Digital food processing – driver for manufacturers embrace of Industry 4.0

Application

Temperature fluctuations, mixing equipment condition, type and conditions of substrates, batter formulations, process step interactions and mixing time parameters can all alter the product quality and performance across batches in batter mixing and coating. In thin-margin sectors like baked goods, batter-coated foods, and confectionery, the downtimes and delay in deliveries due to rejects can seriously hurt profitability. Most of these parameters can be controlled by a system that continuously monitors the batter characteristics and takes corrective actions automatically and adaptively without disrupting the process flow.

Technologies required to deliver such transformational changes in the manufacturing process for food manufacturers already exist. Once the food manufacturer invests in process monitoring equipment and analyses the collected data, it gives them a fair idea to calculate where productivity gains can be made, where energy savings can be achieved and how to reduce downtimes through predictive maintenance.

Drivers for manufacturers embrace of Industry 4.0

The key value drivers for investing in a continuous production process, supported by real-time inline viscosity monitoring equipment by food manufacturers and system integrators are the following:

Automated corrective actions for ensuring product consistency. Closed control loops through sensor-based, in-line quality inspection reduce waste and increase yield through early process deviation detection, root cause analysis, and automatic correction.

More agility in dealing with new product variants in food production, compliance and product provenance. Food manufacturers get a more accurate picture of how the new formulations or recipe changes will react and how they might need to adjust current systems and control parameters. Real-time monitoring facilitates transition of a batch-based process to continuous operation, saving significant operational and capital costs through re-use of the same lines for multiple products.

Acquired data provides robust evidence to base decisions for greater efficiency. The data provided by the process monitoring equipment enables operators to optimize process parameters critical to the manufacturing process. Interconnection and information transparency allow for operators to make decisions both inside and outside of production facilities, thus enabling decentralization of decisions. Automated and transparent processes, along with optimized workflows can ensure an efficient data management and improved quality control system.

Higher customer satisfaction and adapting to customer requests. Industry 4.0 solutions impact food manufacturing companies by driving closer interactions with customers. The technology, data, and information help transform manufacturing operations making the company more responsive to customer needs.

Applications - Food and Beverages

Inline Viscosity Monitoring for Atomization Applications

Atomization is a process used to break up a liquid into fine droplets, usually done by forcing it through a…

Mayonnaise Production and Rheonics Inline Viscosity Monitoring

Mayonnaise, a globally enjoyed condiment, is a classic oil-in-water emulsion, distinct from water-in-oil emulsions like butter and margarine. Its rheological…

Milk of Lime (MOL Slurry) – Real-time monitoring and controlling optimum concentration

For process engineers, it's essential to develop an efficient and reliable method to monitor and control the milk of lime…

Inline viscometers boost efficiencies of spray drying processes in milk powder manufacturing

The process of converting liquid milk into dry powder involves removing most of the water. The amount of water removed…

Cheese coagulation monitoring and cutting automation with inline viscosity measurements

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure…

Optimizing non-Newtonian mixing applications with viscosity management

Key advantages of viscosity management in mixing applications: Accurate and efficient mixing operations – significant savings in material costs and…

Continuous monitoring of frying oil degradation in industrial food fryers

Summary: a single sensor to monitor effects of oxidation (TOTOX), fatty acid (TBA), and Polar compounds (TPC) on frying oil…

Optimizing liquid packaging, filling operations with inline viscosity management

Challenge Fluctuations in liquid products consistency in packaging, filling, dispensing operations means companies run risk of underfilling (which can be…

Controlling the rheological behaviour of dairy food items to create consistent products – cheese, cream, ice-cream, milk, butter, yogurt

Texture and product consistency are of utmost importance to customer - in manufacturing, viscosity is the correlated parameter to ensure…

Online viscosity monitoring for quality control in emulsions formulation, testing and processing

Emulsions are used in almost every aspect of daily lives. Their processing and development expands across many industries – chemicals,…

Batter mixing and coating: Using lab rotational viscosity measurement for real-time process control with an inline viscometer

Customer application of the Rheonics SRV sensor to measure batter viscosity in a batter mixing and coating system is an…

Wastewater management in beverage and food processing with inline viscosity monitoring

Food and beverage industry is one of the key industrial segments and major contributor to global economic and societal growth.…

Key benefits of Rheonics Viscosity and Density meters in food applications to support the factory digitalization and Industry 4.0 adoption

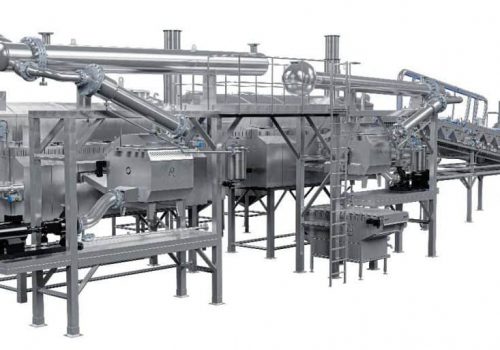

Rheonics inline viscometers (and density meters) empower food manufacturers with capabilities to produce superior quality and consistent batter-coated products of great variety, with least involvement of operators on factory floor – a significant advantage over other measurement alternatives or process control solutions. Inline blending with continuous viscosity monitoring solutions solves major challenges of batch production processes such as losses during product changeovers and inefficacies of ingredient handling in a recipe-based approach. It supports scaling up of blending capacities with ease.

