Consumer care products enclose a wide range of personal and household items designed to support hygiene, grooming, and overall well-being. Viscosity and density monitoring play a crucial role in the filling and formulation accuracy of these products, as they provide insights into product flow behavior, stability, and packaging performance. Inline monitoring ensures smooth filling operations, consistent product net content, and shelf-life stability, and prevents stringing, under/over-filling, or phase separation.

Table of Content

- 1. Introduction

- 2. Filling Lines in Consumer Care Products

- 2.1 Key applications

- 2.2 The importance of viscosity and density in Filling Lines in Consumer Care Products

- 2.3 Production/Application process

- 3. Rheonics Type-SR Inline Sensors Overview

- 3.1 Hygienic certification

- 4. Recommended installation

- 4.1. Mechanical Installation Considerations

- 4.1.1. SRV and SRD Installation Requirements

- 4.1.2. SRD Additional Installation Requirements

- 4.2. Common solution by Rheonics

- 5. Process Conditions and Best Practices

- 6. References

Introduction

![Figure 1 - Various types of packaging for consumer care products for filling and storage [1]](https://rheonics.com/wp-content/uploads/2025/10/figure-1-various-types-of-packaging-for-consumer-care-products.jpg)

Figure 1 – Various types of packaging for consumer care products for filling and storage [1]

Care product manufacturers require precision in formulation and packaging to ensure product consistency, consumer safety, and regulatory compliance. Filling lines are central to this process and face diverse challenges, including handling products with a wide range of viscosities, preventing foaming or stringing during dispensing, and ensuring accurate net content across different packaging formats.

Viscosity and density variability in raw materials and final product, temperature sensitivity, and batch-to-batch stability during the process make production more complicated. Usually, traditional lab-based sampling methods are used, but these provide occasional insights that are not able to capture real-time changes in fluid properties. On the other hand, inline measurements give continuous and real-time visibility of the process, allowing to have faster control response.

Rheonics sensors offer significant operational and economic advantages for consumer care filling lines, going beyond measurement accuracy to improve efficiency, reliability, and cost savings:

-

Measure accurately the viscosity, consistency, density, concentration, and temperature of consumer care products.

-

Deliver reliable performance under high pressure and temperature conditions.

-

CIP-compatible and EHEDG-certified, with hygienic process connections such as Tri-Clamp, Varinline, and more.

-

Easy integration with PLC/DCS systems via Profinet, Modbus, Ethernet/IP, 4–20 mA outputs, and more.

-

Factory-calibrated and suitable for any fluid; no recalibration required.

-

Improve line efficiency, reduce product giveaway and rejected batches, leading to an offset sensor investment within the first year.

Filling Lines in Consumer Care Products

Care products, such as shampoos, lotions, creams, gels, and toothpastes, require precise production control. Filling lines for these products need precise control over rheological properties like viscosity and density. This ensures product stability and consistent dosing during packaging and quality control.

These products can be categorized into two main groups: liquids and semi-solids, and these can be filled into different types of packaging like bottles, sachets, tubes, jars, and aerosols.

Key applications

Products in each category group require a distinct type of packaging that needs different manufacturing techniques. These include:

Rigid containers (Bottles, Dispensers, and Jars)

Usually made of plastic and sometimes glass, these are the most common presentation designed for thin liquids and creamy products (e.g., shampoos, conditioners, liquid detergents, liquid soap, mouthwash, creams, and lotions). Some common filling methods are by gravity, overflow, piston, progressive cavity pumps, or vacuum filling.

![Figure 2 - Overflow Filling Process [2]](https://rheonics.com/wp-content/uploads/2025/10/figure-2-overflow-filling-process.jpg)

Sachets (Flexible pouches)

Also common for liquid and creamy products, but these are popular in mass markets for their economical and simple presentation. These require different filling processes, like form-fill-seal (FFS) or pouch filling systems equipped with dosing pumps.

