Rheonics inline sensors enable real-time monitoring of coolant’s concentration by measuring viscosity. This allows operators to keep an effective cooling for protection of tooling and machinery, and prevention of health and environmental issues.

Table of Content

- Introduction

- Coolants in machining

- Soluble Oils (Emulsions) and Semi-Synthetics

- Straight Oils (Neat Oils)

- Monitoring of coolants in machining

- Rheonics sensors

- Sensor integration

- Sensor installation

Introduction

Coolants, or cutting fluids, are essential substances used in machining and metalworking processes (like milling, turning, drilling, and grinding) to ensure the efficiency, quality, and safety of the operation. Their primary functions are to cool the cutting zone and lubricate the tool-workpiece interface.

Monitoring specific fluid parameters is essential to ensure the fluid remains effective, protects tooling and machinery, and prevents health and environmental issues.

Figure 1: Coolants or cutting fluids application during machining

Coolants in machining

Coolants serve two primary and critical functions in machining: cooling and lubrication. Machining processes generate intense friction and plastic deformation, causing temperatures at the tool tip to soar, often exceeding 500°C. Without cutting fluids, this heat would rapidly lead to:

- Tool wear: Premature dulling, thermal cracking, and failure of the cutting tool.

- Workpiece distortion: Thermal expansion and warping of the material, leading to poor dimensional accuracy.

- Poor surface finish: Adhesion and welding of the workpiece material to the tool (built-up edge).

The four main classes of cutting fluids are: straight oils, soluble oils (emulsions), semi-synthetic fluids, and synthetic fluids.

For milling and similar chip-forming operations, the most commonly preferred coolants are soluble oils (emulsions) or semi-synthetic fluids. These fluids are engineered to provide a balanced combination of cooling power and lubrication, which is crucial given the intermittent nature of the cutting action in milling.

- Soluble Oils (Emulsions): These are concentrated mineral oils mixed with water (typically 5% to 10% oil) using emulsifiers. They are cost-effective and provide excellent cooling ability due to the high specific heat capacity of water. Their oil content ensures good lubrication, which is necessary to reduce friction and improve chip evacuation in the milling process.

- Semi-Synthetic Fluids: These represent a balance between soluble oils and fully synthetic fluids. They contain a lower percentage of mineral oil (2% to 10%) combined with chemical additives and water. They offer superior cooling and better tool life than straight emulsions, along with improved stability and resistance to bacterial growth (which is a common issue with water-based coolants). The efficient cooling they provide is vital in milling, where the cutter is constantly entering and exiting the workpiece, subjecting the tool to thermal cycling that can cause cracking if not managed.

Brands that specialize in oils, emulsions, semi-synthetics, and synthetics used in industrial metalworking processes like milling, turning, and grinding are listed below.

Table 1: Common coolant brands and fluids for machining

| Brand | Fluid | Further information |

|---|---|---|

| Soluble Oils (Emulsions) and Semi-Synthetics | ||

| Blaser Swisslube | Blasocut | Well-known line of high-performance cutting oils and water-miscible (soluble) fluids. |

| Castrol | Hysol | Legacy line of soluble cutting fluids and semi-synthetics. |

| Syntilo | Line of synthetic and semi-synthetic fluids offering excellent cooling and biological stability. | |

| Houghton International (Quaker Houghton) | Hocut | A flagship series of water-soluble cutting and grinding fluids. |

| Mobil Industrial Lubricants | Mobilcut | A range of high-performance water-miscible and neat cutting fluids |

| Fuchs Lubricants | Ecocool | A major product line featuring high-performance semi-synthetic and soluble coolants. |

| Straight Oils (Neat Oils) | ||

| Shell | Garia/Macoma | Offers various neat cutting oils for high-precision or heavy-duty machining where lubrication is paramount. |

| ExxonMobil | Vacmul | Offers chlorine-free straight cutting oils. |

Figure 2: Coolants soluble oils examples

Monitoring of coolants in machining

In machining, maintaining the coolant concentration (the oil-in-water emulsion ratio) is a critical factor because:

- If concentration is too low (too much water): Lubrication is poor, which leads to catastrophic tool wear, high friction, rust, and potential part failure.

- If concentration is too high (too much oil): Concentrate is wasted, creating a risk of foaming, which reduces the coolant’s ability to cool effectively.

The viscosity of the emulsion has a direct and stable correlation to its oil-in-water concentration. By continuously measuring viscosity, Rheonics sensors provide a precise, real-time proxy for the coolant’s concentration.

