ISO 9001 Certification – Rheonics Quality Management System is now ISO 9001 certified

We are pleased to announce that Rheonics has been awarded ISO 9001 Certification. ISO 9001 Certification is globally recognized seal of approval for our quality management system’s ability to serve customer needs consistently and at the highest quality.

Rheonics has always valued the importance of a fully functional QMS to meet customer needs. The accreditation process enabled us to further develop a robust quality management system to maintain a high level of quality throughout our organization. With ISO 9001 accreditation, we demonstrate both our focus on providing the best service to our customers and our dedication to investing in the latest engineering and production facilities.

Rheonics products and services are delivered with quality and transparency in mind.

Our commitment to quality is at the heart of everything we do, and we strive to maintain high standards of quality while always remaining compliant with regulations and specifications.

Updates on ISO 9001 certification

After relocating to a larger research and production focused new facility, Rheonics successfully passed the surveillance audits and is pleased to announce the release of its new ISO 9001:2015 certifications. The certifications project started with the goal to better serve our worldwide customers, in broad range of industries. Rheonics GmbH facility has successfully implemented and put to practice a Quality Management System (QMS) along the requirements of ISO 80079-34 & ISO 9001.

As a global leader in development and innovation of fluid-sensing solutions, Rheonics is continuously identifying and designing new solutions and protections that our customers trust in their applications.

Scope of the certificate

Design, development, production, marketing, sale, repair and maintenance of process automation products and solutions

Products Description

Rheonics SRV sensors are used to measure and control the viscosity of fluids, mainly under harsh process conditions. Rheonics SRD sensors measure, in addition, fluid density as well as true dynamic and kinematic viscosity. Each sensor is built on patented balanced symmetric torsional resonator technology.

To know more about our technology, check out the whitepapers.

Industries and Applications

Some of the industries that are covered by our products are the following:

- Oil + Gas refineries, Off-shore platform rigs and processing plants

- Automotive refueling stations or petrol/gas stations

- Chemical processing plants

- Coal mining

- Printing industries, paper and textiles

- Aviation, refueling and hangars

- Gas pipelines and distribution centers

- Sugar refineries

- Metal surface grinding, especially aluminum dusts and particles.

- Surface coating industries

- Waste treatment, sewerage plants

Examples of Applications in which Rheonics Sensors are deployed

Inline Viscosity and Density Monitoring for Gelatin Capsule Production

Capsules are a solid oral dosage form used for the delivery of medical drugs, vitamins, minerals, and other health-related ingredients.…

Automating and optimizing mining operations with Rheonics Sensors and Solutions

The mining industry has always been known for its complexity and hard environments. From ore extraction to final product recovery,…

