FTA Flexo Magazine features Rheonics FTA Technical Innovation Award winning Technology – “Excellence via Viscosity Control”

Overview

Flexographic printing focused magazine – Flexo (https://www.flexography.org/flexo-magazine/) publishes an in depth article showcasing the Rheonics SRV viscometers and the RPS InkSight Multi-Station Ink Control solution and how it enables excellence in color control in printing.

Find the link to the publication.

To download the pdf copy of the article, please use the link below.

Introduction

A LOOK INSIDE RHEONICS’ FTA TECHNICAL INNOVATION AWARD-WINNING INKSIGHT

A central goal of flexographic printing is to produce the best possible print quality, most economically. In today’s brand conscious market, high print quality is of paramount importance in attracting customers and maintaining a loyal customer base.

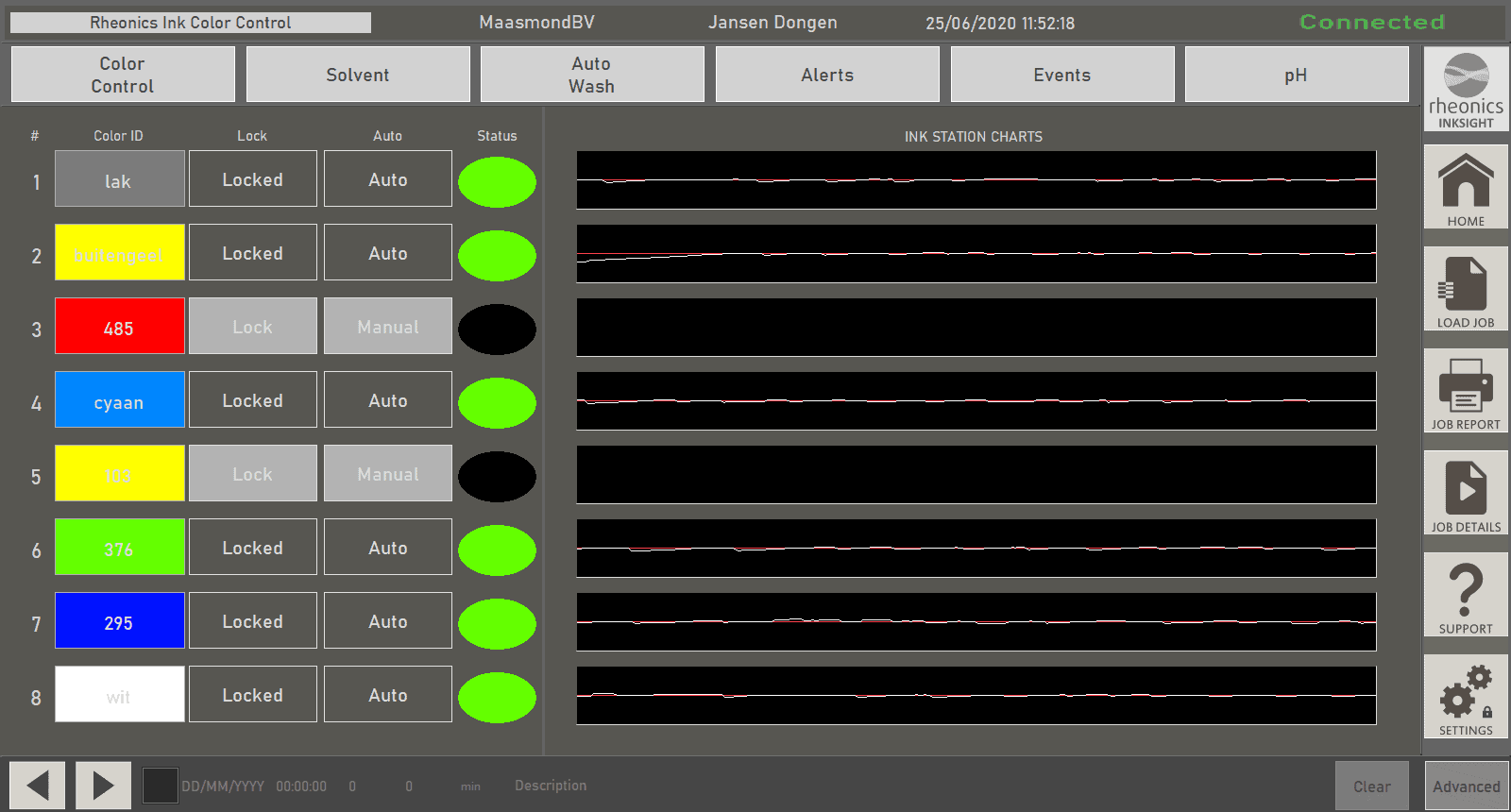

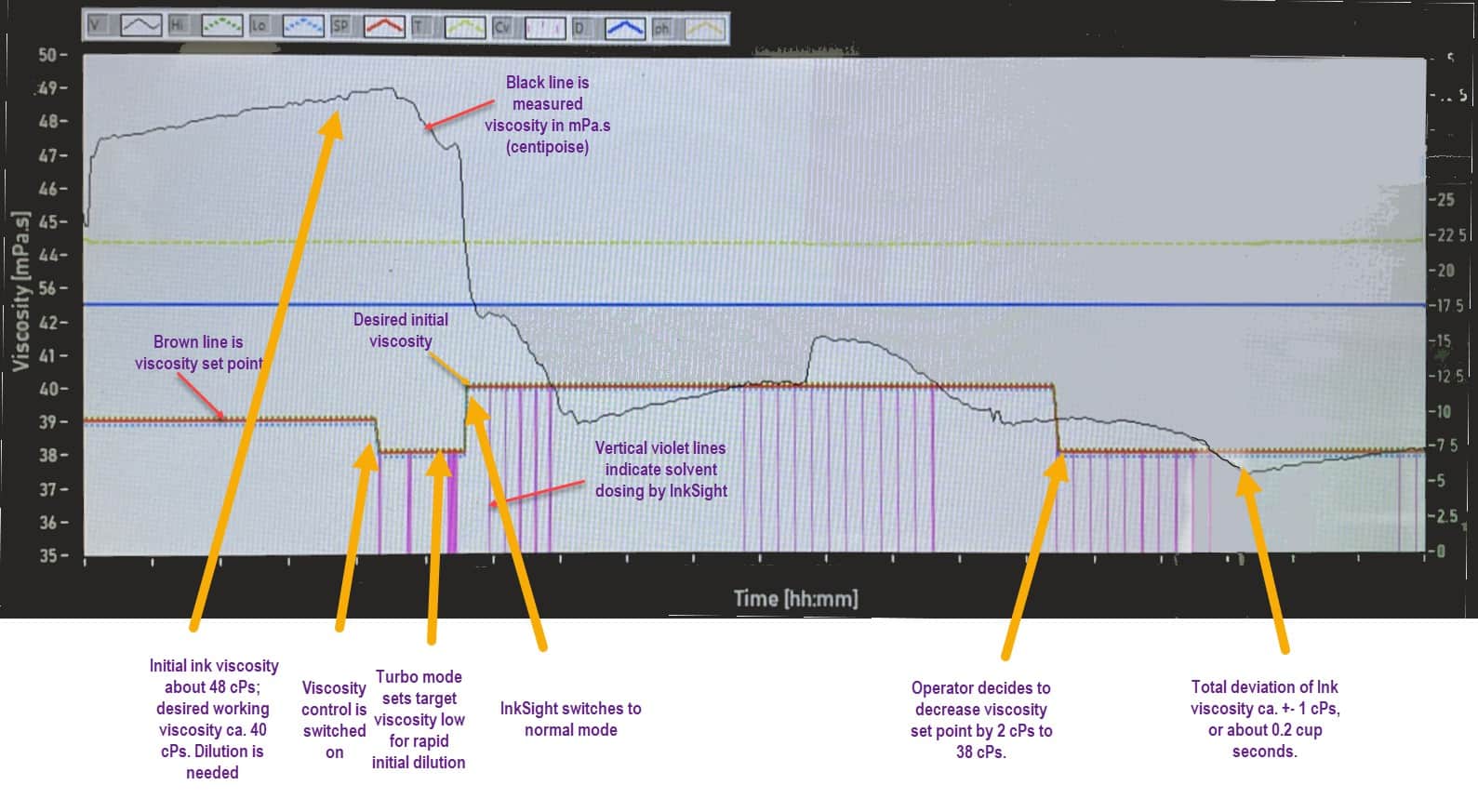

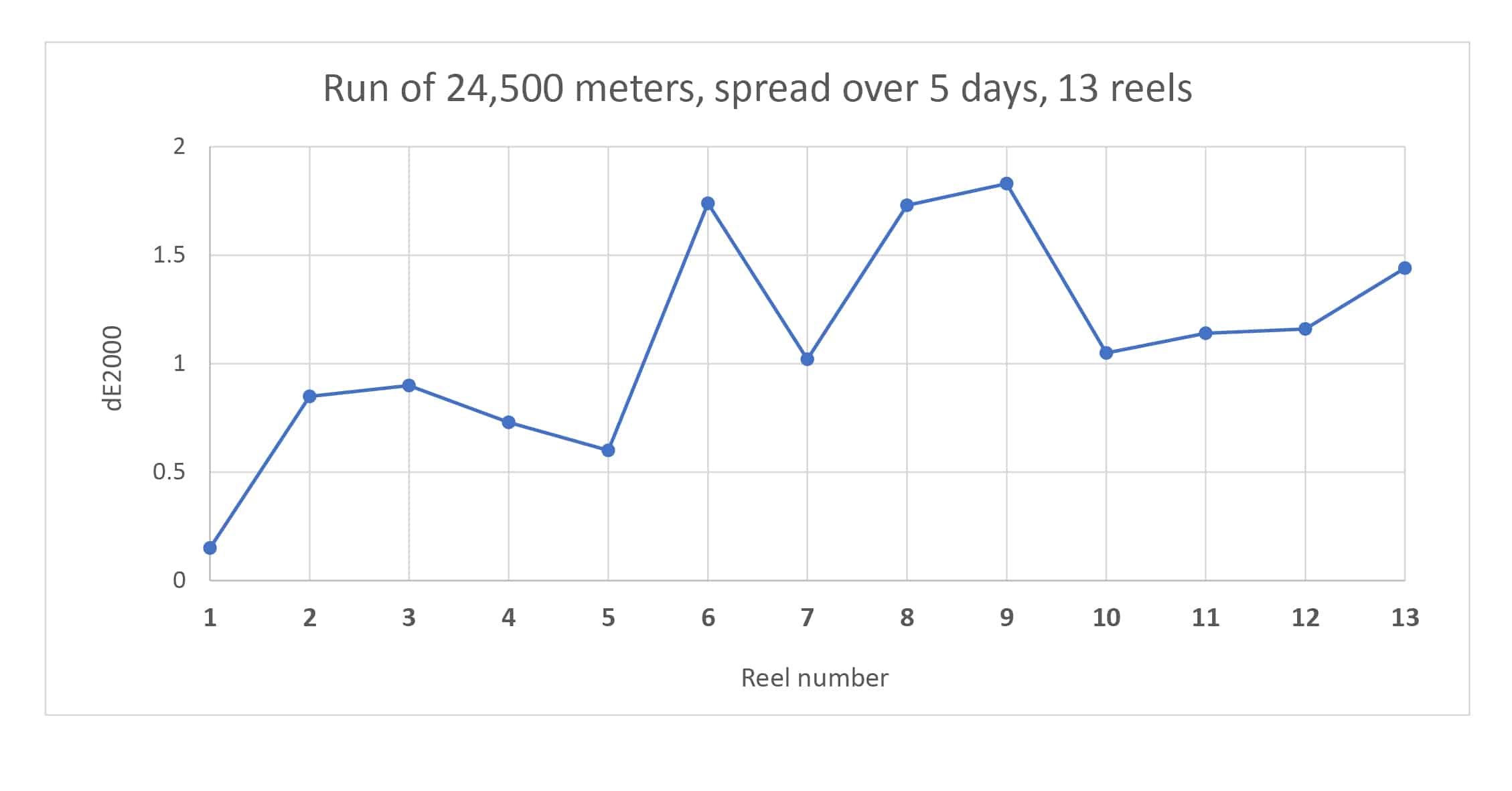

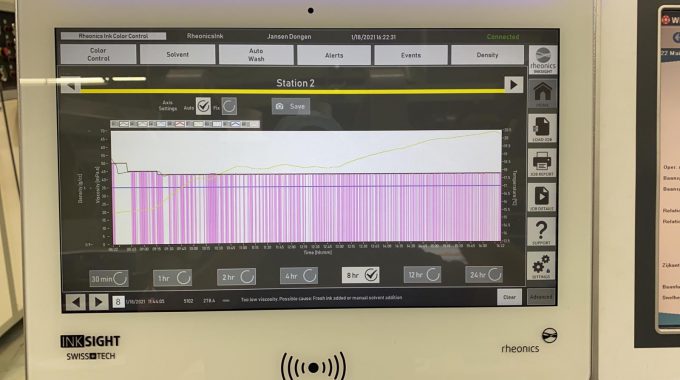

ColorLock locks in the initial match of the printed color to the master; InkSight ensures this match is maintained over the entire printrun, no matter how long, and no matter how many times fresh ink must be added.