![Figure 3 - Form Fill Seal Filling Machine [3]](https://rheonics.com/wp-content/uploads/2025/10/figure-3-form-fill-seal-filling-machine.jpg)

Tubes

Common for semi-solid products such as toothpaste, gels, ointments, and creams. Tubes are usually made of plastic or aluminium, and are filled by a piston or pump fillers, and then sealed.

![Figure 4 - Tube Sealing Process [4]](https://rheonics.com/wp-content/uploads/2025/10/figure-4-tube-sealing-process.jpg)

![Figure 5 - Tubular Form Fill Seal Technology [5]](https://rheonics.com/wp-content/uploads/2025/10/figure-5-tubular-form-fill-seal-technology.jpg)

Spray cans (Aerosol, Atomization presentation)

Found in products like deodorants, shaving foams, hair sprays, and some skincare products. These require handling both the liquid formulation and the propellant (compressed gas or liquefied gas).

![Figure 6 - Aerosol Filling Process [6]](https://rheonics.com/wp-content/uploads/2025/10/figure-6-aerosol-filling-process-758x1024.jpg)

The importance of viscosity and density in Filling Lines in Consumer Care Products

Viscosity measures a fluid’s resistance to flow. In consumer care filling applications, it affects how products move through the line, how accurately they are dispensed, and how cleanly they are packaged.

-

Filling accuracy and dispensing precision: Viscosity determines if a product flows smoothly through nozzles or creates issues like stringing, dripping, or splashing.

-

Product stability and shelf-life: Proper viscosity helps emulsions and suspensions remain stable, preventing phase separation, sedimentation, or texture degradation.

Density refers to the mass of a material per unit volume. In consumer care filling applications, it is directly related to product consistency, packaging compliance, and formulation quality.

-

Net content control: Density impacts the volume-to-mass ratio, ensuring containers meet declared weight or volume requirements and preventing underfilling or overfilling.

-

Formulation consistency: Variations in density could indicate deviations in raw material proportions, temperature effects, or process instabilities that can alter product performance.

