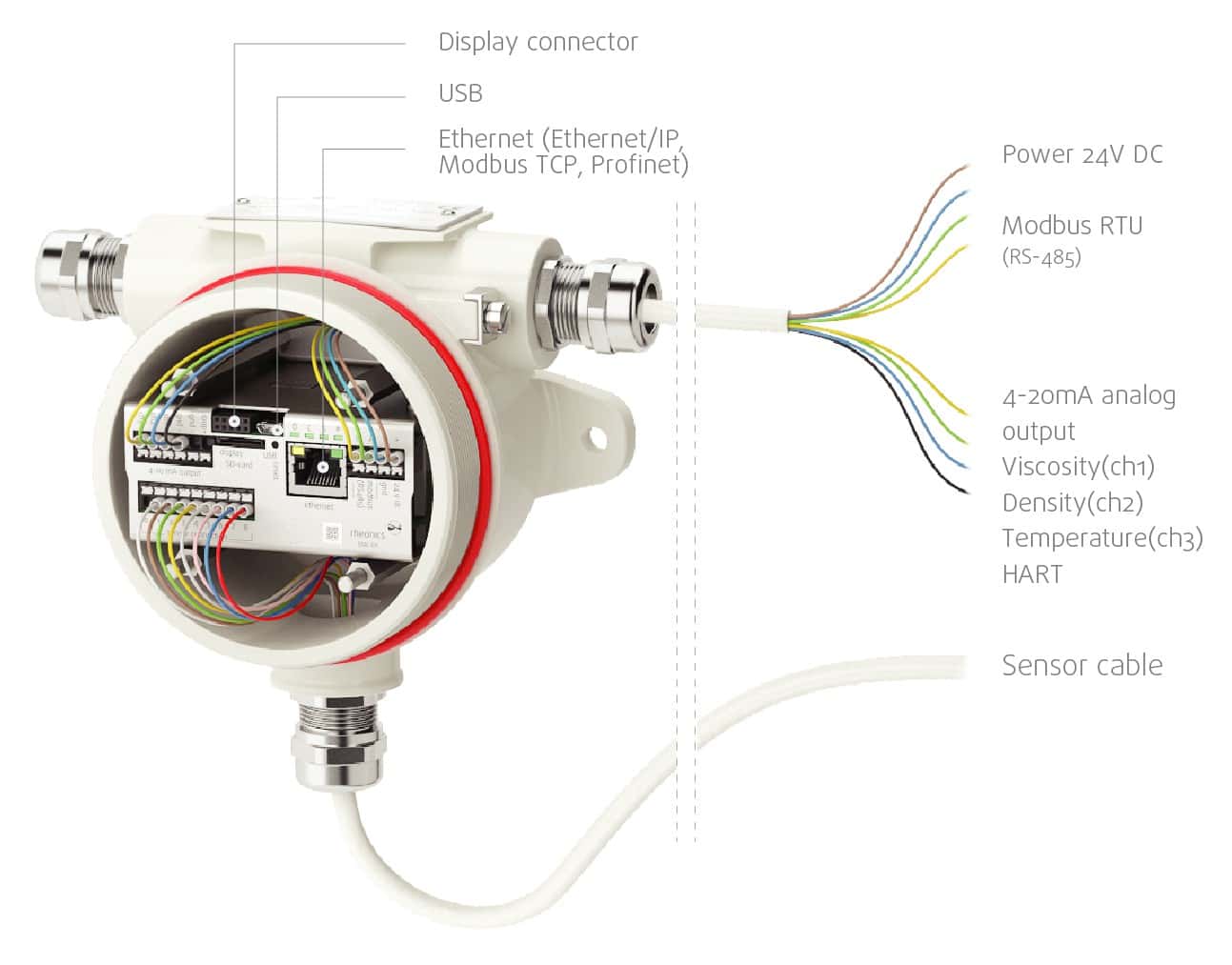

Sensor Data Integration

Rheonics sensor electronics are powerful units that handle the data measured by the probe and allows its integration through multiple communication protocols as Modbus TCP, Modbus RTU, Profinet, HART, Ethernet/IP, etc.

