Introduction

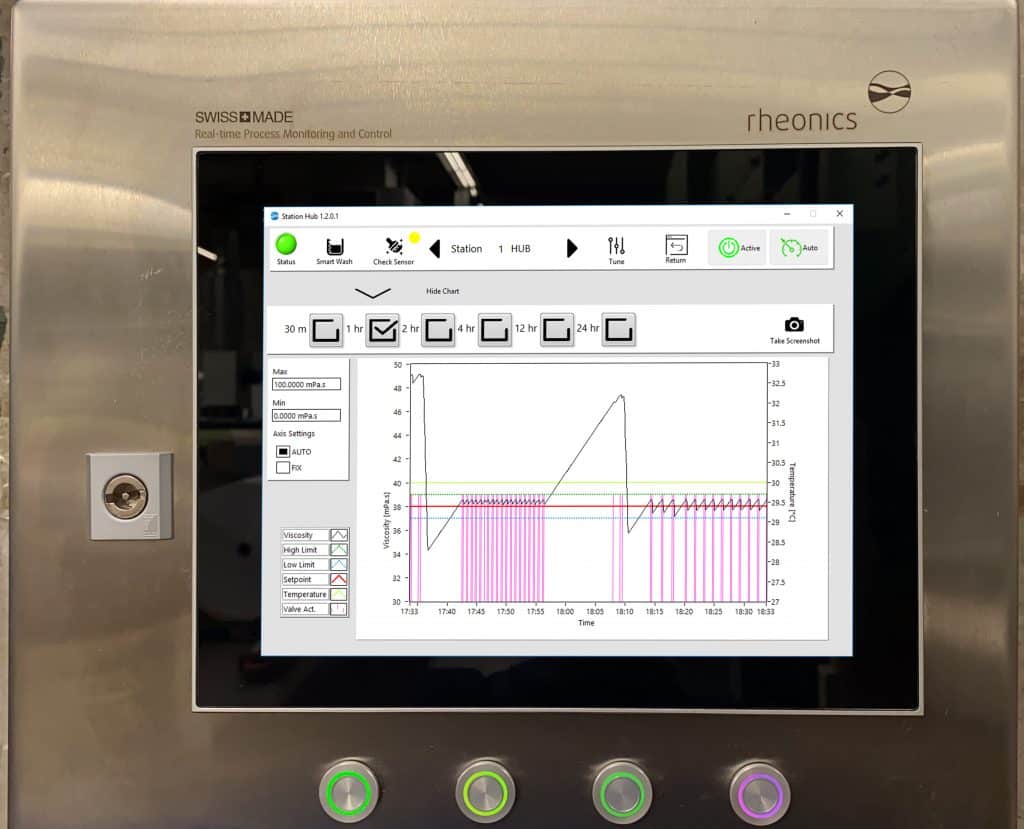

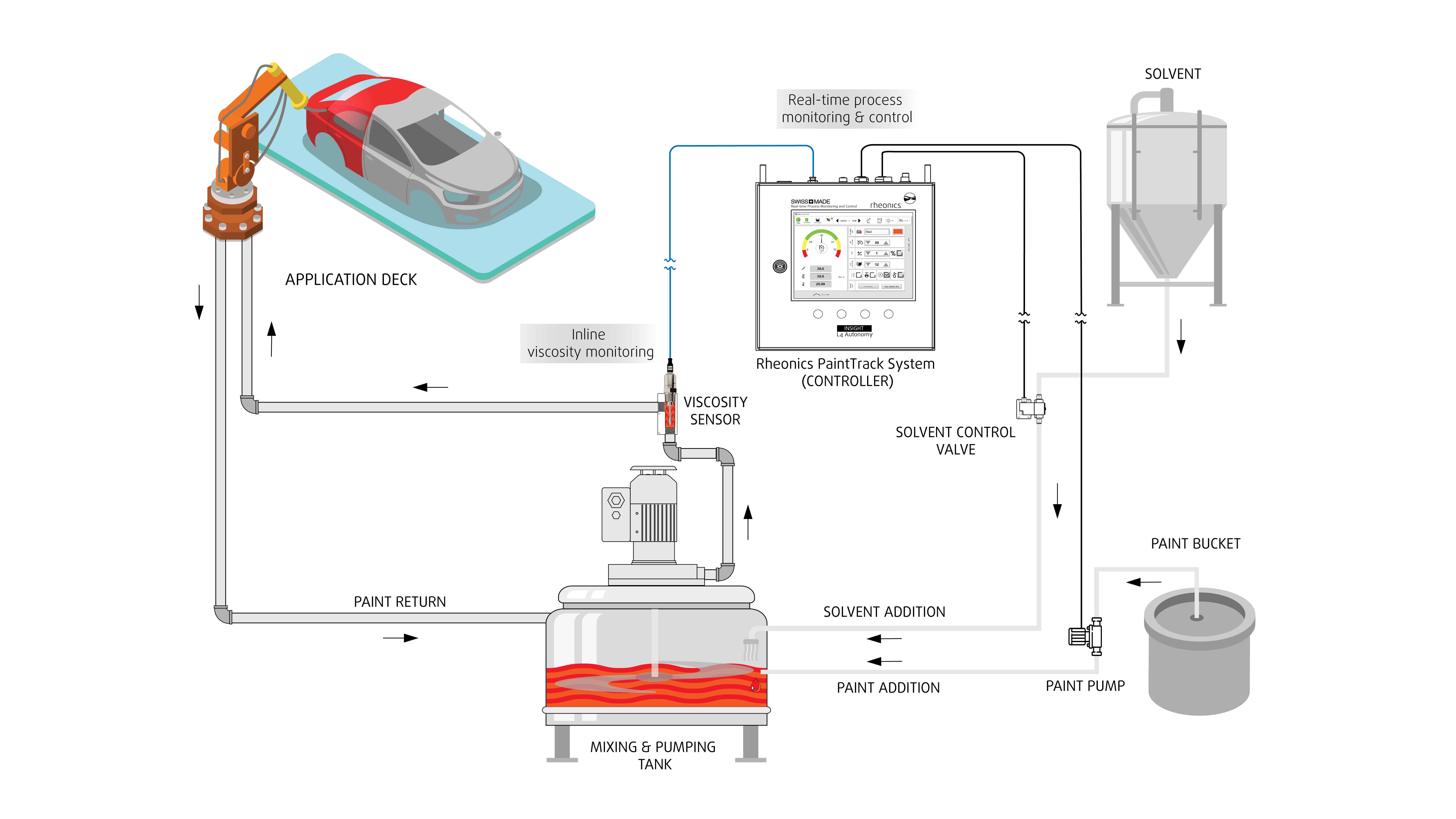

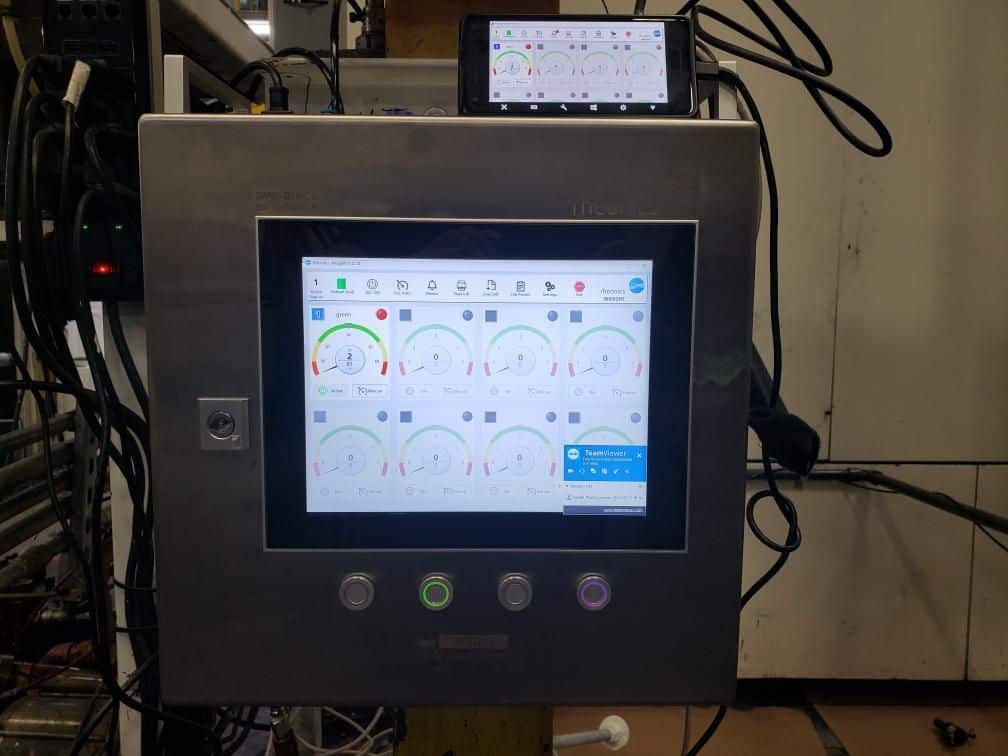

This system is the miniature variant of the process monitoring & control solution by Rheonics. It consists of an industrial embedded PC mounted inside a stainless-steel cabinet with integrated 10.4” display and touch screen. The industrial PC runs a control application which measures viscosity, density using Rheonics inline sensors and optional pH/Level by external third-party sensors. The process is controlled by up to two electrical and two pneumatic outputs which can control valves/pumps/mixers/chillers, etc.

Industrial communication options include an Ethernet connection, WiFi and USB. Additional user interface elements include a buzzer + alarm light and 4 buttons including LEDs.

Specifications

Table shows all options. However, the actual system will only contain the options that were selected during ordering.

