ASI Magazine: Real-Time Monitoring of Adhesive and Sealant Properties

Real-time monitoring of adhesive and sealant properties

Novel insruments for inline and production applications

Correct adjustment of the flow characteristics of sealants and thermosetting adhesives is crucial to their performance in highly automated, high speed production environments.

Automated application of sealers and adhesives in, for instance, automotive production requires that predictable, reproducible quantities are applied, and that they flow properly and remain in place during the final setting period. In the printing industry, lamination of plastic films is done on specialized high-speed machines that require close control of adhesive viscosity. Resins that are applied to fiber textiles and mats to make composite prepregs require exact staging of the matrix resin.

Flow characteristics of sealers and adhesives are traditionally measured by means of a rheometer, a delicate precision laboratory instrument that requires a skilled operator to give accurate and consistent results. Rheometer measurements are time-consuming, limiting their use to resin components before mixing, and in the case of slow-curing systems, soon after mixing. And finally, the results of rheometric testing in the laboratory are often of limited use in production monitoring, since they give insight into the past, rather than the present state of the material being applied.

Viscometers based on vibrating elements offer a viable alternative to rheometric measurements. They give fast, consistent readings, and are especially suitable for inline installations. Resonant sensors can be installed directly in process lines carrying sealants, adhesives or other fluids, and can be used to either monitor the characteristics of the flowing fluid, or can be connected to control systems that dynamically adjust the flow characteristics of the fluid by addition of diluents or other additives. Such feedback control of process viscosity is a well-known and proven method to, for instance, maintain color accuracy during long, high-speed runs in flexographic and gravure printing plants. [1]

Figure 1. Inline viscometer (left) and installed in a flowline adapter for inline applications.

Adhesives and sealants offer an additional challenge to viscosity measurement and control because of their highly non-Newtonian flow characteristics. A Newtonian fluid displays the same viscosity no matter what the spindle speed of a rotating instrument, such as a rheometer or viscometer. Non-Newtonian fluids are shear-rate sensitive – their measured viscosity depends on the spindle speed of a rotational rheometer, or on the vibrational characteristics of a device based on a mechanical resonator.

Shear-dependent behavior is essential for most adhesives and sealants. They must flow freely as they are applied to the substrate, but must remain in place until they are fully set, without sagging or dripping from the joint. Such materials are not only shear-rate dependent, but may require a certain amount of force to get them moving. They behave like solids when undisturbed, but when a certain yield stress is exceeded, they flow like liquids. And they may be time dependent, or thixotropic, remaining fluid after they are sheared and only reverting to solid form after a certain recovery time.

Rheometers (and to a lesser extent, rotating viscometers) are capable of giving a whole series of measurements that can completely characterize the behavior of even complex non-Newtonian fluids in a laboratory environment. Interpretation of rheometric data to predict the real-world behavior of these complex materials is challenging, and often not readily applicable to industrial processes. On the other hand, sensors relying on vibrating elements generate single-point measurements; they read an apparent viscosity at a single value of shear rate that is often substantially higher than the shear rates used in rotational instruments. For this reason, measurements done on non-Newtonian fluids with resonant viscometers usually do not agree with those from rotational instruments. Despite this difference in indicated viscosities between the two types of instrument, vibrational viscometers have proven valuable for the monitoring and control of viscosity of highly non-Newtonian fluids.

There are two application areas in which the convenience and robustness of vibrational viscometers makes them ideal for monitoring and control of adhesives and sealants. The first is inline viscosity monitoring for applicators. The second is cure-monitoring for batch operations in which it is critical to detect when a mixed batch of material is approaching the end of its pot life.

Inline viscosity monitoring for applicators

Sealants must flow freely during the application process, but must not run or sag after application before they are fully cured. This requires that the material’s effective viscosity must be highly shear-dependent, having a low viscosity under the high shear rates that occur in the lines serving the applicator and in the applicator nozzle itself, and a high viscosity, or even a yield strength after dispensing.

Despite the importance of flow characteristics of adhesives and sealants, particularly in the case of high-speed automatic dispensing and application, there is little or no information available about inline instrumentation being applied to either monitor or control adhesive and sealant consistency.

Rheonics has installed SRV inline viscometers in a high-speed laminating press in which viscosity control is essential. The operator of the press has tried rotational viscometers for monitoring adhesive viscosity, but fouling of the rotating parts by dried adhesive made their use impractical. Currently, efflux cups are used for viscosity monitoring, but these are notably imprecise and are not a truly inline measurement. Their use is time-consuming, making frequent measurement impractical and therefore allowing large-than-desired fluctuations in the viscosity, and therefore the flow characteristics of the laminating adhesive. The problem is compounded in high-speed laminating machinery because the application roller typically runs in an open trough of adhesive, from which the solvent is constantly evaporating, as shown in the following illustration:

Figure 2. Adhesive reservoir in a high-speed laminating machine.