Production/Application process

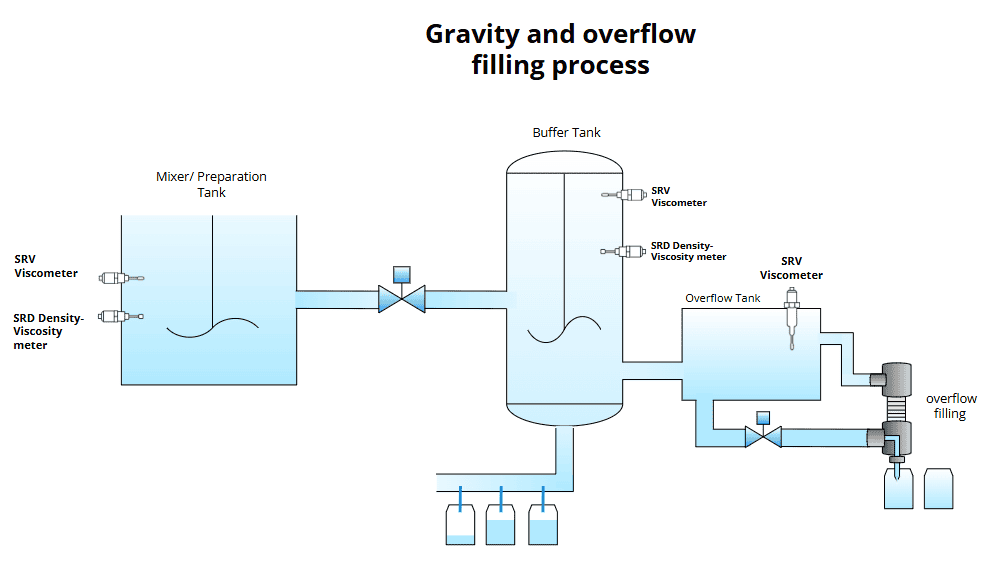

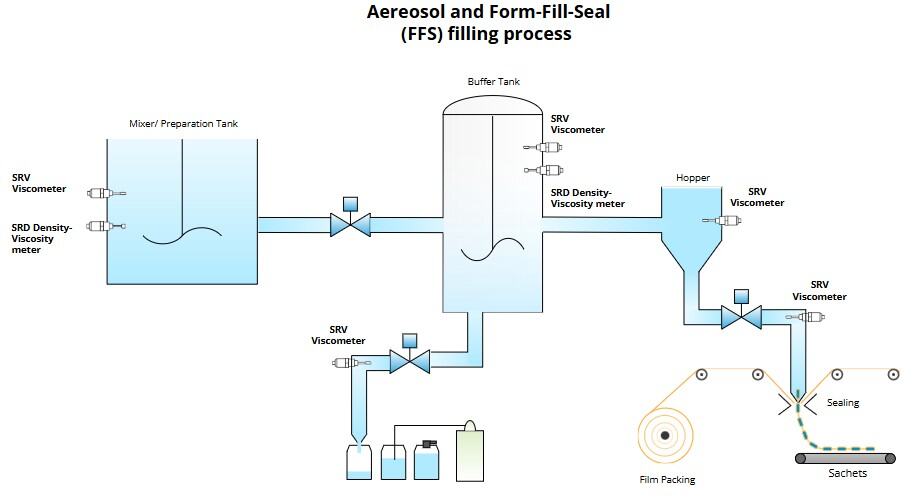

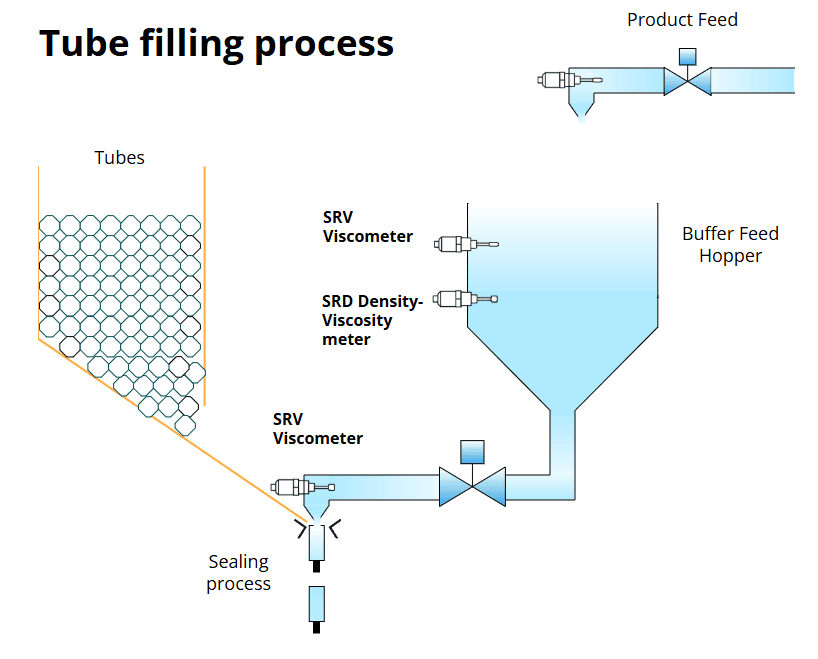

All filling processes begin in a mixer or preparation tank, where the product is either prepared or stored after production to maintain proper mixing and homogenization. At this stage, monitoring density and viscosity helps ensure product uniformity, which directly impacts downstream filling quality and batch consistency. From here, the mixture can be directed to different filling processes. Typically, the product is first pumped to a buffer tank, where sensors can be installed either along the transfer line or on the buffer tank itself to monitor the final product before filling.

For gravity filling and overflow filling processes (Figure 7), sensors can be installed in the buffer tank or transfer line to monitor product condition before filling, ensuring that the product maintains proper flowability through the filling lines. This guarantees repeatable batch performance, reducing the risk of failed batches due to flow inconsistencies.

For aerosol and Form-Fill-Seal (FFS) filling processes (Figure 8), sensors can be placed upstream of the filling nozzles to verify that the product maintains the correct state for injection. Monitoring in this stage helps prevent nozzle clogging and over- or under-filling product, ensuring proper net mass filling in sachets and spray cans.

