PCI (Paint & Coatings Industry) Magazine features Rheonics’ SRV and PaintTrack system – “Towards Zero Automotive Paint Quality Issues”

Overview

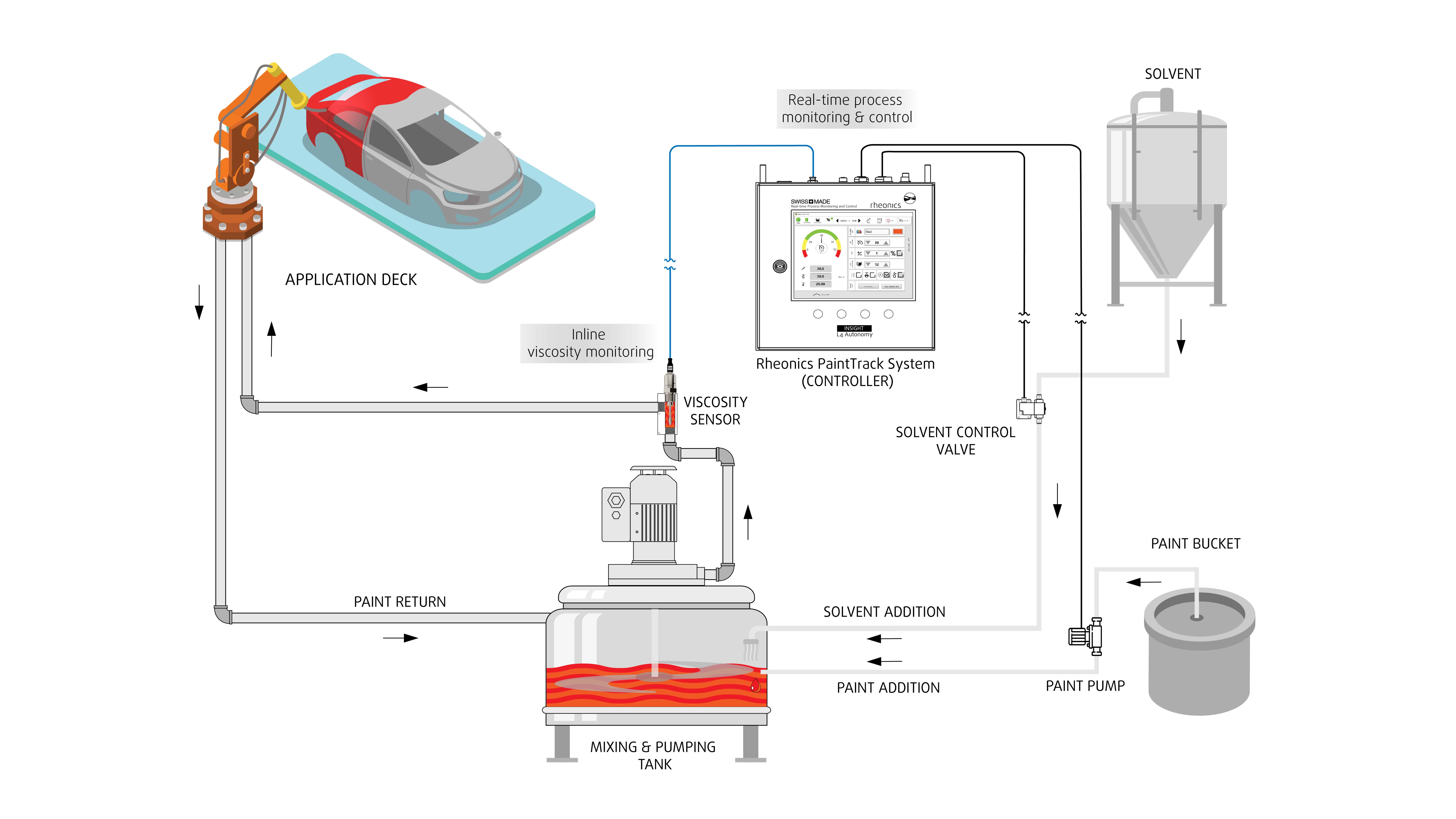

Paint & Coatings industry focused magazine – PCI publishes a feature article covering the Rheonics inline viscometer SRV and PaintTrack. The article discusses how coating consistency across painting lines in the factory can be achieved even under varying temperatures and evaporation conditions through automation of the dosing system with a controller using continuous, real-time viscosity measurements.