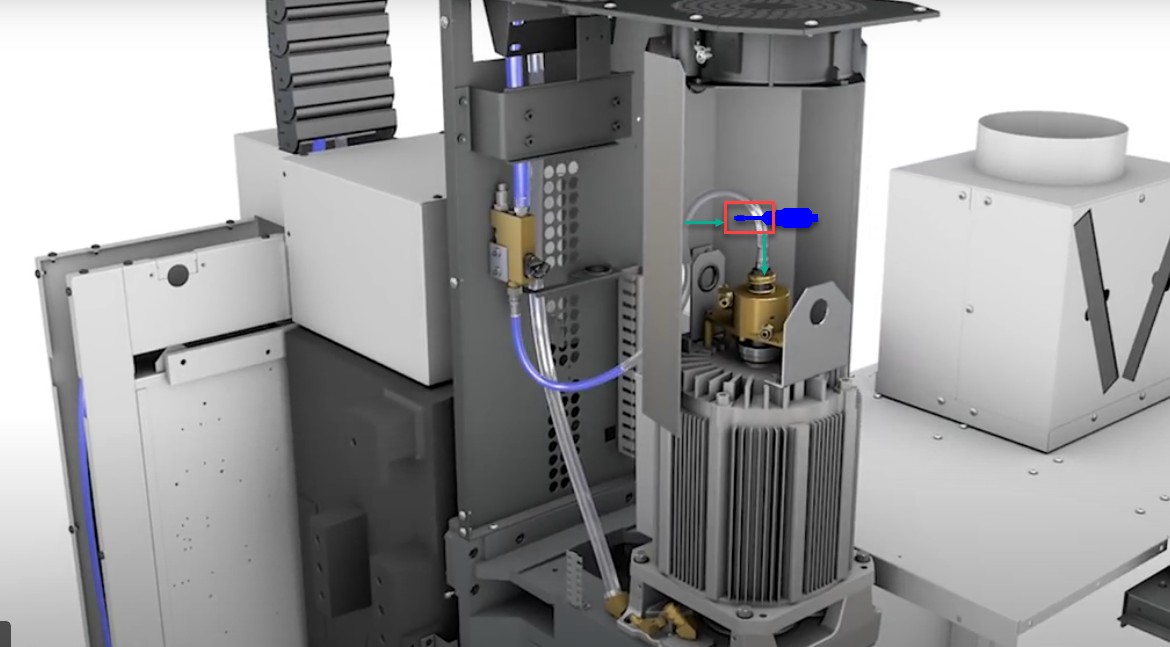

Figure 3: Rheonics sensors in cutting fluids recirculation in machining

Rheonics sensors

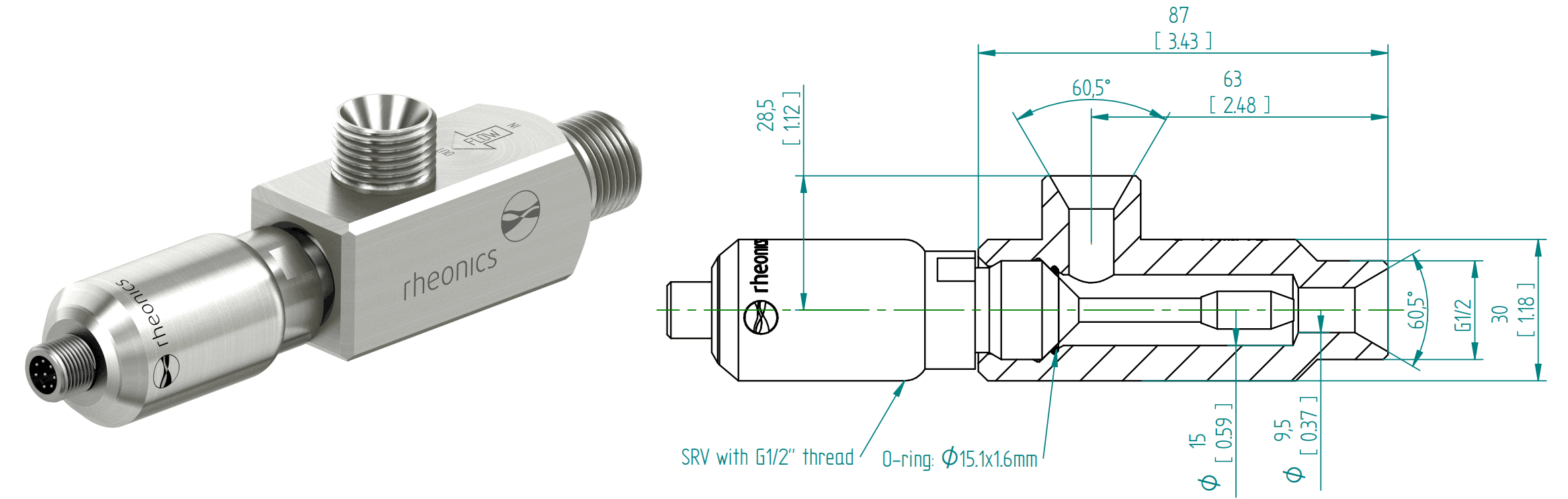

Rheonics offers an inline sensor for viscosity and density with the Type-SR sensors line. Rheonics SRV Inline Viscometer is the recommended sensor for monitoring coolants in machining. It allows the measurement of viscosity and temperature in line, while being robust against strong vibrations, bubbles, and foam in the fluid. Its compact design is especially suited for installation in tight spaces and small lines.

Rheonics SRV allows the evolution of manual or time-fixed measurements to inline continuous measurements of coolants. While current coolant recirculation systems are checked periodically using refractometers or other gauges, Rheonics SRV continuously sends data to a remote or local monitoring system. Allowing full automation, avoiding wasting time and rapid reaction to drifts in concentration by viscosity and density of the fluid.

Sensor integration

- Use SRV sensor electronics 4-20mA output, or communication protocols such as Modbus RTU, Profinet, Ethernet/IP, HART, etc.

