Rheonics SRV and SRD sensors

Rheonics viscometer, SRV, and the density and viscosity meter, SRD, are inline sensors for monitoring and controlling industrial processes.

The type-SR sensors are used in various applications, requiring different process connections and designs to suit each working condition. This article lists below common process connections but does not limit the compatibility of the sensors with other industrial connections.

These connections can be ordered for Rheonics SRV and SRD variants. The Type-SR sensor variants are listed next.

Process connection codes

- X1: Threaded (e.g. NPT, G, M, PC, etc.)

- X2: Custom connection for short probe

- X3: Tri-Clamp

- X4: Flush probe variant

- X5: Long insertion probe variant with custom connection

- X6: Slimline probe variant with custom connection

- X7: Reactor probe variant with compressed connection

- X8: Teletube probe variant, ultra-long probe

Visit the Rheonics support portal for more information on each SRV and SRD codes:

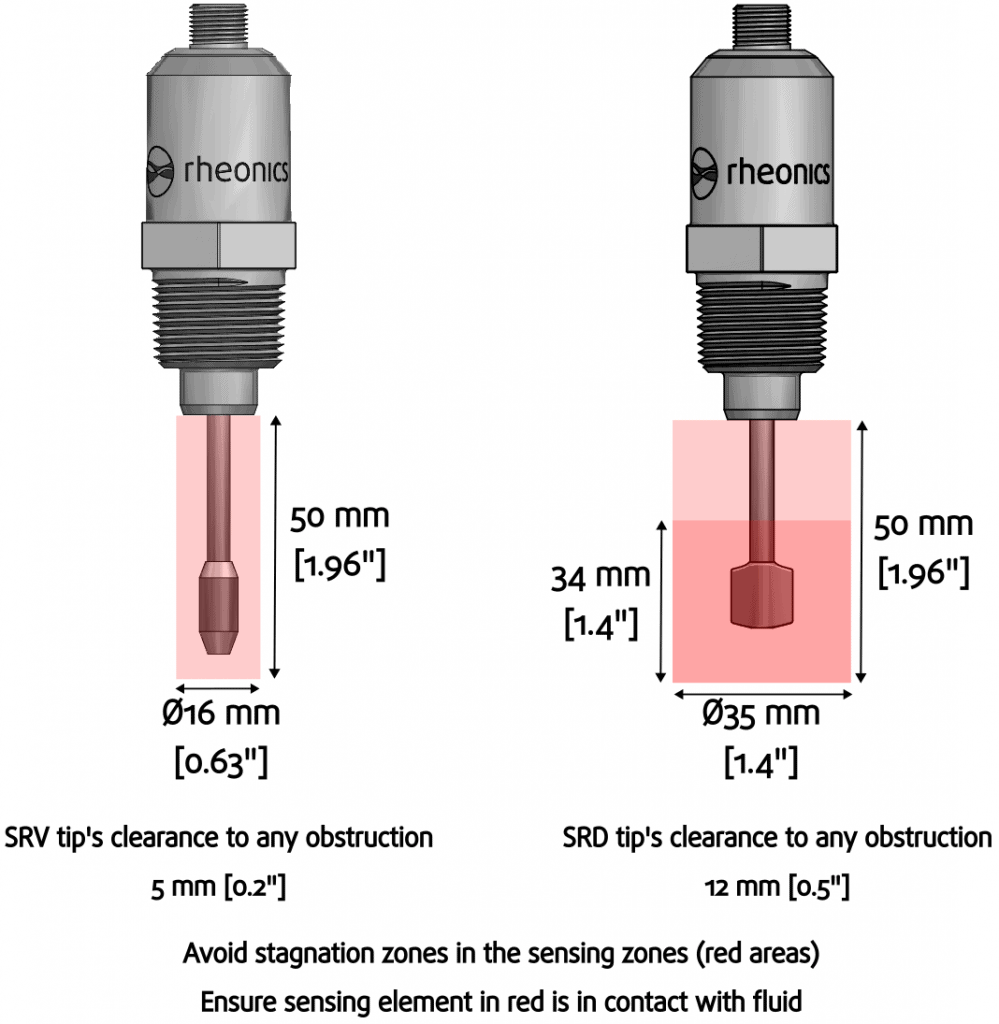

Regardless of the process connection, the SRV and SRD have each some installation requirements related to the sensing area of the probes. These are areas that should be free of deposits or obstructions and only filled by the fluid of interest.