We also encounter processes involving highly viscous fluids such as semisolids or pastes, examples include toothpaste, gels, ointments, and creams, where the products are typically packaged in tubes, (Figure 9), this process is closer to an extrusion system: the product is first loaded into a hopper and then fed by a dosing piston pump that injects the material into the tube before it is sealed. In this setup, the sensor can be installed in the product feed line or hopper to monitor product condition and ensure proper flowability through the injection nozzles. Alternatively, the sensor may be placed in the injection line itself; however, this is only practical when the product is injected in a continuous process rather than in short, unit-based filling cycles.

Rheonics Type-SR Inline Sensors Overview

Rheonics Type-SR sensors (SRV and SRD) provide continuous in-line measurements of viscosity, density, and temperature for process monitoring and control. The SRV is designed to measure viscosity and temperature, while the SRD adds density to the measurement.

These sensors are factory-calibrated and do not need recalibration over their operational lifetime. However, clients may require calibration or verification for instruments used in their industry as part of their Quality Control. Optional re-adjustments or offset corrections can be performed if needed to match specific references.

All sensors are factory-calibrated and can go throughout their service life without requiring recalibration. However, certain industries may demand verification or calibration as part of their Quality Control procedures. Also, re-adjustments or offset corrections can be applied to align with specific reference standards. For more information, see Calibration of inline process viscometer SRV in field and factory.

Rheonics sensors work with a patented technology, Balanced Torsional Resonator (BTR). This technology offers clear advantages compared to alternative technologies: the sensors are compact, lightweight, and resistant to external vibrations.

Rheonics SRV and SRD sensors are proven solutions in consumer care product filling lines. They deliver real-time measurements of viscosity and density, ensuring that products such as shampoos, lotions, creams, gels, and aerosols maintain consistent flow properties throughout the filling process. Continuous inline monitoring improves batch-to-batch uniformity, minimizes product waste, and enhances overall filling line efficiency and reliability.

Hygienic certification

By default, Rheonics Type-SR probes are built with a hygienic mechanical design, which ensures their suitability for sanitary applications. When required, they can also be delivered with certifications from recognized organizations like 3-A and EHEDG.

For more details, visit Rheonics hygienic and sanitary installation.