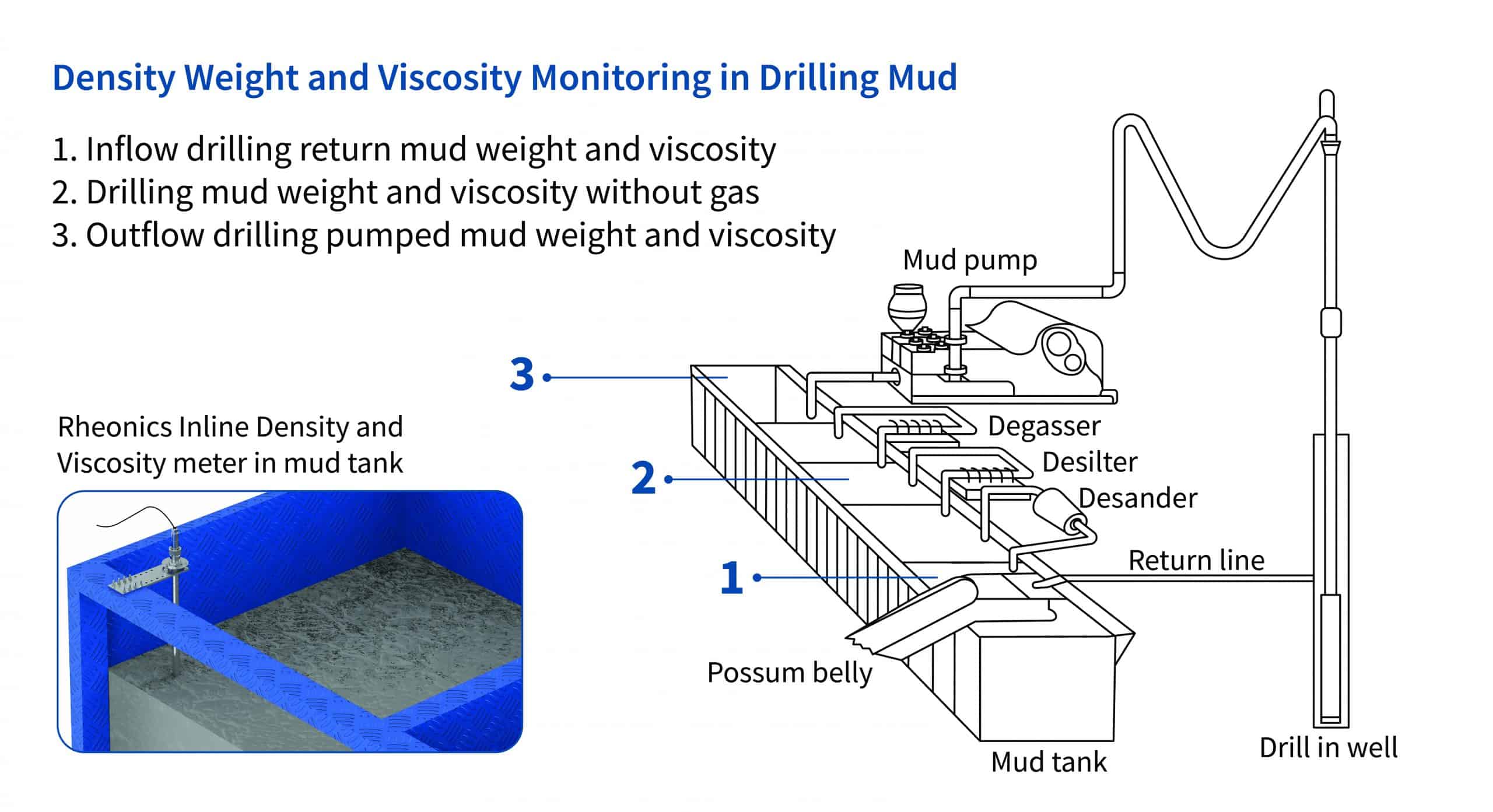

Drilling Mud Weight and Viscosity Monitoring to Optimize Well Performance

Drilling mud density and viscosity are critical parameters that directly influence drilling performance, borehole stability, and operational safety. Density, or…

Inline Viscosity Monitoring for Atomization Applications

Atomization is a process used to break up a liquid into fine droplets, usually done by forcing it through a…

Adhesives and Sealants Industry Overview and Rheonics Sensors Use

Find out the variety of applications in the adhesive industry and how Rheonics viscosity and density sensors are used and…

Density and Concentration Brine pond monitoring in lithium extraction process

Density and Concentration are critical parameters in Brine Lithium Extraction process for monitoring and control concentration, purity level, and process…

Monitoring Density and Viscosity in 3D Cement Printing

Density and viscosity are critical parameters in 3D cement printing as they directly affect the printability, structural integrity, and layer…

Monitoring Viscosity, Concentration and Degradation in Glycol-based Cooling Systems

Fluid cooling systems are an essential component in data center technology. As the power density of data center processors increases,…

Realtime Melt Viscosity Monitoring in Polymer Extrusion and Injection Molding

Polymer melt viscosity measurement during extrusion process has a paramount relevance for the melt quality, a much bigger relevance than…

Certificates and QANs

List of updated certificates available for viewing/download.

| Title | Summary | Link |

|---|---|---|

| Certificate – ISO 9001 | Certificate for Quality Management System (QMS) – ISO 9001:2015 | |

| Certificate – ATEX Quality Assurance Notification (QAN) – German | ATEX-QAN (Quality Assurance Notification) in German – Requirements according to directive 2014/34/EU have been fulfilled | |

| Certificate – ATEX Quality Assurance Notification (QAN) – English | ATEX-QAN (Quality Assurance Notification) in English – Requirements according to directive 2014/34/EU have been fulfilled. | |

| Declaration of Conformity – CE Declaration of Conformity according to directive 2014/34/EU (ATEX) for SRV & SRD | Rheonics’ EU Declaration of Conformity according to directive 2014/34/EU (ATEX) and relevant standards for SRV, SRV-FPC, SRD & SRD-FPC | |

| Certificate – ATEX Certificate for SRV & SRD – Issue 02 | Certificate for Equipment and Protective Systems intended for use in Potentially Explosive Atmosphere – Directive 2014/34/EU – Issue 02 | |

| Certificate – IECEx Certificate of Conformity for SRV & SRD – Issue 02 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standards listed in the Certificate Issue 02 |