It has become crucial to continuously monitor the performance of coolants, such as glycol water-based mixtures, by evaluating the characteristics like thermal degradation, glycol concentration, contamination, biofouling, Brix levels, freezing point, etc., which can be traced back to direct measurements with Rheonics’ inline density and viscosity sensors.

Table of Content

- Introduction

- Cooling and Refrigerant Systems

- Liquid-based cooling

- Direct to Chip Liquid Cooling

- Immersion cooling

- Monitoring and control

- Rheonics sensors

- Sensor installation

- HPT-12G (valid for SRV only)

- IFC-34N (variants available for SRV and SRD)

- FET Tri-Clamp elbow tee

- References

Introduction

As data centers scale in density and computational demand, traditional air-cooled architectures increasingly struggle to meet thermal management, energy-efficiency, and reliability requirements. Liquid recirculation loop cooling—using water or water-glycol mixtures as the primary heat transport medium—has emerged as one of the most efficient and scalable solutions. It has then become crucial to continuously monitor the cooling performance, which can be achieved, among other methods, by evaluating the characteristics of the coolant in line. Characteristics such as thermal degradation, glycol concentration, contamination, biofouling, Brix levels, freezing point, etc., can be traced back to direct measurements with Rheonics’ inline density and viscosity sensors.

Figure 1 – Data center room

Cooling and Refrigerant Systems

The basic function of a cooling system is to remove heat from one location and transfer it to another, making the original location colder. Heat naturally flows from warmer areas to cooler areas through conduction (solid contact), convection (fluid movement), and radiation (electromagnetic waves).

- Refrigeration Systems: These systems rely on a refrigerant undergoing phase changes—evaporation to absorb heat and condensation to reject heat—as in chillers, air conditioners, and heat pumps.

- Sensible Heat Systems: These systems rely on sensible heat transfer using coolant liquids or air rather than refrigerants. These typically consist of two loops:

- a. A primary loop that uses a fluid to absorb heat from the source.

- b. A secondary loop that removes heat from the warmed primary fluid. The secondary loop is often a refrigeration system or an external heat-rejection system, such as cooling towers or dry coolers, which release the heat to the environment.

Liquid-based cooling

The core advantage of liquid-based cooling is that liquid is much more efficient than air when it comes to heat transfer. This makes pure liquid-based cooling essential for modern high-density data centers, especially those supporting AI and High-Performance Computing (HPC).

Liquid recirculation loops (LRLs) offer:

- Higher heat capacity compared to air

- Lower pumping energy for the same heat transport

- Greater thermal stability

- Compatibility with both direct-to-chip (D2C) and immersion cooling solutions

Both D2C and immersion cooling are recirculation systems that utilize a primary loop to absorb heat and a secondary loop to reject it.

Direct to Chip Liquid Cooling

D2C cooling consists of the recirculation of liquid coolant directly over the hottest components in a data center, typically the CPUs and GPUs, using cold plates on top of them. The fluid used in the primary and secondary loop is either a deionized (DI) pure water fluid or a mixture of it with glycol.

Propylene glycol (PG) is nowadays the preferred coolant to be mixed with water as it is nontoxic, nonflammable, does not contribute to global warming and provides optimal performance compared to other secondary fluid alternatives. PG has a lower thermal conductivity and higher viscosity that pure water, so the mixture of glycol-water will create a lower heat exchange and require more energy to be pumped, however, PG has a lower freezing point and higher boiling point than water, so it is used when there is a risk that DI water freezes or evaporates in the line. PG also avoids the formation of bacteria in the water line.

D2C is often chosen for its easier integration into existing, large-scale data centers (like Hyperscalers) where the IT hardware is designed to operate with standard chilled water or specialized non-conductive fluids, and a lower supply temperature is desired for a high safety margin.

Figure 2: Direct to chip cooling

Immersion cooling

Immersion cooling is gaining attraction with very-high-density centers. It requires the complete immersion of the data center or racks of CPU and GPUs into a dielectric fluid such as mineral oil or synthetic fluids. Heat is then transferred from the racks to the fluid by conduction and convection. How the fluid is recirculated to keep the desired temperature for cooling defines the type of immersion cooling.

One-phase immersion cooling always keeps the fluid in a liquid state using a secondary loop, usually through a heat exchanger, with liquid or air. Glycol-water mixtures are again common in the secondary loop.

Two-phase immersion cooling has the fluid changing from fluid to vapor by dissipation. A condenser coil on top of the immersion tank traps the liquid vapor and reduces its temperature thanks to a secondary loop to transform it to liquid phase again, so liquid can fall into the tank again.

Immersion cooling is highly effective at operating at higher coolant inlet temperatures because the entire server is submerged, providing uniform cooling across all components and eliminating hotspots. This higher operating temperature is a major factor in its high energy efficiency.

Figure 3: Immersion cooling one-phase method

Monitoring and control

Control of coolant fluids is based in the Coolant Distribution Units (CDUs). These are key to maintaining cooling efficiency by keeping a constant circulation, pressure, and flow distribution. They are integrated with external controllers to manage pump speeds, valves, alarms, and redundancy logic.

Inline sensors are essential for Prognostics and Health Management (PHM), allowing operators to monitor the health and concentration of the coolant directly.