Recommended installation

Mechanical Installation Considerations

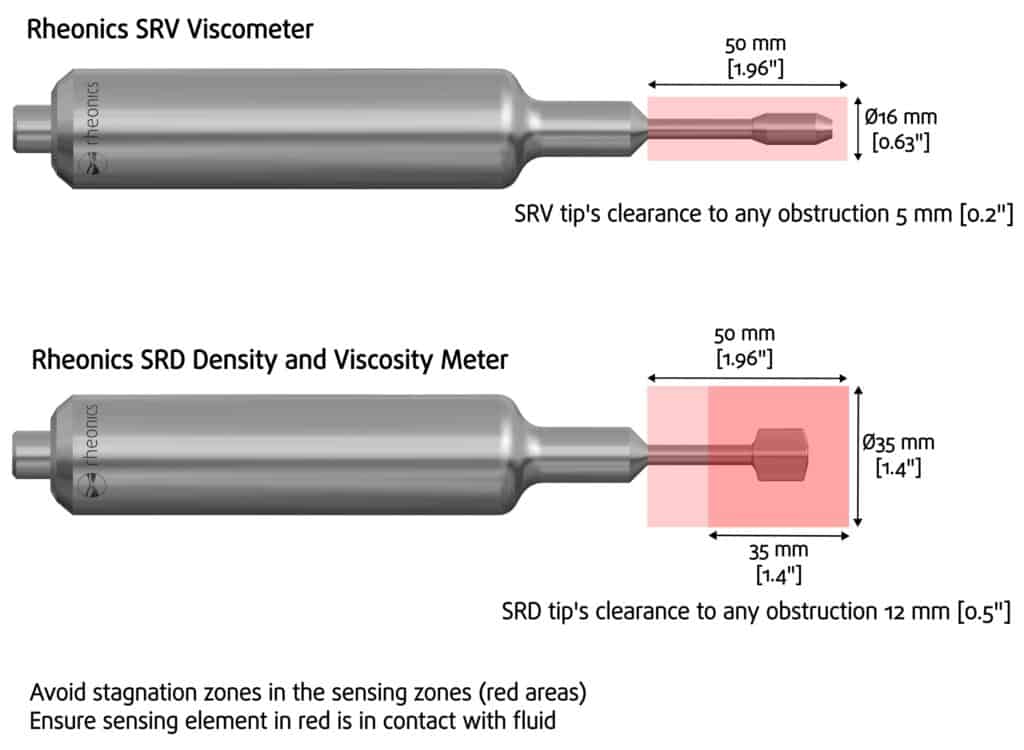

It is important to highlight certain installation aspects that apply to both Rheonics sensors, SRV and SRD. Regardless of the variant, each shares the same resonator design across all its variants, and proper installation depends on the correct positioning of the probes’ sensing area (red-marked areas in Figure 13). The main points are:

SRV and SRD Installation Requirements

-

The area should be free of deposits or obstructions

-

The area should be completely immersed in the fluid of interest.

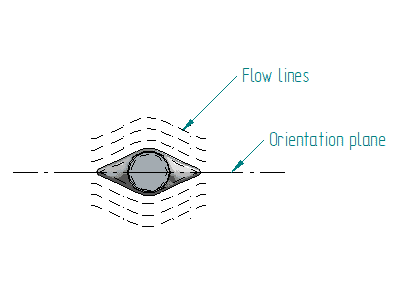

SRD Additional Installation Requirements

In addition to the two main requirements above, the SRD sensor has two additional considerations:

-

Maintain thermal stability when the fluid and the external environment have a temperature gradient greater than 15°C. (Only for SRD, more information here: Maintaining the SRD’s temperature balance for high-density accuracy)

-

Align the sensing tip with the fluid flow direction as shown in Figure 14. (Only for SRD, more information here: SRD fluid end orientation)

These conditions can be reviewed in more detail in the next article, SRV and SRD Suitable Installations.

Common solution by Rheonics

The Rheonics Type-SR sensors have a modular and compact design that allows them to be implemented in a wide range of configurations depenging on the conditions of the application. For example:

