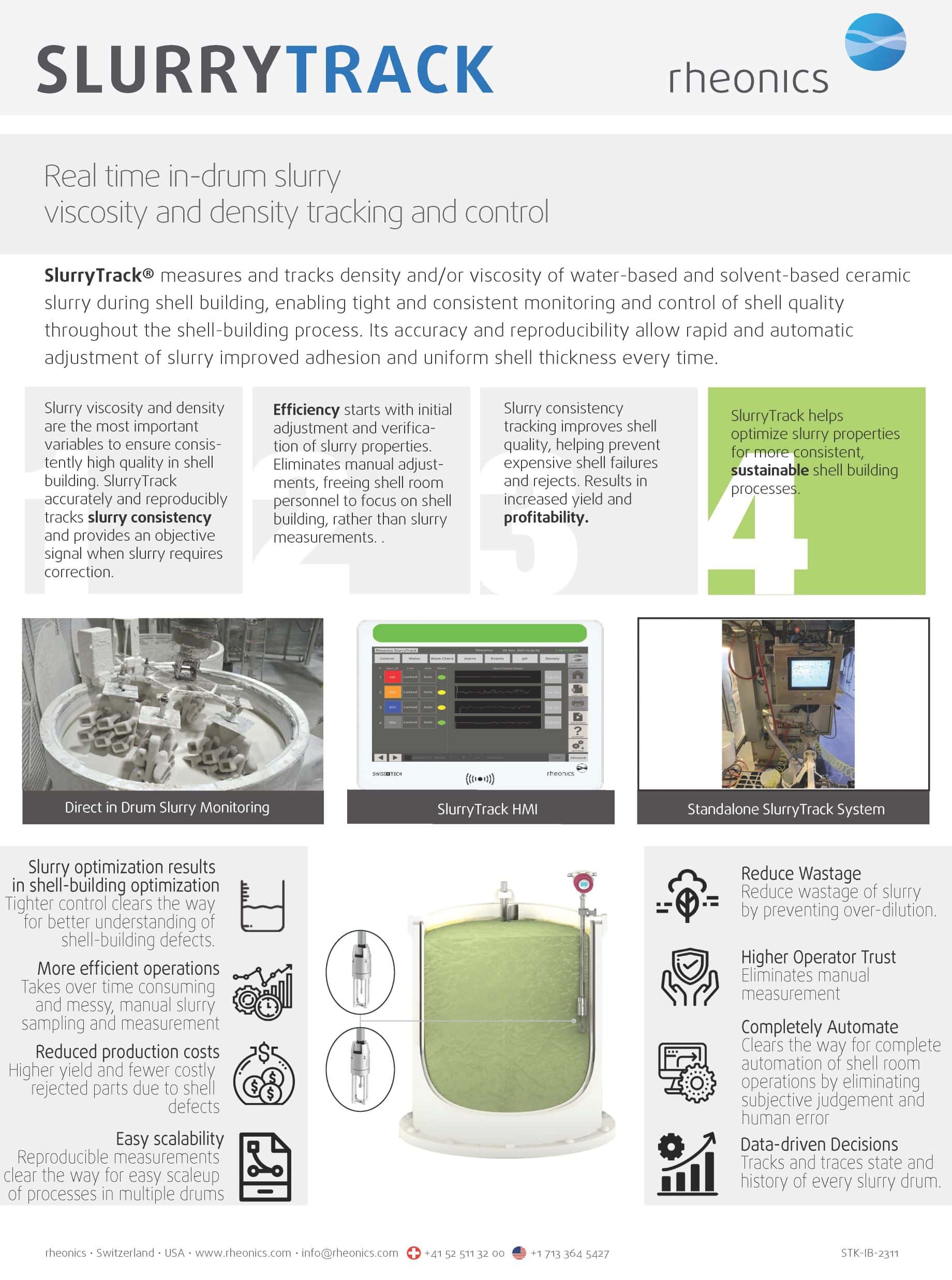

Rheonics SlurryTrack technology offers a simple and efficient bridge to bring slurry management up to the modern standards that prevail in today’s highly automated shell rooms. Key benefits are:

- Rugged sensor probe cage for tough enviornments

- External sensor for complete information: pH sensors, level sensors.