Figure 1: SRV and SRD sensing areas

Next, some process connections available for the SRV and SRD probes are shown.

The G or BSPP standard (British Standard Pipe Parallel) is used for cylindrical parallel threads following norm ISO 228. Rheonics offers the SRV and SRD short probes with the G 1/2” size and offers accessories such as weldolets (HAW-12G for thick and thin walls) and flow cells (HPT-12G only for SRV). Installation of an SRV or SRD G1/2″ probe and the HAW weldolet have a 3-A certification available for hygienic and sanitary environments.

Learn more:

- Visit the SRV G1/2”: SRV-X1-12G

- Visit the SRD G1/2”: SRD-X1-12G

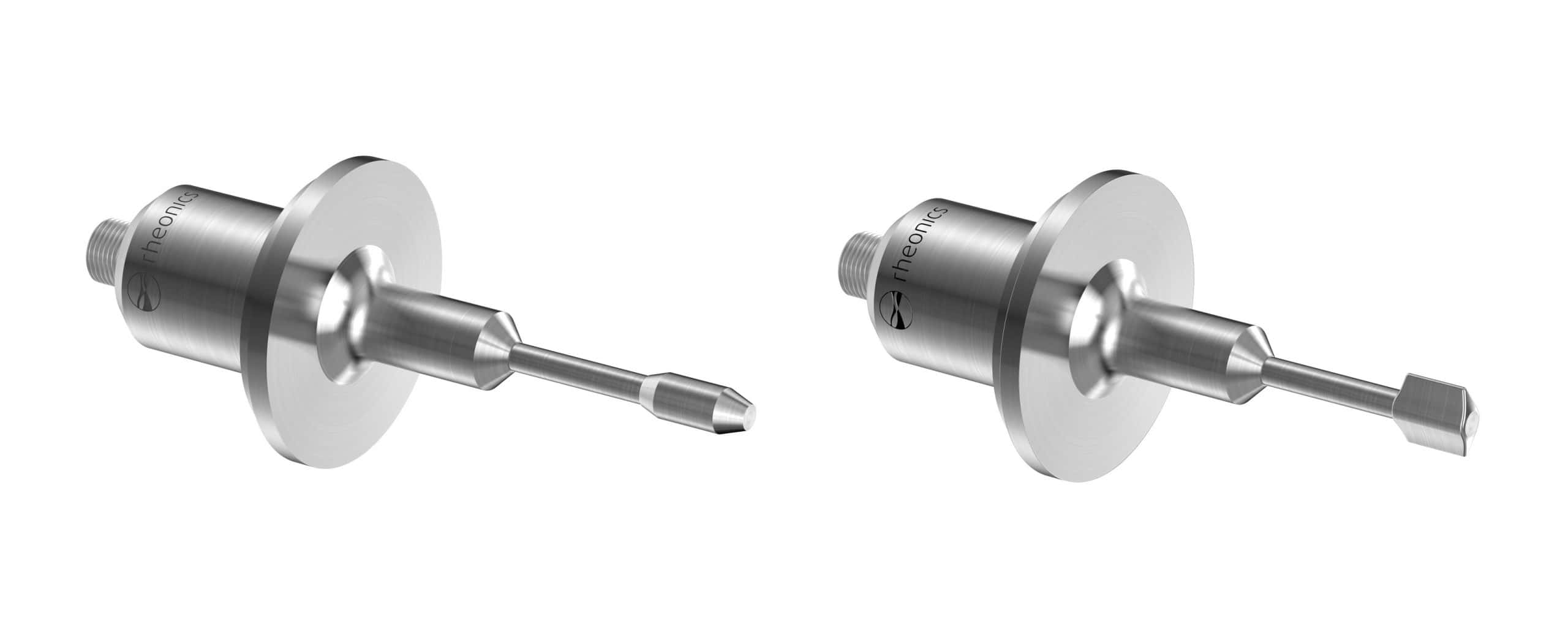

Figure 2: SRV and SRD G1/2 probe

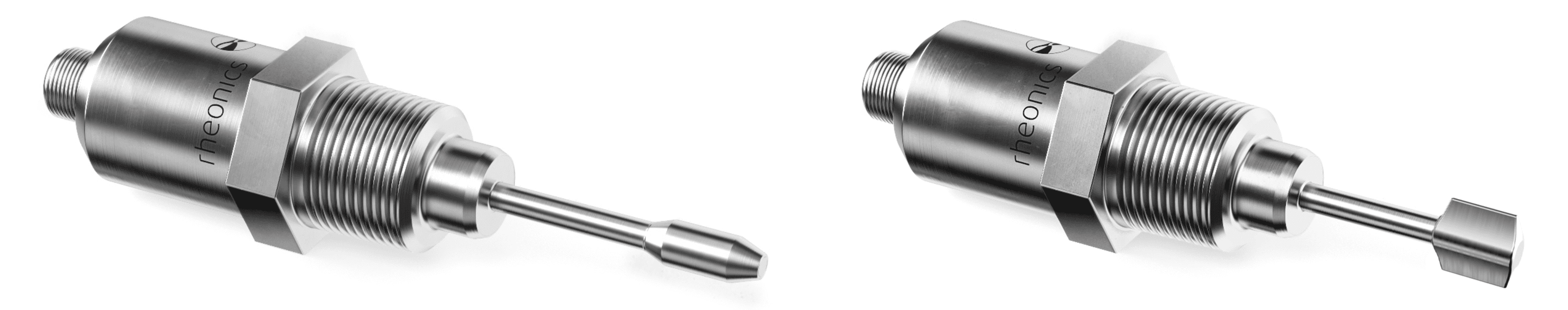

- NPT stands for National Pipe Thread, a standard from North America used for tapered threads. Rheonics offers the SRV and SRD probes with 3/4” NPT connection and these are the most common probe designs offered. Learn more:

