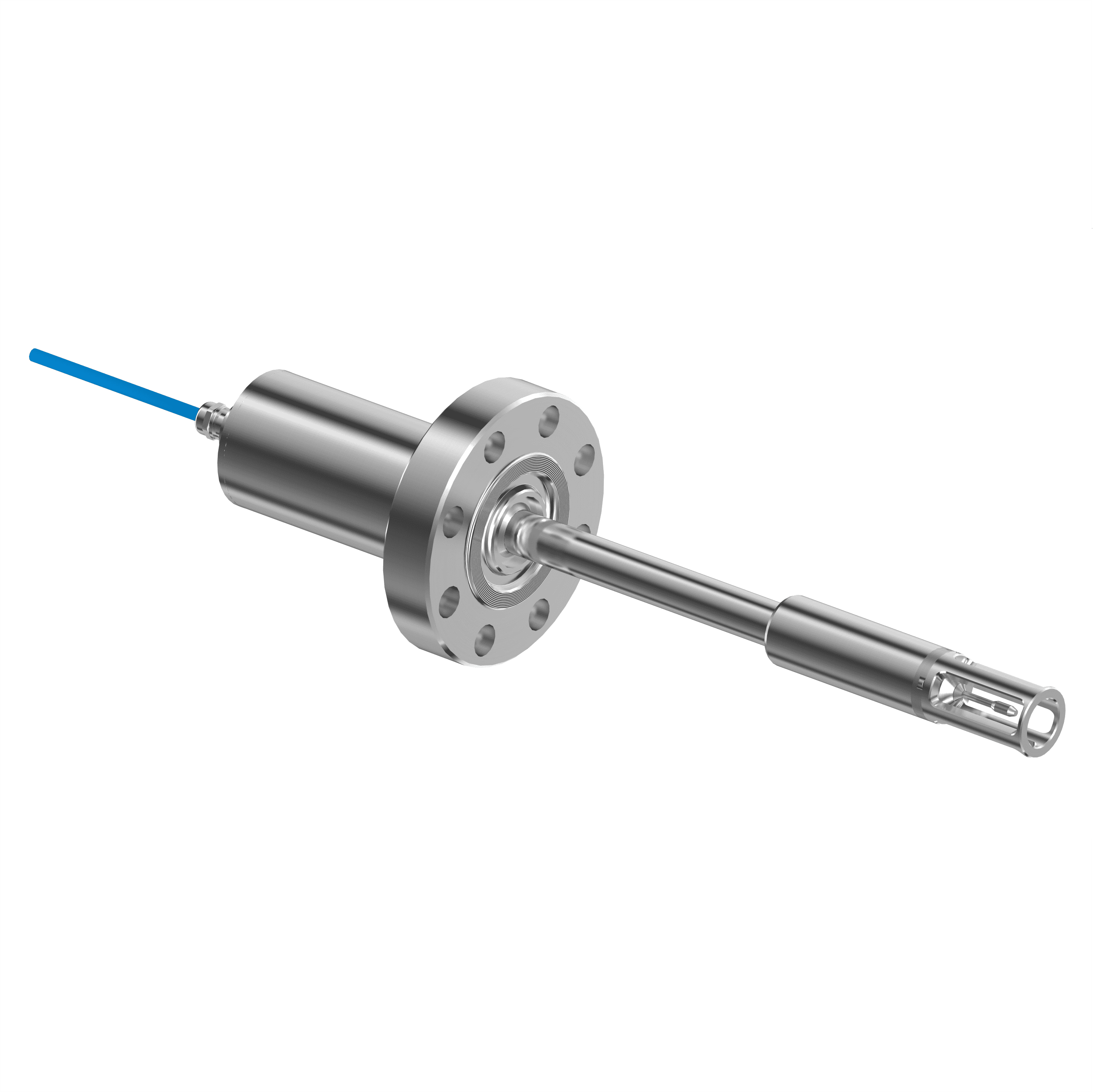

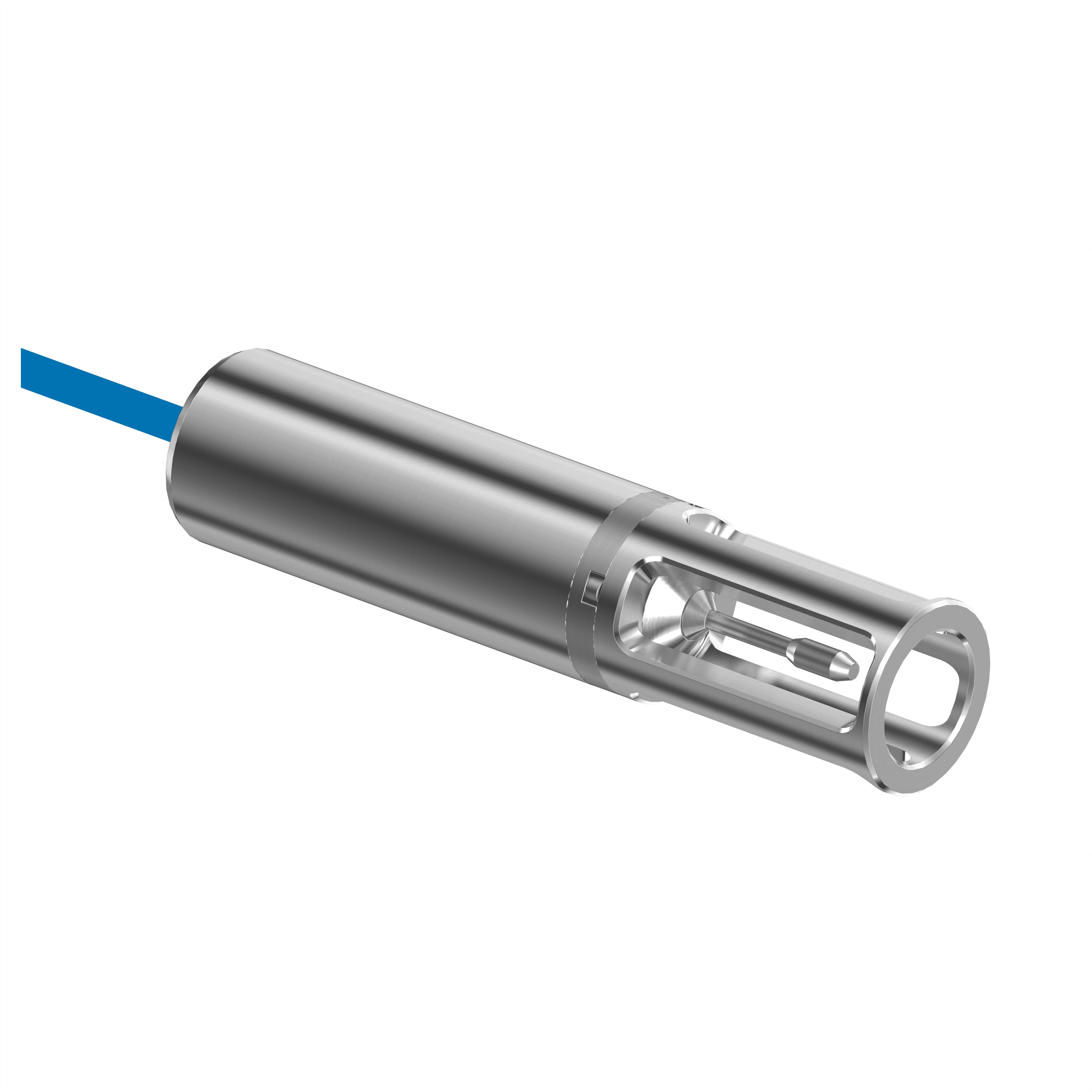

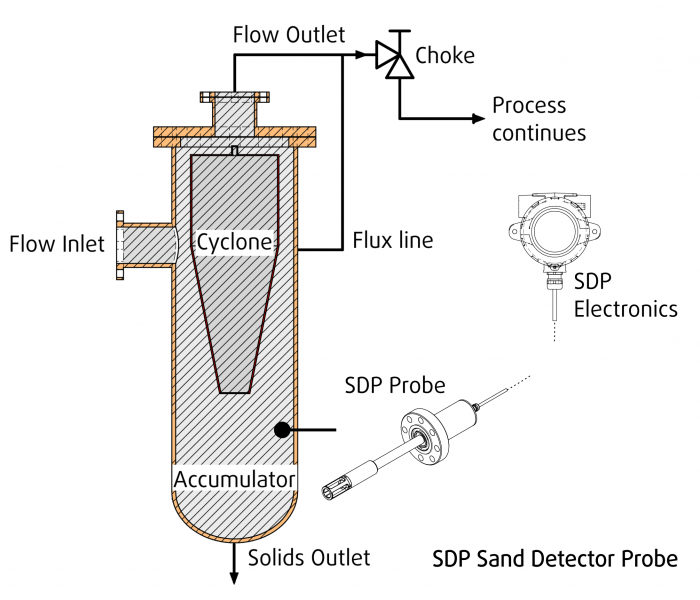

Rheonics Sand Detector Probe (SDP) is a switch level sensor used to detect the accumulation or presence of particles in fluid e.g. sand in a desander vessel or pipelines used in oil and gas industries. Rheonics SDP is designed to sustain high pressure environments such as those found in desanders. Rheonics Ostrich software that comes with the sensor makes real-time monitoring possible and recognitizion of phases in the fluid such as oil, water, sand, or a mix of them.

