AIMCAL’s Converting Quarterly Magazine features Rheonics Technology – “Ink viscosity optimization and automation – The key to quality, efficiency and sustainability in printing and coating”

Overview

Web processing & finishing focused magazine – Converting Quarterly (https://www.convertingquarterly.com/) publishes an in depth article about how SRV revolutionizes ink viscosity management in gravure printing and enables “getting it right the first time”. In this article, readers can understand how printers improve color quality, reduce setup time and scrap and achieve sustainability in their operations with complete automation of ink viscosity management.

Find the link to the publication.

To download the pdf copy of the article, please use the link below.

Introduction

Ink viscosity is one of the most important factors for achieving high and consistent color quality in gravure printing. Despite the sophisticated measurement and control systems built into today’s printing machines, ink viscosity is still frequently measured with inefficient and inaccurate methods, such as efflux cups and falling ball viscometers.

The variability of these measurements makes consistent color quality difficult to maintain. They underscore the need for a viscosity measurement and control system that can help operators obtain the very best color quality over the very long print runs that are characteristic of gravure.

Viscosity plays an important role in the final quality of printed matter. Ink layer thickness and flow behavior deviate from the optimal values when the viscosity is incorrect, resulting in substandard print quality. Poorly adjusted ink viscosity can also lead to excessive ink consumption and unnecessary costs. Accurate viscosity measurement and control can substantially improve print quality, while reducing waste and improving efficiency.

Even though methods are now available for continuous inline measurement of ink viscosity, many are sensitive to contamination, installation variables, and baseline shifts, which can impair operator confidence and cast doubt as to their long-term reliability. We will show the value of stable, easily cleanable, and repeatable viscosity sensors in printing processes. We will support our conclusions with experience and data from printers who have been using our sensors and automation systems over a period of several years.

A further benefit of high-accuracy viscosity measurement and control is online, automatic, dynamic control of color accuracy within previously unattainable narrow limits, thus ensuring high and consistent print quality over even the longest runs.

Topics Covered in the article

- Why is ink viscosity a crucial variable to be controlled in printing presses?

- Technical challenges in online ink viscosity control

- Installation on printing press

- Gravure challenges

- How viscosity affects the color precision and quality in printing? Benefits of tight viscosity control for print quality and ink economy

- Challenges with traditional viscosity measurement units

- Benefits of printing press automation (Industry 4.0) and predictive tracking control in terms of quality and efficiency improvements, VOC emissions and waste reductions

Some figures from the article (Part -1)

Unique advantages with the Rheonics SRV sensors

Rheonics sensors have built-in temperature measurement, permitting the temperature of the ink to be monitored. This permits the viscosity readings to compensated for temperature, which is essential for ensuring consistent production through typical daily and seasonal temperature variations.

There are many benefits to using an inline viscosity sensor like the SRV for printing applications. and some include:

- Works accurately in most coating systems with a broad range of ink compositions and viscosities – water-based, solvent-based, UV inks, metallic inks etc.

- Maintains the set ink viscosity, extremely responsive to fresh ink additions

- Rugged, hermetically sealed sensor head. The SRV can be cleaned inline with all standard CIP processes, or with a wetted rag, without the need for disassembly or recalibration

- No moving parts to age or foul with sediment

- Insensitive to particulate matter; no narrow gaps to foul with particulates

- All wetted parts are 316L stainless steel—meets sanitary norms with no corrosion problems

- Certified under ATEX and IECEx as intrinsically safe for use in hazardous environments

- Wide operational range and simple integration—Sensor electronics and communication options make it extremely easy to integrate and run in industrial PLC and control systems.

