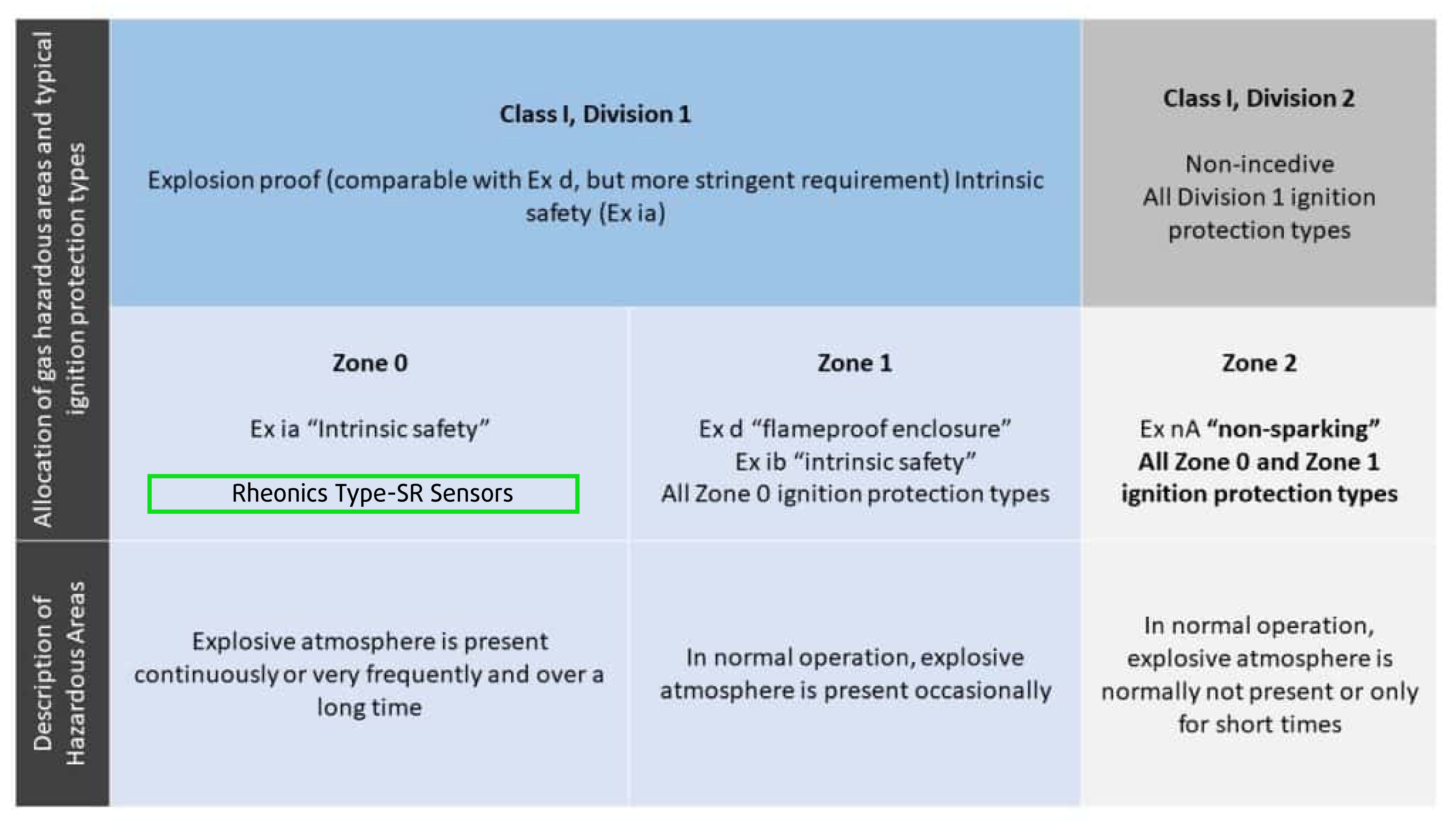

Ex protection – The difference between the Zone and Division model

“The product is suitable for use in Zone 1, as well as for use in Class 1, Div 1.” This statement is heard or read again and again in the descriptions for products for use in hazardous areas. But what is the difference between Zone 1 and Class 1, Div 1? Let’s compare the Zone model with the Division model.

International view

Pressure sensors and equipment, for example, receive explosion protection in the IEC 60079 series of standards. The ATEX series of standards, which is also the basis for EU directive 2014/34/EU (ATEX), describes, among other things, the types of ignition protection for electrical equipment as well as the evaluation or classification of hazardous areas within plants according to different categories.