- An alarm can be trigger for the operator to take action.

- Dosing pumps can be activated to add either more water or more concentrate, bringing the system back to the precise setpoint immediately.

An automated control including the SRV sensor ensures the coolant is always at the optimal concentration, maximizing tool life, ensuring part quality, and reducing coolant waste.

Sensor installation

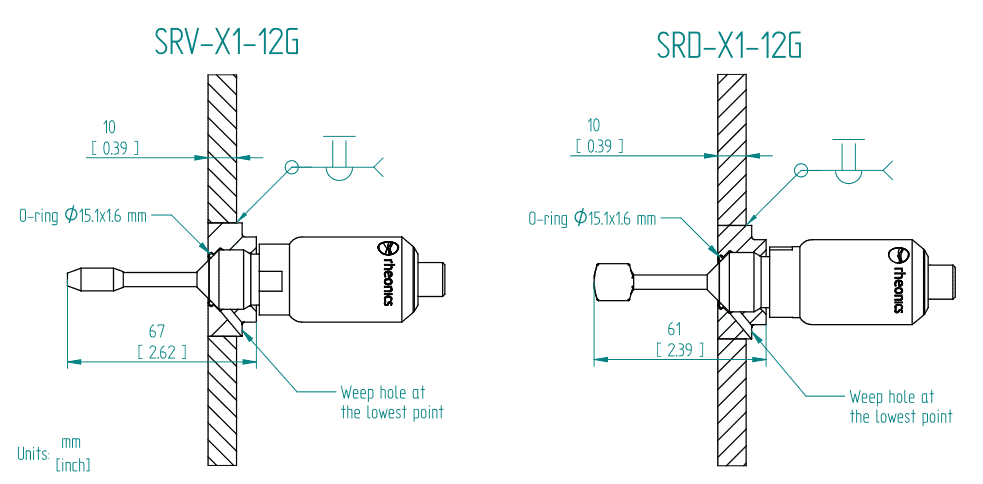

For coolant monitoring in machining, the recommended sensor variant is the SRV-X1-12G. Its compact design allows for straightforward installation, even in narrow coolant lines.

To ensure seamless integration, Rheonics provides several mounting options:

Inline Flow Cells: Use Rheonics HPT-12G or HPT-SRV flow cells for easy installation directly into your existing pipework.

Figure 4: Rheonics SRV-X1-12G in HPT-12G flow cell

Reservoir Mounting: The probe can be installed directly onto the coolant reservoir using a weldolet, such as the HAW-12G, similarly to an installation in a tray or narrow tank.

Figure 5: Rheonics SRV-X1-12G in HAW-12G weldolet

Point-of-Use: For critical measurements, the sensor can be mounted just before the coolant nozzle.