Wireless integration is possible usually through external adapters based on Modbus communication. Contact Rheonics Support Team for assistance in the integration.

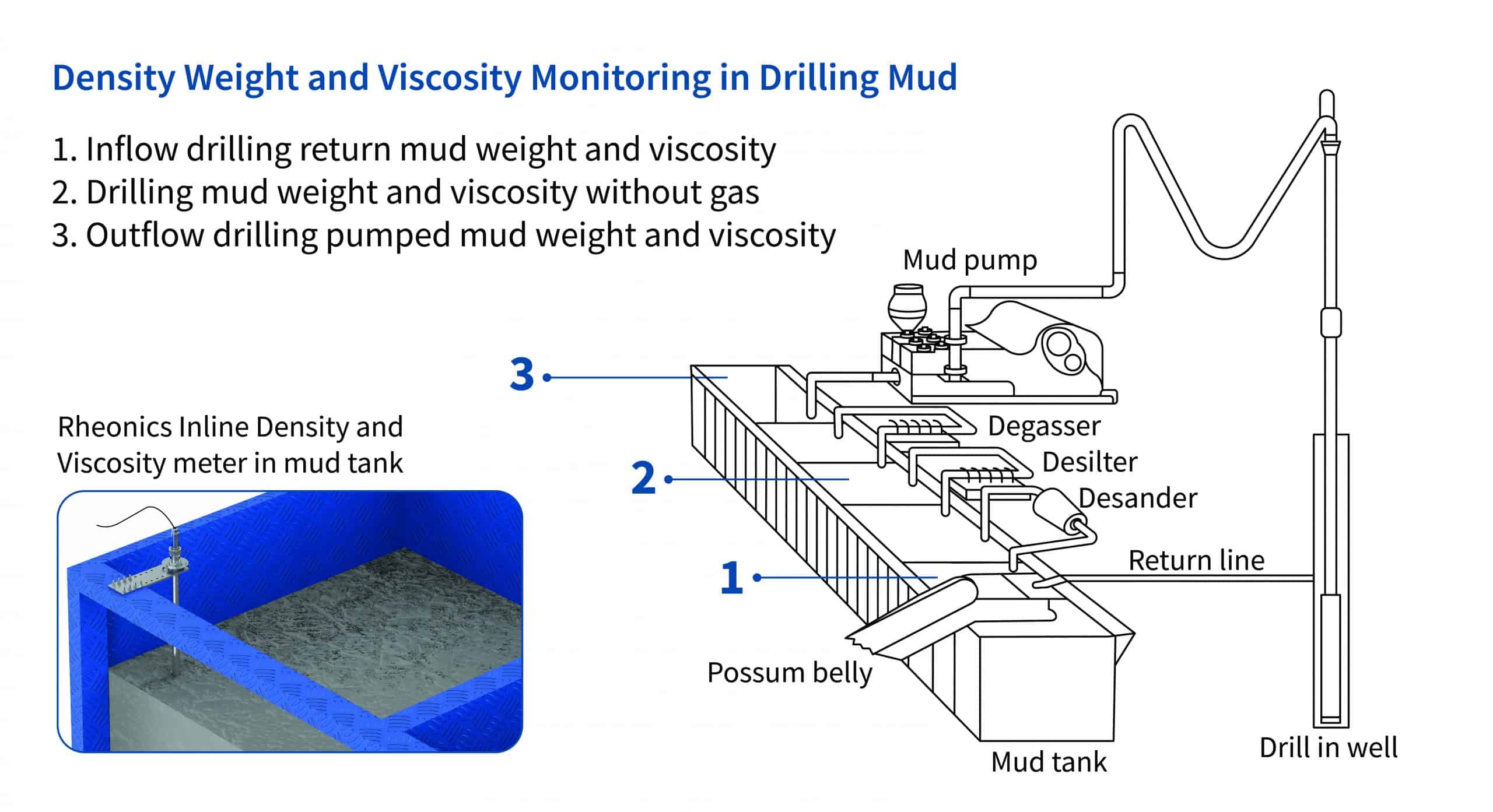

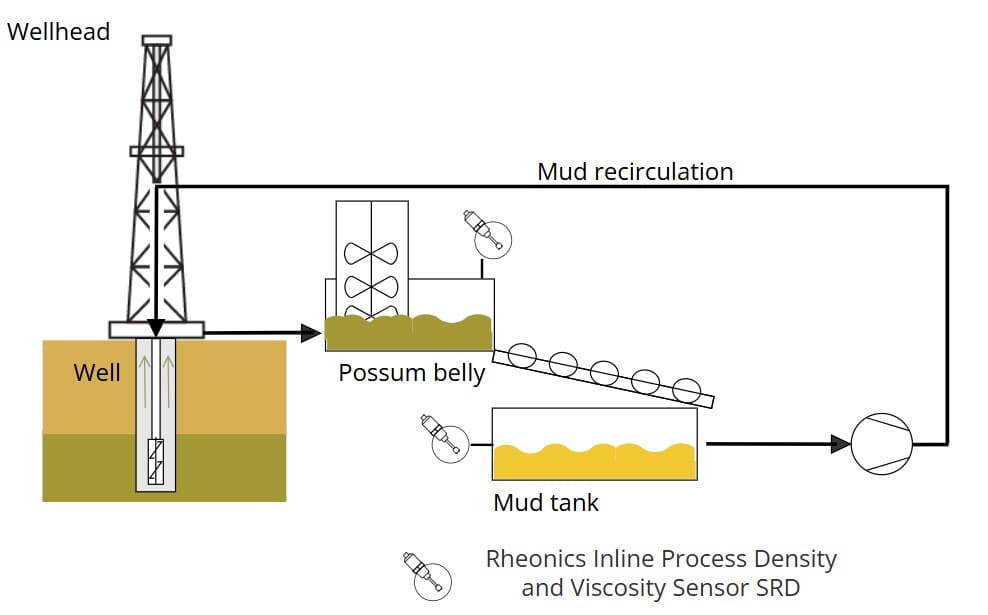

Recommended installations for drilling mud monitoring