National particularities

There may be deviations from this standard in national regulations. North America, for example, uses different electrical systems for the construction and operation of its infrastructure. Regulations are outlined in the National Electrical Code (NEC) in the US and in the Canadian Electrical Code (CEC) in Canada. One of these differences is the determination and classification of hazardous areas. Below is a simplified comparison of the various designations for gas hazardous areas.

The NEC and CEC have been updated to include more international standards, so that both of them now support the Zone model for the classification of hazardous areas, and the CEC even requires it for new installations.

Rheonics Sensors are available with ATEX & IECEx Certifications

Rheonics offers intrinsically safe sensors certified by ATEX and IECEx for use in hazardous environments. These sensors comply with the essential health and safety requirements relating to the design and construction of equipment and protective systems intended for use in potentially explosive atmospheres.

The intrinsically safe and explosion proof certifications held by Rheonics also allows for customization of an existing sensor, allowing our customers to avoid the time and costs associated with identifying and testing an alternative. Custom sensors can be provided for applications that require one unit up to thousands of units; with lead-times of weeks versus months.

Rheonics SRV & SRD are both ATEX and IECEx certified by TÜV Rheinland.

Certified Products

- Wide range viscosity measurement (also density with SRD) with built in fluid temperature measurement

- Hermetically sealed, all 316L stainless steel wetted parts

- Stable and repeatable measurements in non-Newtonian fluids like paints and coatings

- Small form-factor for simple installation in existing flow lines and nozzle heads

- Easy integration with existing data acquisition systems using digital and analog data communication

- Smart self-detection of sensing element cleanliness, easy to clean and verify calibration