Unique benefits with the SRV & SRD for food applications include:

- Works accurately in most coating systems with a broad range of batter compositions and related products – adhesion batter, glazes, sauces, marinations, breaders, pre-dust

- Maintains the set viscosity regardless of process conditions

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline with all standard CIP processes, or with a wetted rag, without the need for disassembly or re-calibration

- No moving parts to age or foul with sediment

- Insensitive to particulate matter; no narrow gaps to foul with particulates

- All wetted parts are 316L stainless steel – meets sanitary norms with no corrosion problems

- Hygienic, sanitary design for food and beverage applications – available in tri-clamp and DIN 11851 connections for easy operation and cleaning

- Certified under ATEX and IECEx as intrinsically safe for use in hazardous environments

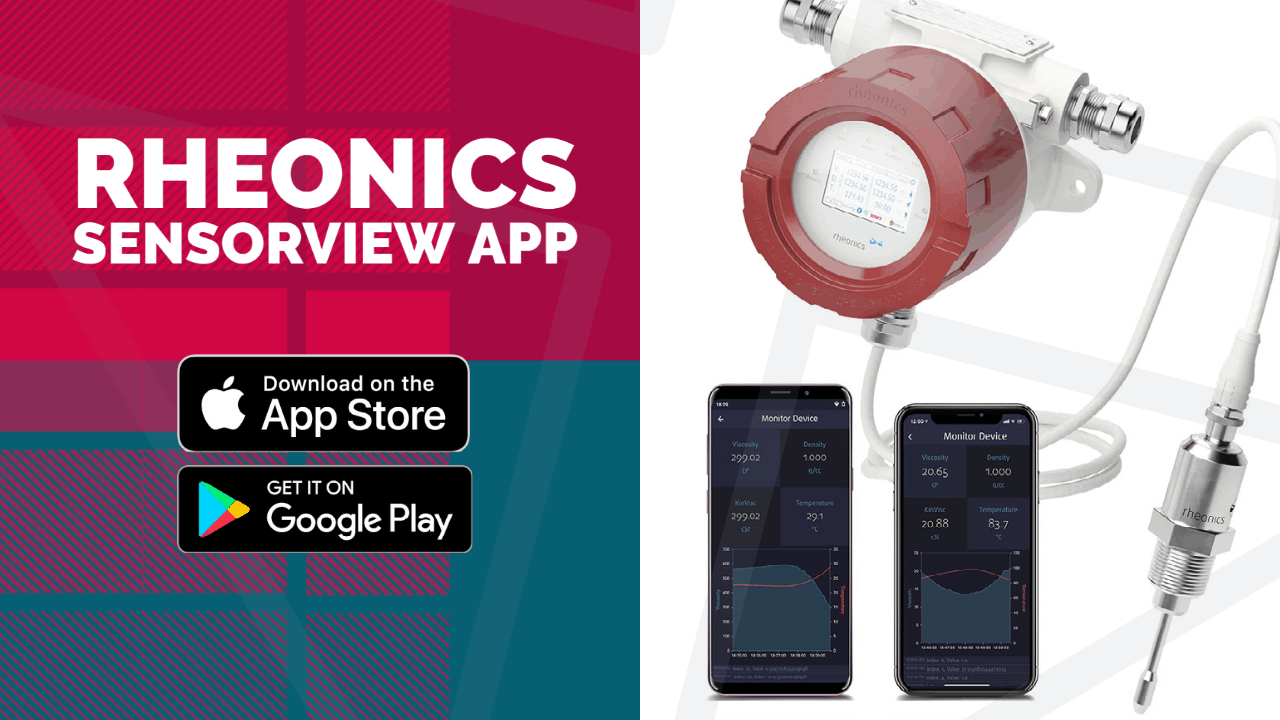

- Wide operational range and simple integration – Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

Rheonics has worked with several customers in the food industry and continues to add value to their processes with inline viscosity and density measurement and control. Rheonics sensors integrate very well in almost any process environment and are internally tested and qualified to operate reliably with the fluids in food processing. Our in-house application engineering team gives machine builders advanced knowhow to achieve seamless integration of our sensors in their system and help provision food quality control data to their end users through on-premise, edge or cloud connectivity.

Rheonics density meters and viscosity meters are available as probes and flow-through systems for installation in tanks, process lines and reactors. All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.