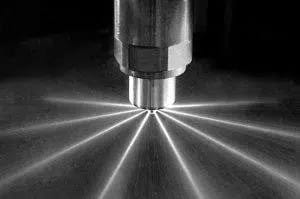

Atomization is a process used to break up a liquid into fine droplets, usually done by forcing it through a nozzle, sometimes helped by a high-velocity or high-pressure gas. Familiar examples include perfume sprays, garden hoses, and aerosol deodorants. Viscosity plays a crucial role in atomization, directly affecting droplet size, spray pattern, and flow rate. Inline viscosity monitoring ensures consistent performance and prevents uneven coverage, clogging, or equipment wear.

Table of Content

- Introduction

- Rheonics SRV Inline Viscometer

- The Importance of Viscosity in Atomization

- Key Applications

- Process Conditions and Best Practices

Introduction

In industrial environments, atomization plays an important role in applications where droplet size, distribution, and consistency can affect product quality and performance. Industries that use this process include food and pharmaceuticals (spray drying), automotive and electronics (spray coating), agriculture (pesticide and fertilizer spraying), and manufacturing (paint application).

Usually, traditional lab-based sampling is used, but these provide occasional insights that are not able to capture real-time changes. On the other hand, inline measurements give continuous and real-time visibility of the process, allowing to have a faster response.

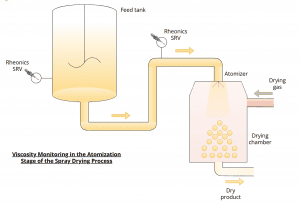

Figure 2: Rheonics viscosity monitoring on spray drying.

Rheonics SRV Inline Viscometer

Rheonics SRV sensor measures a wide range of viscosity and temperature in real-time and is suitable for installation in tanks to monitor mixing processes and in pipelines for continuous measurement of flowing fluid. It is specially suited for high-speed mixing processes and is unaffected by the presence of bubbles in the fluid or external vibrations.

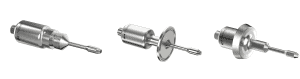

Figure 3: Rheonics SRV sensor probes versatile design for installation.

This sensor is factory calibrated and does not need recalibration over its operational lifetime. However, clients may require calibration or verification for instruments used in their industry as part of their Quality Control. Optional re-adjustments or offset corrections can be performed if needed to match specific references. For more details, see Calibration of inline process viscometer SRV in field and factory.

Rheonics sensors technology is based on a balanced torsional resonator (BTR). This patented technology has a significant advantage over competitors since it allows the sensors to be compact, lightweight, and unaffected by external vibrations.

The SRV is available in configurations compatible with high-pressure applications, making it ideal for pre-spraying setups where lines have small diameters and operate at high pressure.

Rheonics offers dedicated high-pressure flow cells and adapters. For example:

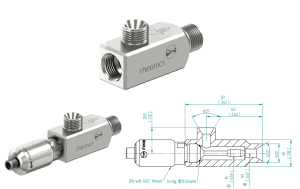

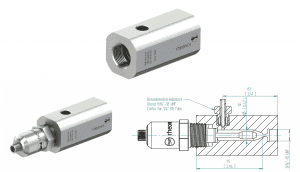

Figure 4: Rheonics HPT-12G installation and dimensions

G1/2 Hygienic Flow Cell

Properties:

- Threaded G 1/2″ connection

- Max pressure: 500 bar (7250 psi).

- Fluid volume: 9 mL.

- Material: Stainless steel 316L.

- Ideal for small lines (DN5 to DN25) or bypass in larger pipelines.

- Hygienic design, suitable for clean-in-place (CIP) applications, requires O-ring sealing.

- Recommended to install according to the flow direction (labeled on surface), but can be reversed.

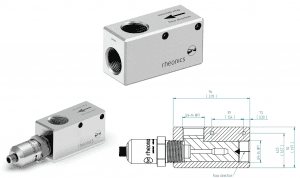

Figure 5: Rheonics HPT-SRV installation and dimensions.

High Pressure Flow Cell

Properties:

- Threaded 3/4″ NPT sensor probe connection, 9/16″-18 UNF inlet/outlet ports.

- Max pressure: 690 bar (10,000 psi).

- Fluid volume: 4.3 mL.

- Compact design for high-pressure, high-temperature applications.

- Designed for optimal fluid contact in small-bore lines or bypasses.

- Needs PTFE sealing and specific inlet/outlet adapters (not included).

Figure 6: IFC-34N-SRV installation and dimensions.

3/4” NPT Flow Cell

Properties:

- 3/4″ – 14 NPT sensor and pipe connections.

- Max pressure: 200 bar (2900 psi).

- Fluid volume: 60 mL.

- Suitable for inline installation or bypass on larger pipelines.

- Ensures stable flow profile around the SRV sensing element.

- Standard NPT installation, Teflon tape sealing required

These accessories enable reliable installation and performance in pressurized systems. For more accessory options, please follow Rheonics SRV Viscometer Accessories.

The Importance of Viscosity in Atomization

A variety of factors affect atomization and how easily a stream of liquid atomizes after emerging from an orifice. Among these factors are fluid properties of surface tension, viscosity, and density.

