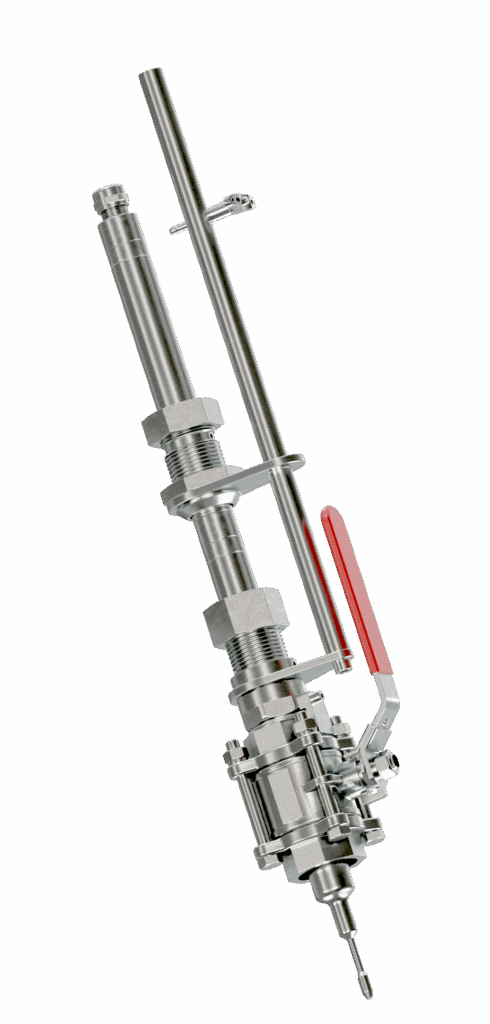

Robust in-line, online, retractable probe - used in lines when the probe needs to be checked or cleaned during operation, the retractable assembly is able to remove it from the process line for in-situ or external verification and cleaning.

- Compact, ultra-robust design

- Pressure rating up to 580 psi (40 bar)