| Mechanical | ||

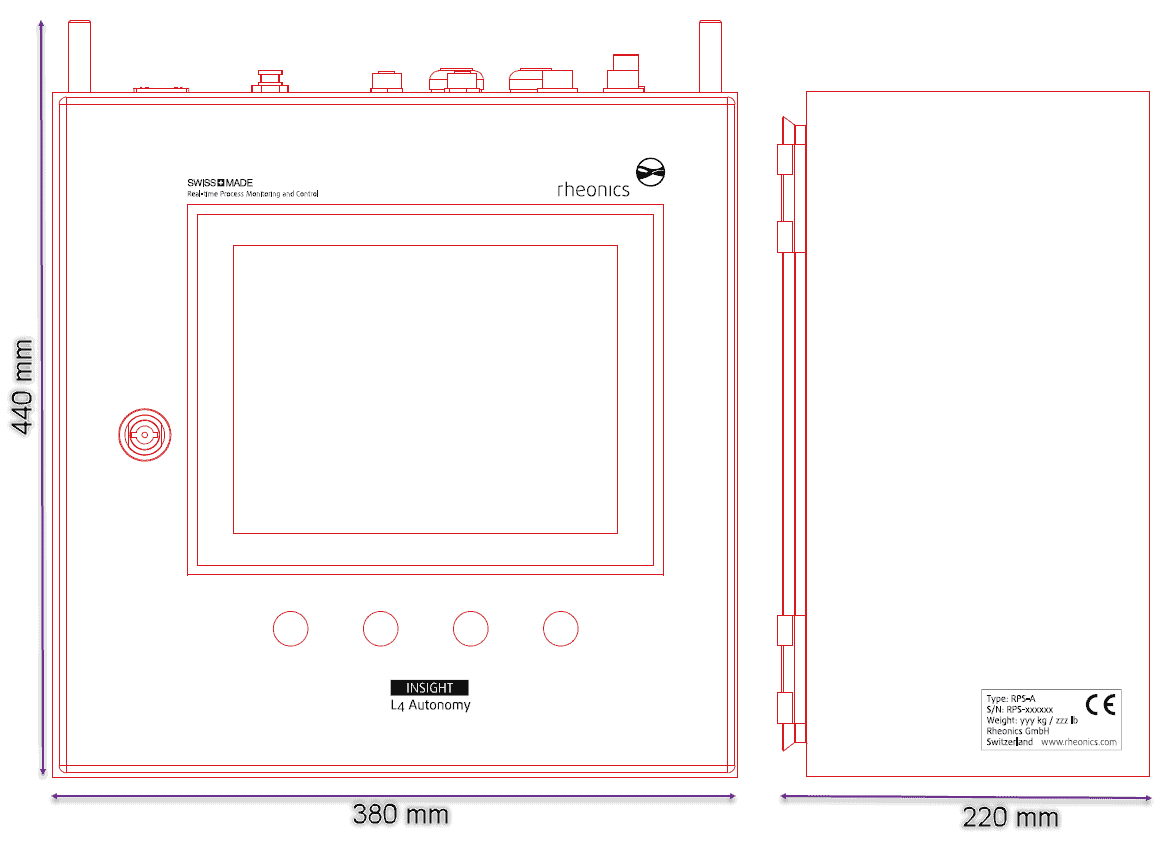

| Dimension | Width/Height/Depth, mm (inch) | 380/444/222 (15/17.5/8.75) |

| Weight | kg (lb) | 17 (38) |

| Protection | IP | IP54 |

| Electrical Interfaces | ||

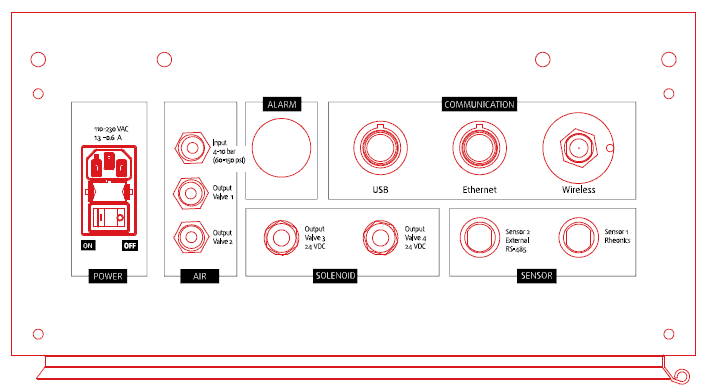

| Rheonics M12 process connection | 1 x 12-pin M12 female connector for DVM/DVP/SRV/SRD sensor | Connected to internal SMET For monitoring only system, multiple M12 connections are possible up to 6x each cabinet |

| Power Input | 230VAC | Input range: 85VAC – 264VAC |

| Power Loss Max. Load | 4W | 50Va, cos phi 0.6 |

| Optional Electrical Interfaces | ||

| M12/4-pin process connection | 1 x 4-pin M12 female connector (pH/Level/other RS485 sensor) | Connected to the RS485 D-Sub of the industrial PC |

| Pneumatic Output | 2 x pneumatic process connection, 4mm, push-pull fitting | Pneumatic Valve 1: ADAM 6060, CH0 Pneumatic Valve 2: ADAM 6060, CH1 |

| Pneumatic Input | 1 x pneumatic process connection, 4mm, push-pull fitting | Input range: 4-10bar / 60-150psi |

| Human Interface Elements | ||

| Display | Projective capacitive 10-point 10,4” TFT LCD Touchscreen (1024*768) | Mounted on the industrial pc |