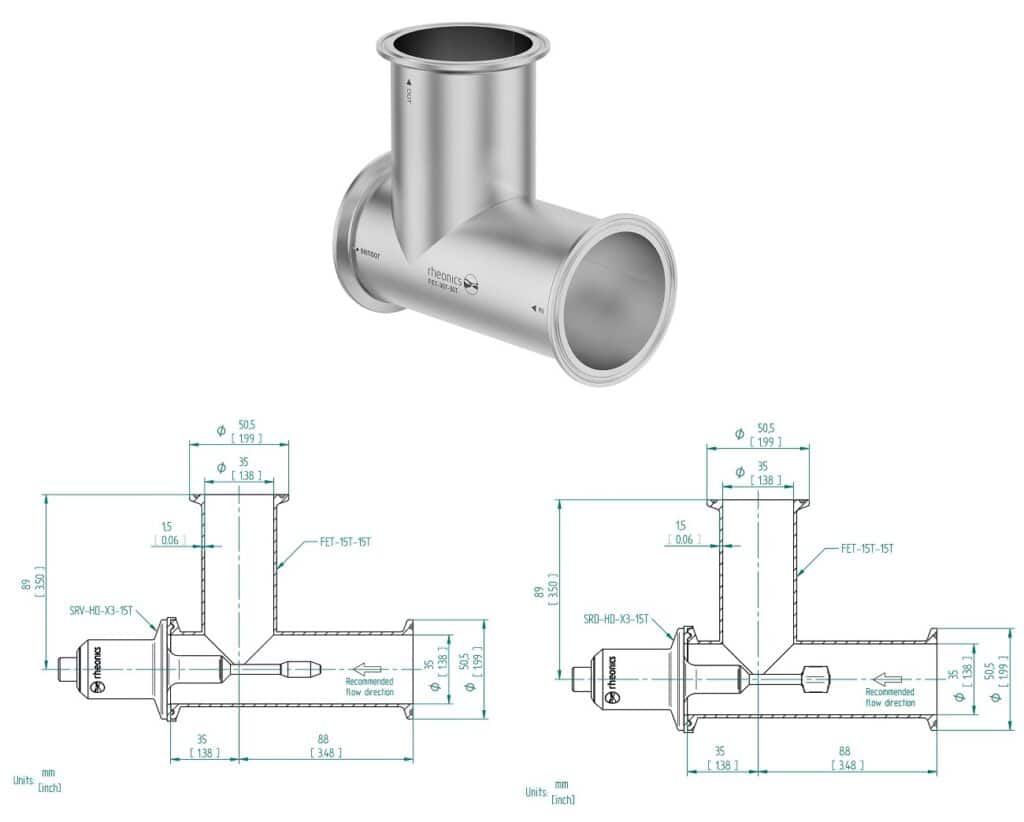

FET-XXT: Tri-Clamp elbow tee

In applications with highly viscous fluids or particle sizes beyond the micron scale, an elbow installation is recommended. For such cases, Rheonics offers the FET (see Figure 15), a hygienic Tri-Clamp elbow tee with a shortened port that ensures proper sensor installation.

The FET is designed for the SRV-X3 and SRD-X3, short-version sensors with Tri-Clamp connections. It is available in multiple sizes (1.5”, 2”, 3”, 4”, etc.) and is supplied with a clamp and clamp seal for the probe. For further details, see FET-XXT.

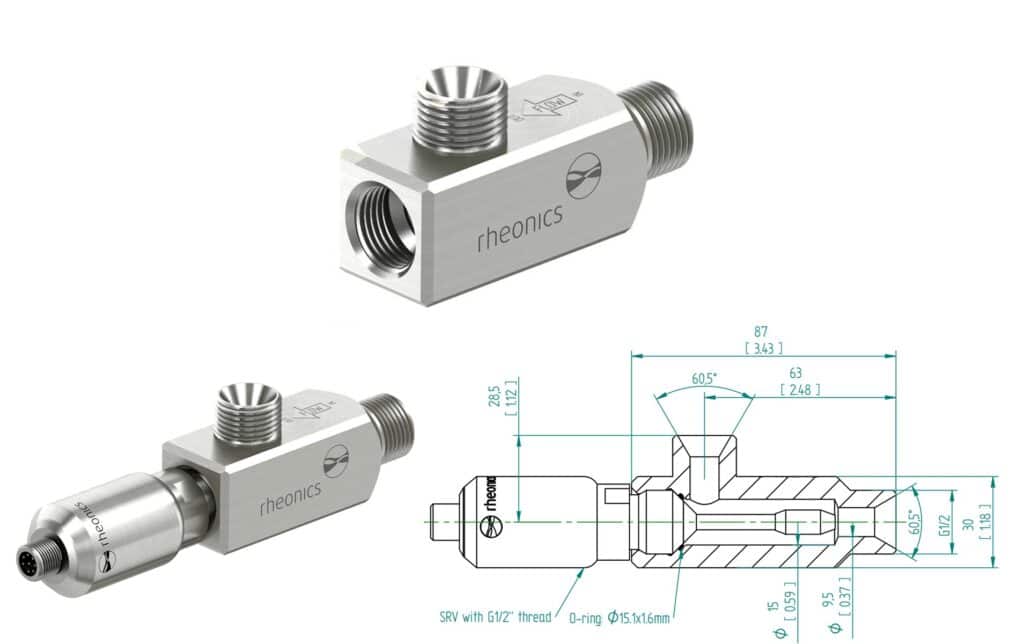

HPT-12G: HPHT Hygienic Flow Cell

For hygienic applications involving small pipelines or hose installations, Rheonics offers the HPT-12G (see Figure 16). This flow cell is designed for high-pressure, high-temperature processes and places the sensor in an elbow configuration using a threaded process connection.