- Superior shell quality, due to uniform coating

- Efficient operations – reduction in man hours by 40%

- Improved productivity – faster, automated system = more molds

- Higher Profitability

- Reduced costs

- Easy scalability of operations

- Reduced scrap, rejects, diluent consumption

- Reduction in setup times and significantly easier cleaning procedures

- Safer and cleaner workplace

- Complete tracking and traceability of every job

- Industry 4.0 connectivity enabling data-driven decision making and fault analysis

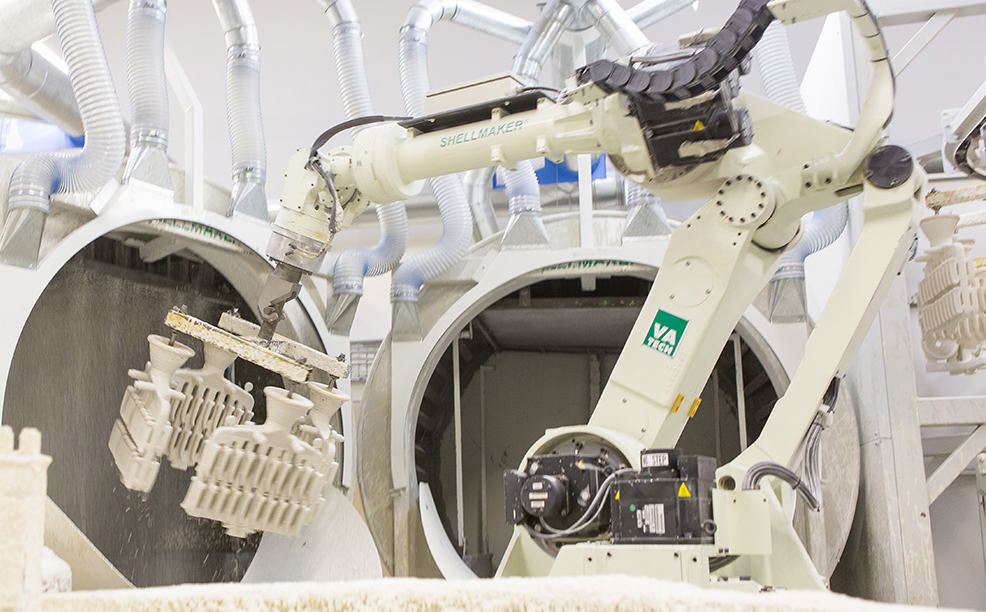

Investment casting is a manufacturing process to create highly accurate and intricately detailed metal components. This process, also called lost-wax casting or precision casting, uses disposable wax patterns, mirror replicas of the final part, surrounded by casting slurry after immersion in slurry drums. The wax pattern with the slurry layer is melted to result in a solid slurry cavity, where the molten metal is poured into, cooled down and solidified. The slurry solid layer is removed, resulting in the metal finished piece.

The process is relatively simple, which enables rapid production rates while ensuring consistent dimensional accuracy. Industries that commonly rely on investement casting produced parts are Aerospace, Automotive, Medical, Military, Industrial Machinery, etc.

Ceramic slurry is used in the investment casting process to create hollow molds or shells where molten metal is poured into. The slurry is a mixture of liquid and solid materials, that can have a fluid- or solid-like behavior depending on the percentage of the materials that compose it. Key aspects for its performance and quality have to do with its rheology properties. The viscosity of the slurry affect properties such as:

- Layer & final thickness

- Surface finish

- Permeability

- Strength

- Edge coverage

- Edge strength

- Bending strength

- Thermal characteristics

- Investment shells must comply with process specifications.

- The viscosity of the slurry will highly impact the surface finish, consistency, thermal conductivity, strength and other relevant characteristics of the shell

- External factors like temperature, shear rate and others, affect viscosity.

- Offline measurement techniques are time-consuming and cost-ineffective.

- Traditional Zhan cups instruments for viscosity measurement are inaccurate, inconsistent and non-repeatable.

