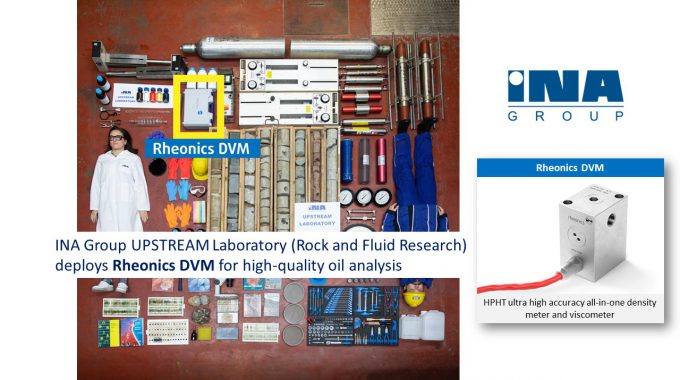

INA Group UPSTREAM Laboratory (Rock and Fluid Research) deploys Rheonics DVM for high-quality oil analysis

Overview

About INA Grupa

INA-Industrija nafte, d.d. (INA, d.d.) is a medium-sized European oil company. INA Group has leading role in Croatian oil business and a strong position in the region in the oil and gas exploration and production, oil processing, and oil and oil products distribution activities. Learn more

INA Upstream Laboratory – ‘Tetris’ challenge

In a LinkedIn post as a part of the ‘Tetris challenge’, INA Grupa shared a picture showcasing tools and equipment which enables their scientists, geologists, engineers and technicians in their Upstream Laboratory with insights and expertise to provide high-quality analysis and innovative solutions for the oil & gas industry.

And we joined the Tetris Challenge. We are proud of our colleagues from UPSTREAM Laboratory (Rock and Fluid Research) in which our laboratory scientists, geologists, engineers and technicians with great knowledge and experience provide high-quality analysis and innovative solutions for the daily challenges of the oil and gas industry.

– INA Group (in the LinkedIn Post)

Find the link to the the post by INA Group.

PVT study is difficult with traditional instrumentation: It needs innovative, cutting-edge solutions

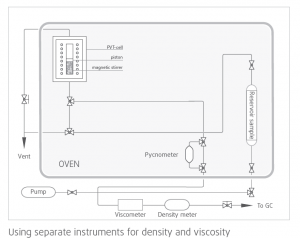

In PVT analysis, operators use either an offline or an inline instrument to measure density and another instrument to measure viscosity (mostly offline). There are major issues in using two separate instruments for measuring density and viscosity:

- Most traditional instruments used for density and viscosity measurement need separate fluid samples for analysis which are extracted from downhole fluid sample cylinders, using up large quantities of an extremely valuable fluid sample that cannot be reused in PVT

- Same temperature and pressure conditions are harder to achieve in two separate instruments leading to measurement errors

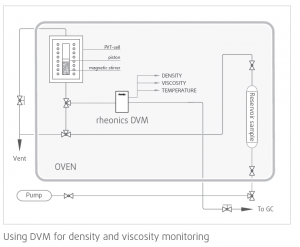

- Difficult to co-locate large, bulky density meters and viscometer inside PVT ovens due to space and mounting constraints

- Manual operation and needs long time for measurement

- Needs significant integration work in hardware and software to synchronize measurement data and ensure compliance

How is Rheonics DVM helping solve these challenges?

New reservoirs are increasingly ultra-deep with very high pressure conditions (>25000 psi) and high temperature (>400 °F). It is very expensive to acquire sample fluids from ultra-deep wells so it is important that density and viscosity measurements be carried out with minimal volume of the reservoir fluid. Overall for PVT studies, density and viscosity measurements should be done:

- At HTHP (High Temperature High Pressure) conditions to reduce reservoir uncertainty

