In battery manufacturing, viscosity and density play a critical role in achieving consistent slurry quality, optimizing performance, and improving the overall lifespan and recyclability of batteries. Rheonics inline sensors offer powerful tools for real-time process control and automation at every key stage of battery slurry preparation and coating.

Table of Content

- 1. Introduction

- 2. Overview of battery production

- 2.1 Battery slurry and electrode manufacturing

- 2.2 Importance of process parameter control

- 3. Rheonics inline sensors

- 3.1 Recommended sensor placements

- 3.2 Correlation with lab measurements

- 3.3 Interpreting mixing data

- 4. References

Introduction

Batteries play a central role in modern life—powering smartphones, electric vehicles, and renewable energy systems. As battery demand grows, the need for high-quality, efficient, and safe production methods becomes increasingly important. One of the most critical steps in battery manufacturing is ensuring consistent and accurate formulation of the anode and cathode slurry.

Even small variations in slurry properties can lead to defects that reduce performance, shorten battery lifespan, and increase environmental impact. Monitoring viscosity and density throughout the production—especially during electrode manufacturing— significantly improves final product quality and production efficiency.

Overview of battery production

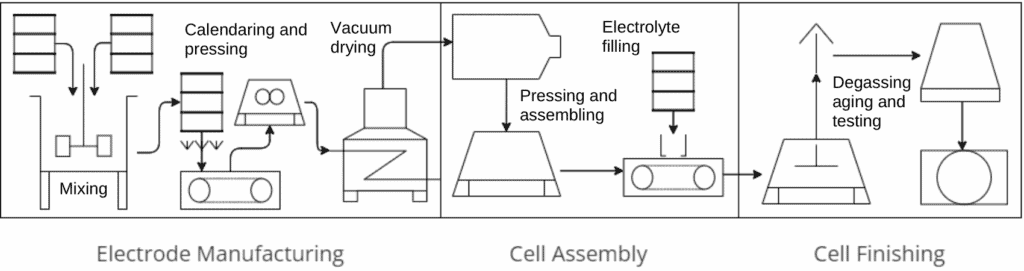

Battery production is typically divided into three main stages:

- Electrode manufacturing (mixing, coating, drying, calendaring, slitting, vacuum drying)

- Cell assembly (stacking, packing, electrolyte filling)

- Cell finishing (forming, degassing, aging, testing)

Each stage involves several unit operations, but the electrode manufacturing stage is where consistent quality must be ensured early on. Battery cells are built from stacks of coated electrode sheets—so the performance of the entire cell depends on the quality of each individual sheet.

Battery slurry and electrode manufacturing

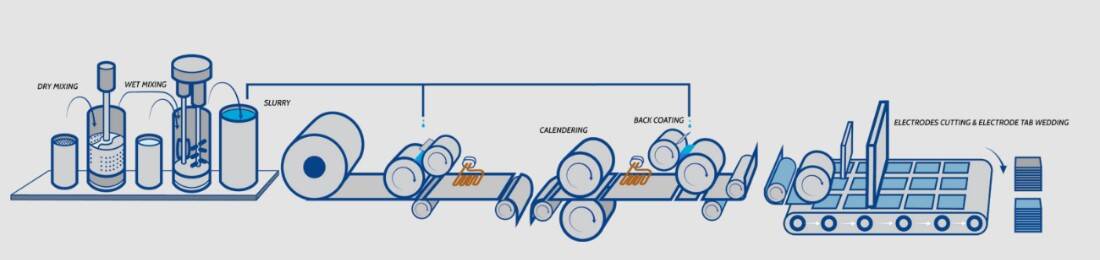

The process begins with the preparation of the battery slurry, a mixture of active material, binders, conductive additives, and solvents. Cathode and anode slurries differ in formulation, but both require homogeneity and stability.

Slurry mixing takes place in large vessels where variables such as temperature, mixing speed, blade design, and atmospheric conditions, all affect final quality. After mixing, the slurry is transferred (via piping or sealed tanks) to the coating station, where it’s applied onto metal foils that are then dried and processed into electrode sheets.

Importance of process parameter control

According to the report by RWTH Aachen [1], key factors that determine slurry quality include:

- Homogeneity

- Particle size

- Purity

- Viscosity

Maintaining these parameters within strict tolerances is essential for producing uniform high-performance batteries. Rheonics inline sensors enable this by providing continuous, real-time viscosity and density monitoring—eliminating delays from offline sampling and allowing immediate corrective action.

Rheonics inline sensors

Rheonics offers two advanced inline sensor types tailored for battery slurry and electrolyte applications:

- SRV Sensor – Measures viscosity and temperature

- SRD Sensor – Measures viscosity, density, and temperature simultaneously

Both sensors are designed to withstand challenging industrial conditions and deliver accurate, reliable measurements directly in the process line or tank.

Key benefits:

- Continuous inline monitoring

- No recalibration required

- Less waste by reducing sampling delays

- High precision and repeatability

- Enable full process automation

Recommended sensor placements

Rheonics sensors can be installed at multiple key stages in the battery slurry and coating process:

- Incoming Raw Materials: Verify viscosity or density before entering production.

- Mixing tanks: Install SRV inside the mixer for real-time viscosity tracking. Helps detect homogeneity, formulation errors, or contamination early.