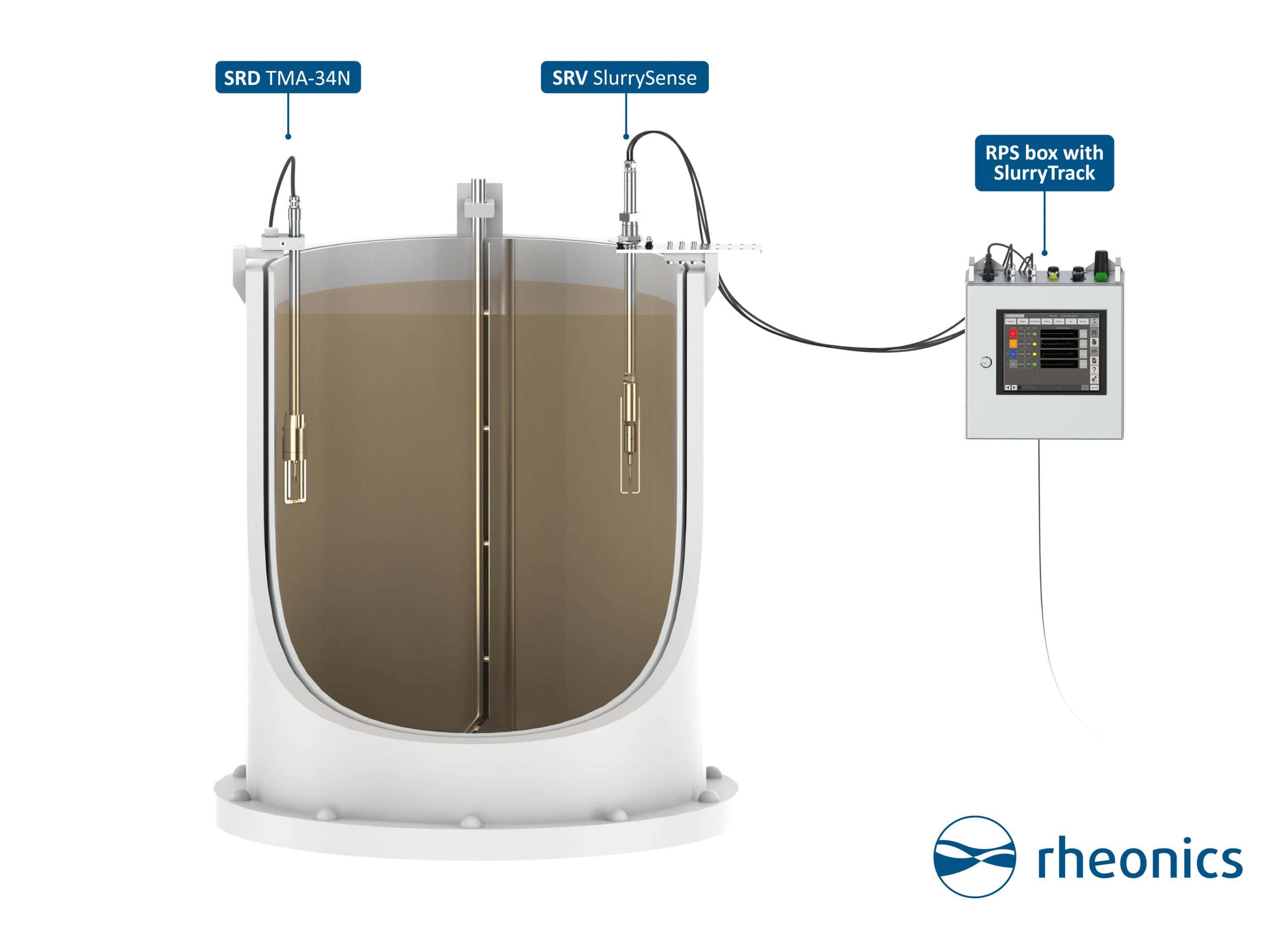

Rheonics SlurryTrack is an integrated solution that involves Rheonics sensors, controller, software, actuators and optional additional components. It is used to efficiently monitor and control the viscosity and density of the casting slurry during the mold coating process in slurry drums by precise addition of solvent/diluent to the slurry.