The HPT-12G is compatible exclusively with the SRV-X1-12G, which features a G 1/2” threaded connection. This ensures a reliable hygienic seal with CIP/SIP compatibility, making it ideal for hygienic applications. For more details, see HPT-12G.

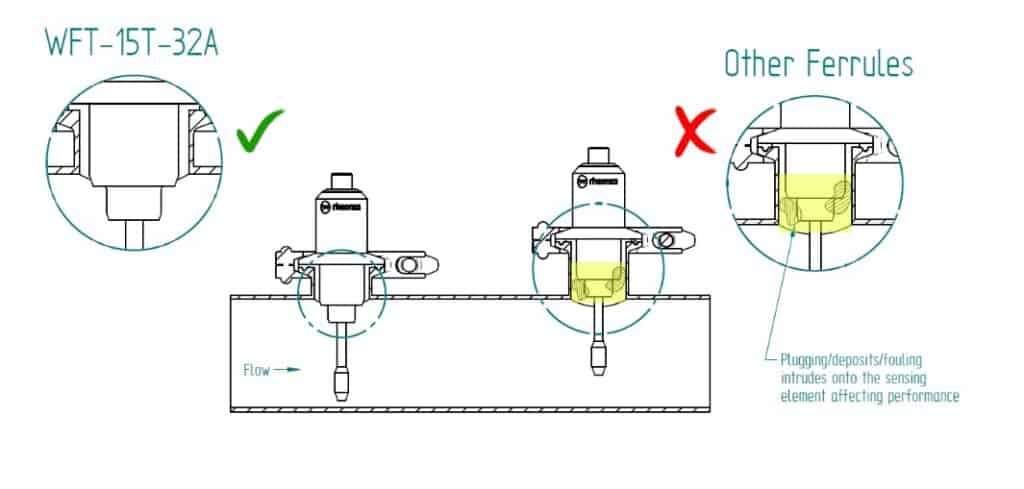

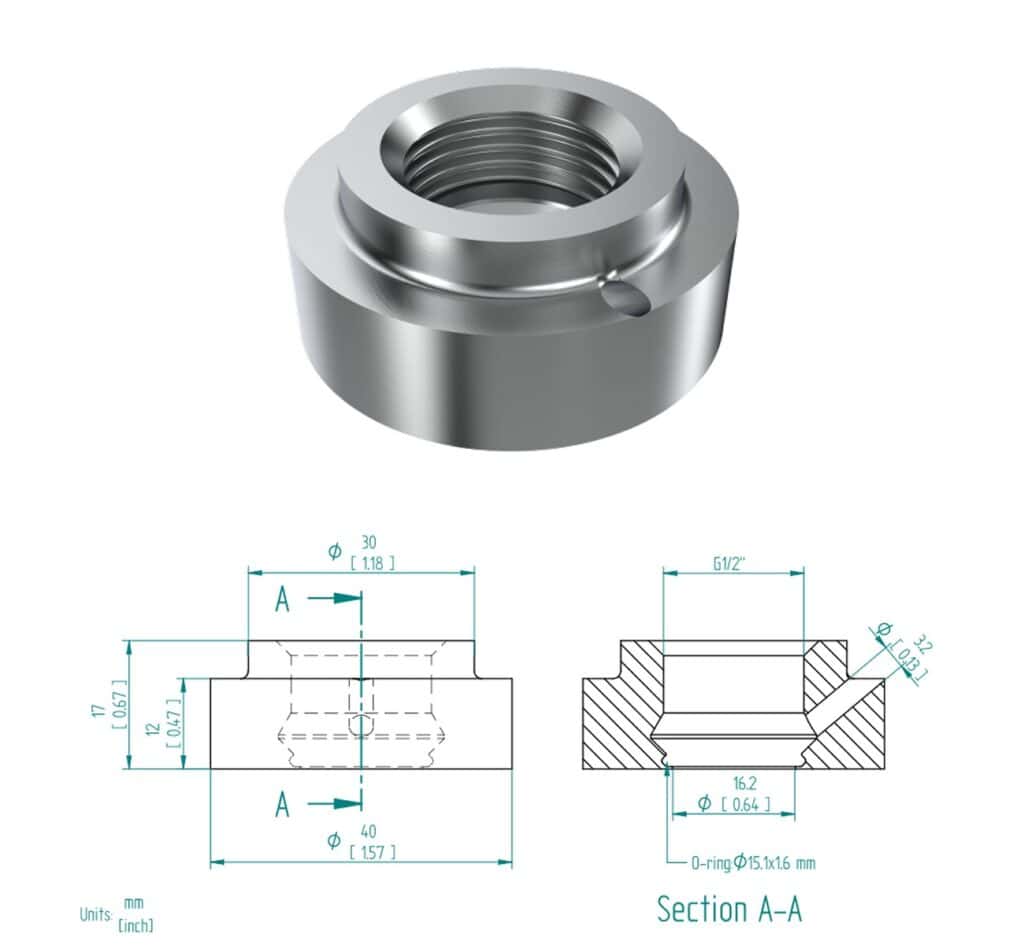

Hygienic weldolet and ferrule for Type-SR sensors

A perpendicular installation on a pipeline, tank wall, or base is one of the most common setups. This is typically achieved with welded ports. For hygienic applications, Rheonics offers dedicated solutions for both Tri-Clamp and G 1/2” process connections. In these cases, a shorter ferrule ensures proper immersion of the sensing element compared to a standard ferrule (see Figure 17).

The WFT-15T (see Figure 18) is a hygienic Tri-Clamp weldolet designed for sensors with Tri-Clamp process connections. It ensures a reliable, hygienic seal and proper immersion of the sensing element in hygienic applications. For more details, see WFT-15T.

The HAW-12G-OTK (see Figure 19) is a hygienic adapter weldolet designed for sensors with G 1/2” thread connections. It provides a secure, hygienic seal and proper immersion for hygienic applications. For more details, see HAW-12G-OTK.

Process Conditions and Best Practices

Here are some important considerations for filling lines in consumer care products applications:

Cleaning Process and CIP/SIP Procedures

In consumer care product filling lines, deposits from viscous materials such as lotions, creams, and gels can gradually accumulate on the sensing surface of the SRV or SRD. Regular inspection and cleaning of the probe help prevent buildup and ensure stable, reliable measurements. Guidance on proper cleaning methods is provided in How to clean your Rheonics probe?.