- EX Intrinsically Safe sensor certification (IECEx, ATEX) available

- Suitable for installation in pigging, big lines, and tanks

- Isolation process through a 1 1/2” NPT ball valve

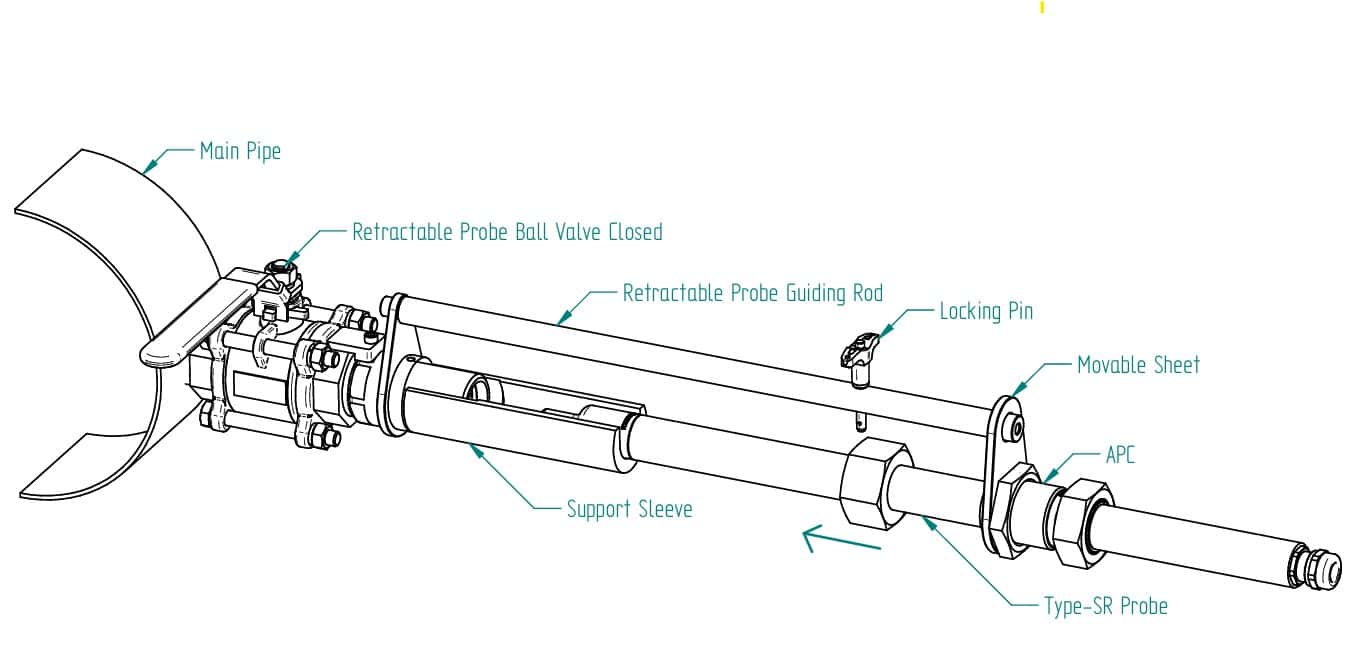

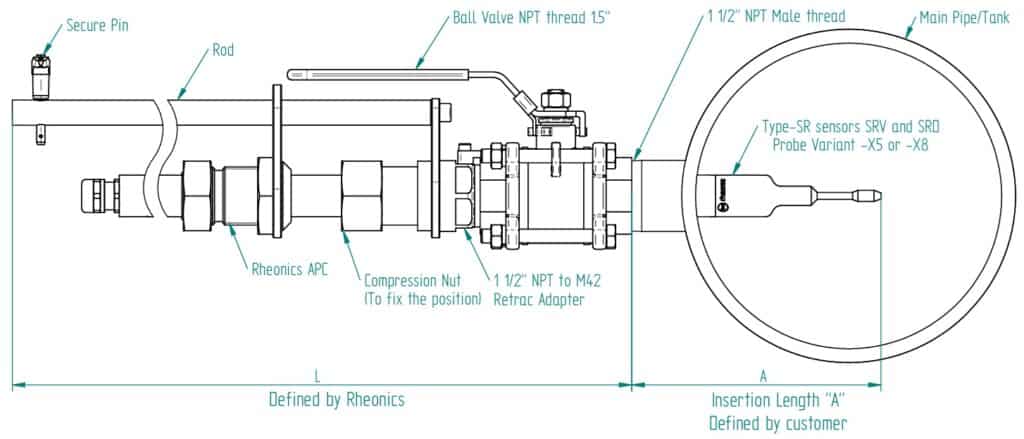

Rheonics RPA is a Retractable Probe System designed for the SRV inline process viscometer and SRD inline density and viscosity meter in variants Type-SR X8: Teletube Ultra-long Insertion Probe, and long insertion probes SRV-X5, SRD-X5.