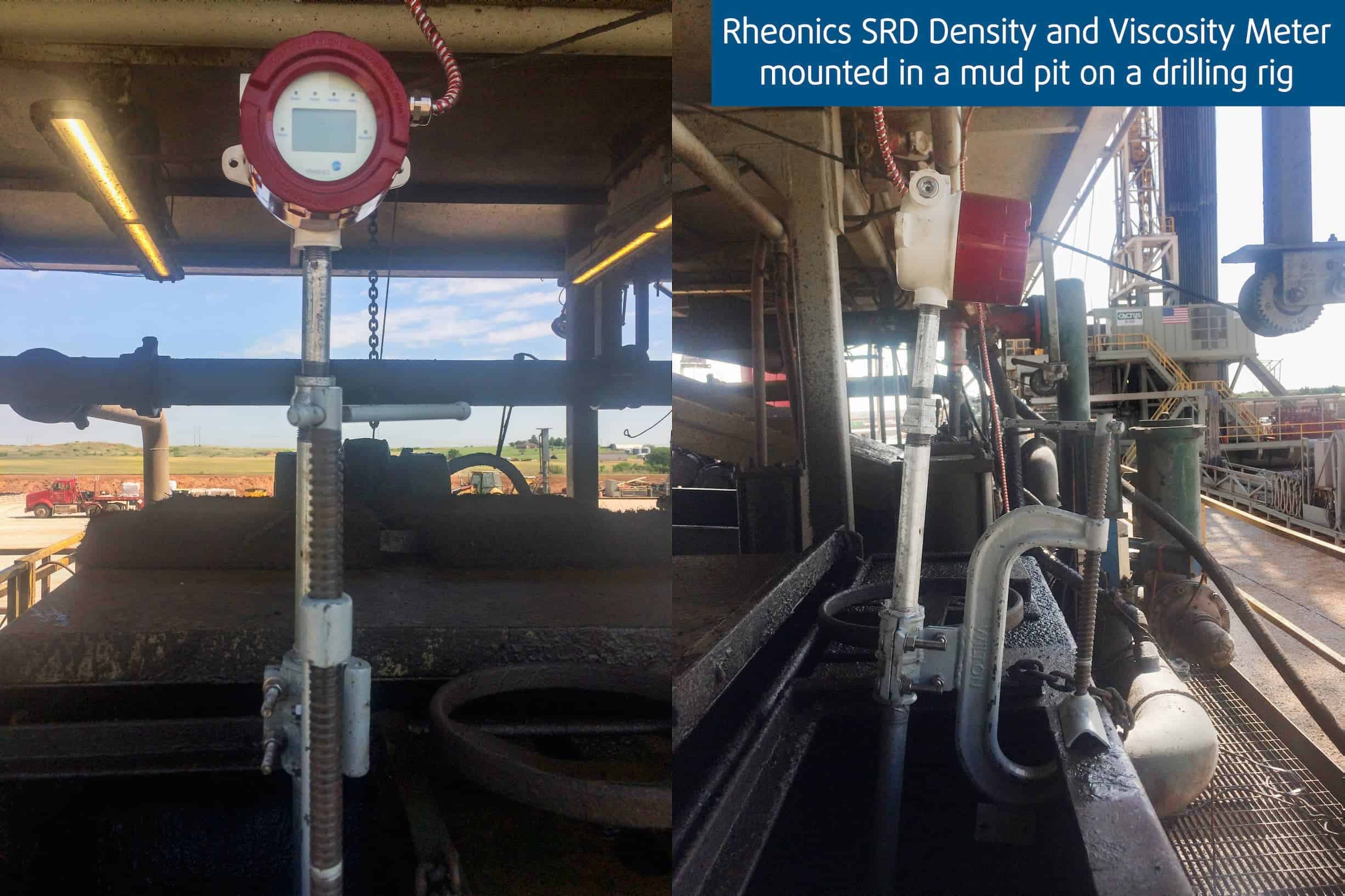

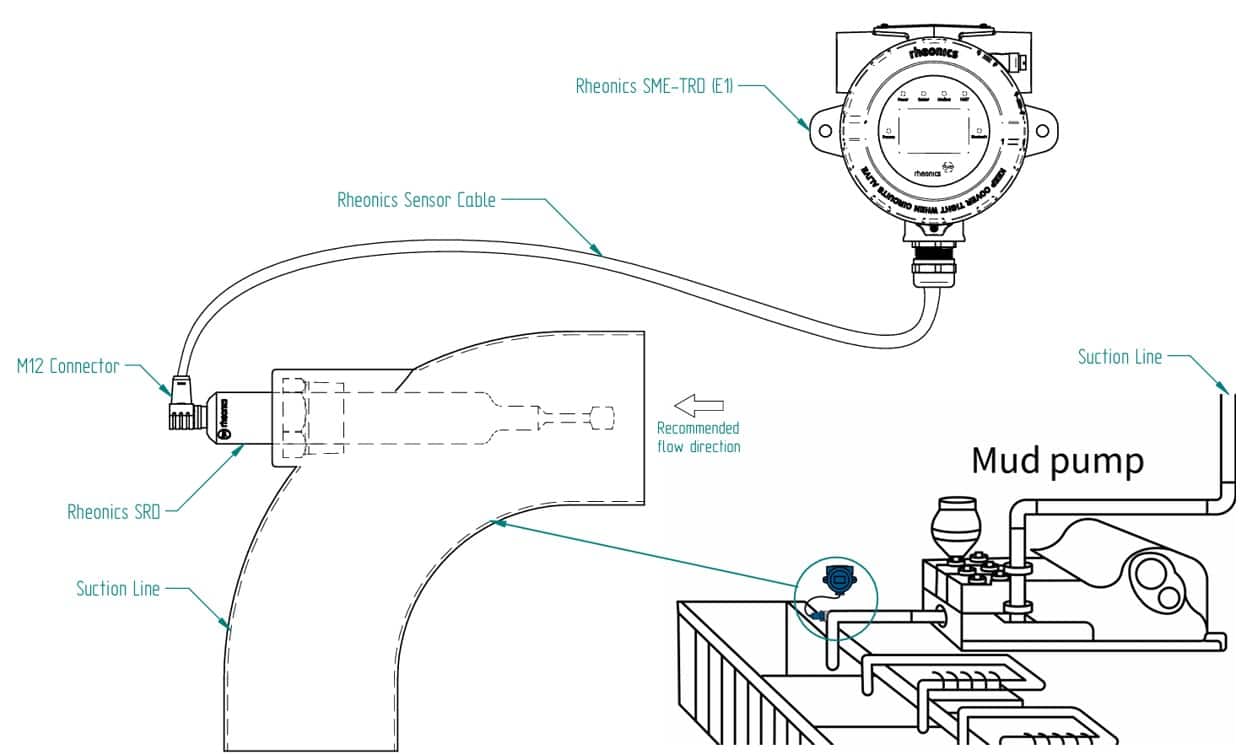

Rheonics sensors are recommended to be installed either in the drilling mud tank/vessel or suction line. Find more information about installation options here.

Installation in a drilling mud tank or vessel

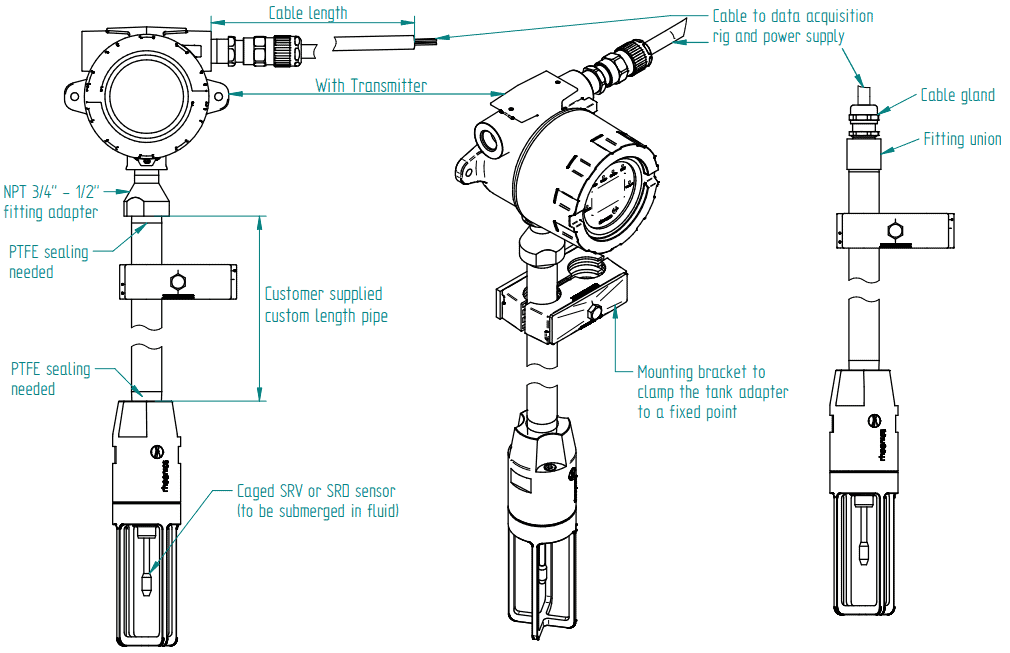

For this kind of installation, the sensor can be installed using the TMA-34N Tank Mount Adapter or the Teletube line; both are ideal here as they simplify immersion and retraction of the probe by the operator for probe cleaning, check or reinstallation in different vessels.

The TMA-34N works as a protection cage for the probe and allows the connection through a 3/4” NPT thread of a tube with a custom length to be attached to a fixed point from the top. When the TMA-34N is used, proper sealing is fundamental to avoid fluid getting into the electric connection of the probe. Follow the assembly steps in our TMA-34N article.

