Looking beyond Coriolis Flowmeters for density, viscosity and rheology in tough drilling operations

Application

“Tired of the expense, bulk and issues with measurement accuracy of the Coriolis meter for fluid density and viscosity?”

Now there is a state-of-the-art alternative. The Rheonics Symmetrically Resonant Densitometer – SRD. In tough environments of oil and gas drilling the Rheonics SRD delivers constant super accurate drilling fluid density, viscosity and temperature in a footprint that literally fits in the palm of your hand. Previous issues with gas cut mud affecting the Coriolis measurement accuracy are not a problem for the SRD. Deployment is completely nonintrusive both in the shale shaker for drilling fluid out and the mud pits for drill fluid in.

Rheonics SRD – an alternative to Coriolis flowmeters; with the SRD, get rid of issues related to accuracy, cleaning, installation and susceptibility to corrosion

Biggest challenges with the Coriolis for density, viscosity and rheology

- Expensive: The biggest and most often mentioned disadvantage of Coriolis flowmeters is its high price compared to other flowmeters. This may often lead to investment decisions in favour of other cheaper flowmeter types, especially in facilities where lots of them are needed. In the drilling industry most Coriolis flowmeters are found on offshore units because the higher cost is worth the higher safety gained through higher accuracy.

- Accuracy issues at high temperatures: Some models that are not built and calibrated for high temperature operation compromise performance decreasing accuracy at higher temperatures. This becomes an issue especially in high temperature wells and geothermal drilling where temperatures over 200°C can be expected. Furthermore, the measurement electronics are limited to an ambient temperature range between -40°C and +60°C which might become critical in arctic or desert environments.

- Difficulty in cleaning: Cleaning of the flowmeter tubes can be difficult; therefore, a bypass line has to be in place. Since the pipe is split into two smaller flow tubes in the Coriolis flowmeter, they clog easily. This has to be kept in mind during drilling operations because of the high solids content in drilling fluids and the rheological behaviour of the fluid in static conditions. During operations where bigger more problematic pieces of material are expected to come up the bypass line should be used, requiring manual intervention and creating safety hazards.

- Material selection issues and susceptibility to corrosion: Flowmeters are built with different materials for the inner measurement tubes. These vibrating tubes are especially susceptible to corrosion so the materials used for construction have to be carefully chosen. This may be an issue while drilling sour gas wells or circulating backflows of acid jobs.

- Extremely difficult installation: The necessary changes in the rig layout in order to install a Coriolis flowmeter can become complex and might in some cases be impractical. A big part why the installation might be a challenge is because the device does not work in partially filled pipes hence it requires a setup that ensures it is always filled with liquid.

Rheonics' solutions for continuous inline viscosity measurements

Rheonics in-line viscometer SRV and density meter SRD are built by a team that cut its teeth on building the world’s first commercially available downhole density and viscosity sensor. The Fracturing, drilling and completion fluid viscosity and density sensors are built to operate reliably in the high pressure and high flow rate environment encountered in drilling operations.

