BatterySlurry Monitoring

Batteries play a central role in modern life powering smartphones, electric vehicles and renewable energy systems.

Learn more

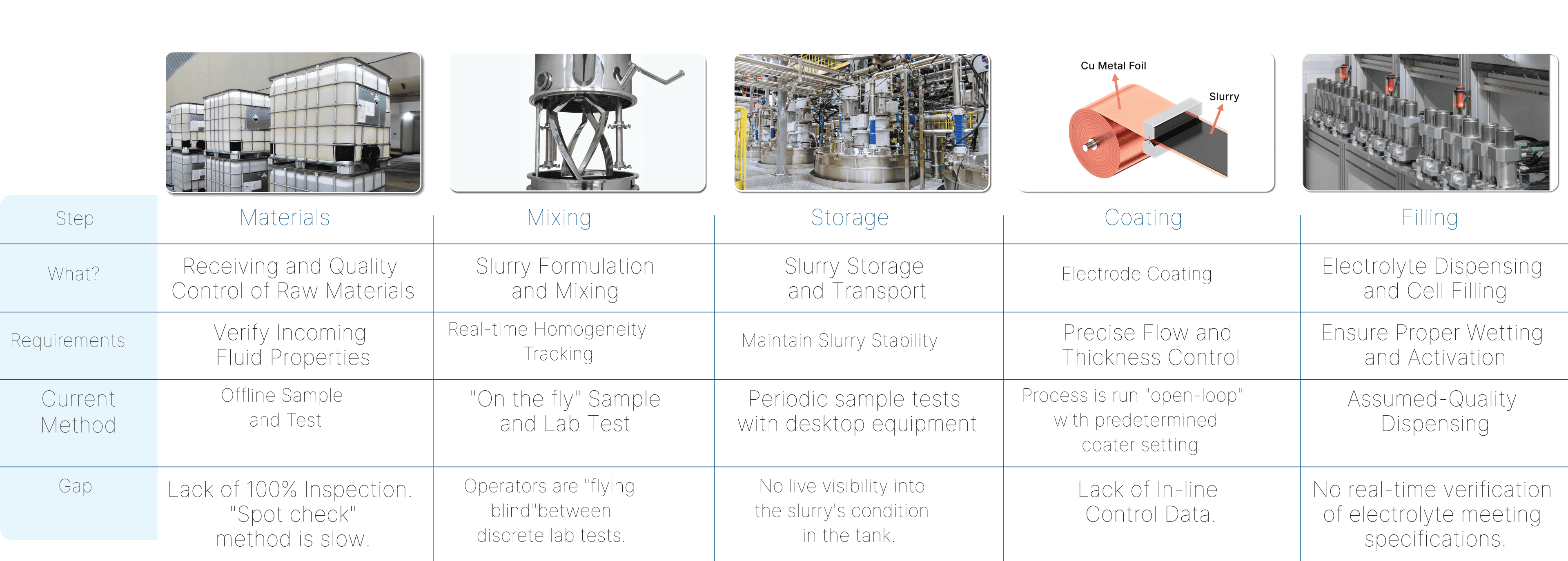

Problem statement

Battery manufacturing

is a rapidly growing industry that demands

consistent quality and process control.

Electrode slurry

preparation remains largely research-driven,

relying on manual, sampling-based measurements that lack

real-time and autonomous data collection for large scale

processes like mixing, coating and filling

Quality control

need vary across production stages, from

incoming material inspection, requiring full traceability of

high-value ingredients from multiple suppliers to process and

final product assurance.

Lack of unified system to control battery electrode slurry across the complete ecosystem