Topics Covered in the article

- Goals of flexographic printing

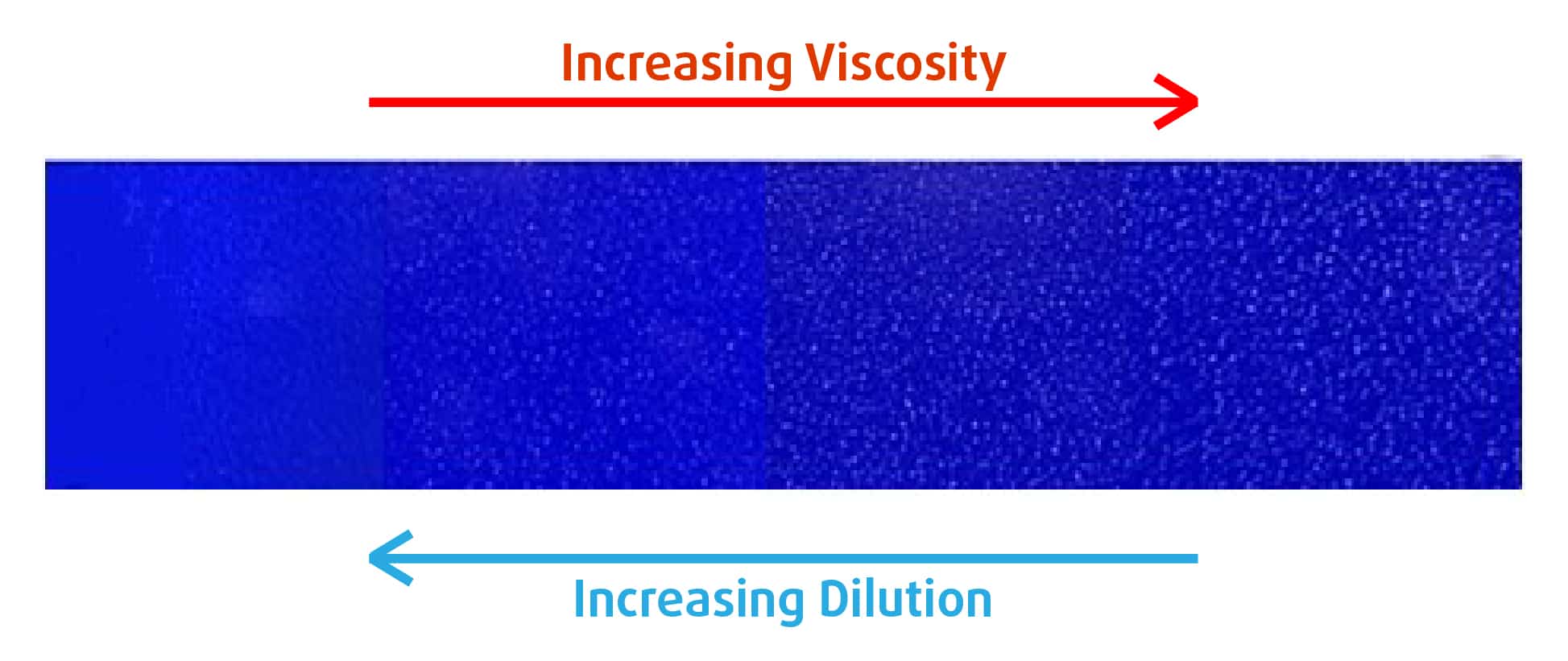

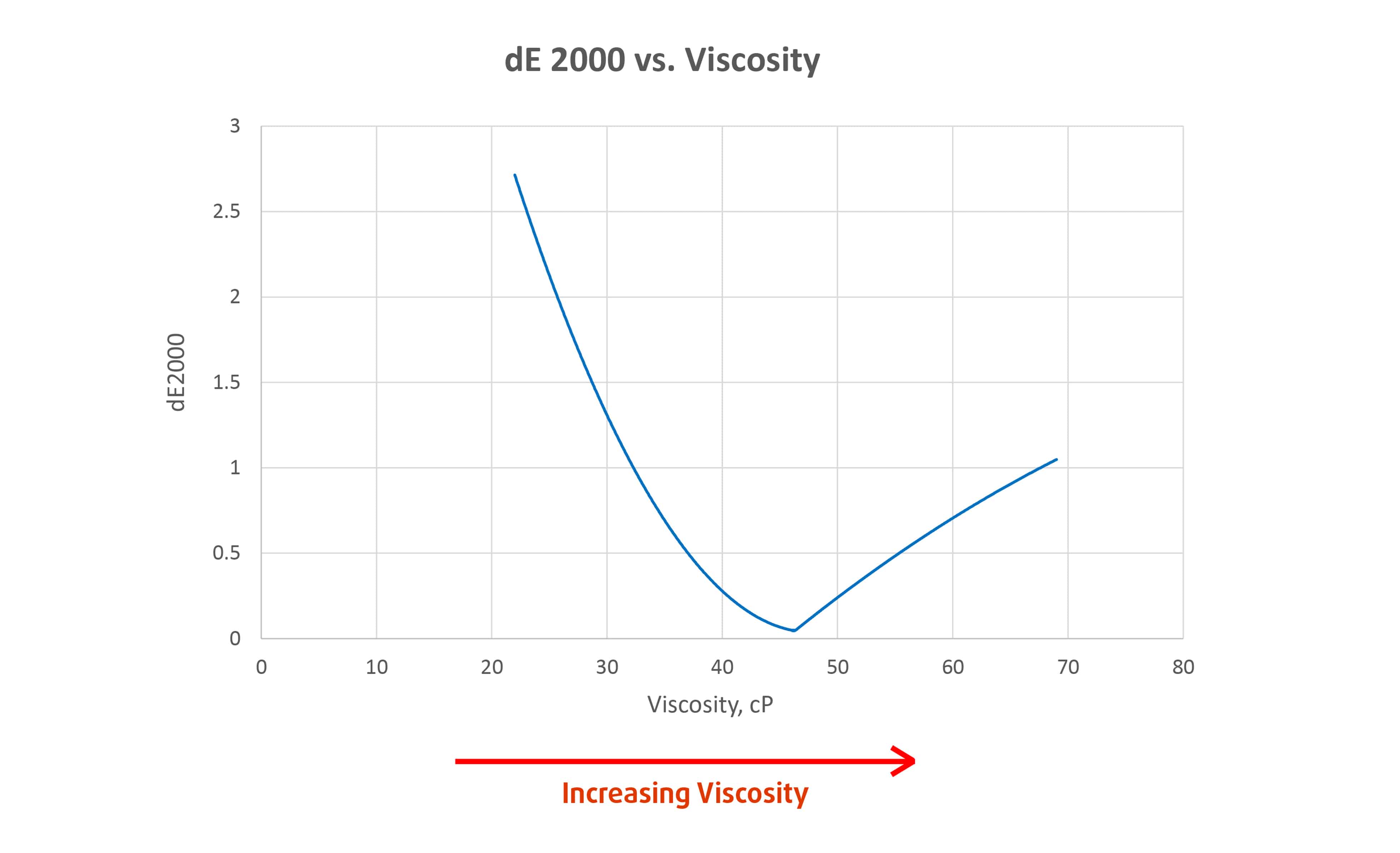

- Color & viscosity control

- Viscosity control is the key

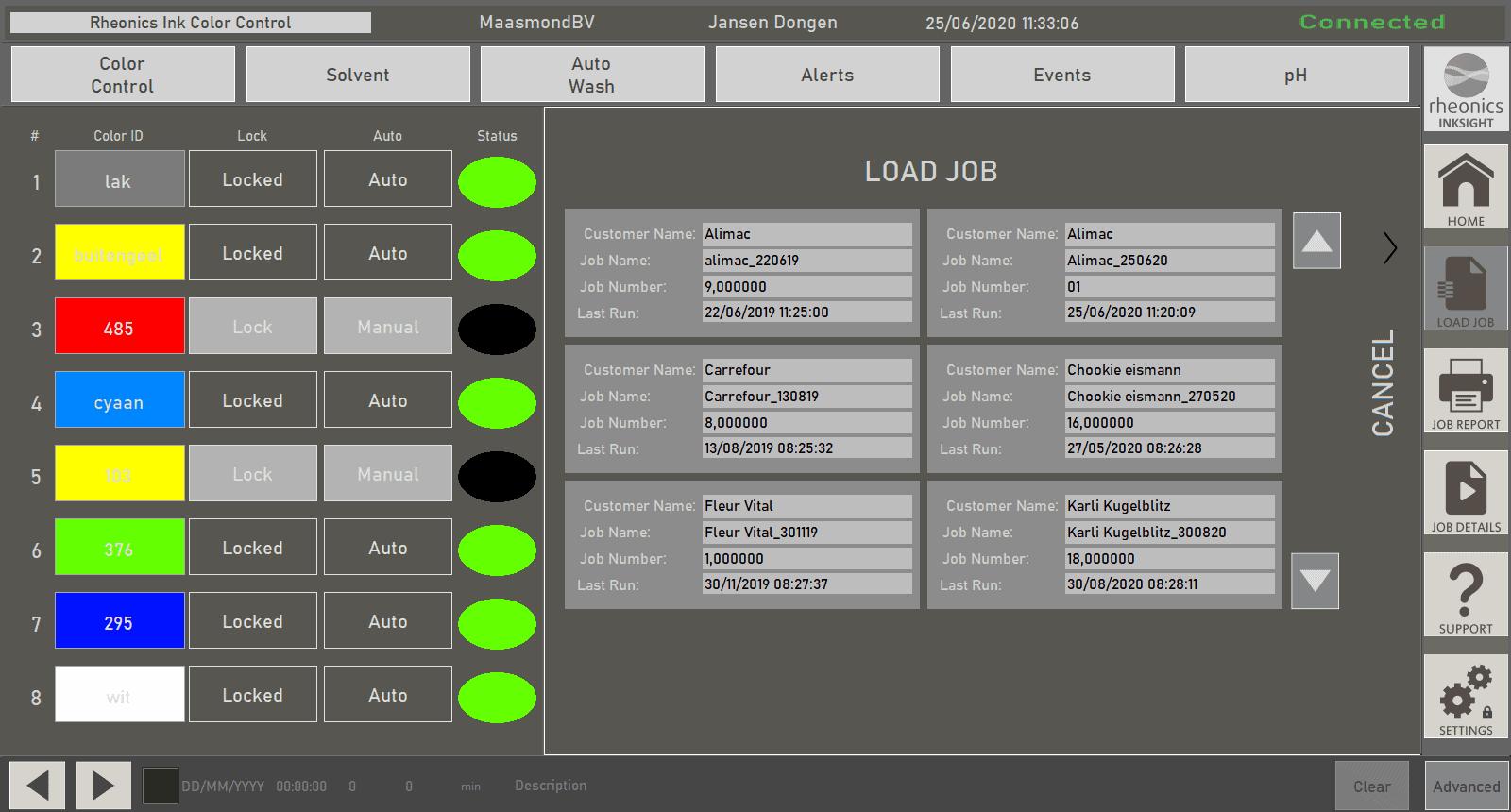

- COLORLOCK Software

- InkSight in use

Some figures from the article