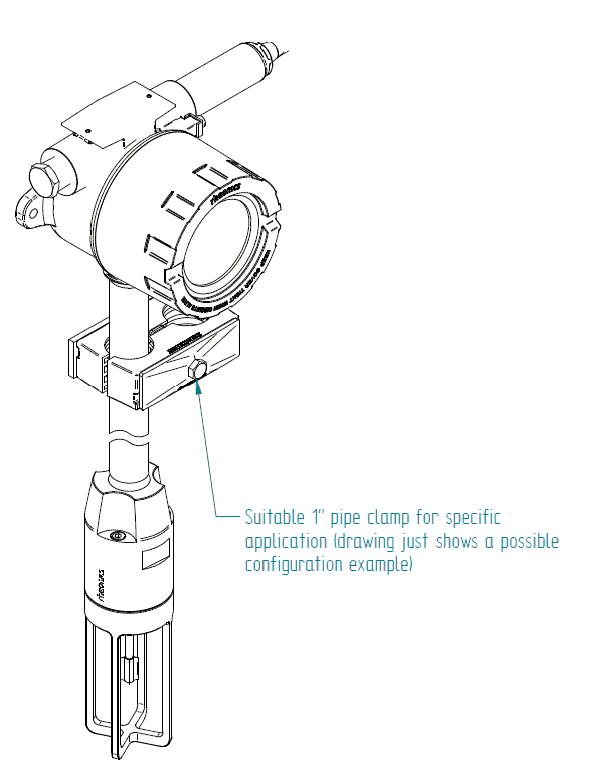

SRV and SRD are non-nuclear sensors, one of its kind that can be installed directly at the frac fluid mixing pump and injection pumps. With these sensors, frac fluid and drilling mud can be monitored continuously through the complete mixing, pumping and backflow operations. Installing the sensors at rig-sites is straightforward with variety of available flow through adapters, extended arms for installation in tanks, etc.

In addition, the SRV and SRD

- Operates across the complete viscosity range including from water to the highly visous viscosifier gel

- High pressure operation – operational to 5000 psi and even 10,000 psi (700 bar)

- High temperature operation to 550 °F (300 °C)

- Works with guar-based gel, glycols, viscous slickwater (engineering fracturing fluid), with crosslinker, inhibitor, breaker, friction reducer, surfactants, scale inhibitors

24x7x365 assistance in easy and low-cost installation and commissioning from the team that designed the sensor.

Rheonics’ SRD is a unique product that replaces three different instruments with one single instrument for viscosity, density and temperature measurements. It eliminates the difficulty of co-locating different instruments and delivers extremely accurate and repeatable measurements in harshest of conditions.

Read how SRD, a rugged inline online density meter and viscometer is revolutionizing the drilling mud monitoring and control during drilling in the application note:

Related application notes and blogs

Getting Frac Fluid Rheology Right!

Hydraulic fracturing (also called as fracking, fracing, hydrofracturing) involves high-pressure injection of ‘fracing fluid’ (primarily water, containing sand or other proppants suspended…

Downhole DV measurements in LWD, MWD, Wireline tools

The engineering of well logging sensors into the drill collars is simulating a revolution in logging and drilling. LWD, MWD…

Mud Weight Monitoring

As a part of the industry’s drive for continuous cost-effectiveness, drilling fluid performance and management have come under closer scrutiny.…

Improve Production with Optimized viscosity and density

Viscosity and density are basic drilling fluid properties. Viscosity of the fluid measures carrying capacity and gel development. A high viscosity drilling fluid is desirable to carry the cuttings to surface and suspend weighting agents in the mud. But if viscosity is too high, friction may impede the circulation of mud, decrease drilling rate, wastes fuel, causes loss of circulation and hamper the solids removal equipment. The flow regime of mud in the annulus is also affected by its viscosity. Density measures hydrostatic pressure in the borehole and solids content of unweighted muds. Proper density ensures sufficient hydrostatic pressure required to prevent the borehole wall from caving in and to keep formation fluid from entering the wellbore. But too high mud weight decreases rate of drilling and increases chances of differential sticking, fracturing the well, causes equipment wear, loss of circulation and increased mud cost. Abrasive solids cause excessive wear on pumps, drill string and bit. The drilling rate is reduced; a thick filter cake is deposited on permeable formations, and the pump does unnecessary work recirculating solids that have been allowed to collect in the mud. Mud weight affects filter cake properties and formation damage as well.

For HPHT wells, proper planning and execution of drilling operations requires complete and accurate knowledge of the behavior of drilling fluid density and viscosity as the pressure and temperature change during the drilling operation. Prediction of the drilling mud density at various pressures and temperatures is, therefore, very useful for mud and drilling engineers in planning drilling operations. Controlling and optimizing the drilling mud viscosity and density allows the operators to:

- Increase drilling rates, production and ROI with reduced mud costs

- Improve operational efficiency & equipment life, reduce waste fuels

Rheonics FracRight and MudMon Software

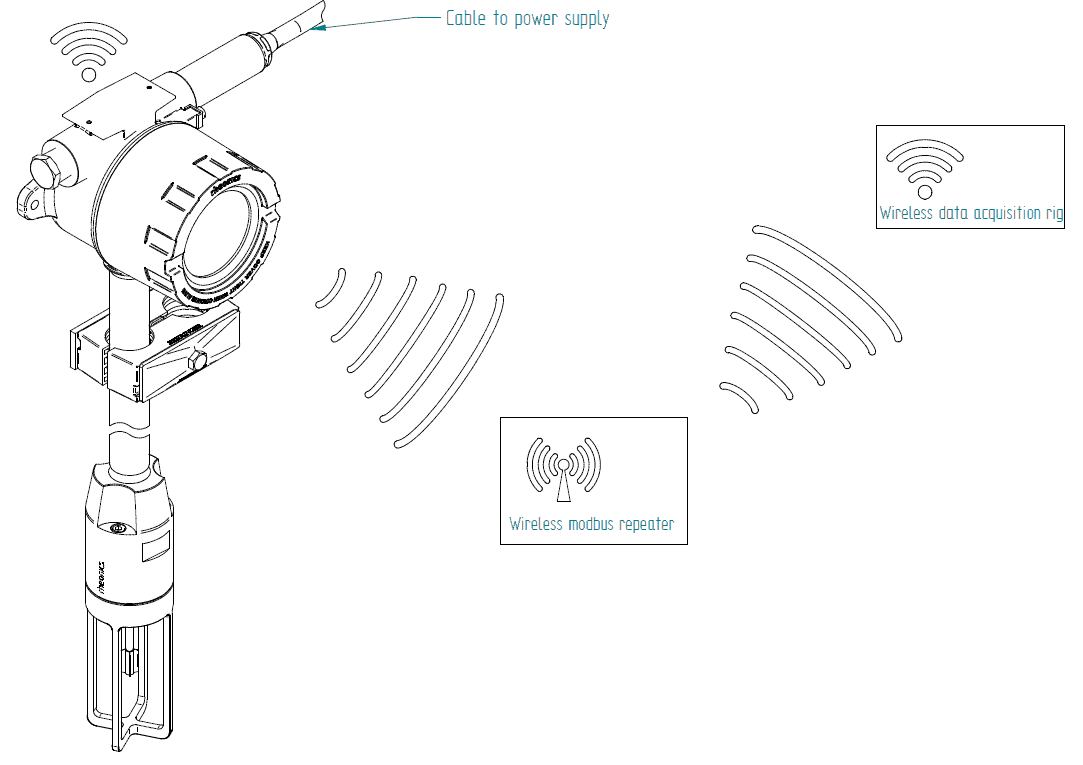

Rheonics’ FracRight software monitors and controls the density and viscosity of the frac fluid giving the operator fine control over the consistency of the frac fluid rheological characteristics. The system operates using single touch lock-in of the frac fluid property and ensures consistent fluid is pumped down the well through-out the operation. Communication over ethernet, wireless and modbus enables seamless transmission of information from FracRight to customer PC or Cloud.

Rheonics’ ModMon software monitors and controls the density and viscosity of the drilling mud giving the operator fine control over the consistency of the drilling mud weight and rheological characteristics. The system operates using single touch lock-in of the drilling mud property and ensures consistent mud is pumped down the well through-out the operation. Communication over ethernet, wireless and modbus enables seamless transmission of information from MudMon to customer PC or Cloud. Artificial intelligence forensics and event detection enables detection of gas in the mud and other safety and drilling related parameters.

Rheonics in Oil & Gas

Rheonics is a leader in harsh environment density and viscosity monitoring and control. It provides oil & gas industry with high-pressure high-temperature sensors and solutions that are used in cementing, reservoir analysis, crude oil applications, drilling mud monitoring & control, sand level detection in separators and frac fluid rheology optimization.

ATEX and IECEx Compliance

SRV and SRD are intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres. The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Rheonics SRV & SRD are both ATEX and IECEx certified. (Read more)

Rheonics density meters and viscosity meters are available as probes and flow-through systems for installation in tanks, process lines and reactors. All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.