- Viscometer SRV 3/4” NPT: SRV-X1-34N

- Density and Viscosity SRD 3/4” NPT: SRD-X1-34N

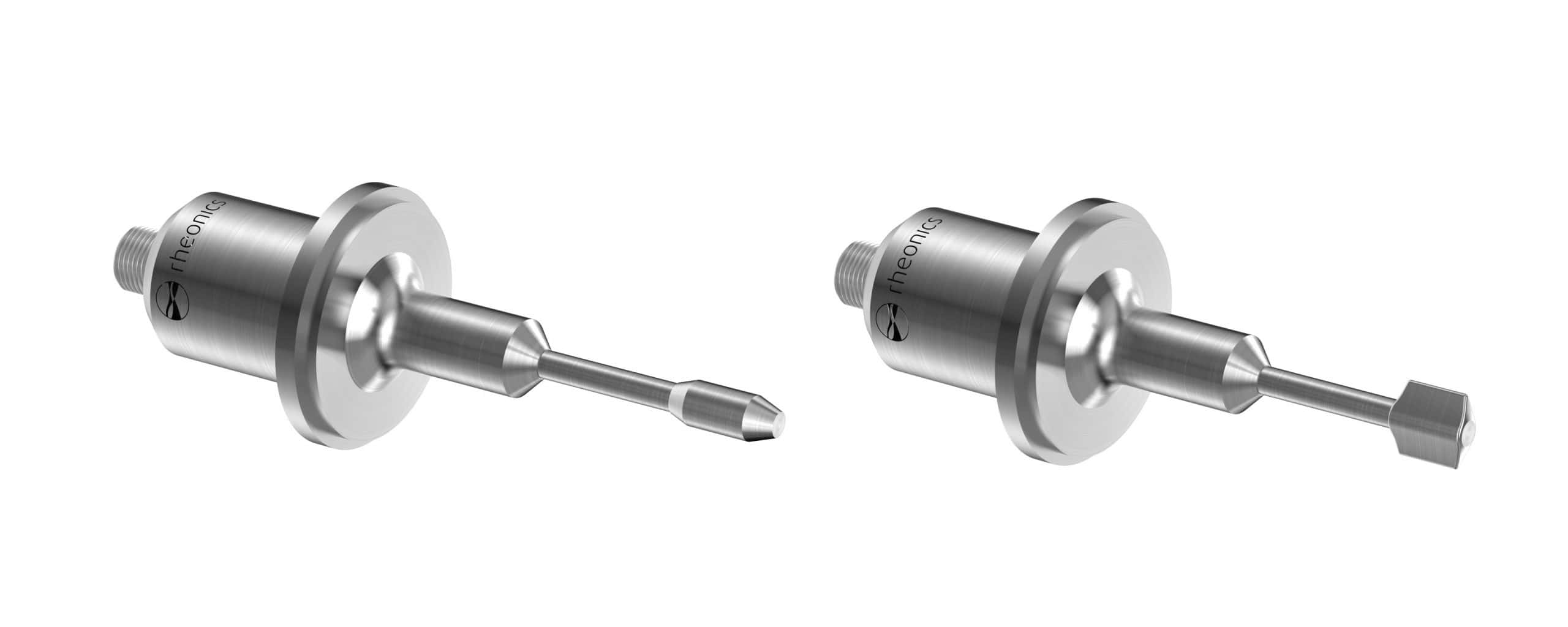

Figure 3: SRV and SRD NPT 3/4” probes

Figure 4: SRV and SRD Long Insertion NPT 1.25”

Other sizes for NPT and G (BSPP), such as 1” or 0.5” NPT, and other thread standards, like M, and PG threads, can be requested as long as they don’t interfere with the operation of the sensor probes. Contact the Rheonics Sales Team for these custom requests.