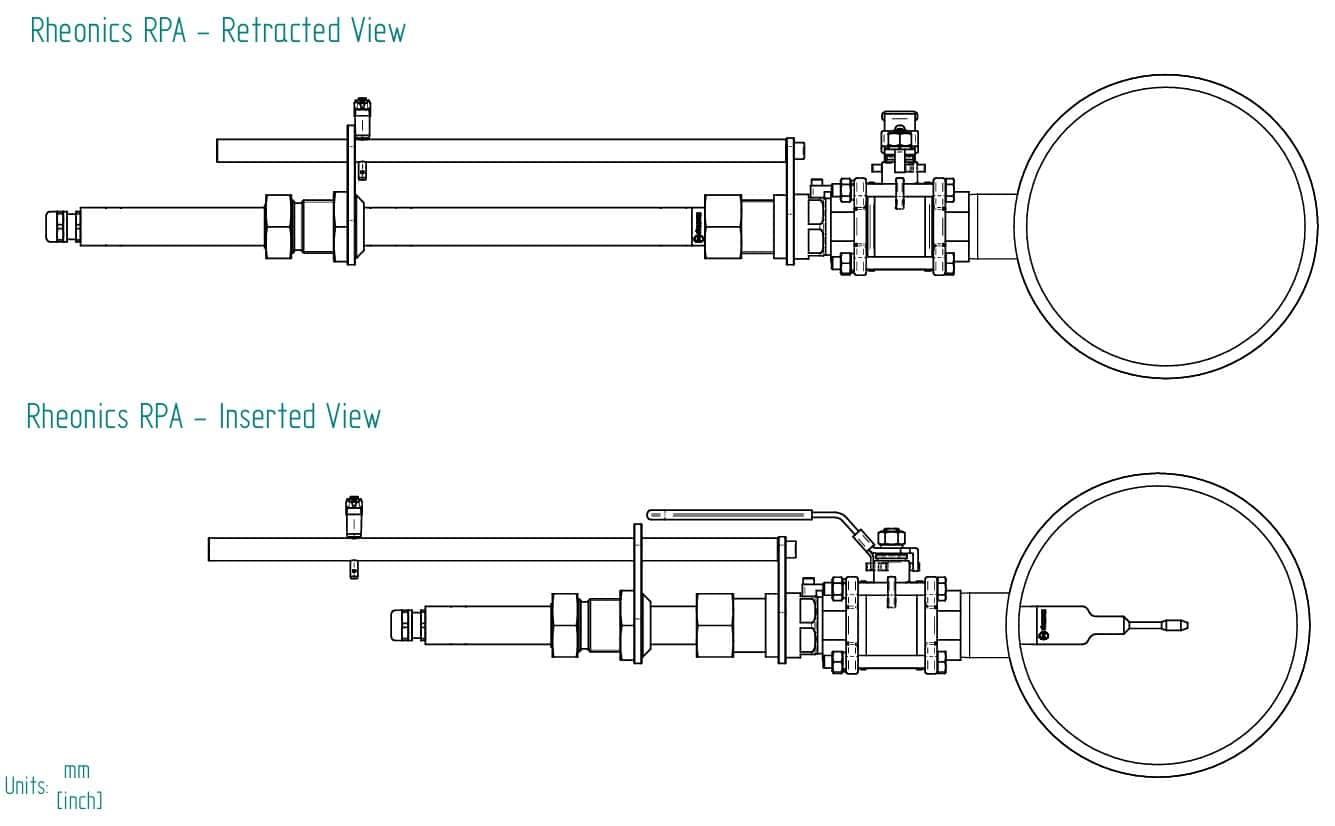

This retractable system is used to remove or isolate the probe from the process without draining the line or tank where it is installed by opening and closing the 1 1/2” ball valve attached to the system, which can be necessary for maintenance, cleaning, or replacement without interrupting the production processes. Rheonics RPA system sustains high pressures (Max. 40 bar) during operation, and requires ambient pressure for manual retraction and immersion of the probe.

The retractable assembly is highly beneficial when a line must be piggable, as it allows for the probe to be removed from the line during the pigging operation. Rather than completely removing the probe, a more time-efficient approach is to utilize retraction to withdraw the probe from within the line, thereby eliminating any obstruction in the path of the pigging device. Once the pigging operation is complete, the probe can be reinserted.

Additionally, the retractable assembly serves another important function: it facilitates the inspection or cleaning of the probe during operation. This assembly enables the probe to be removed from the process line for in-situ or external verification and cleaning, ensuring optimal performance and maintenance.

Video Explanation:

| Sensor compatibility | Viscometer SRV and Density and Viscosity meter SRD |

| Probe material | Stainless Steel 316L |

| Probe Length | Customizable |

| Process Connection | 1 1/2” NPT Thread |

| Pressure Range | Up to 580 psi (40 bar) |

For this product, the insertion length (A) is determined by the customer, which refers to the probe’s immersion required to be integrated in the process. Meanwhile, the total length of the system is defined by Rheonics based on the insertion length (A).

Rheonics RPA is offered with the -X5 or -X8 Type-SR sensor probes, the 1 1/2” Ball valve (BV1N50-RPA), and a whole retractable system which uses the Compression Nut (CN-RPA), to ensure that the whole assembly is rated up to 40 bar.