Rheonics Solution

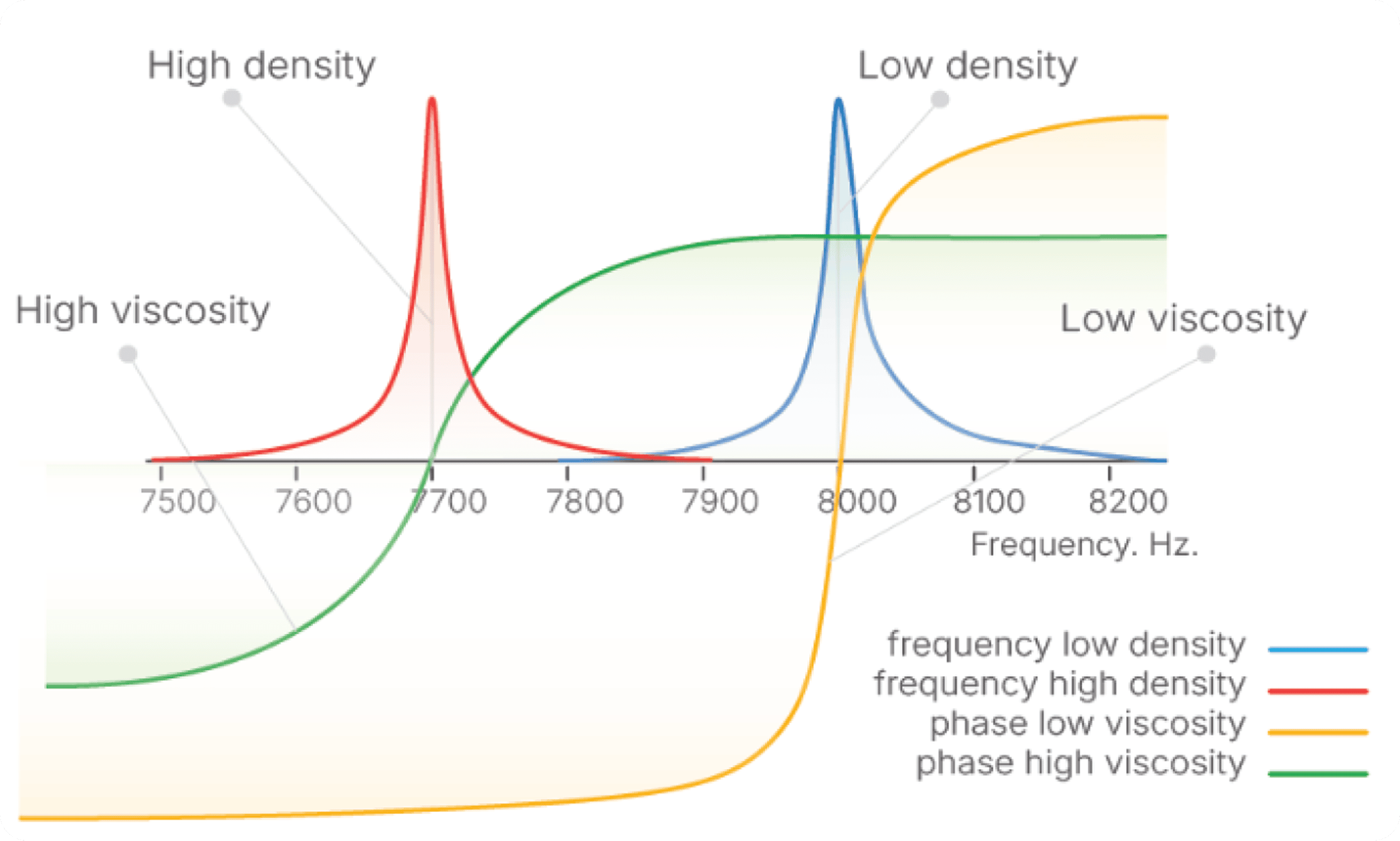

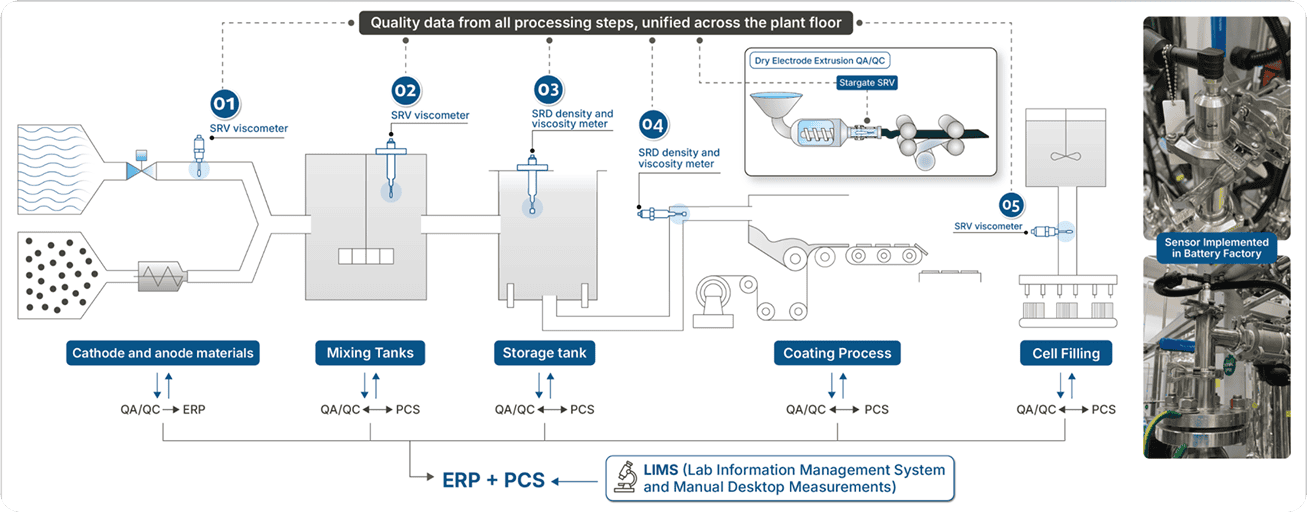

Resonance Response

- • Patented BTW (Balance Torsional Resonator) technology

- • Unaffected by external vibrations

- • Plug and play design

- • Different certifications avaible for hazardous zones

- • Robust and hermetically sealed

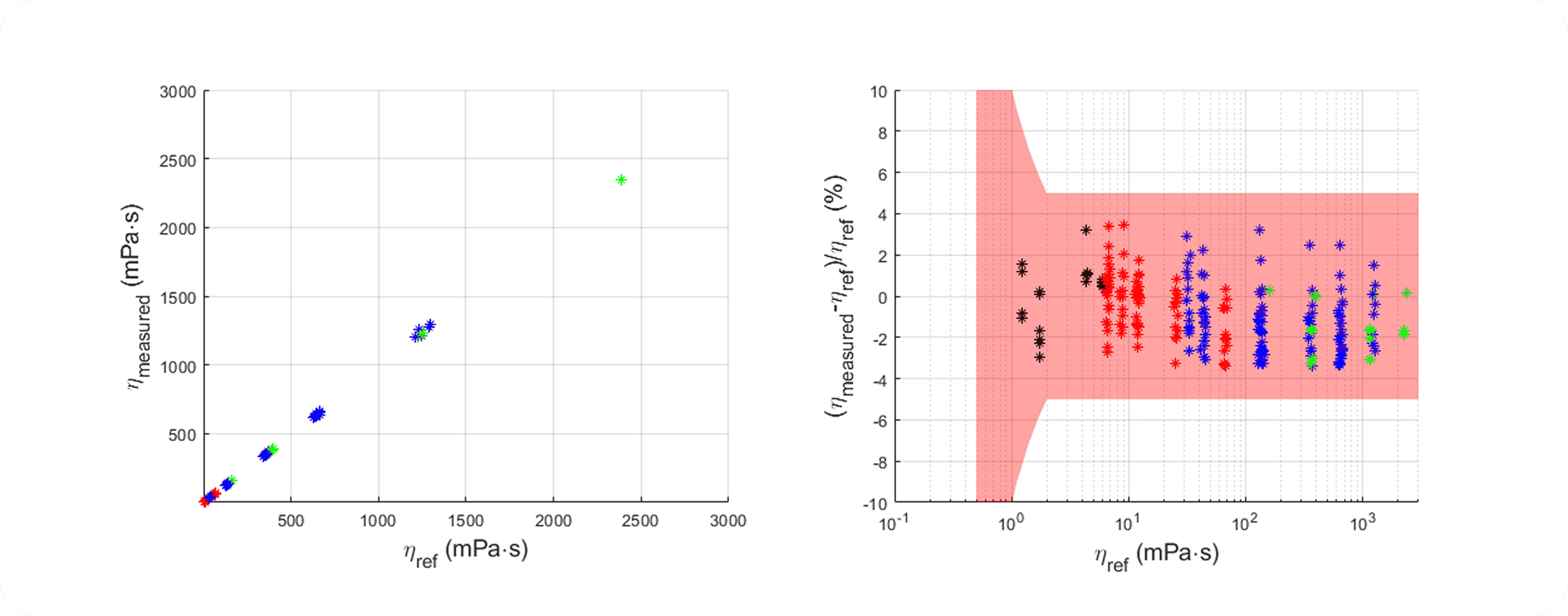

Measurements – SRV

- • Viscosity Range 0.4-250,000+ cP

- • Reproducibility Better than 1% of reading

- • Process Temperature -40 C to 300 C (-40 F to 575 F)

- • Pressure Rating Up to 500 bar (7500psi)

Measurements – SRD

- • Density Range 0.4-4.0 g/cc (0-4,000 kg/m3)

- • Viscosity Range 1 to 3,000 cP

- • Reproducibility Better than 1% of reading

- • Process Temperature -40 C to 300 C (-40 F to 575 F)

- • Pressure Rating Up to 500 bar (7500psi)

