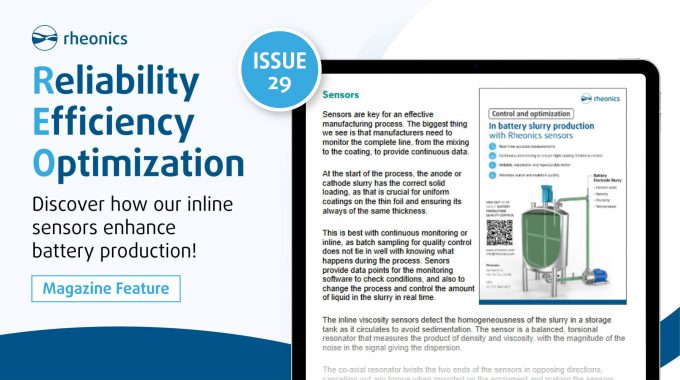

Discover Rheonics SRV process viscometer and variants

Overview

For more information check our latest updates on our social media channels.

Why Choose Rheonics SRV Process Viscometer?

- Real-time viscosity measurement for improved process control.

- Easy installation in existing ports with threaded, flanged, and other process fittings. Available with standard and custom process fittings.

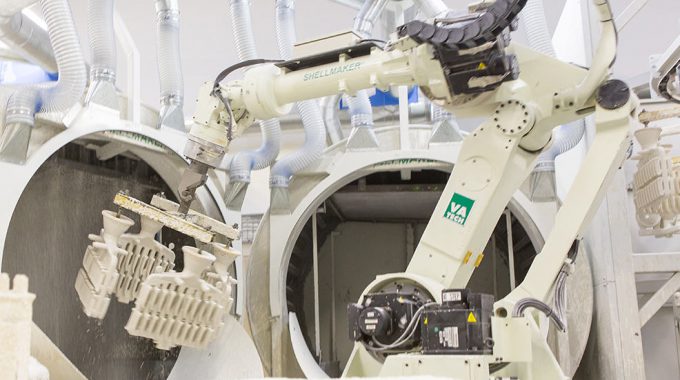

- Durable and reliable for harsh industrial environments.

- Easy to clean, no maintenance or re-configurations needed for scaling across the factory

Conclusion

Rheonics SRV sensors support a wide range of industrial process connections, making them adaptable to various industries such as food & beverage, pharmaceuticals, chemicals, and oil & gas. Their ability to integrate with different connections ensures seamless installation and operation.

Optimize your process with Rheonics enhancing quality, efficiency, and performance!