As in the case of printing inks in flexographic and rotogravure machines, this gradual evaporation gradually raises the viscosity of the medium, requiring periodic dosing of solvent to stabilize the medium at a nearly constant viscosity, ensuring proper application throughout long, high-speed runs.

Vibrational viscosity sensors have resonators that typically operate at frequencies from several hundred hertz, up to tens of kilohertz, depending on the particular operating principle. Although it is not possible to determine the actual shear rate, the range of shear rates is high, equaling or exceeding those found in the dispensing equipment. For this reason, vibrational viscosity sensors are useful for monitoring the consistency of the adhesive and how it will act during the dispensing operation.

Vibrational viscometers operate by measuring the damping of a vibration induced in a mechanical resonator immersed in the fluid. Resonators used in vibrational viscometers fall into two general categories, those that vibrate transversely, such as tuning forks and cantilever beams, and those that vibrate torsionally. Torsional resonators are particularly advantageous for measuring the higher viscosities often encountered with sealants and adhesives, since transverse vibrations tend to be more strongly damped by high-viscosity fluids. Torsional resonators also tend to be less sensitive to their proximity to the walls of pipes and other vessels, making installation options more flexible. When viscosities are to be measured inline with an application system, mechanical compactness can be advantageous, since the flow lines are often of small diameter with relatively low flow rates compared to other process applications. Since vibrational sensors tend to produce reaction forces in their mounting that can influence their sensitivity, sensors that are vibrationally balanced are particularly free from environmental influences that affect unbalanced resonators. Rheonics SRV inline viscometer is based on this patented torsionally balanced resonator. [2]

Monitoring the degree of cure in batch-mixed adhesives

Another important area of interest in adhesive is monitoring of the degree of cure of adhesives and resins. This is important in adhesive applications for determining whether a particular batch of material has achieved the necessary mechanical properties, rather than just relying on manufacturers’ specifications and adjustment of process parameters. It is important in molding operations to determine when it is safe to de-mold the cured part, and in composite manufacturing to determine when a laminated part is fully cured.

Many methods have been published for monitoring degree of cure, but most rely on indirect measurements, such as of electrical or optical characteristics, rather than direct measurement of mechanical properties. Experimental ultrasound methods are available, but these tend to be limited to very small samples in closely controlled conditions, since attenuation of ultrasound waves can be quite large during curing processes[3]. Also, ultrasound measurements are typically conducted in the range of megahertz frequencies, which for non-Newtonian materials, may not reflect their behavior at strain rates closer to those found in their real-world applications.

A device, the Rheonics CureTrack™, is currently being tested by Rheonics GmbH. It predicts gelation in batches of pre-mixed adhesives and sealants. Fig. 2 below shows a CureTrack instrument, with its use in a laboratory trial.

Figure 3. CureTrack instrument with closeup of sample tube and needle tip

The CureTrack device is based on a Rheonics SRV viscosity sensor with a Luer taper on its tip to permit connecting a conventional disposable dosing needle to extend its sensitive element. By using a disposable extension, the sensor itself is not exposed to the adhesive; the needle can simply be detached and disposed of along with the gelled or hardened material.

The CureTrack outputs two numbers: the damping and the frequency of the instrument’s resonator. The damping is dependent on the viscosity of the material, while the frequency depends on its rigidity. The output of the CureTrack therefore gives a snapshot of the viscoelastic behavior of the material as it goes through its gelation and curing processes.

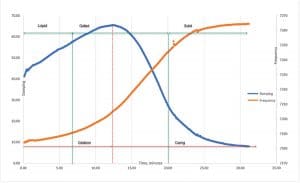

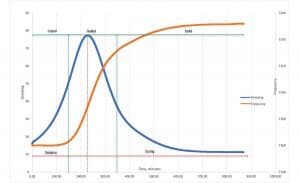

Figs. 3 and 4 show the curing curves of two different epoxy systems, as recorded by the CureTrack. The first is a consumer epoxy adhesive with a thiol-based hardener, Pacer Technology PT39 Z-Poxy 30 Minute Epoxy. This is specified as having a 30 minute cure time, and is commonly sold in hobby shops for model building. The second is Axson Epolam 2017 resin with Epolam 2018 hardener, an amine-curing system used for wet layup laminated composites. The rated gelation time is 6 hours at a resin/hardener weight ratio of 100:30 at 23 °C in a lamination process, in which the large surface area restricts exothermal heating and acceleration of the curing process

Figure 4. CureTrack curing curves of a fast-curing consumer epoxy adhesive Pacer Pt39 Z-Poxy. Plot shows the damping and frequency of the CureTrack with Liquid, Gelled and Solid-Cured phases of the adhesive.

Figure 5. CureTrack curing curves of a slow-curing epoxy laminating resin Epolam 2017 resin with 2018 hardener in 100:30 weight ratio. Plot shows the Liquid, Gelled and Solid-Cured phases of the resin.