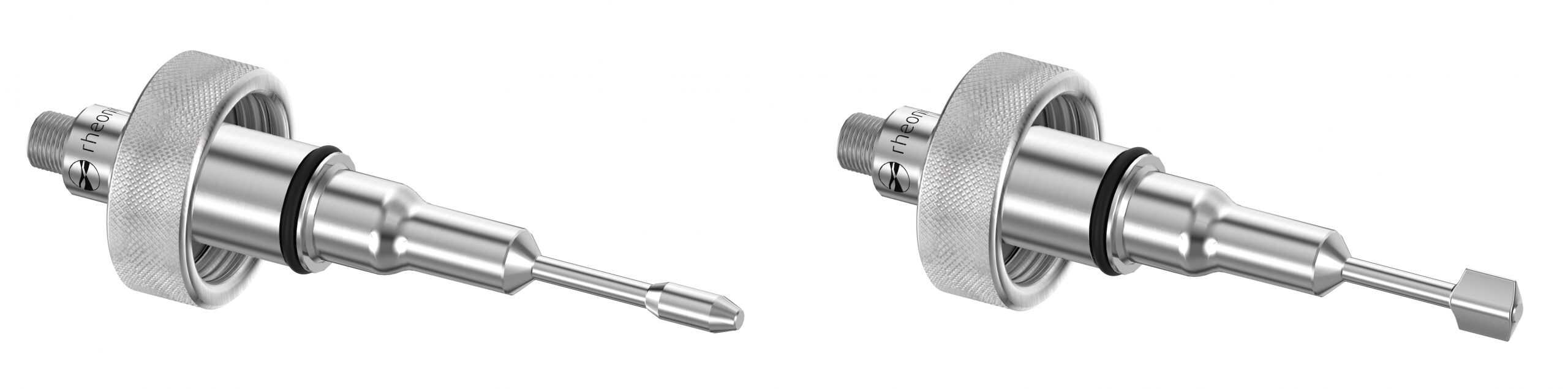

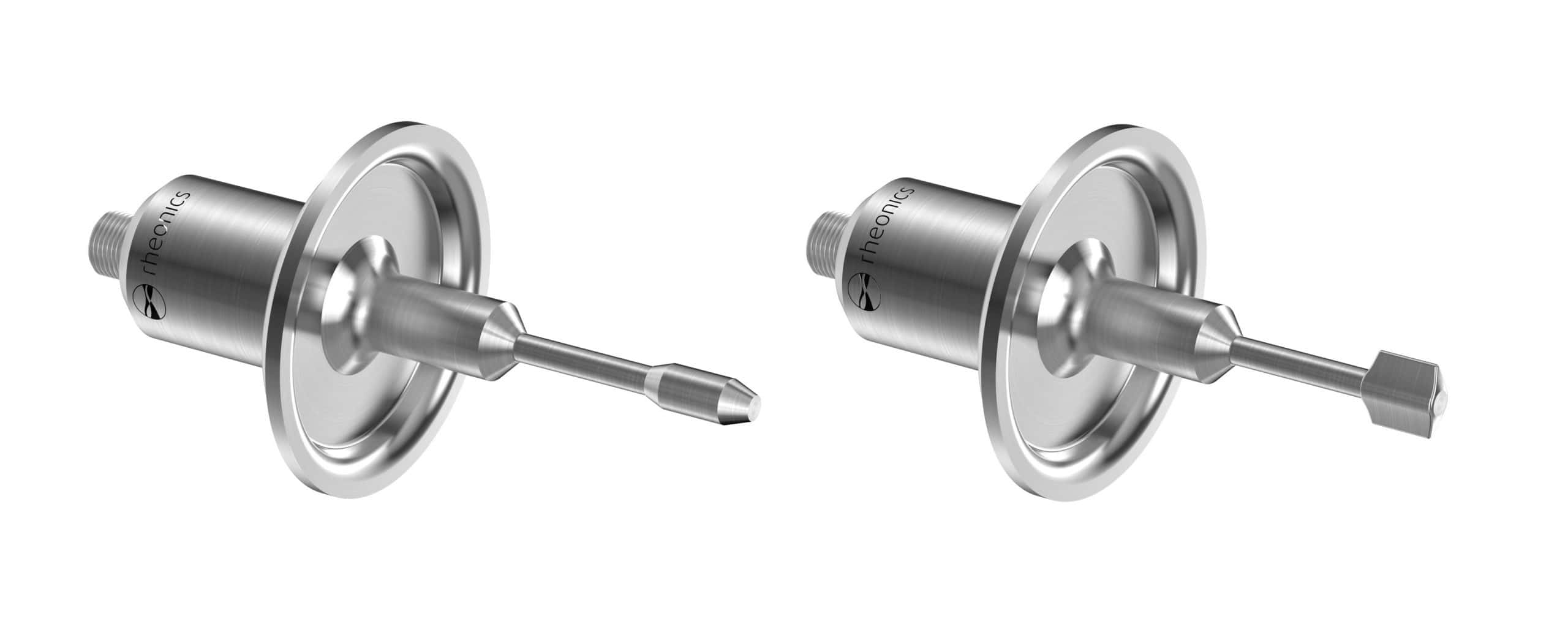

Tri Clamp connections are used mostly in hygienic applications for the food and beverage, and pharmaceutical industries. Its simple installation and disassembly favor its use in other industries as well. Rheonics can offer all Tri-Clamp sizes from 0.5” (D34) up, by varying the probe design to avoid affecting the operation of the sensor. Visit this article to review the Tri-Clamp sizes available for the SRV and SRD. Rheonics SRV and SRD Tri-Clamp probes are certified by EHEDG and 3A.

These Tri-Clamp sizes have the same TC or ferrule outer diameter of 34 mm (1.338”). It is available for the flush (-X4) and slimline (-X6) probes. The small size flange shouldn’t affect the sensing areas required for the SRV and SRD sensing element, as shown in Figure 1.

Visit the SRV Slimline suitable for the smallest Tri-Clamp: SRV-X6

Visit the SRD Slimline suitable for the smallest Tri-Clamp: SRD-X6

Figure 5: SRV and SRD Slimline Tri-Clamp DN 20

This Tri-Clamp connection is the same used for 1” TC ferrules. It is available for all SRV and SRD variants. Rheonics offers flow cell accessories for the 1.5” size, such as the IFC-15T-34N-SRV, IFC-15T-34N-SRD, FET-15T and FTP-15T.

Learn more:

Figure 6: SRV and SRD Tri-Clamp probes

This Tri-Clamp size is available for all SRV and SRD variants. Rheonics offers the FET-20 as a flow cell with this connection size.