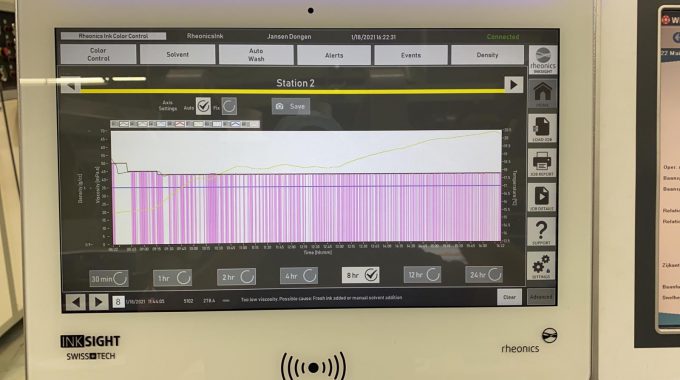

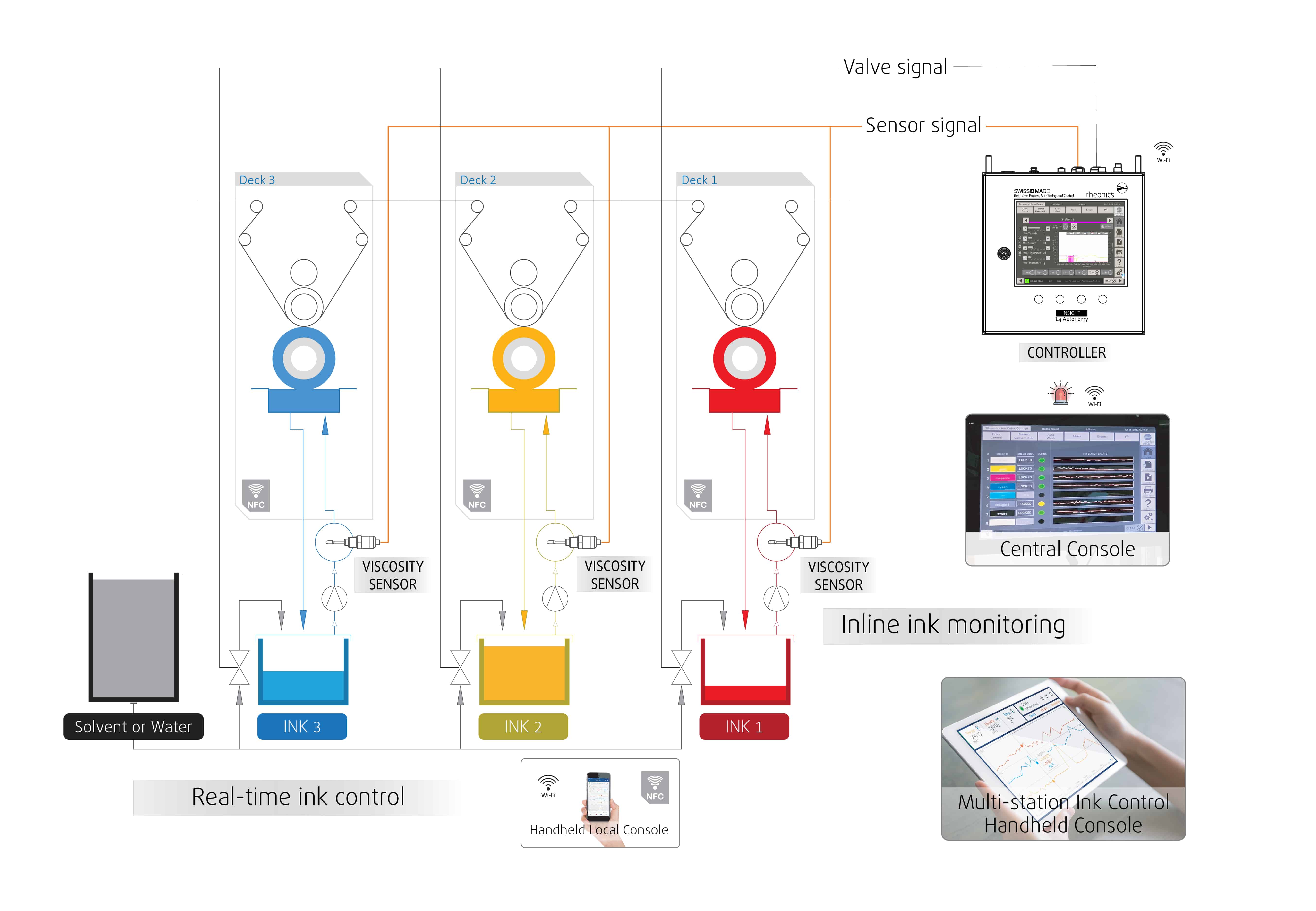

Some images of the RPS InkSight system

- Rheonics SmartView console integrated in printing machines

- Some pictures showing the SRV viscometers inline installation inside the press

- Standalone control cabinet

Related Articles

Rheonics awarded Sustainable Innovation Packaging – Innovation Prize 2021 by European Rotogravure Association

Rheonics wins a Sustainable Packaging Innovation Award by the European Rotogravure Association. Dr. Sunil Kumar received the award at the Annual & Packaging and Decorative Gravure Conference in Thessaloniki, Greece on 21-23 September, 2021. “Gravure – the sustainable print process” was the theme of the conference, which pointed out an encouraging perspective for gravure’s future. Our viscosity automation technology ensures…

Interprint, Inc. optimizes and automates printing operations in the decorative gravure market segment with the RPS InkSight auto viscosity control

Challenge Fluctuations in material throughput related to market demand can also be seen as a disturbance which needs to be compensated for to assure product quality. Solution Inclusion of automated supervisory process control in the manufacturing process becomes essential to automatically assure that critical quality attributes are consistently in agreement with the acceptance criteria in real-time.

Optimizing flexographic, gravure and corrugated printing applications through inline viscosity monitoring and control

Printing presses have numerous applications – newspapers, magazines, catalogues, packaging and labels. The global printing industry is forecast to reach $980 billion by 2018 according to market research firm Smithers Pira. The rapid growth is expected to be driven mainly by the growth in packaging and labels – analog printing for packaging is expected to grow by about 28% and…

All Rheonics products are designed to withstand harshest process environments, high temperature, high level of shock, vibrations, abrasives & chemicals.

Conclusion

As printing speeds increase, and profit margins get tighter, “getting it right the first time” becomes much more important. An error in initial viscosity setting can result in producing several thousand meters of waste in no time at all. Tight control with an accurate sensor, combined with a responsive control system, has enabled us to streamline our printing process while improving color quality and reducing waste.