The principle indicator of impending gelation is therefore a rapid rise in indicated viscosity, followed by an increase in the resonant frequency of the sensor’s resonator.

These curves show two distinct processes, and three regions.

The processes are gelation and curing. Gelation is the process characterized by rising damping and rising frequency, reflecting a rise in both the viscosity and the rigidity of the resin. The material is moving from a liquid to a gelled state. Curing, which is characterized by decreasing damping and increasing rigidity, is the process following gelation, which transforms the material from a highly viscous, sticky mass into a rigid solid. These processes also define three states that the material moves through during gelation and curing:

- A liquid region, in which the rigidity of the material is very low, reflected in the low and relatively constant frequency of the CureTrack’s resonator. In this region, the viscosity is also relatively low, indicated by the low value of damping.

- Gelled region, in which both rigidity and damping of the material are rising rapidly. The material in this region is sticky – it has a high viscosity which reaches a maximum, indicating the peak of the gelation process before solidification sets in. It is becoming more rigid, forming a rubbery mass before final curing.

- Solid region. Damping has once again decreased to a low and relatively constantly value. The resonator now is producing primarily elastic shearing of the material, with little dissipation due to viscous forces.

The two sets of curves illustrate the ability of the CureTrack to sense the onset of the gelation process, as well as giving quantitative data that permits tracking of the entire curing process.

Shimkin [4] has published an excellent article reviewing the state of adhesive cure monitoring. He concludes that although a number of methods for monitoring gelation time are available, there is both a lack of a commercial instrument base, as well as a general lack of standards, and therefore of agreement among the various measurement methods.

Most of the methods that Shimkin discusses are indirect, such as dielectric analysis, in that they measure a property of the resin system that is correlated with its mechanical properties, but do not directly measure the properties that are functionally important in the application of the resin system. In this sense, any measurement technology that directly measures properties such as gelation and solidification provide immediate, direct feedback on the state of the resin.

Applications of CureTrack technology

Direct measurement of the mechanical properties of a resin system has applications both in the laboratory and on the factory floor, where resins are mixed, applied and cured in a production environment.

In the laboratory, a robust mechanical analysis tool such as the CureTrack technology can be used both for research and development and for quality control. In the R&D lab it can be used to analyze curing properties of new resins and formulations. Its simplicity, and the use of inexpensive and disposable sensing elements makes it possible to economically analyze large numbers of samples without risk of damaging expensive sensors, or requiring extensive and time-consuming cleaning of difficult-to-remove residues. For quality control purposes, mixed resin samples can be monitored in the laboratory without time consuming preparation or cleanup.

Similarly, for quality control purposes, the robustness of the technology can move monitoring of mixed production batches to the factory floor, instead of needing to grab samples for laboratory analysis. Instruments such as the CureTrack can be inserted directly in a resin bucket to monitor its state as production progresses, and to issue a warning alarm when gelation is impending, and any remaining material must be disposed of before it solidifies.

Future development of the technology will also focus on monitoring gelation in actual production scenarios. For instance, the probe tip can be brought into contact with the surface of a resin-infused layup to monitor the state of the matrix material. Or the tip of the probe can be inserted to a controlled depth in a poured molded component and removed as gelation sets in.

Since temperature is an essential factor in determining cure rates, CureTrack has included a temperature sensor that measures the temperature at the probe tip. It can measure the temperature exactly where gelation and curing are being measured, enabling both monitoring the temperature of the resin, and tracking heat production during the curing process.

References

- Links to information about use of inline viscometry for printing applications can be found in https://rheonics.com/solutions/

- https://rheonics.com/products/inline-viscometer-srv/

- Materials 2013, 6, 3783-3804; doi:10.3390/ma6093783 materials ISSN 1996-1944 www.mdpi.com/journal/materials Review Monitoring the Cure State of Thermosetting Resins by Ultrasound Francesca Lionetto and Alfonso Maffezzoli

- ISSN 1070-3632, Russian Journal of General Chemistry, 2016, Vol. 86, No. 6, pp. 1488–1493. Pleiades Publishing, Ltd., 2016.Original Russian Text A.A. Shimkin, 2014, published in Rossiiskii Khimicheskii Zhurnal, 2014, Vol. 58, Nos. 3–4, pp. 55–61.

Authors

Overview

Adhesives and Sealants industry focused magazine – ASI publishes a feature article covering the Rheonics inline viscometer SRV and Rheonics CureTrack™, currently being tested by Rheonics. The article discusses the technology and working principles with a special focus on R&D, actual production scenarios and quality control purposes for adhesives and sealants industry applications.

Find the link to the the publication.

Related Application Note

Sealants and adhesives viscosity & rheology in formulation, testing and application

Adhesives and sealants are used widely for joining , protecting and sealing systems in construction, manufacturing and maintenance. This industry is facing challenges due to the limited raw materials (reserve of oil) and the negative impact of synthetic compounds on…