Figure 7: SRV and SRD Long Insertion Hygienic Tri-Clamp 2”

Flanges are used for non-hygienic process connections of pipes and peripheral instruments in the industry usually with high-pressure conditions. The connection requires two matching flanges, bolts, and, in most cases, a seal.

There are different norms or standards for flanges that are classified mainly by size, pressure rating, and face type. Some standards are listed below.

- ANSI Flanges: North American standard for flanges. ANSI/ASME B16.5 standard defines flanges by pipe size, pressure rating (lbf) and type, raised face (RF), flat face (FF), or ring-type joint (RTJ).

- DIN Flanges: German standard for flanges. DIN 2527 standard defines the sizes available in DN (Nominal Diameter) and PN (Nominal Pressure) while flange type can be flat or raised face.

- JIS Flanges: Japanese Industrial Standards. JIS B2220 standard defines nominal sizes from 10 A to 1500 A and nominal pressure from 5K to 63K.

- BS/EN Flanges: British Standard. BS/EN 1092 standard is used to categorize flanges by dimensions (DN) and nominal pressure (PN).

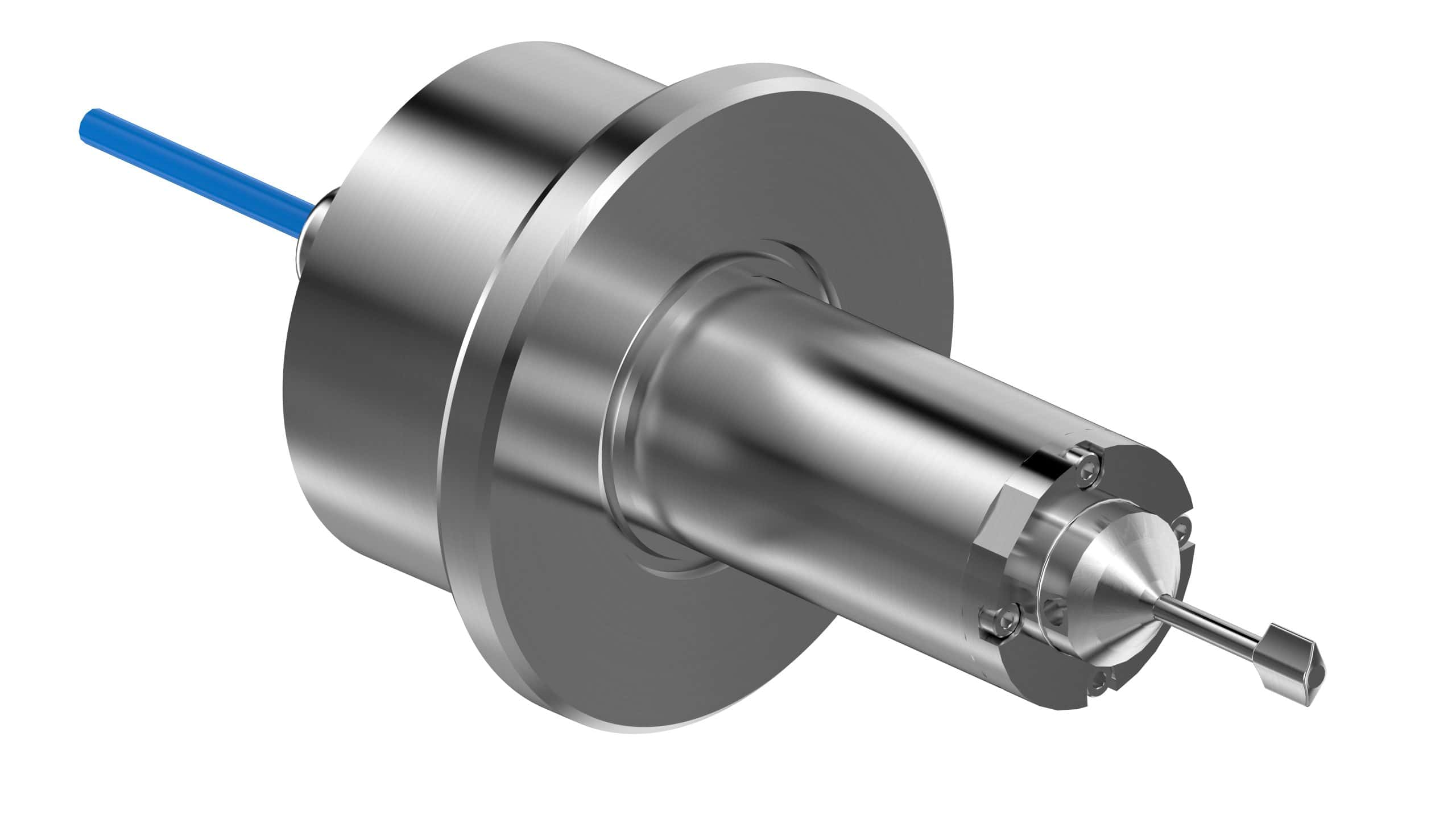

These and additional flange standards can be ordered for the SRV and SRD. For big flanges, a long insertion probe will be needed to ensure the sensing element is immersed in the fluid.

Figure 8: SRV and SRD Short Custom Flange

API Hubs or Grayloc connections can be used as a lighter, smaller, and easier-to-install alternative to flanges used in the petroleum industry, according to API standards (American Petroleum Institute). Rheonics offers the API hubs in a special HPHT (High pressure and temperature) variant for the SRV and SRD probes. Users can define the insertion length and hub size, also available for any other compatible flange.

Learn more: SRD-HPT-API

Figure 10: HPHT SRD with API 6A

The DIN 11851 is a German specification for a hygienic connection, planned for the food and beverage industry, and also used in dairy and pharmaceutical applications. It may also be referred to as Dairy Union and is very similar to the SMS hygienic connection. This connection requires a female port threaded on the outside, a seal, and a threaded nut to compress the male connection against the port.

Learn more:

- Type-SR Hygienic Sanitary Fittings: Read article

- Visit the Viscometer SRV Flush sensor for Hygienic and Sanitary applications: SRV-X4

- Visit the Density and Viscosity Meter SRD Flush sensor for Hygienic and Sanitary applications: SRD-X4