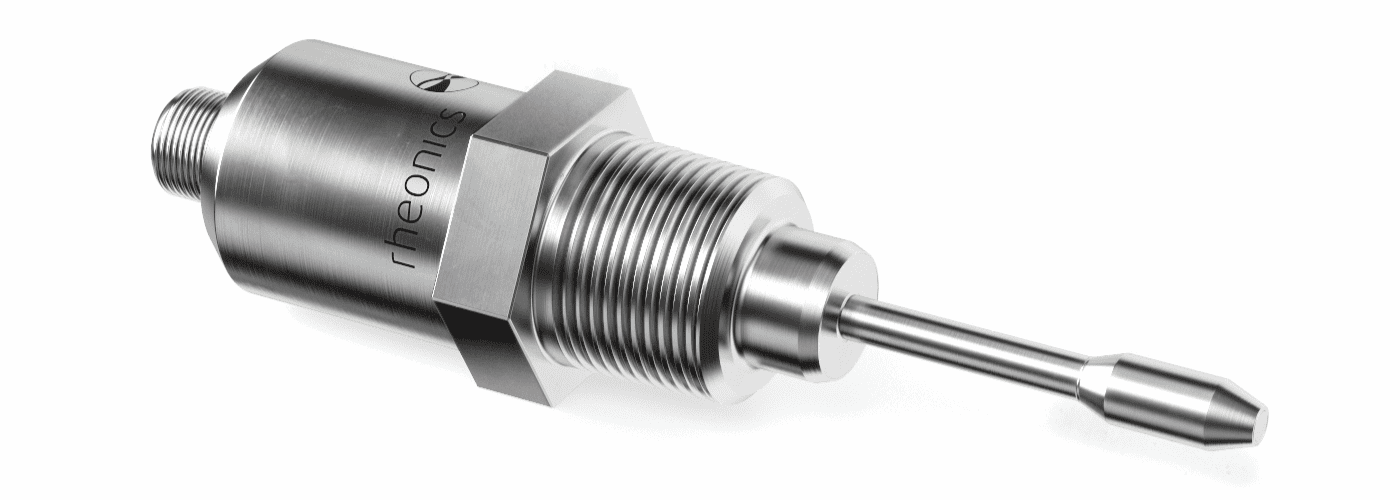

Inline Process Viscometer SRV

- Viscosity/Consistency measurement

- Temperature measurement

- Small and compact design

- Easy to install

- Easy to clean

- Unaffected by external vibrations

Inline Process Density and Viscosity Sensor SRD

- Density measurement

- Viscosity measurement

- Temperature measurement

- Small and compact design

- Easy to install

- Easy to clean

- Unaffected by external vibrations

SlurrySense with CleanWave™

Inline Self-Cleaning Density and/or Viscosity Meter SLS

- Pneumatic based self-cleaning technology that is integrated to the SRV or SRD sensor