Unique advantages with the Rheonics SRV sensors

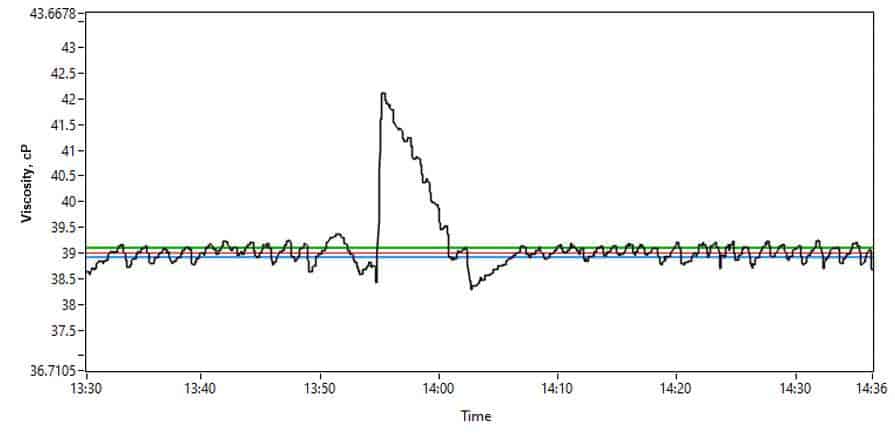

Rheonics sensors have built-in temperature measurement, permitting the temperature of the ink to be monitored. This permits the viscosity readings to compensated for temperature, which is essential for ensuring consistent production through typical daily and seasonal temperature variations.

There are many benefits to using an inline viscosity sensor like the SRV for printing applications. and some include:

- Works accurately in most coating systems with a broad range of ink compositions and viscosities – water-based, solvent-based, UV inks, metallic inks etc.