Figure 11: SRV and SRD DIN 11851

An ingold connection relies on a threaded connection with a seal. It is property of Mettler Toledo and is suitable for installation in reactor vessels. The connection can vary in DN size and length, Rheonics offers the DN25 Ingold connection for the Slimline Probes (-X6) variants.

Learn more:

- Viscometer SRV Ingold Connection: SRV-X6-BI25

- Density and Viscosity Meter SRD Ingold Connection: SRD-X6-BI25

This is a hygienic connection that requires a clamp and an O-ring for the correct seal. It is mostly used in the food and beverage industry, in lines for breweries, dairies, and similar. It was created by GEA company as a solution for deposit-free and easy-to-clean connections.

Rheonics offers the SRV and SRD probes in sizes DN25 (varinline connection type F) and above (varinline connection type N). Varinline Housings are especially useful for installations in small pipes, like a 1” line, since the housing has a bigger space around the sensing element, the small line doesn’t affect the readings.

Learn more:

The SMS 1145 connection follows the Swedish Manufacturing Standard (SMS), developed by the Swedish Standards Institute (SIS) for hygienic sealing used in the food, chemical, and pharmaceutical industries. It consists of a male threaded part, a liner, a seal gasket, and a nut that threads onto a female part to secure the sanitary connection. This connection is assembled similarly to the DIN 11851, but with differences in dimensions and thread profiles.

The SMS connection is a cost-effective hygienic connection, but limited in pressure rating and requires correct alignment for sealing.

The IDF connection, based on International Dairy Federation standards, is designed for hygienic applications in the dairy, brewing, and pharmaceutical industries. It consists of a male threaded part, a liner, a T-shaped seal, and a hexagonal nut that secures the connection. While less common than DIN 11851, it offers precise, sanitary performance and complies with BS 4825 tube standards.

The RJT (Ring Joint Type) connection is designed for hygienic applications in the food, dairy, and beverage industries. It consists of a male threaded part, a pressed liner, a seal, and a hexagon nut. The RJT complies with BS 4825 and ISO 2037 standards, offering a reliable solution for low to moderate pressure systems.

Sensor Technology, Working principle and Applications

Viscometers

Density Meters