- With minimal volume of reservoir fluid

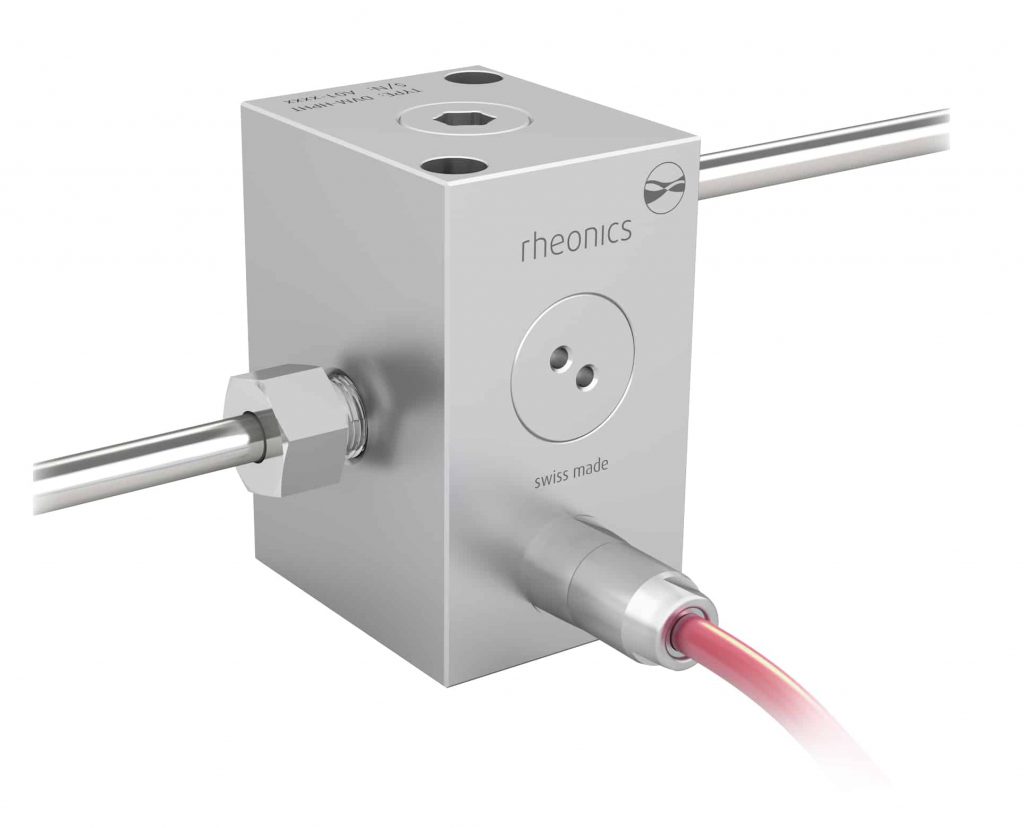

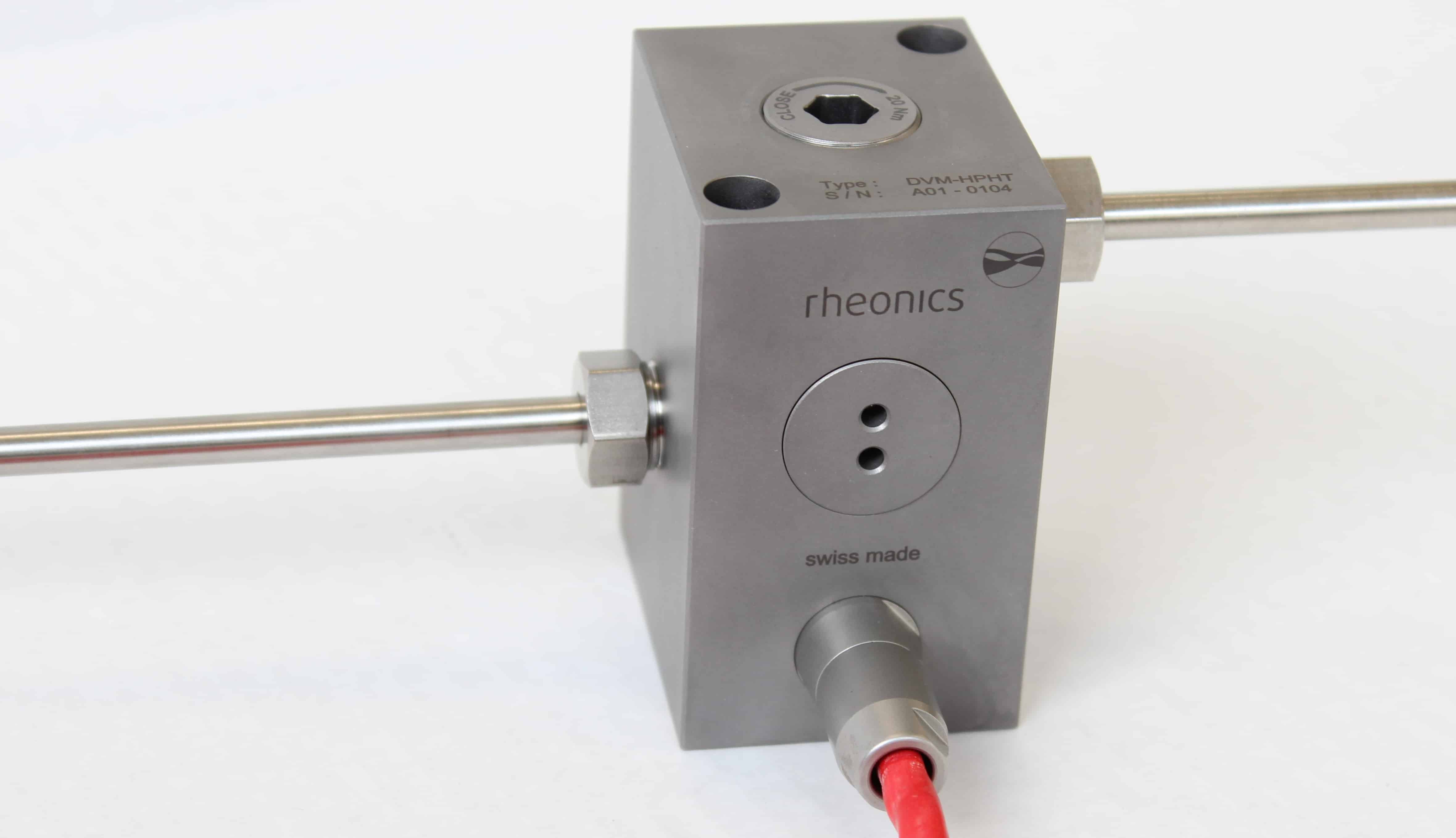

Rheonics’ DVM is a single instrument combining HTHP density meter and viscometer that delivers simultaneous density, viscosity and temperature measurement in the harshest of conditions.

Please read the application note on PVT study with the DVM in HPHT conditions using Rheonics instruments.

Density Viscosity for PVT studies

PVT analysis is performed to relate surface production to underground withdrawal for an oil reservoir and to simulate what takes place in the reservoir during production. PVT data have far-reaching applications in reservoir engineering, from estimating reserves to planning surface…

Rheonics DVM helps INA engineers with accurate, reliable PVT studies

INA uses DVM as part of their reservoir toolkit. DVM is a unique 3-in-1 process instrument. Density meter, Viscometer and Temperature gauge all-in-one: it is a small form-factor robust device.

Single instrument, dual function

Rheonics’ DVM is a unique product that replaces two alternatives and offers better performance while operating at true reservoir conditions. It eliminates the difficulty of co-locating two different instruments in any application needing density-viscosity monitoring of the process fluid.

Minimal sample size requirement

Minimal reservoir fluid is used for testing in the DVM since there is no requirement of a separate line or sampling system. Safe and cost-effective to operate, DVM requires only 0.7ml of sample to measure viscosity and density across the complete P,T range saving time and money.

Laboratory instruments have only limited application for measuring fluid properties under reservoir conditions. Very high pressures and temperatures, shock and vibration, limited availability of power, and severe space constraints.

Despite the importance of density and viscosity, they are notoriously difficult to measure under the extreme conditions found in the oil and gas industry. Resonant fluid property sensors are pushing back the limits of measurements thought to be possible only with laboratory-grade instruments.