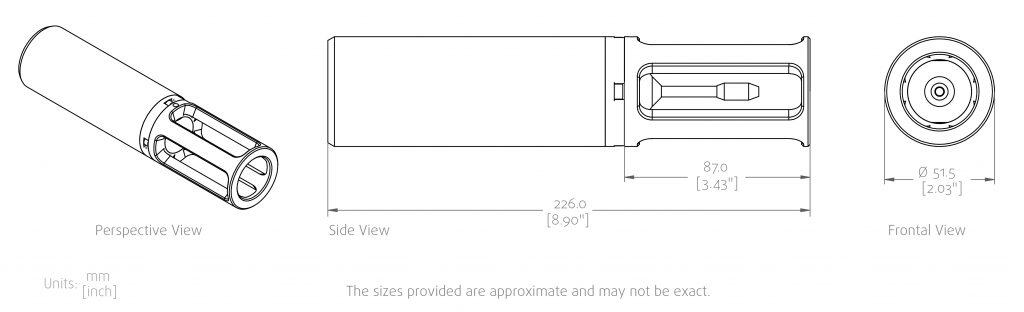

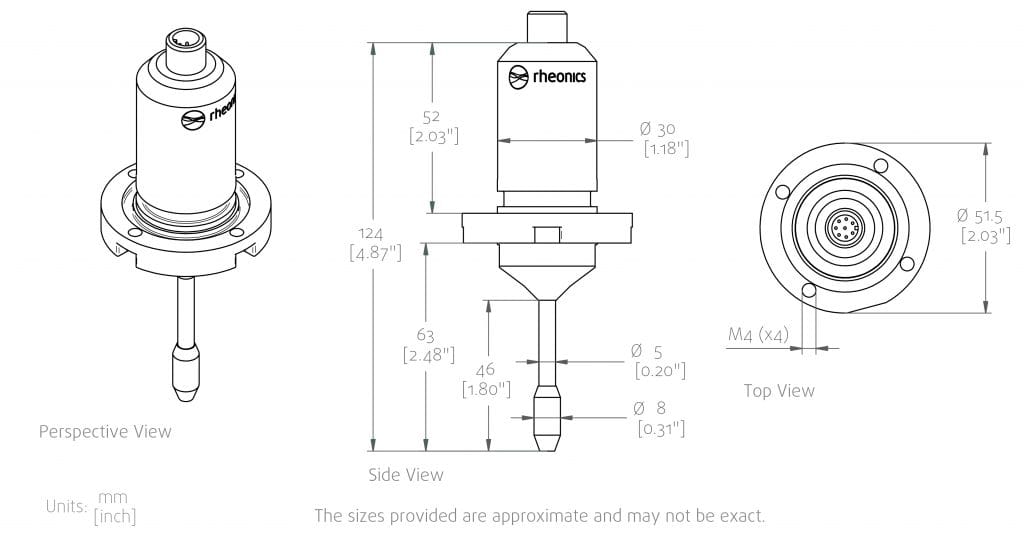

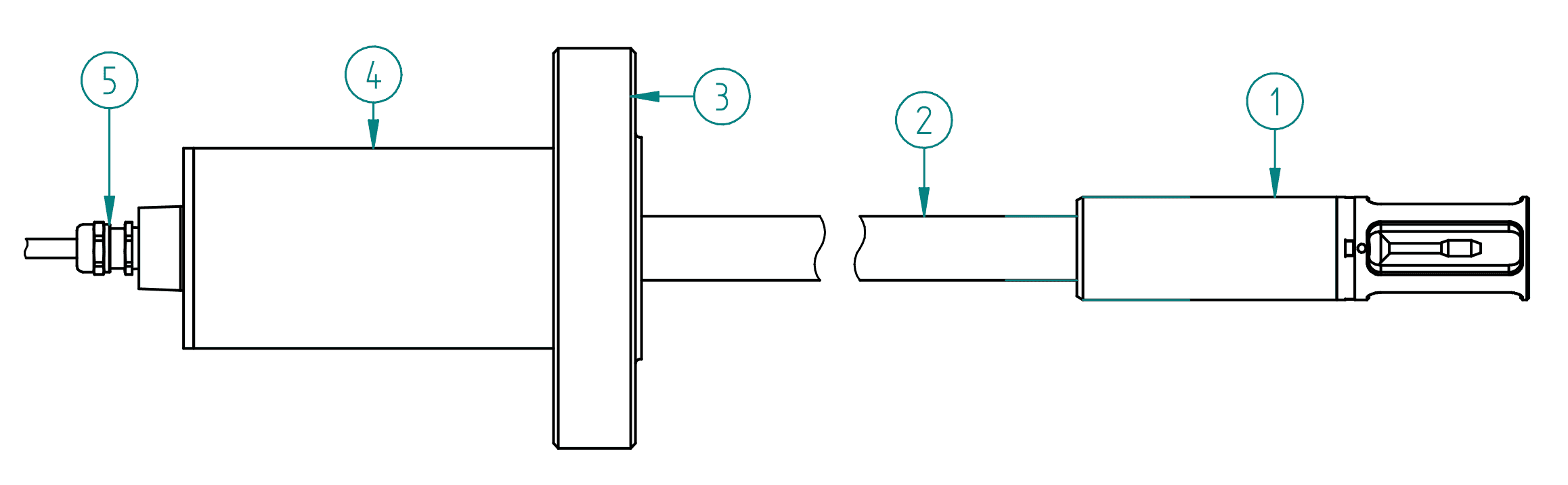

Rheonics SDP is offered with the SDP-X9 probe and the HP weld adapter (HPWA-SDP). The protection sleeve (SPS-SDP) may also be used in order to protect the probe from unwanted collisions during handling. Product number: SDP-X9-HPWA.