Key parameters monitored in the LRL (especially the glycol-water loop):

- Supply/Return Temperature: Critical for determining thermal load and system efficiency

- Flow Rate and Pump Differential Pressure: Key indicators of pumping energy (PUE) and potential blockages (fouling).

- Glycol Concentration: Density and Viscosity sensors are useful to precisely monitor the percentage of glycol. This is critical because:

- It verifies the glycol concentration and freezing point of the coolant.

- It allows for the calculation of the actual mass flow rate and ensures the pump is not wasting energy overcoming excessive viscosity.

- Conductivity and Water Quality: Measures the purity and corrosion potential of the water (especially in DI water loops), as even trace contaminants can lead to component damage.

Rheonics sensors

Rheonics inline density and viscosity sensors are based on a Balanced Torsional Resonator (BTR) technology that measures fluid’s properties by direct contact and evaluation of fluid effects on resonator resonance frequency and damping.

Rheonics inline sensors, such as the SRV inline viscometer and SRD inline density and viscosity meter are suited for monitoring heat-transfer fluids such as glycol-water coolants and mineral oils in D2C and immersion cooling.

The Rheonics advantage are:

- Compactness: Rheonics sensor probes are small and compact, which make them ideal for flexible mounting in small spaces such as racks, coolant recirculation lines and immersion tanks.

- Robustness: Sensor operates regardless of fluid flow, low temperature or multi-phase fluids: dirty water, corrosion products, biofilm, scattered particles within the fluid can be presented as small noise in readings, however, sensor is able to measure fluid’s viscosity and density reliably.

- No maintenance: No moving part that can generate drift over sensor’s operating life.

Sensor installation

Integrate the Rheonics sensor probe into the polymer tubing or stainless steel pipes using Rheonics inline flow cells and weldolets or standard connection and flanges.

HPT-12G (valid for SRV only)

This small flow cell has minimal fluid volume requirement and has G1/2” male thread ports on the inlet and outlet. Sealing is achieved using FKM or FFKM (for high temperature) O-Ring. See product page.

IFC-34N (variants available for SRV and SRD)

This flow cell has variants available for Rheonics SRV and SRD. It has 3/4” NPT female ports, making it the ideal choice for small lines, especially of sizes 3/4” or 1”. See IFC-34N-SRV and IFC-34N-SRD.

FET Tri-Clamp elbow tee

Available in sizes 1.5”, 2”, and 3”, this accessory uses Tri-Clamp connections at inlet, outlet and probe port. See product page.

FTP Tee spool piece

Available in sizes 2” or bigger, this cell places the probe perpendicular to the fluid flow while maintaining dead zones minimal. See product page.

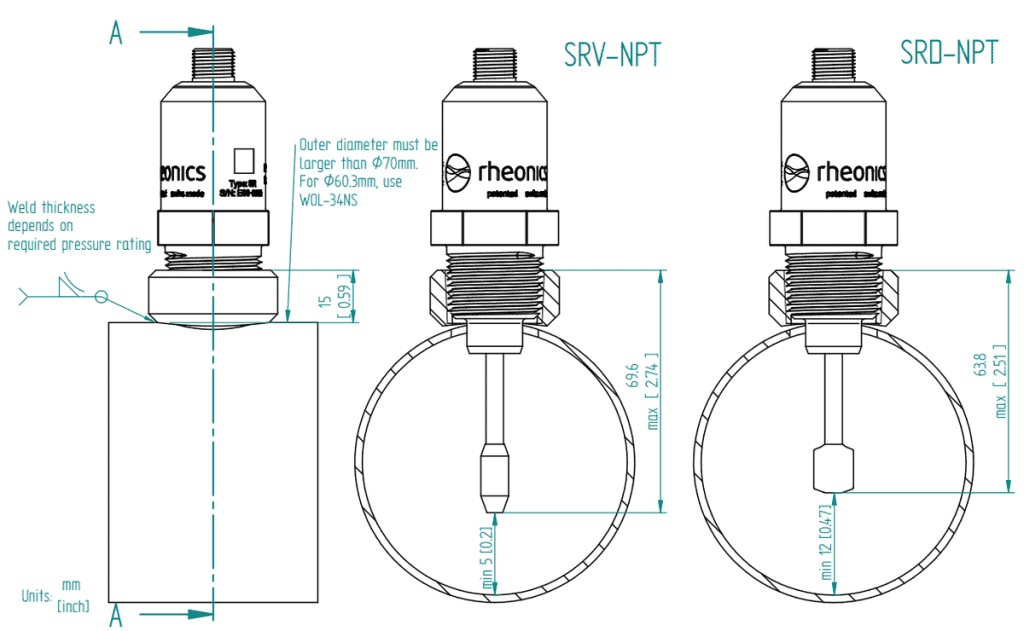

Direct installation of Rheonics SRV and SRD probes in the coolant main or supply lines is possible with weldolets such as:

WOL-34NL (suitable for SRV and SRD)

HAW-12G-OTK (valid for SRV and SRD), FKM or FFKM (for high temperature) is used to create a connection seal.

References

Understanding Coolant Distribution Units (CDUs) for Liquid Cooling