| Industrial PC | 4x2GHz, 8BG RAM, 128GB | Windows 10 IoT preinstalled |

| Buttons | Piezo Buttons normal open | Actuating force: 2 – 6N Different colour options |

| USB | USB 3.0 | |

| Ethernet | Ethernet LAN 10/100 Mbit/s full duplex | Internal communication over Ethernet Completely plug & play service components |

| WIFI | 802.11 b/g/n WIFI 300Mbit/s | Embedded Webserver accessible over Factory LAN on handheld devices |

| Alarm Buzzer with LED | 85 to 96db(A) acoustic signal with a red LED | Customer configurable alerts Email alerts |

| Power Consumption | ||

| Maximum | 26,4W | Total cabinet using standard connections |

| Environmental | ||

| Temperature range | -10 ℃ ~+50 ℃ | Sensors can be installed in higher temperature process lines, check rating of ordered sensors |

| Humidity range | 10~95%@10 ℃ (No condensation) | |

| IP | 54 | |

| Installation | ||

| Connectors | All on top | Leave 60mm space on top for connectors and cables Total Height of installation area recommended 500mm |

| Handles | Two (2) | For carrying cabinet |

| Wireless Antenna | Top | Protect against damage, sticks above handles |

| Wall mount | Two (2) | |

| Outside installation | Not recommended without proper protection | All connectors come with caps, however the unit is not built for direct install in outside areas where connectors are exposed to environmental element. Protect against ingress of water, dust, etc. |

