FTA Flexo Magazine May 2021 features Rheonics – “RHEONICS PREVAILS IN 2021 FTA TECHNICAL INNOVATION AWARDS COMPETITION”

Overview

Flexographic printing focused magazine – Flexo (https://www.flexography.org/flexo-magazine/) publishes brief synopses of the 2021 Technical Innovation Award recipients. Rheonics SRV viscometers and the RPS InkSight Multi-Station Ink Control solution become a part of the elite group of winners of the Silver Anniversary of the FTA’s Technical Innovation Awards.

To download the pdf copy of the website, please use the link below.

Article from the Flexo Magazine May 2021 Issue

FATHOM OPTICS, RHEONICS, HYBRID SOFTWARE PREVAIL IN 2021 FTA TECHNICAL INNOVATION AWARDS COMPETITION

At press time, FTA announced the selection of three individual firms to be presented with 2021 Technical Innovation

Awards. Honors were bestowed on Tuesday, May 11, in the Association’s Virtual Conference Center, the site of FORUM & INFOFLEX 2021. The announcements came as part of the Awards Presentation.

What makes FTA’s Technical Innovation Award so prestigious? Recipients are deemed by a panel of industry experts to have the potential power to change package printing and converting’s future for the better, thanks to newly developed tools, equipment, instruments, processes and practices, specifically designed to enhance flexographic printing.

This year marks the Silver Anniversary of the Technical Innovation Award. In the past 25 years, 37 products, made by 29 firms, received the accolade. Seven repeat winners populate the list and this year will add an eighth. Of that number, three took the honor three times and one topped the repeat winner list, appearing four times.

Members of the Silver Anniversary class are:

» Fathom Optics, for its Light Field Technology Software (in the Prepress/Graphics category)

» Rheonics, for its RPS InkSight Viscosity Control System (in the Prepress/Pressroom category)

» And the repeat winner—Hybrid Software, for its Intelligent Flexo CLOUDFLOW Module (in the Prepress/Graphics category)

Full reports on the development, introduction, acceptance and benefits associated with implementation of the award-winning technologies will be conveyed in a collection of technical articles set to appear on FLEXO’s pages in July.

Brief synopses of the 2021 Technical Innovation Award recipients, as outlined by entrants, follow.

MEASURE, TRACK, CONTROL

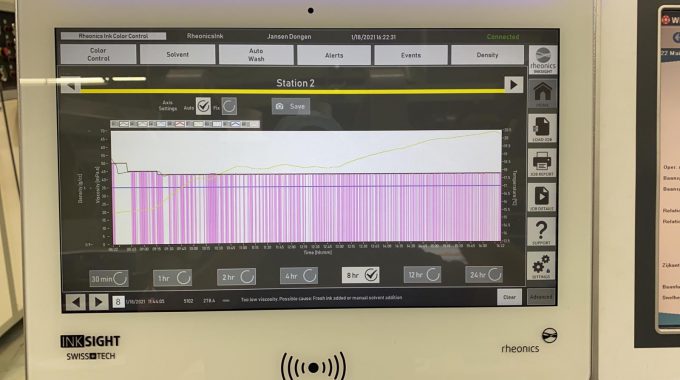

Rheonics RPS InkSight Predictive Tracking Controller and SRV viscometers enable tight viscosity control throughout the

print job, due to the system’s ability to autonomously maintain viscosity within extremely narrow limits. Developers promised, “Printers can achieve unmatched color accuracy and quality with the RPS InkSight system and ColorLock software, designed in collaboration with printers, for printers.”

SRV sensors, like the one pictured, serve as the foundation on which the RPS InkSight Viscosity Control System is built.

Benefits delivered were listed out like this: “Achieve best in class print quality, dramatically reduce setup time and optimize use of pigments and solvents. Improve productivity and efficiency through complete automation of color control on press… Reduce solvent emissions, achieve better operator safety, automate operations, make data-driven decisions and reduce printing costs.”

Built on the same physics used to control NASA Mars entry guidance, Rheonics noted, “InkSight is a highly accurate multi-station ink viscosity control system.” It consists of three elements:

» SRV sensors serve as the foundation upon which a robust, operator-friendly control system is built. They deliver the same readings from beginning to end of long jobs, and do not need calibration or special cleaning procedures between jobs

» Rheonics Predictive Tracking Controller predicts and compensates for evaporation before the ink change

» RPS InkSight ColorLock software keeps track of every process variable during a printrun. The print data is stored on the system and made available to the machine PLC and factory data acquisition systems. Bi-directional communication between machine, job servers and RPS InkSight makes loading and running jobs easy. Plant managers, quality personnel and production supervisors get powerful print job reports to better evaluate performance on job dashboards.

Engineers explained, “InkSight fundamentally changes the nature of the flexo printing process, from initial job setup all the way to jobs that, once delivered, secure a clear path to repeat business… It can produce a change in the very culture of the flexo industry by adding job-length consistency, accuracy and efficiency.”

Unique advantages with the Rheonics SRV sensors

Rheonics sensors have built-in temperature measurement, permitting the temperature of the ink to be monitored. This permits the viscosity readings to compensated for temperature, which is essential for ensuring consistent production through typical daily and seasonal temperature variations.

There are many benefits to using an inline viscosity sensor like the SRV for printing applications. and some include:

- Works accurately in most coating systems with a broad range of ink compositions and viscosities – water-based, solvent-based, UV inks, metallic inks etc.

- Maintains the set ink viscosity, extremely responsive to fresh ink additions

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline with all standard CIP processes, or with a wetted rag, without the need for disassembly or recalibration

- No moving parts to age or foul with sediment

- Insensitive to particulate matter; no narrow gaps to foul with particulates

- All wetted parts are 316L stainless steel—meets sanitary norms with no corrosion problems

- Certified under ATEX and IECEx as intrinsically safe for use in hazardous environments

- Wide operational range and simple integration—Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Some images of the RPS InkSight system

- Rheonics SmartView console integrated in printing machines

- Some pictures showing the SRV viscometers inline installation inside the press

- Standalone control cabinet