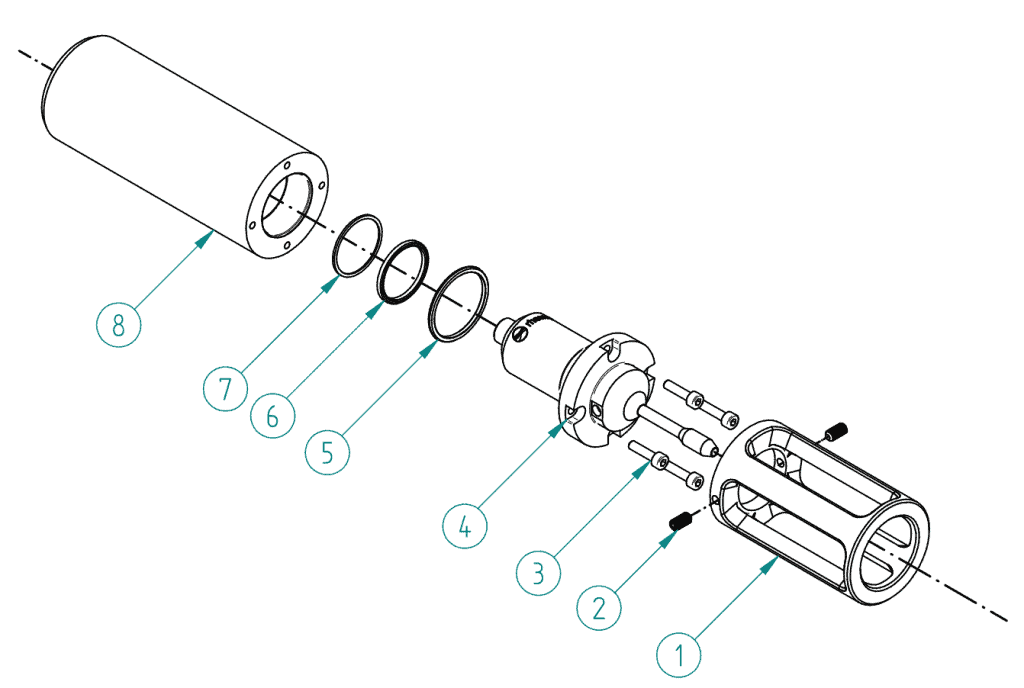

| Nr. | Code | Description | Qty. |

|---|---|---|---|

| 1 | SPS-SDP | Protection Sleeve SDP | 1 |

| 2 | M5X10-ST | M5 Set Screw | 2 |

| 3 | M4X15-BT | M4 Bolt | 4 |

| 4 | SDP-X9 | SDP Probe | 1 |

| 5 | OR1-SDP | O-Ring 32x2.5 - 90 shore - FKM | 1 |

| 6 | OR2-SDP | O-Ring 30x2 - 90 shore - FKM | 1 |

| 7 | BR-SDP | Back-up Ring - 30x2 - PTFE | 1 |

| 8 | HPWA-SDP | HP Weld Adapter for SDP | 1 |

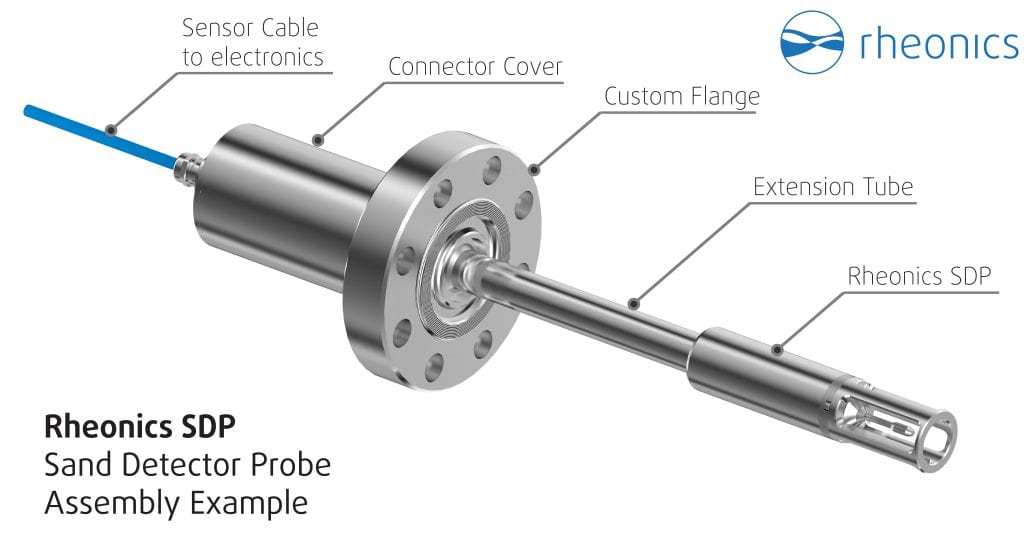

Add a custom extension tube and flange to the Rheonics SDP by welding. This can also be done by Rheonics under request. See Rheonics SDP Drawing for details.

| Nr. | Description | Note |

|---|---|---|

| 1 | SRD-X9-STD | Supplied by Rheonics |

| 2 | Extension Tube | Customer or Rheonics supplied - Define length and material compatible for welding on HPWA-SDP |

| 3 | Custom Flange | Customer or Rheonics supplied - Define norm, size, pressure and material compatible for welding on HPWA-SDP |

| 4 | Connector Cover | Protection for cable connection - Optional |

| 5 | Connector End | Cable gland - Optional |

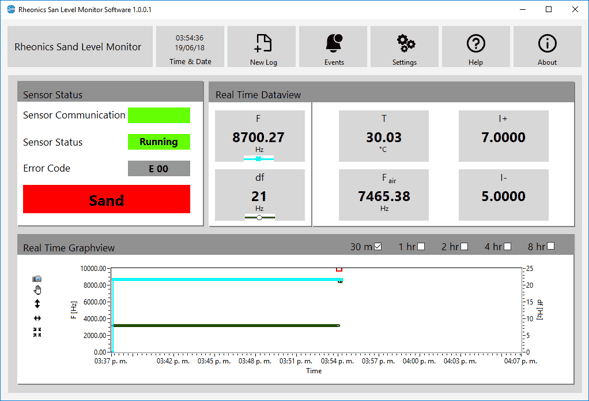

Software basic interface

- Shows sand presence

- Shows water detection

- Shows air detection

Software expert interface

- Shows sensor characteristics