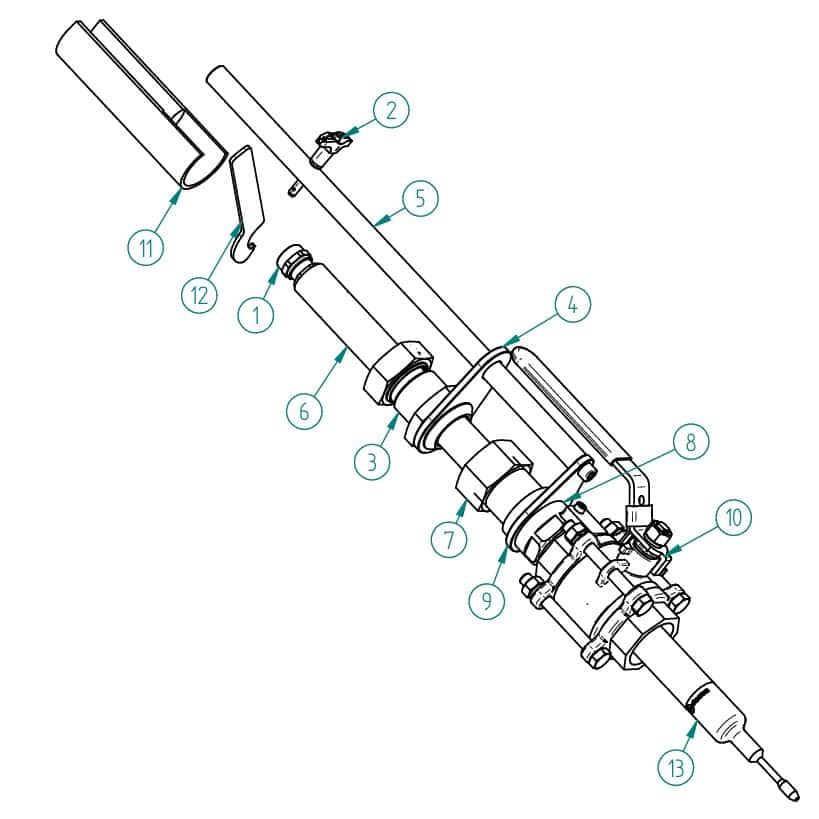

| Item | Name | Code |

|---|---|---|

| 1 | Teletube Cable Gland (for X8) | CG-TT |

| 2 | Securing Pin | SP-RPA |

| 3 | Rheonics APC | APC |

| 4 | Movable Guide Slab | MS-RPA |

| 5 | Retract Guiding Rod | RD-RPA |

| 6 | Teletube Body (for X8) | BD-TT |

| 7 | Compression Nut | CN-RPA |

| 8 | 1 1/2” NPT Retract Adapter | 1N50-RPA |

| 9 | Static Guide Slab | ST-RPA |

| 10 | Ball Valve 1 1/2" NPT Thread | BV1N50-RPA |

| 11 | Retract Support Sleeve | RSS-RPA |

| 12 | 50 mm Wrench | WRC-50 |

| 13 | Sensor Probe Variant | SRV/SRD-X8 or SRV/SRD-X5 |

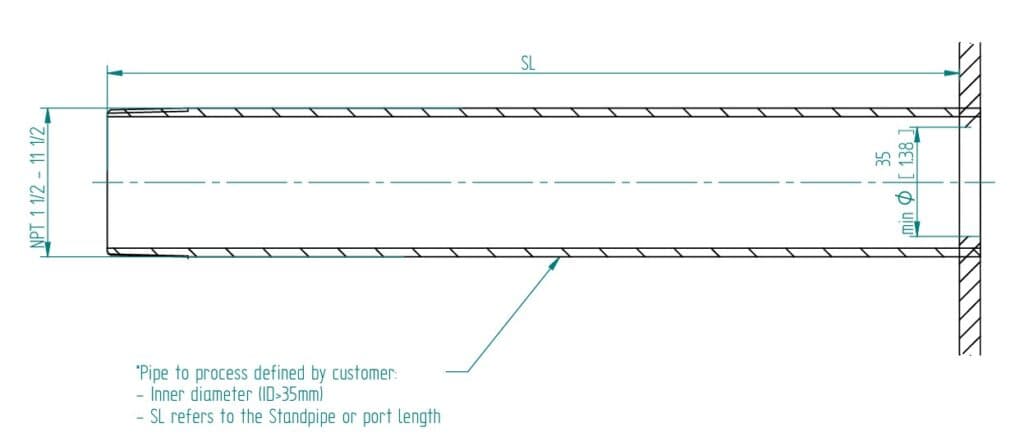

The Rheonics Retractable Probe (RPA) can be seamlessly integrated into the process by using a male 1 1/2” NPT thread, allowing for the valve to be securely threaded. This could be, for example, using a standpipe or an existing port with an adapter to transition to the required thread.