- Storage and supply tanks: Use SRD in recirculation lines to prevent sedimentation and ensure stable slurry composition.

- Coating process: SRV ensures consistent slurry flow and coating thickness, directly impacting battery quality.

- Cell filling: Both SRV and SRD can monitor electrolyte flow characteristics to ensure proper wetting and activation during cell assembly.

Correlation with lab measurements

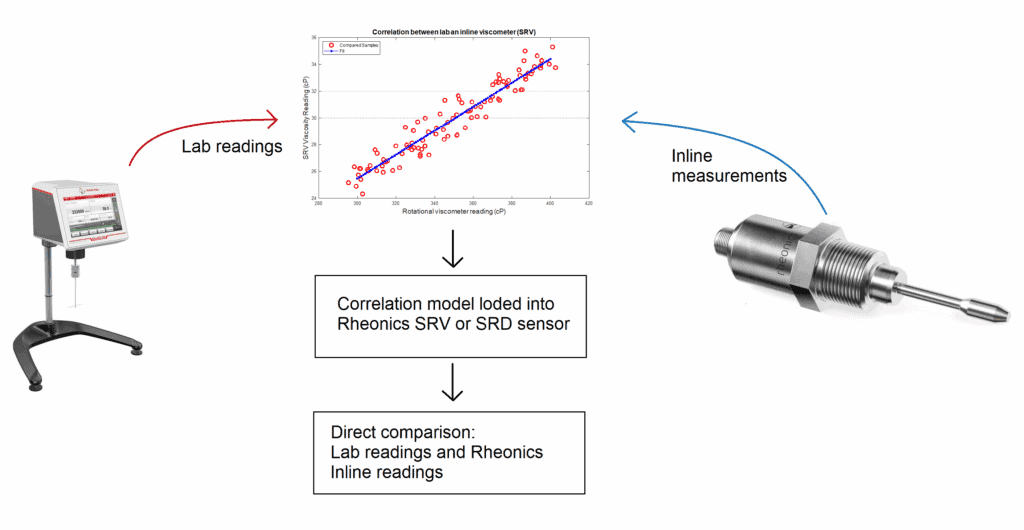

Rheonics sensors operating in a non-Newtonian fluid-like battery slurry will most likely not give the same viscosity reading as a laboratory viscometer like rotational meters, as technologies operate at very different shear rates. Rheonics SRV and SRD are predominantly process control instruments. From their readings, the smallest deviations from the baseline in production can be detected, which make them ideal for process monitoring and control.

However, if alignment with lab readings is required, it’s possible to create a correlation model that transforms inline readings to match lab results. This model can be uploaded to the sensor firmware for real-time adjusted output.

Interpreting mixing data

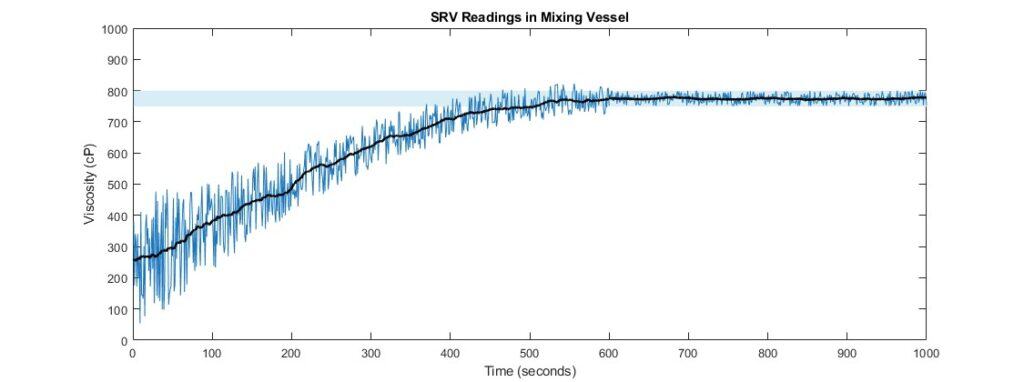

Using Rheonics sensors in mixing tanks give very insightful information about the process, the fluid composition change and the overall process performance. However, mixing processes can also induce noise in readings, predominanly in viscosity. This noise can also be representative of the process evolution, as the reduction in measurement noise as the process reaches the setpoint viscosity is an indicator of the homogeneity of the system. Later deviation from the setpoint tolerance envelope can indicate artifacts, bubbles, or aging in a slurry. Ensuring viscosity and density remain in the setpoint envelope is an excellent way to confirm the end product is meeting the composition and consistency targets for quality control.

Real-time viscosity and density data provide deep insights into slurry behavior:

- Stable viscosity values over time indicate consistent mixing.

- Sudden deviations may signal contamination, air bubbles, or material degradation.

- Low measurement noise during setpoint achievement indicates homogeneity.

References

[1] LITHIUM-ION BATTERY CELL PRODUCTION PROCESS. https://www.pem.rwth-aachen.de/global/show_document.asp?id=aaaaaaaaabdqbtk

[2] Battery Materials. https://www.freemantech.co.uk/applications/battery-materials

[3] Electrolyte Filling of a Lithium-Ion Cell . https://www.youtube.com/watch?si=6ksqM2v-ksH7vB_z&v=ceUSPNzxwls