- Avoids the need to remove the sensor for periodic manual cleaning

- Easy to install

- Unaffected by external vibrations

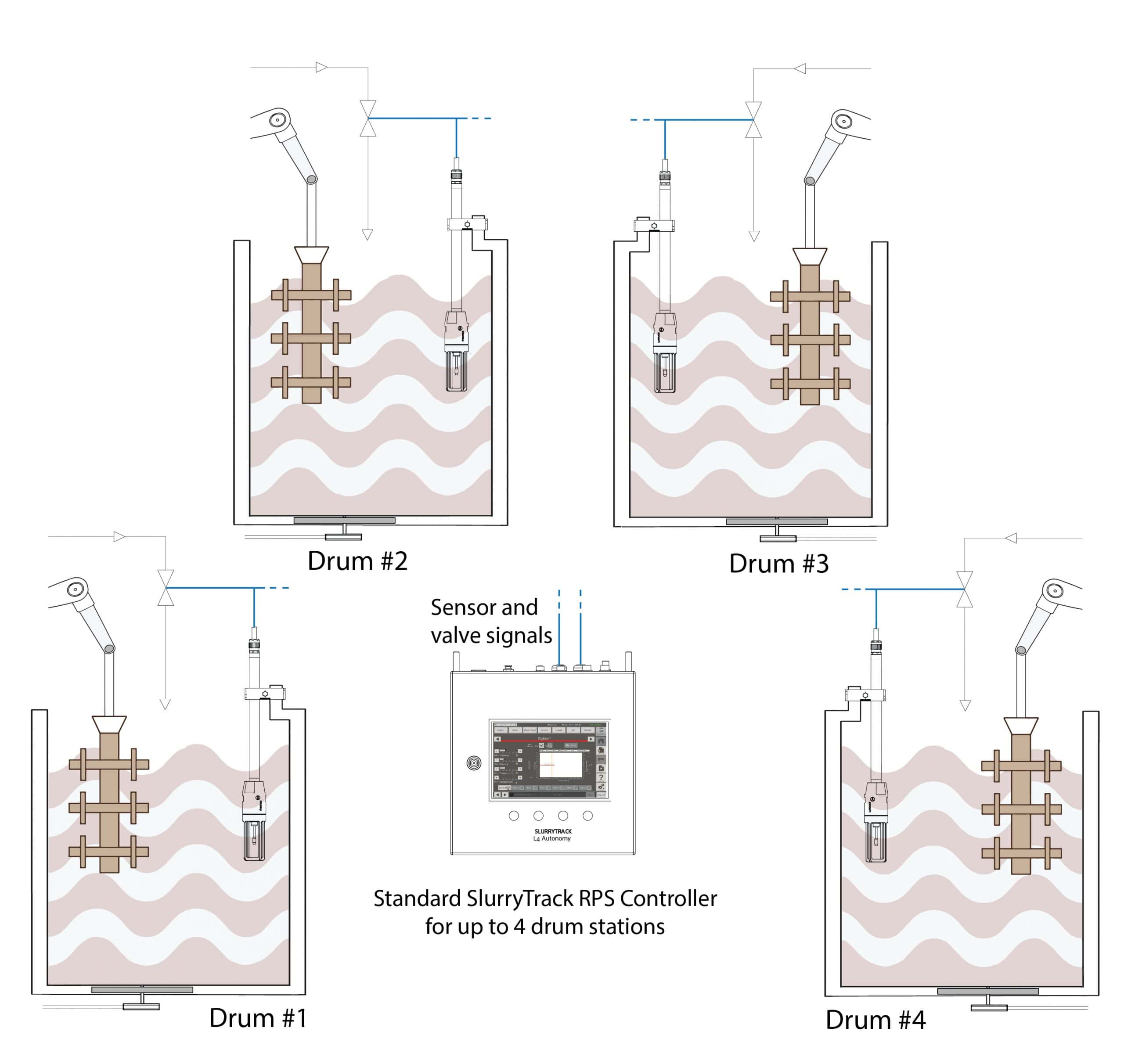

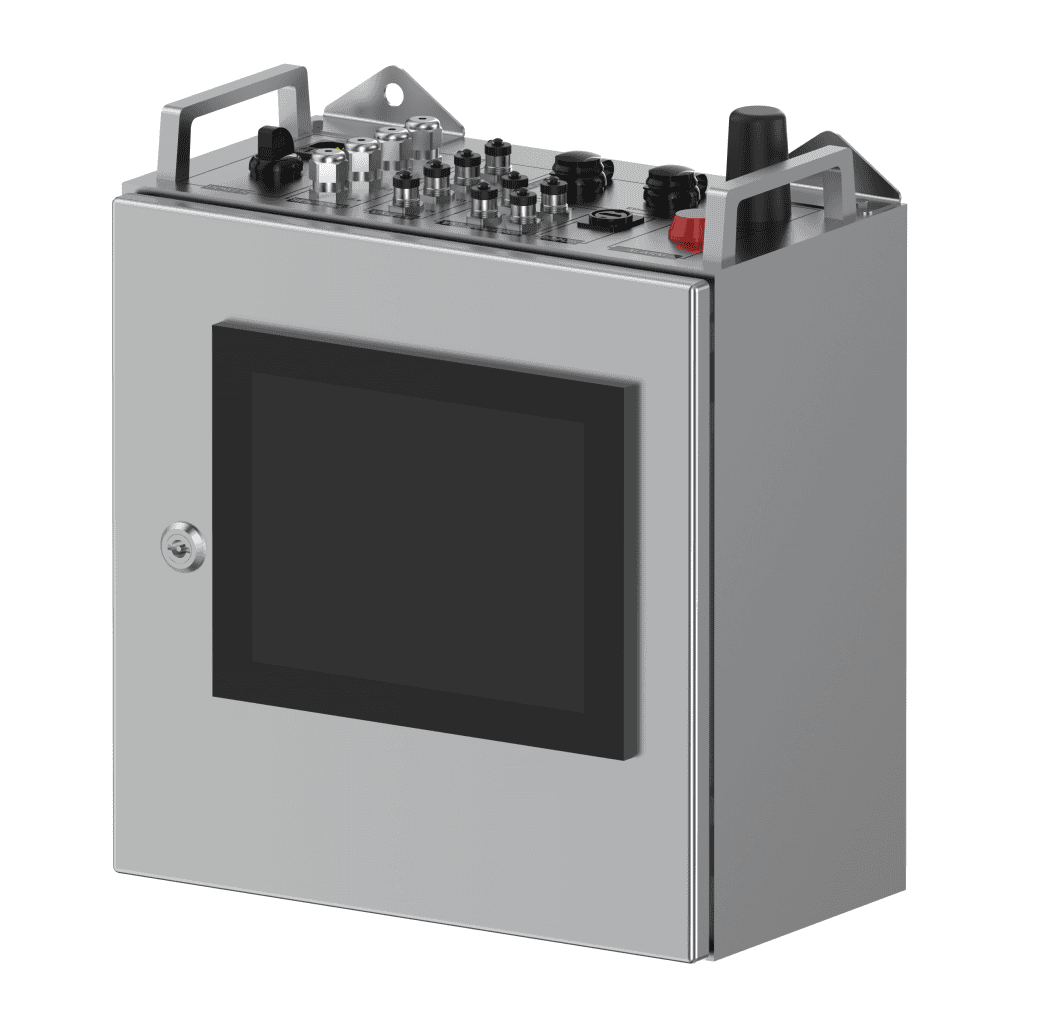

RPS-A Cabinet

- Stainless Steel cabinet includes sensor electronics (SME), Industrial PC with SlurryTrack Software running and Valve Control Device for solvent addition

- Standard RPS-A allows monitoring and control of 4 stations (sensors), and monitoring only of 6 stations (sensors)

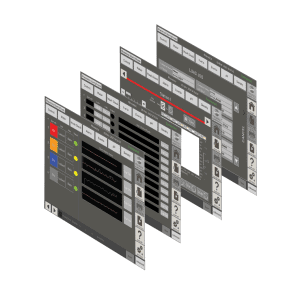

SlurryTrack Software

- Real-time visualization of viscosity and/or density

- Single click control activation per station

- Save run parameters for repeated process

- Access web server remotely

Solenoid or Pneumatic Valves

- On-Off valve

- Custom size

- Installation in diluent/solvent line

pH Sensor

- Third party sensor

- Enable integration to SlurryTrack Software for pH monitoring

Level Sensor

- Third party sensor

- Installed in solvent tank for level monitoring

- Possible integration to SlurryTrack Software to monitor solvent consumption and level moree accuretly than system internal calculation