Find the link to the the publication.

Introduction

Correct paint viscosity is the key to good finish quality. Performance parameters are all linked directly to the viscosity of the liquid coating at the point of application. These include coating film build, paint transfer efficiency, coating thickness and deposition, color match, finished surface qualities and chemical resistance. Viscosity is the main factor influencing the thickness and adherence of the coating. Proper viscosity control assures the quality and lifetime of the coat, helping meet the highest demands on the quality and productivity of the painting process.

Conventional viscometers do not reach the high shear rates found in the spray process, so can only indirectly give information about the performance of the paint at the point of application. Temperature is also a crucial variable in determining viscosity, but cup measurements have neither temperature measurement nor control, so cannot be directly compared with actual spraying temperature. This can lead to variations in coating quality as the process temperature varies.

Unique advantages with the Rheonics SRV sensors

Rheonics sensors have built-in temperature measurement, permitting the temperature of the paint to be monitored at the point of application. This permits adjustment of the viscosity readings to a temperature-compensated viscosity value, which is essential for estimating pigment loading from real-time measurements.

Unique benefits with the SRV for automotive paint and coating applications include:

- Works accurately with both solvent-based and water-based paints and coatings.

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline or with a solvent wetted rag, no need for disassembly or re-calibration.

- No moving parts to age or foul with paint sediment.

- Unaffected by mounting conditions – can be mounted in any part of the painting system.

- Insensitive to particulate matter; no problem of fouling or any narrow gaps in the sensor.

- All wetted parts are 316L stainless steel – no corrosion problems with commercial paints, additives or solvents.

- Certified under ATEX and IECEx as

intrinsically safe – can be used in all

solvent-based operations. - Wide operational range and simple integration – Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

- Powerful software – Rheonics PaintTrack software is convenient and intuitive, and is powered by a proprietary, advanced, fifth-generation AI system for simple click lock and run. It supports multiple HMIs for operator, production supervisor, quality manager and management view. Designed for automated instrument control and data acquisition in factory environment

To explore more about our solutions for automotive painting quality control, please read the application note.

Integrated Solution

Rheonics resonant sensors, together with Rheonics PaintTrack control system and software, make possible on-line control of temperature-compensated viscosity of primers and coats in multiple painting lines. Coating consistency across painting lines in the factory can be achieved even under varying temperatures and evaporation conditions through automation of the dosing system with a controller using continuous, real-time viscosity measurements.

Key benefits of the PaintTrack control system and software include:

- Reduce and eliminate setup times and scrap by loading pre-run jobs for repeat orders.

- Improve painting quality and reduce costs: Achieve color consistency, reduce coating errors by ensuring correct paint properties during the process.

- Complete automation for improved productivity and efficiency: Maximize paint operation speed, decrease reliance on manual machine adjustments and manual measurement techniques.

- Robust accuracy and repeatability: No maintenance, no recalibration = no attention needed.

- Temperature-compensated viscosity with proprietary Predictive Tracking Control: Solution that precisely locks color and coat quality from start to finish on every job with repeatable results.

- You can take the cup out of the equation: Coating process is set to scientific standards, 100 times greater accuracy and resolution than average efflux cups.

Conclusion

- Vibrational viscometers, such as the Rheonics SRV, come closer to matching the high shear rates in spray paint application than do rotational or cup viscometers. Therefore, measurements with the SRV come closest to predicting the behavior of paint under actual spraying conditions.

- Inline viscosity control with the SRV and Rheonics PaintTrack enables continuous viscosity control, making necessary dilutions in real time. Coating quality is guaranteed from the beginning of a new drum to its end.

- Rheonics SRV and PaintTrack control true temperature-compensated viscosity, a key predictor of pigment content and final coating quality.