- Time plot of detection

- Logging

- Automation (Alerts only)

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. Ultra-fast and robust electronics, combined with comprehensive computational models, make our sensors fast and accurate units in the industry. SDP gives real time, accurate fluid measurements every second. Embedded temperature sensor gives instantaneous inline fluid temperature.

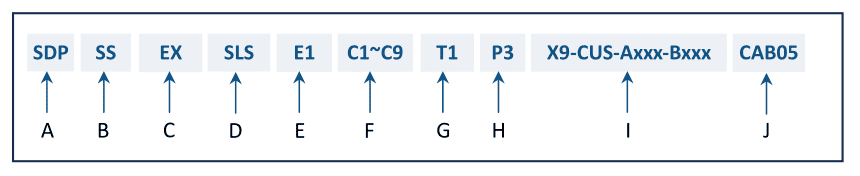

A: Sensor Type

B: Wetted Material

C: Certifications (Optional)

D: Measurement (See options table)

E: Electronics Type

F: Communication Protocols

G: Temperature Rating

H: Pressure Rating

I: Variant Design (See options table)

J: Cable Length

D – Measurement Configuration Options

| Code | Description |

|---|---|

| SLS | Sand Level Switch |

| SEM | Sand Erosion Monitor |

I – Variant Design Configuration Options

| Code | Description |

|---|---|

| X9-HPWA | Rheonics SDP only (no extension tube or custom flange) |

| X9-CUS-Axxx-Bxxx | Define A Insertion Length Define B Process Connection |

| Title | Summary | Link | File Category | Products | Tags | Type | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|---|

| Drawing – Rheonics SDP Sand Detector Probe | 2D drawing of SDP Sand Detector Probe, Parts, Assembly, Installation | Drawings | SDP | drawings |