The installation must have a minimum inner diameter of ⌀35 mm to ensure proper immersion and retraction of the sensor probe.

- Identify and define the installation point.

- Assemble the RPA system.

- Initiate the immersion and retraction of the system.

Note: Never retract the probe when the process is pressurized, as this can lead to damage to the probe, operators, and process.

The image below shows an example of a 100 mm Insertion length (A) using an SRD-X5 Variant with a probe total length (PL) of 488 mm.

| Length in mm | ||||

|---|---|---|---|---|

| Fluid Insertion Length (A) | 100 | 300 | 500 | 700 |

| Probe Total Length (PL) - For SRV-X5 | 494 | 694 | 894 | 1094 |

| Probe Total Length (PL) - For SRD-X5 | 488 | 688 | 888 | 1088 |

| Probe Total Length (PL) - For SRV-X8 | 470 | 716 | 962 | 1208 |

| Probe Total Length (PL) - For SRD-X8 | 464 | 710 | 956 | 1202 |

| Guiding Rod Total Length (GD) | 450 | 650 | 850 | 1050 |

| Recommended Maximum Standpipe Length (SL) | 35 | 235 | 435 | 635 |

| Distance from the Tip to the APC (TD) | 373 | 573 | 773 | 973 |

Sophisticated, patented 3rd generation electronics drive these sensors and evaluate their response. Ultra-fast and robust electronics, combined with comprehensive computational models, make our sensors fast and accurate units in the industry. SDP gives real time, accurate fluid measurements every second. Embedded temperature sensor gives instantaneous inline fluid temperature.

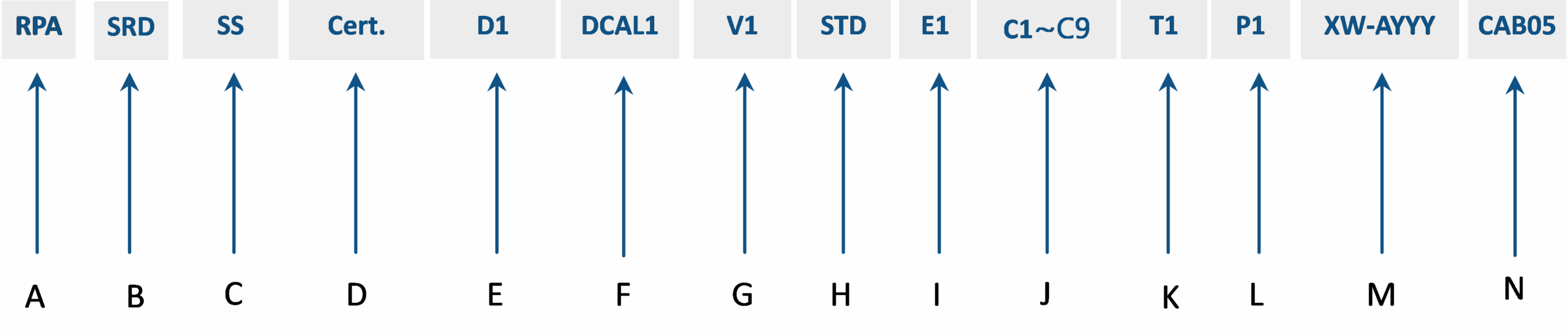

A: Retractable Probe Assembly

B: Sensor Type (SRV or SRD)

C: Wetted Material

D: Certifications (Optional)

E: Density Range (Only for SRD version)

F: Density Calibration (Only for SRD version)

G: Viscosity Range

H: Viscosity Calibration

I: Electronics Variant

J: Communication Protocols

K: Temperature Rating

L: Pressure Rating

M: Variant Design (See options below)

- XW: Select between X5 and X8 Variant

- AYYY: Insertion length required (Consider the Standpipe length and the immersion required)

N: Cable variant and Length