Sensor Description and Installation conditions

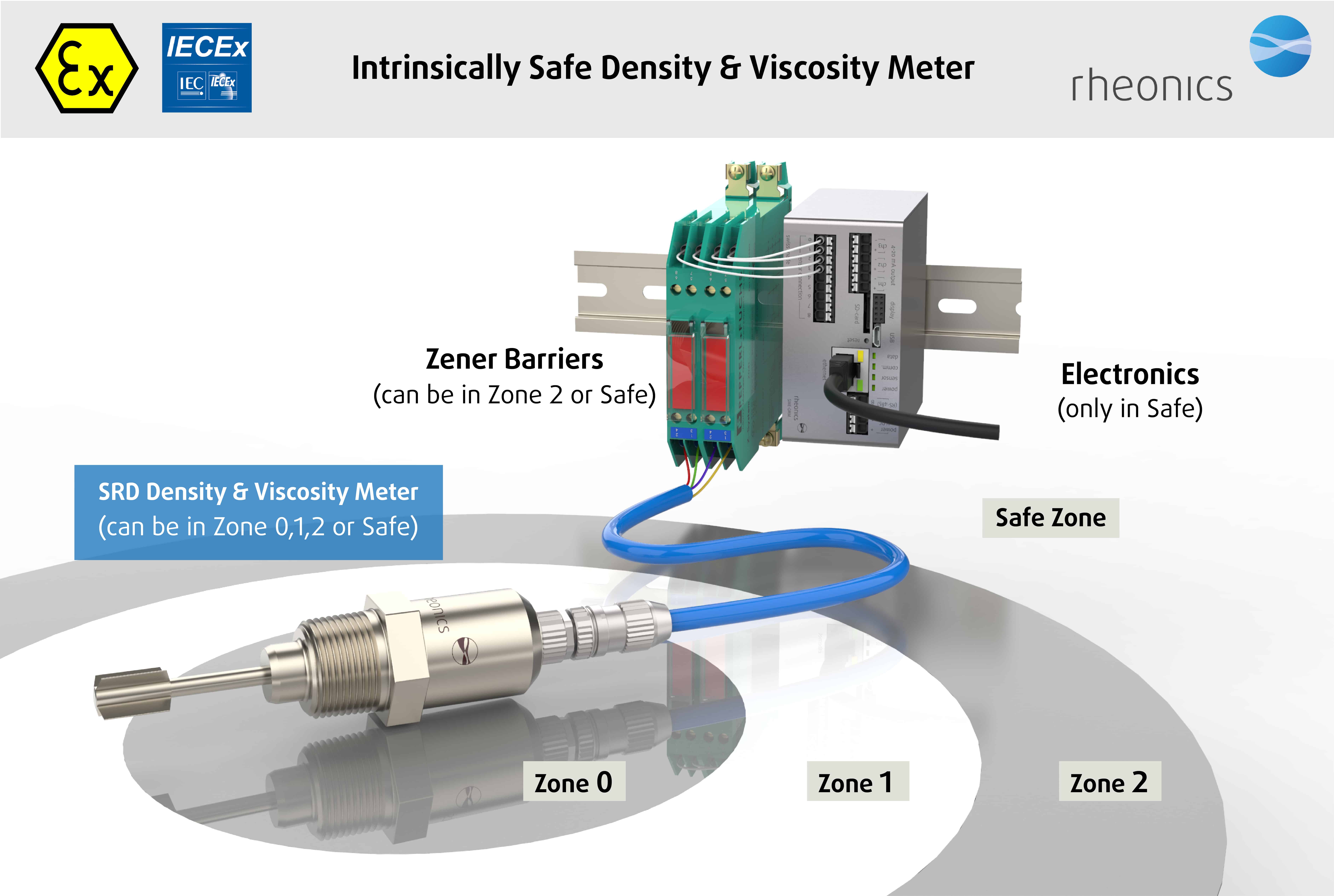

Rheonics SRV sensors are used to measure and control the viscosity of fluids, mainly under process conditions. Rheonics SRD sensors measure, in addition, fluid density as well as true dynamic and kinematic viscosity. Each sensor has a symmetric torsional resonator as its sensitive element. The effect of the fluid in which it is immersed on its resonant response – its resonant frequency and damping – is measured and interpreted by the electronics unit with which it is supplied.

Both of these devices, hereafter referred to collectively as “SR” sensors, are delivered in a version that is intrinsically safe. That means that as long as the sensors are installed and operated as specified in the EX manual, they are incapable of igniting explosive atmospheres in which they operate, provided they are operated within the envelope of parameters described in the EX manual.

Each Rheonics SR sensor is delivered paired with an electronics unit that both operates the sensor and transmits its measurement values over one of a variety of interfaces. When operating Rheonics SR sensors in a hazardous area, one or more Zener diode barriers must be installed between the Rheonics SR sensor and its electronics unit. This barrier serves to limit the amount of current and voltage available to the sensor in case of a fault in its electronics unit and/or within the sensor itself.

The Zener diode barriers themselves must be situated either outside of any hazardous zone, or in the zone specified by the manufacturers as safe for the barriers. The Rheonics SR sensor’s electronics unit must be situated outside the hazardous zone.

Area classifications

Zone 0: Zone 0 is an area in which an explosive atmosphere is present continuously for long periods of time or will frequently occur.

Zone 1: Zone 1 is an area in which an explosive atmosphere is likely to occur occasionally in normal operation. It may exist because of repair, maintenance operations, or leakage.

Zone 2: Zone 2 is a place in which an explosive atmosphere is not likely to occur in normal operation but, if it does occur, will persist for a short period only. These areas only become hazardous in case of an accident or some unusual operating condition.

Certificates and QANs

Here is the list of updated certificates available for viewing/download.

| Title | Summary | Link |

|---|---|---|

| Certificate – ISO 9001 | Certificate for Quality Management System (QMS) – ISO 9001:2015 | |

| Certificate – ATEX Quality Assurance Notification (QAN) – German | ATEX-QAN (Quality Assurance Notification) in German – Requirements according to directive 2014/34/EU have been fulfilled | |

| Certificate – ATEX Quality Assurance Notification (QAN) – English | ATEX-QAN (Quality Assurance Notification) in English – Requirements according to directive 2014/34/EU have been fulfilled. | |

| Declaration of Conformity – CE Declaration of Conformity according to directive 2014/34/EU (ATEX) for SRV & SRD | Rheonics’ EU Declaration of Conformity according to directive 2014/34/EU (ATEX) and relevant standards for SRV, SRV-FPC, SRD & SRD-FPC | |

| Certificate – ATEX Certificate for SRV & SRD – Issue 02 | Certificate for Equipment and Protective Systems intended for use in Potentially Explosive Atmosphere – Directive 2014/34/EU – Issue 02 | |

| Certificate – IECEx Certificate of Conformity for SRV & SRD – Issue 02 | This certificate is issued as verification that a sample(s), representative of production, was assessed and tested and found to comply with the IEC Standards listed in the Certificate Issue 02 |