Both sensors are made with a hygienic design, making them suited for integration into CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems. Optionally, Rheonics also offers hygienic certification.

Particles and Bubbles

Rheonics sensors are robust against the presence of soft particles at the micron scale, with minimal effect on measurement reliability. The sensor electronics automatically filter out small disturbances, though larger particles can still introduce occasional spikes or noise that should be accounted for during data evaluation.

When it comes to bubbles, performance differs between the two models. The SRV maintains stable viscosity readings even in bubbly fluids, while the SRD, which measures both viscosity and density, is more sensitive to entrained air. High bubble concentrations are not recommended for the SRD, as they may compromise density accuracy.

Moving Parts and Obstructions

In mixing or processing tanks that use paddles, stirring arms, or other mechanical agitators, it is important to position the SRV or SRD sensor with proper spacing from moving components. Proper clearance prevents physical interference, reduces the risk of mechanical damage, and ensures good measurement conditions.

References

[1] Plastek Group. “Personal Care Packaging”.

[2] Accutek Packaging. “Overflow Filling”.

[3] Indiamart “Automatic Pouch Packing Machine”.

[4] TWP. “Types of Tube Sealing”.

[5] Bratney. “Tubular Form Fill Seal Technology on the Rise”.

[6] First Class Machines. “Aerosol filling line”.

Visit more related articles:

Optimizing liquid packaging, filling operations with inline viscosity management