Viscosity measures a fluid’s resistance to flow. As viscosity increases, the fluid becomes harder to pump, mix, or transport. So, viscosity measurement becomes a key aspect in the process.

Inline viscosity monitoring before the atomizers allows to have real-time control of droplet formation, ensuring consistent:

- Droplet Size: Higher viscosity usually creates larger droplet sizes. For example, in coatings, incorrect droplet sizes result in uneven surfaces, orange peel, or sagging. In combustion, droplet size affects fuel efficiency and emissions.

- Spray Angle and Pattern: Viscosity changes can affect the spray angle and pattern, leading to inconsistent coverage. This is critical for applications like agricultural spraying or industrial coating.

- Flow Rate and Nozzle Performance: Changes in viscosity can affect the flow rate through the nozzle. Highly viscous fluids can require more pressure and lead to nozzle clogging, reducing efficiency and even causing equipment wear.

Viscosity measurement allows conditions of atomization parameters to be adjusted for repeatable results.

Key Applications

Here are key applications involving atomization and why monitoring viscosity is essential:

Spray Drying (Food, Pharma, Chemicals)

Viscosity directly impacts droplet formation during spray drying, which then affects drying kinetics, particle size distribution, bulk density, flowability, and solubility of the resulting powder. Viscosity monitoring before the nozzle ensures consistent powder quality, prevents nozzle clogging, and increases energy efficiency.

Figure 7: Spray drying system [2].

Coating Applications (Automotive, Industrial, Functional Coatings)

Viscosity of a coating liquid determines droplet size, spray pattern, film thickness, leveling, and final surface appearance, excluding defects like orange peel, runs, or sagging. Inline viscosity control provides uniform thickness, improves finish quality, minimizes waste, and prevents fouling of nozzles.

Figure 8: Automotive coating through spraying [3].

Chemical Processing & Reaction Spray (SCR Systems, Gas Scrubbing, Polymerization)

In processes such as flue gas scrubbing, spray polymerization, or catalytic dosing, atomization is key to mass transfer and reaction effectiveness. Changes in viscosity can lead to a disruption of spray penetration and uniformity. Continuous monitoring helps maintain reaction performance, avoid clogging, and ensure product uniformity.

Figure 9: Chemical gas scrubbers [4].

Fuel Atomization (Combustion Engines, Gas Turbines, Burners)

Fuel viscosity determines the atomization quality, which further affects vaporization, air-fuel mixture, efficiency of combustion, and emission rates like NOx (Nitrogen Oxides) and SO2 (Sulfur Dioxide). Inline measurement is essential in handling various fuel blends like biofuels or heavy oils to avoid coking and ensure stable combustion.

Figure 10: Fuel atomization [5].

Agricultural Spraying (Pesticides, Herbicides, Fertilizers)

Spray droplet size distribution in agricultural applications is greatly influenced by fluid viscosity, impacting drift potential, penetration to the canopy, and biological activity. Real-time monitoring enables precise application, reduced off-target effects, and modification to formulation or temperature change.

Figure 11: Pesticide spraying [6].

Humidification & Air Conditioning (Industrial, HVAC)

In HVAC and industrial humidifiers, viscosity makes droplet size and evaporation rate dependent on it, influencing humidity control, energy usage, and surface wetting. Measuring inline ensures adequate humidity control.

Figure 12: HVAC System.

Medical Device Coating (Stents, Catheters)

Medical coatings require very uniform thickness for effective drug release and functional response. Viscosity is among the important parameters to be regulated in spray deposition. Inline monitoring ensures consistency, meets rigorous validation standards, and reduces batch failure.

Figure 13: Medical Device Industry [7].

Additive Manufacturing (Binder Jetting, Material Jetting)

In 3D printing technologies like binder jetting, viscosity affects droplet form, accuracy, and interaction with substrate or powder bed, which affects resolution and mechanical strength. Real-time monitoring improves part quality, reducing batch failure.

Figure 14: Additive Manufacturing [8].

Process Conditions and Best Practices

Probe cleanability

Rheonics SRV viscometer is easy to install in pipes or tanks. Client should configure the probe process connection and length as required for each application. Probe length is customizable which allows for correct immersion of sensing element in the fluid. A good immersion is key to measure accurate data and minimize deposits on the sensing area, if these are likely to happen due to fluid composition.

Flow speed limit

Rheonics sensors are generally compatible with flow speeds up to 10 m/s. Since in atomizer supply lines, flow speeds can reach such high velocities to prevent settling, it is recommended to install the probe parallel to flow direction in elbows, as this can reduce mechanical impact. However, speeds in this range can still add too much noise to readings. For more details, see Rheonics Type-SR sensors for high flow rate and high viscous applications.

Particles in fluid

Rheonics sensors can handle micron-sized soft particles with minimal impact on accuracy, and any added signal noise can be filtered by the electronics. However, atomization fluids that often include larger particles (millimeter-scale or above) can cause reading instability and mechanical damage to the sensor. So pre-screening or installation away from these particles should be considered.