| Software (options available to order) | ||

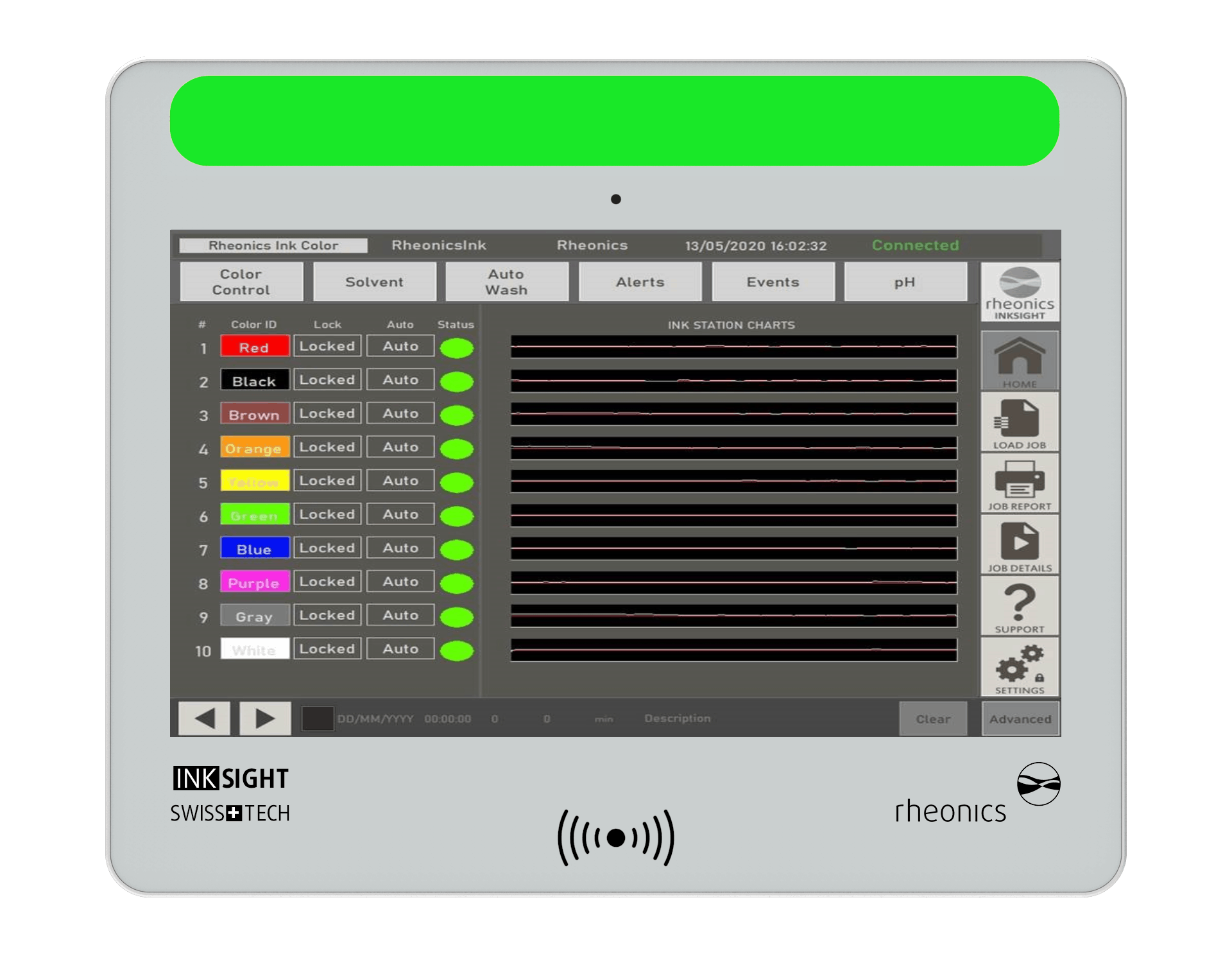

| RPS InkSight with ColorLock | 1-10 station | Monitoring and control using ColorLock functionality |

| RPM RheoPulse | 1-10 station | Monitoring only software |

| RPM SlurryTrak | 1-10 station | Monitoring only software |

| RPM PaintTrak | 1-10 station | Monitoring only software |

| RPS InSight with ProcessLock | 1-10 station | Process monitoring and control software |

System Overview

Standalone Solutions

Turnkey integrated automation solution for full control over your industrial processes. The system measures and controls viscosity within 0.5 cps : 100 times greater resolution than average efflux cups.

Wide range of solutions in the industry

Easy installation and retrofit

Easy mounting. Screws or clamps to ink line fitting. No chambers, O-ring seals or gaskets. Easily removed for cleaning or inspection. Sensors available with flange and tri-clamp connection for quick mounting/dismounting. Drop-in replacements for both sensor and electronics without any software changes – Auto detect!