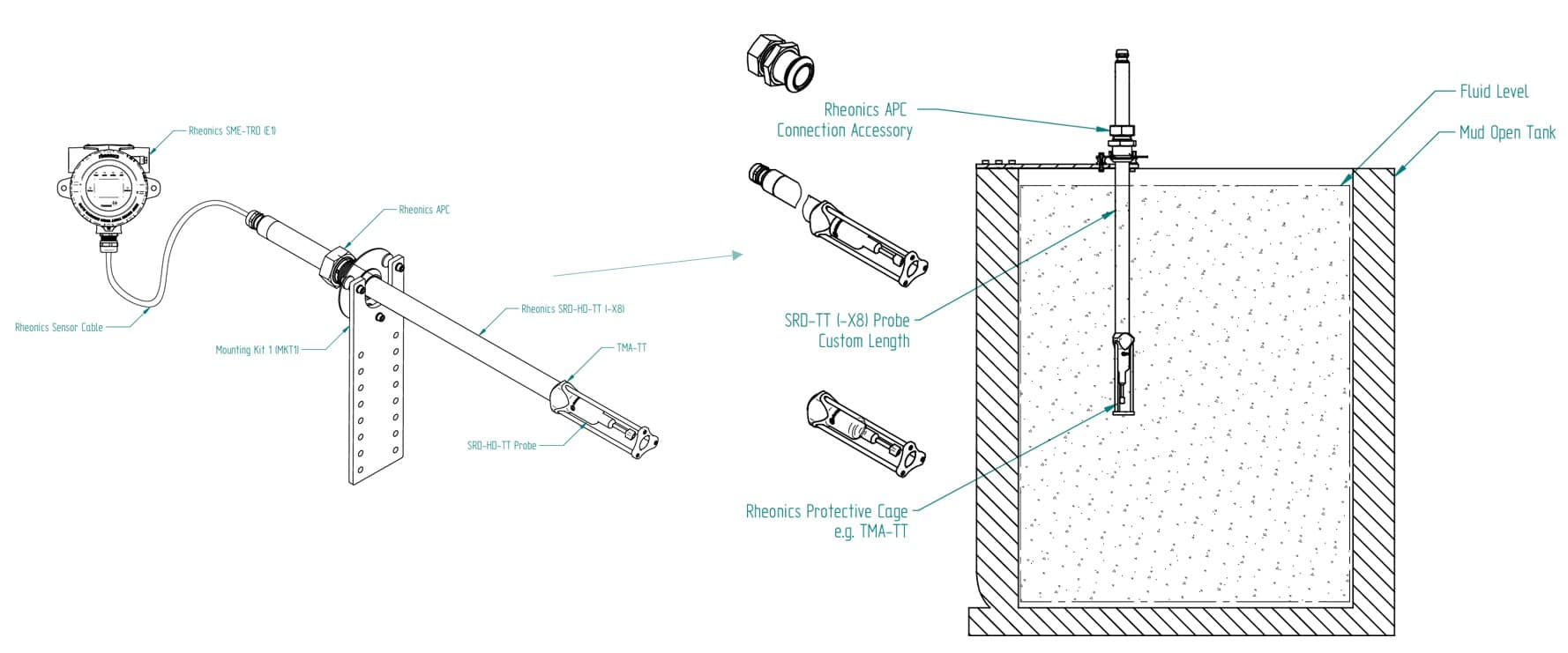

On the other hand, the Teletube probe variant has a modular and versatile design, based on a small probe, extendable with extension tubes and adaptable to protective cage (TMA-TT) and mounting kits (MKT) as shown in Figure 7.

Installation in Suction Line

Rheonics Sensors can also be installed in the suction line to take the mud’s real-time measurements. The recommended installation is to place the sensor in an elbow with the sensing element against the flow direction, see a reference in Figure 8.

Order Rheonics sensors

- Wide viscosity range – monitor the complete process

- Repeatable measurements in both Newtonian and non-Newtonian fluids, single phase and multi-phase fluids

- Hermetically sealed, all stainless steel 316L wetted parts

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing process lines

- Easy to clean, no maintenance or re-configurations needed

- Single instrument for process density, viscosity and temperature measurement

- Repeatable measurements in both newtonian and non-newtonian fluids, single phase and multi-phase fluids

- All metal (316L Stainless Steel) construction

- Built in fluid temperature measurement

- Compact form-factor for simple installation in existing pipes

- Easy to clean, no maintenance or re-configurations needed