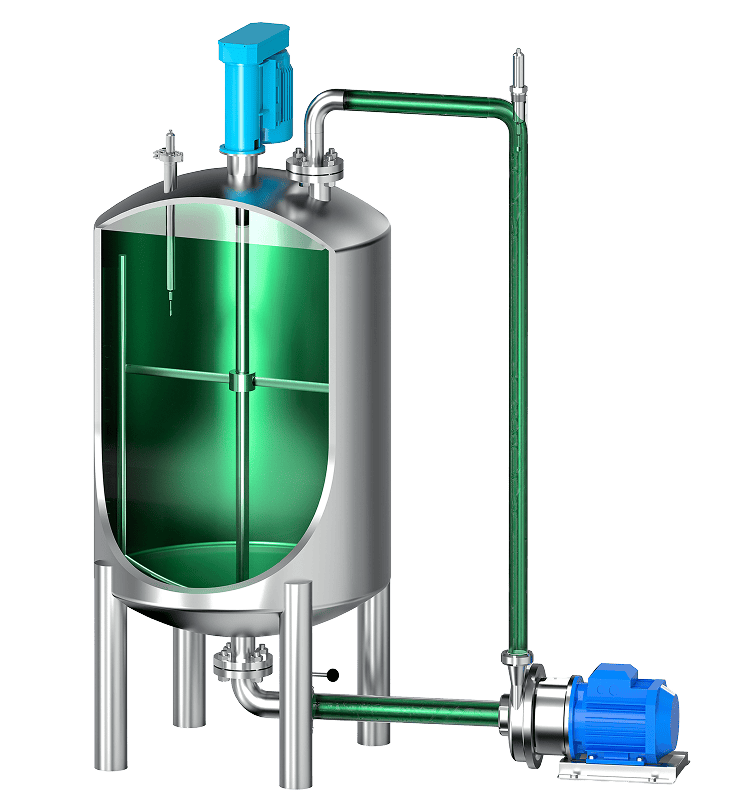

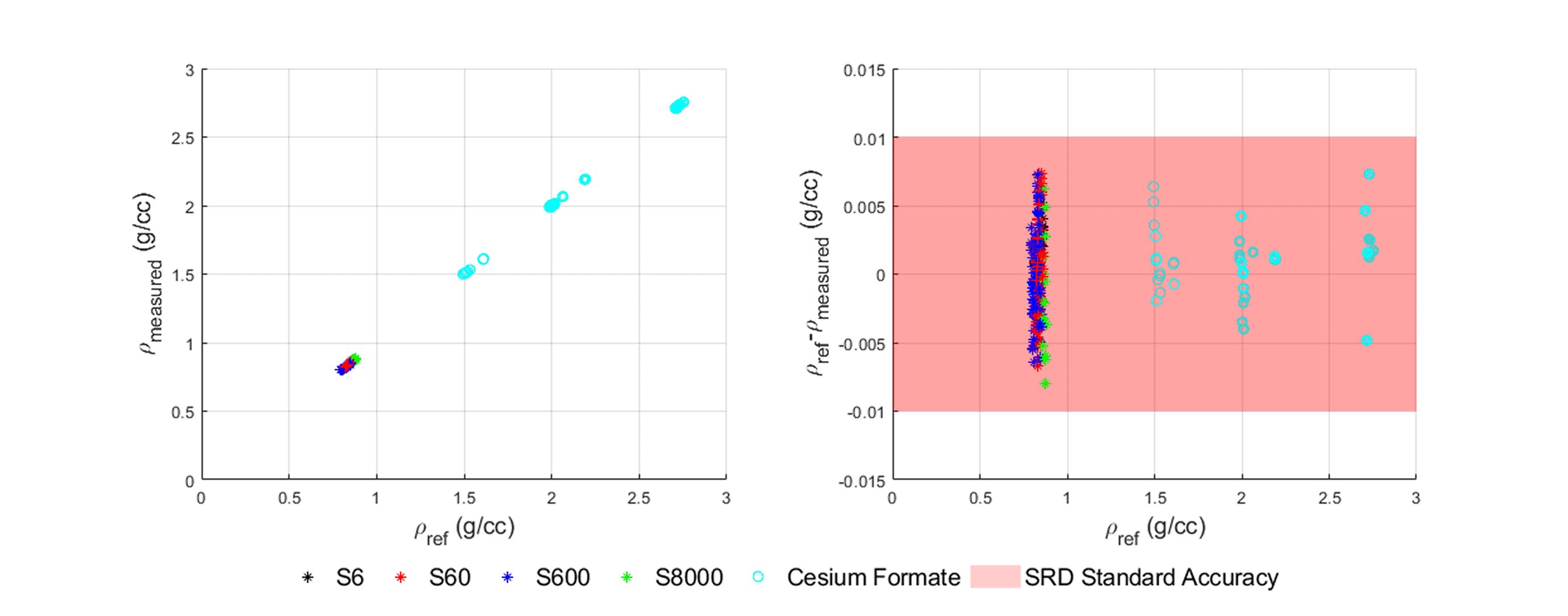

Sensor Implementation

Recirculation line

SRD Density and viscosity meter

Tank Installation

SRV viscometer

Coating line

SRV viscometer

Impact on KPI

Electrode slurry KPI

Viscosity

Homogeneity

Solid loading

Manufacturing Efficiency KPI

Mixing Time

Scrap Rate

Consistency

Cell Performance KPI

Coating Uniformity

Adhesion

Improved Electrode Slurry

Increased Manufacturing Yield

Enhanced Lifetime