ASI Magazine features Rheonics’ inline viscometer and CureTrack technology for real-time monitoring of adhesives and sealant properties

Overview

Adhesives and Sealants industry focused magazine – ASI publishes a feature article covering the Rheonics inline viscometer SRV and Rheonics CureTrack™, currently being tested by Rheonics. The article discusses the technology and working principles with a special focus on R&D, actual production scenarios and quality control purposes for adhesives and sealants industry applications.

Find the link to the the publication.

ASI Magazine: Real-Time Monitoring of Adhesive and Sealant Properties

Novel insruments for inline and production applications

Introduction

The automated application of sealants and adhesives in settings such as automotive production requires that predictable, reproducible quantities are applied, and that they flow properly and remain in place during the final setting period. In the printing industry, lamination of plastic films is done on specialized high-speed machines that require close control of adhesive viscosity. Resins that are applied to fiber textiles and mats to make composite prepregs require exact staging of the matrix resin.

The correct adjustment of the flow characteristics of sealants and thermosetting adhesives is crucial to their performance in automated, high-speed production environments.

Applications

Direct measurement of the mechanical properties of a resin system has applications both in the laboratory and on the factory floor, where resins are mixed, applied, and cured in a production environment. In the laboratory, a robust mechanical analysis tool such as the technology discussed here can be used both for research and development and for quality control.

In the R&D lab, it can be used to analyze curing properties of new resins and formulations. Its simplicity and the use of inexpensive and disposable sensing elements makes it possible to economically analyze large numbers of samples without the risk of damaging expensive sensors or requiring extensive and time-consuming cleaning of difficult-to-remove residues. For quality control purposes, mixed resin samples can be monitored in the laboratory without time-consuming preparation or cleanup.

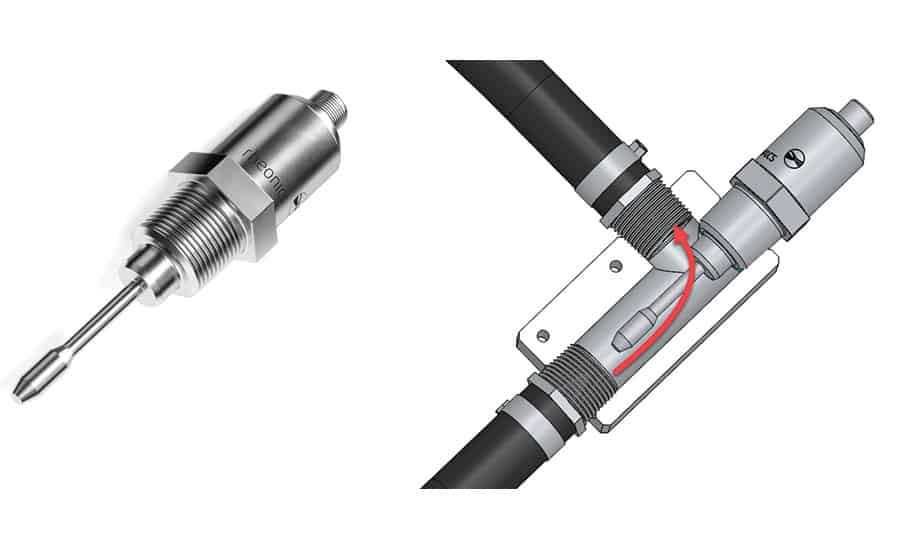

For quality control purposes, the robustness of the technology can move the monitoring of mixed production batches to the factory floor, as opposed to grabbing samples for laboratory analysis. Instruments can be inserted directly in a resin bucket to monitor the resin’s state as production progresses and to issue a warning alarm when gelation is impending and any remaining material must be disposed of before it solidifies.

To explore more about our solutions for sealants and adhesives viscosity & rheology in formulation, testing and application, please read the application note.