- Maintains the set ink viscosity, extremely responsive to fresh ink additions

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline with all standard CIP processes, or with a wetted rag, without the need for disassembly or recalibration

- No moving parts to age or foul with sediment

- Insensitive to particulate matter; no narrow gaps to foul with particulates

- All wetted parts are 316L stainless steel—meets sanitary norms with no corrosion problems

- Certified under ATEX and IECEx as intrinsically safe for use in hazardous environments

- Wide operational range and simple integration—Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

Some images of the RPS InkSight system

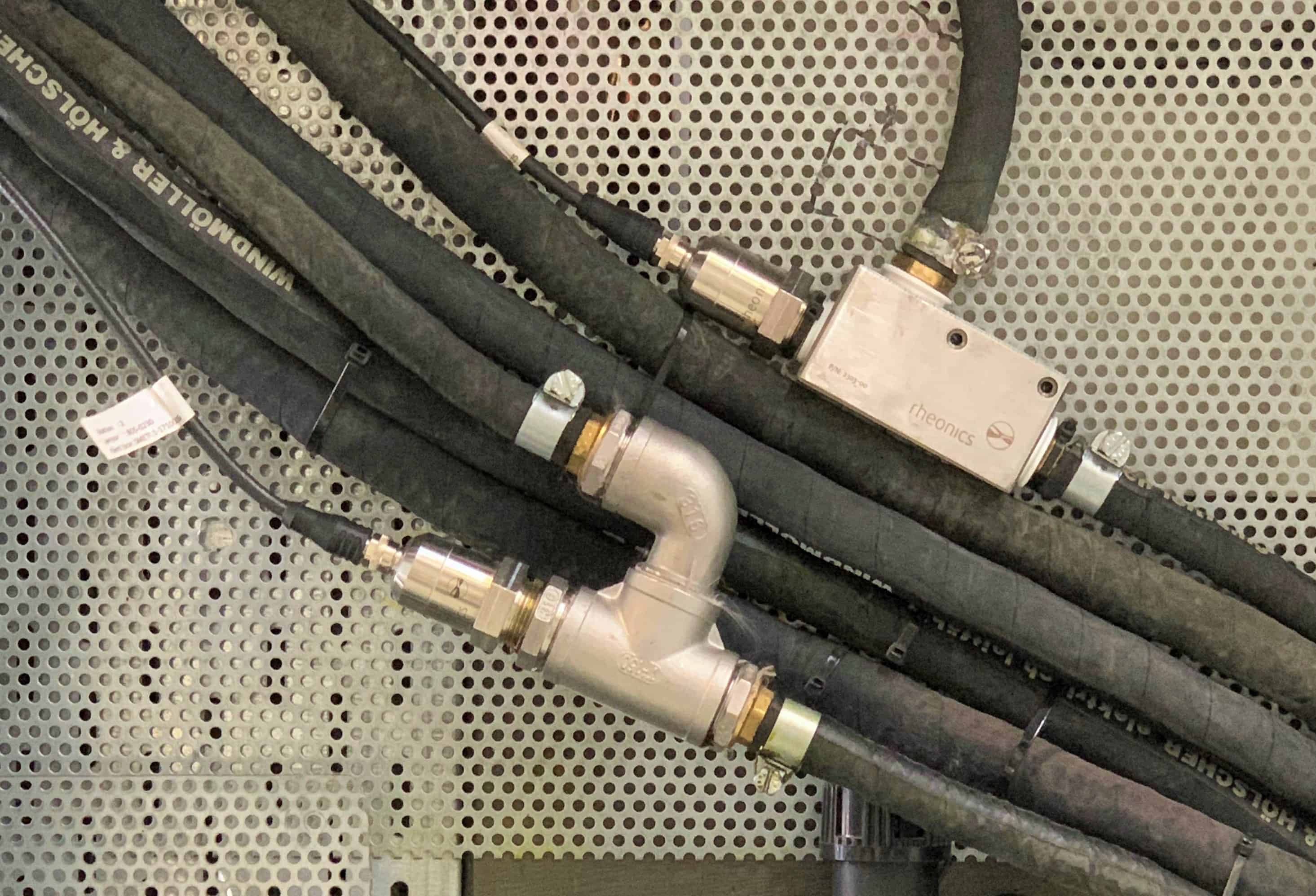

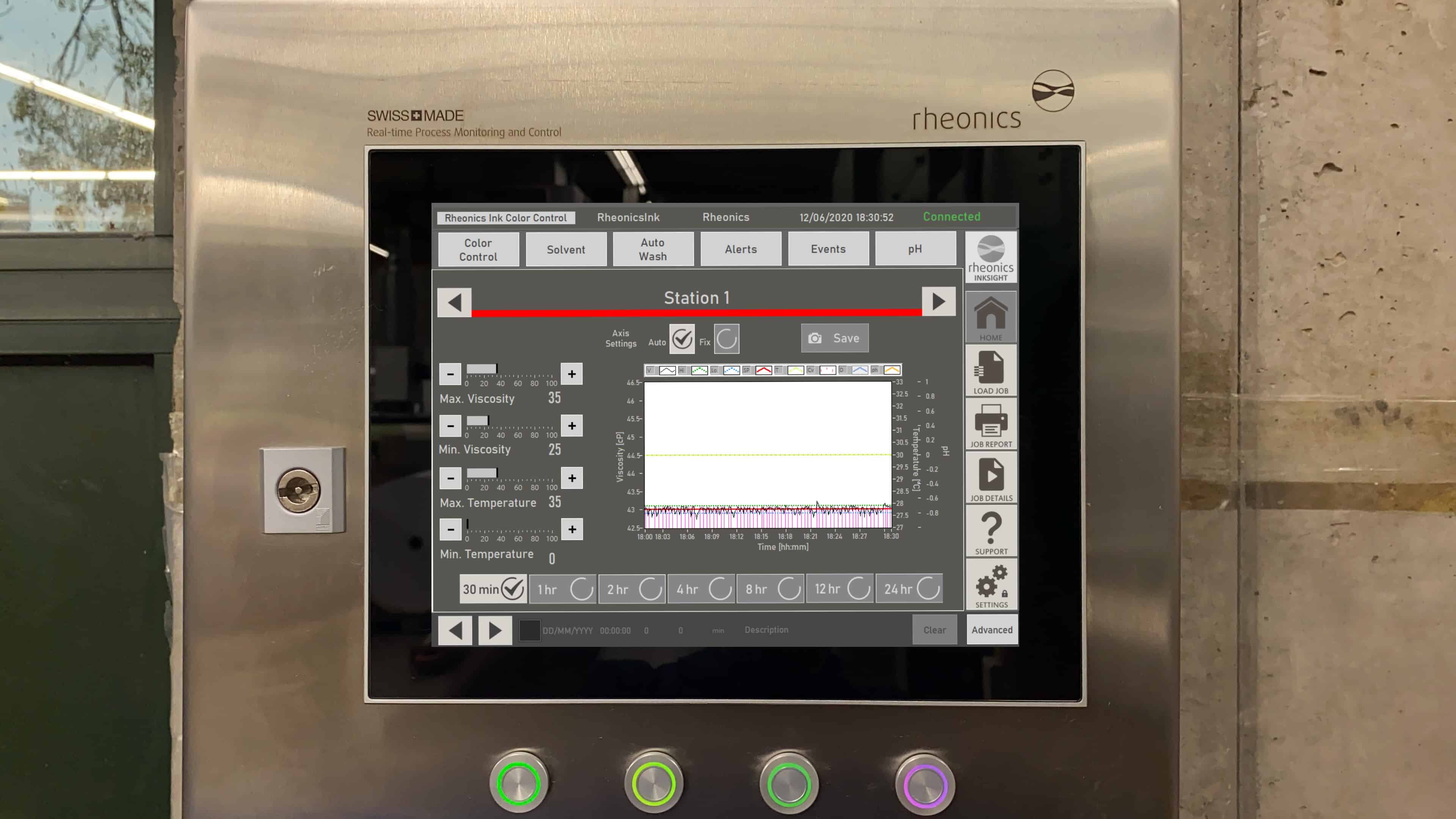

- Rheonics SmartView console integrated in printing machines

- Some pictures showing the SRV viscometers inline installation inside the press

- Standalone control cabinet

Related Articles

Viscosity Standardization in Flexographic Printing

In the history of our company we have applied every type of viscosity sensor: rotational, falling ball, falling piston and acoustic wave. The similarity between these sensors is that they are all calibrated with a cup, in our case the DIN cup with a 4 mm outlet. In itself this worked well and due to lack of a better alternative…

Optimizing flexographic, gravure and corrugated printing applications through inline viscosity monitoring and control

Printing presses have numerous applications – newspapers, magazines, catalogues, packaging and labels. The global printing industry is forecast to reach $980 billion by 2018 according to market research firm Smithers Pira. The rapid growth is expected to be driven mainly by the growth in packaging and labels – analog printing for packaging is expected to grow by about 28% and…

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Conclusion

As printing speeds increase, and profit margins get tighter, “getting it right the first time” becomes much more important. An error in initial viscosity setting can result in producing several thousand meters of waste in no time at all. Tight control with an accurate sensor, combined with a responsive control system, has enabled us to streamline our printing process while improving color quality and reducing waste.