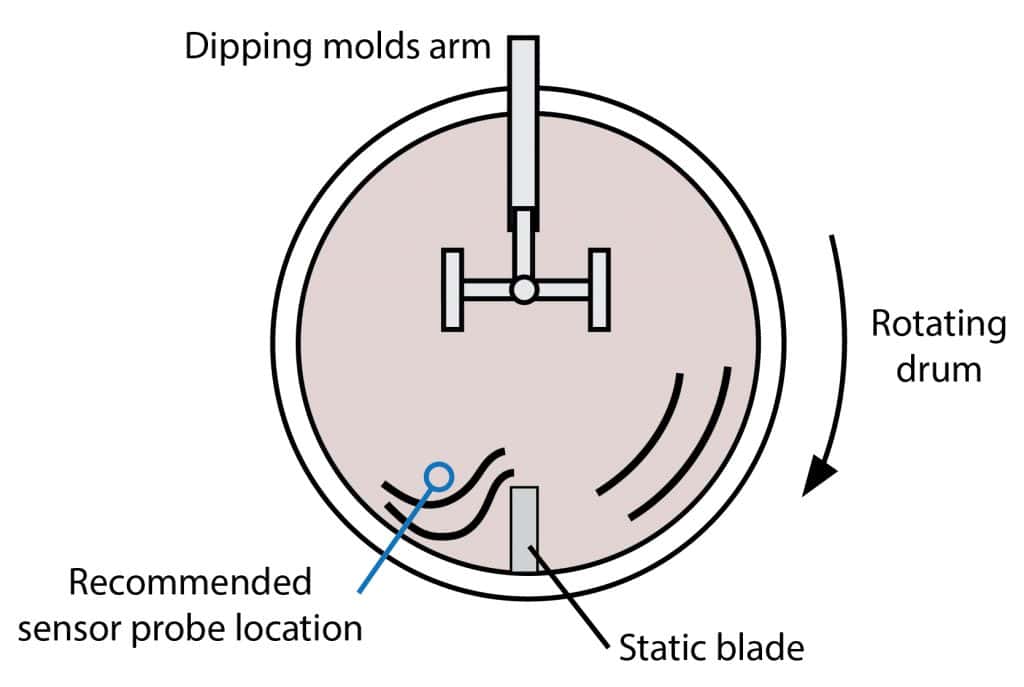

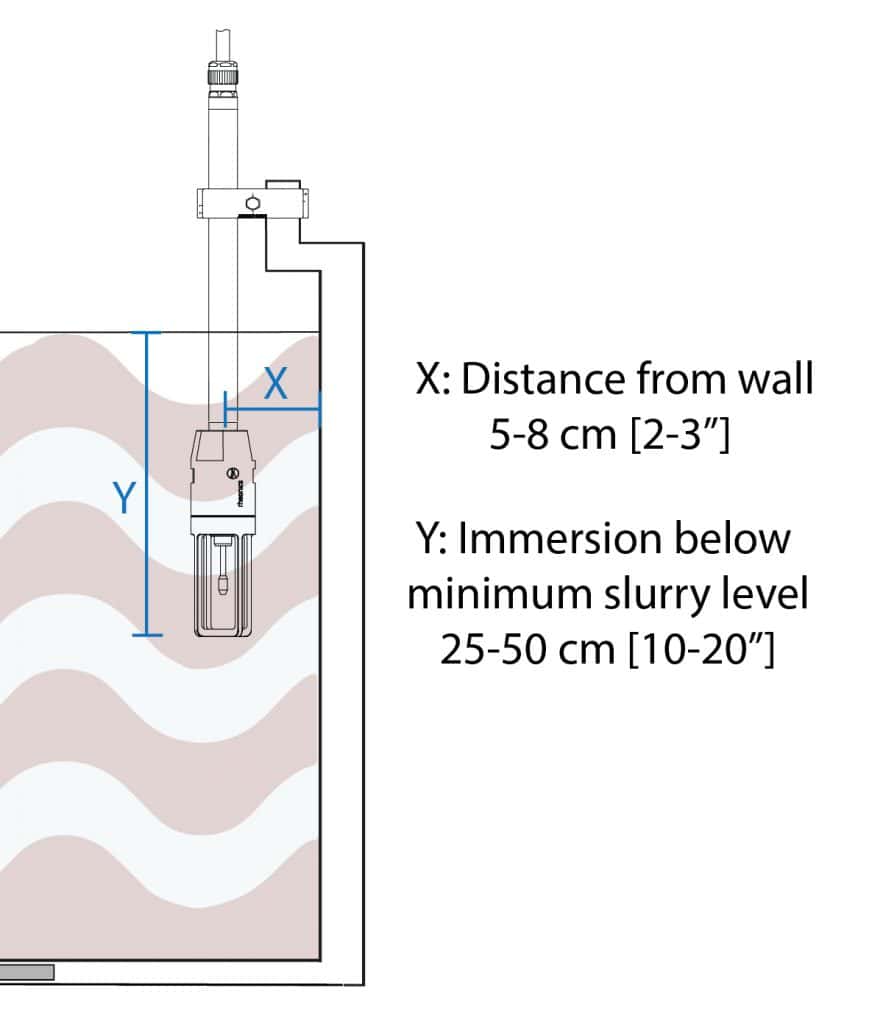

Rheonics sensor probe is installed in the slurry drum. Good immersion and clearance from the drum wall is recommended to prevent slurry solidifications or debries from colliding or depositing on the probe.

| Title | Summary | Link | File Category | Products | Tags | Type | document_categories_hfilter | tags_hfilter |

|---|---|---|---|---|---|---|---|---|

| Presentation Deck – SlurryTrack System | Rheonics SlurryTrack System for in-drum slurry viscosity and density monitoring and control | Information and Training Decks | Rheonics Casting Slurry Solution (SlurryTrack) | training-deck | ||||

| Brochure – SlurryTrack – Ceramic Casting Slurry | General information, benefits and application areas of SlurryTrack (Rheonics Ceramic Slurry Solution) in casting slurry monitoring and control. | Datasheets & Brochures | Rheonics Casting Slurry Solution (SlurryTrack) | Marketing, Application | datasheets | marketing application |