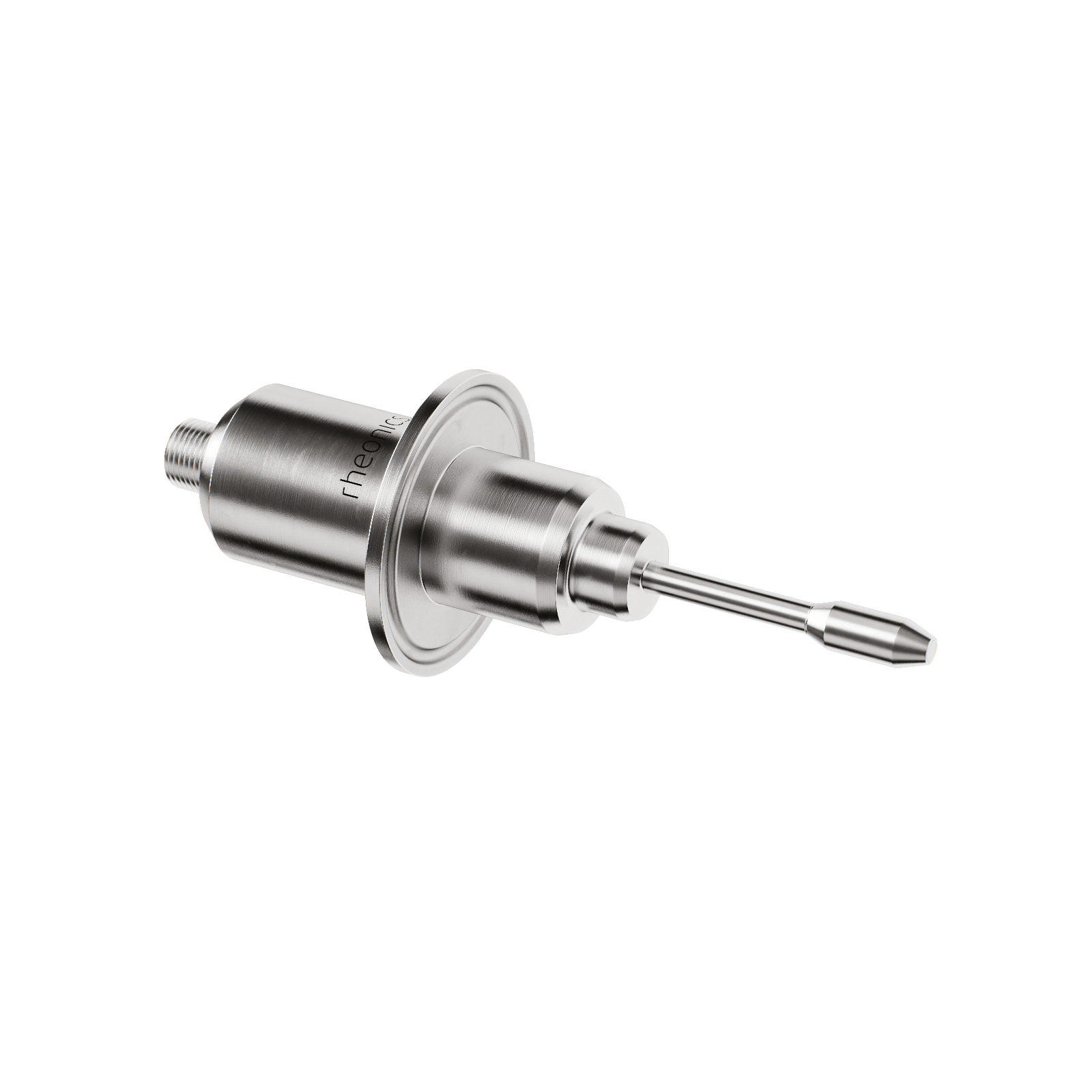

SRV Viscometer & the integrated RPS-A system

Achieve best in class product quality, dramatically reduce setup time and optimise use of materials. Improve productivity and efficiency through complete automation of viscosity control of your process fluid.

• Robust, maintenance free viscosity sensor eliminates need for re-calibration

• Agile viscosity controller reduces viscosity variation to less than 1% over entire print run regardless of length

• One-click, intuitive graphical interface touch-screen

• Tighter, more accurate viscosity control

You can expect the sensor on every station to measure and perform equally on any other station. The Rheonics SRV sensor is factory calibrated and traceable to NIST standards.

- Small Form Factor – Fits in your palm while more robust than any other inline viscometers!

- All 316L stainless steel wetted parts – Hermetically sealed, metal-metal process sealing – no elastomer

- Repeatable, Reproducible – Newtonian, non-Newtonian, Single and Multi-phase fluids

- Wide viscosity range – Air to 50,000+ cP

- Built-in fluid temperature measurement – Excellent thermal compensation to achieve consistency over the years

- No re-calibration needed – ever!

Rheonics’ software is powerful, intuitive and convenient to use. Multiple stations are managed from a single dashboard. It supports multiple HMIs for operator, production supervisor, quality manager and management view.

• Proprietary advanced 5th generation AI system for simple click monitoring and control

• API for data acquisition and integration into press manufacturer’s HMI

• On-demand in-built remote support management of job run

Global Support

Process control experts help when you need it the most.

Rheonics provides a worldwide network of engineers, application experts and technical sales professionals to help you size, select and troubleshoot process automations for your applications.